Recycling later in heating cycle

We have a WM steam boiler with a Becket AFG oil burner and genisys 7505. Last spring the transformer went bad. At that time we also had oil burner/boiler cleaned and tiger loop added.

I noticed previously that the oil burner would run for 5 minutes or so then shut off for 30 seconds before coming back on and running until thermostat stopped calling. I thought maybe our water level was a tad low, so I put some water into the boiler. This evening the oil burner ran for 20-25 minutes then recycled and came back on and ran another 5 minutes until thermostat was satisfied. We have not had any lockouts. It seems like it only will recycle once in any given heating cycle. I’m not sure if it recycles every time the boiler runs. It’s pretty quiet and you have to be in the room directly above the boiler to hear it running. I have a pressure gauge that never goes above 0.6 psi. What would we be dealing with? Thank you.

Comments

-

My bet would be pressure — if that gauge is the standard (and required) 0 to 30 psig gauge, it is unlikely that it woud even budge under normal operation.

What is your pressuretrol set for? Post a picture…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Pressuretrol is set at 0.5 cutin with 1 differential. I have a low pressure gauge that only reads as high as 0.6.

0 -

hmmm… it sounds flip, but unless you can catch it in the act and figure out what is cutting it off…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Flip? I’m not sure what that means.

0 -

Flippant. He essentially said "just catch it doing it, then you'll know what's wrong".

There are instruments that would be helpful here, but they're not exactly something you'd find in the kitchen drawer. I would install a data logger across the various safeties to see what's opening and when; but that's a tool I have access to.

0 -

Is the 7505 blinking "Recycle"? If so, its a burner issue.

0 -

It happened just now. The water level before the boiler ran was about 1.5” above the LWCO probe. After running for about 20 minutes, it shut off and low water light was on. Water was essentially level with the probe. The boiler stayed off for about 30 seconds and no water was added by autofill. Water level slowly rose. It then came back on and finished running. The water is kind of rusty colored. Do you think I need to skim it? Water bounces maybe 1-1.5” but must be going up into the piping.

0 -

where is the normal water line? 1.5" above the lwco probe is pretty low.

does it have an auto feeder? it would be better to keep it filled to the normal water line than to wait for the auto feeder to kick in if it has one.

0 -

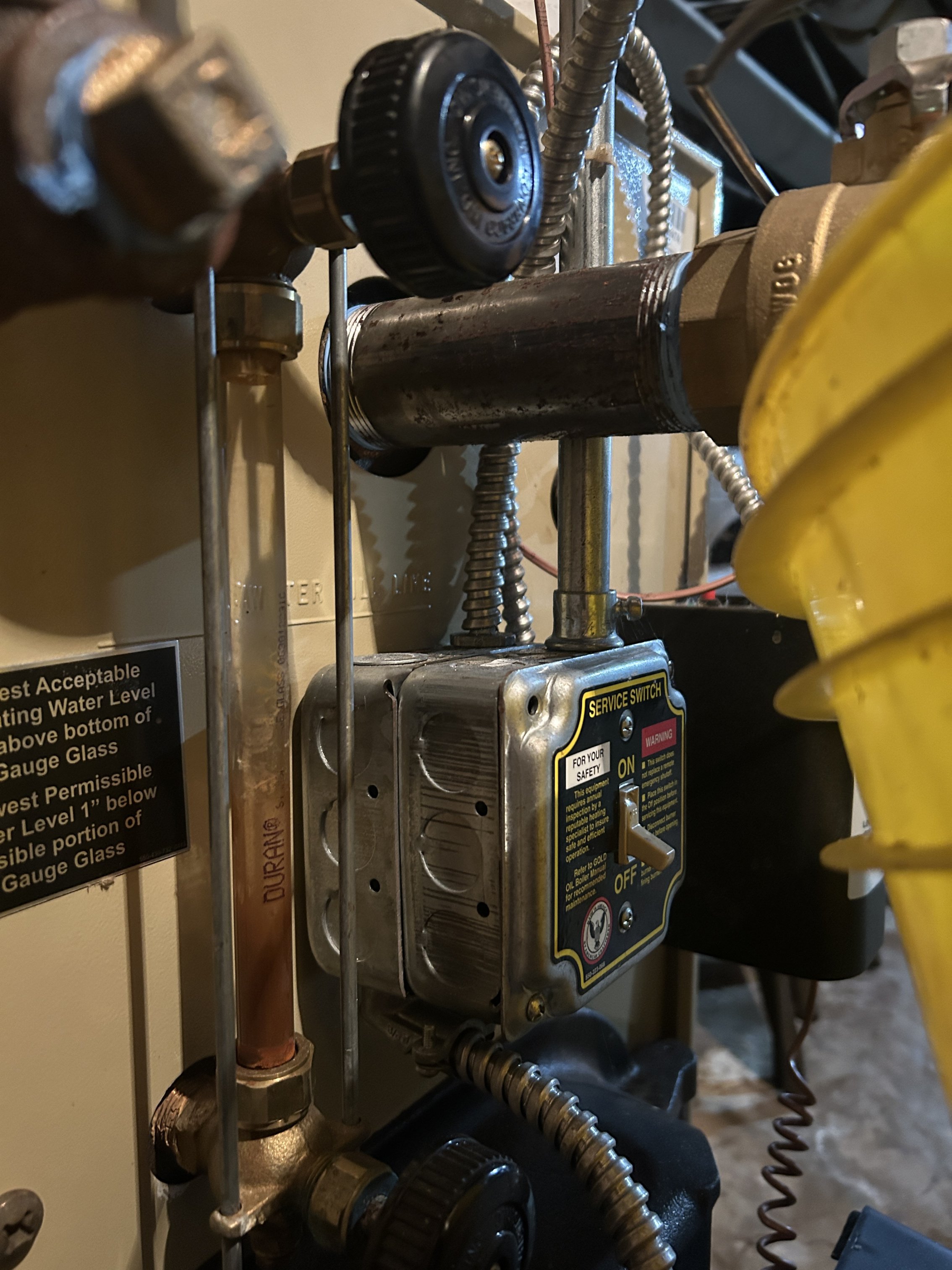

The LWCO is right at the line on the boiler jacket. The line is visible on the left of the photo. I’m skimming so that’s why there is a bucket visible. Probe is on the right (black box). I thought that was kind of high, but that is where the WM manual shows it. I normally keep the water level halfway between the line on the jacket and the top of the sight glass. Should I keep it higher?

0 -

Slow wet returns may do that. In fact, it isn't that uncommon. And there is an easy fix: run the cold water level higher. So long as the steaming water line is somewhere in the middle third or so of the site glass, the cold water line can be nearer the top without problems.

But… you are going to have to do that ,manually.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

is that where is shows the skim tapping in the manual? That tapping on the left seems more to be the right level but I don't know where the actual block is inside the jacket.

If that is the correct skim tapping you are pretty close to filling the block completely at an inch above the water line. You can try higher but if you have issues with wet steam you will have to keep it lower.

0 -

The normal water line for that boiler is stamped in the metal jacket, you can see it in the photo. It is level with the top of the black label to the left of the gauge glass.

—

Bburd0 -

Yes. And the LWCO is essentially level with that line on boiler. I had the water level about 1.5” above that line but it was triggering LWCO when boiler was really steaming.

0 -

You can see where the probe is for the lwco if you take the cover off but it is about in the middle of that box.

0 -

Oh. I thought it was near the top where I see the brass connector behind the box. I’ll take a look. The correct place for the skim port is where I have it per the manual.

0 -

That’s good to know! It seems like the water returns to boiler within 30 seconds or so and boiler restarts. But this shutting off only happens max of once per heating cycle. When you say steaming water line can be in middle third of sight glass, do you mean halfway between the line stamped in jacket and top of the glass?

0 -

is that a sfgard or cyclegard? The cyclegard stops the burner in the middle of the cycle and checks the level.

0 -

It’s a McDonnell and Miller PSE-801-120. Waterfeed says VXT

0 -

Cold vs. steaming water level is a little tricky, and opinions will differ. However… What you want to achieve is the steaming water level — full song, happy camper — above the low water cutoff far enough to keep things going. Now depending on the boiler that may be somewhere in the middle third of the sight glass — but on some setups it could well be higher, say a bit more than half way up. If the water level is bounding while steaming (but not excessive) you want the bottom of the bounce… (if the bounce is excessive, try skimming).

However, if you have long returns or slow returns, that may mean that the cold water level will be near the top of the sight glass. There is no harm to that, but it must still be within the sight glass.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thank you. I appreciate it. I skimmed for a couple hours and just restarted boiler. Watching the water level, it typically varies less than an inch while steaming, but will then suddenly drop 2 inches before coming right back up within a second or so. Not sure if it needs more skimming. I have the cold water level about an inch below the upper brass fitting for the sight glass.

0 -

That quick drop and recovery is a bit odd, but… I'd say so long as it steams well with those settings, just keep an eye on it and let it rum.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Ok. Thank you.

0 -

Water level bouncing an 1 1/2" while steaming is a bit much. What does the near boiler piping look like? You are skimming it so that is good.

I think your LWCO is in the correct tapping. Check the attached it is supposed to be in the "P" tapping

Try keeping a little more water in it. It is possible if it is doing this after a long run you could have a slow return(s)

0 -

It’s weird. Most of the time it bounces ½” to maybe 1”. But every 10 seconds or so, there is a larger drop (2” or so) and then an instant recovery of the level again. I’ll take a video. Tapping for LWCO is definitely as in the manual above. I have water level much higher in sight gauge now and no recycling.

0 -

the 2" sudden drop sounds like surging. the oil inhibits the steam from leaving the surface of the water easily so it builds up then suddenly erupts violently.

0 -

Surging or the piping isn't right.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements