Heat exchanger between wood boiler and propane boiler?

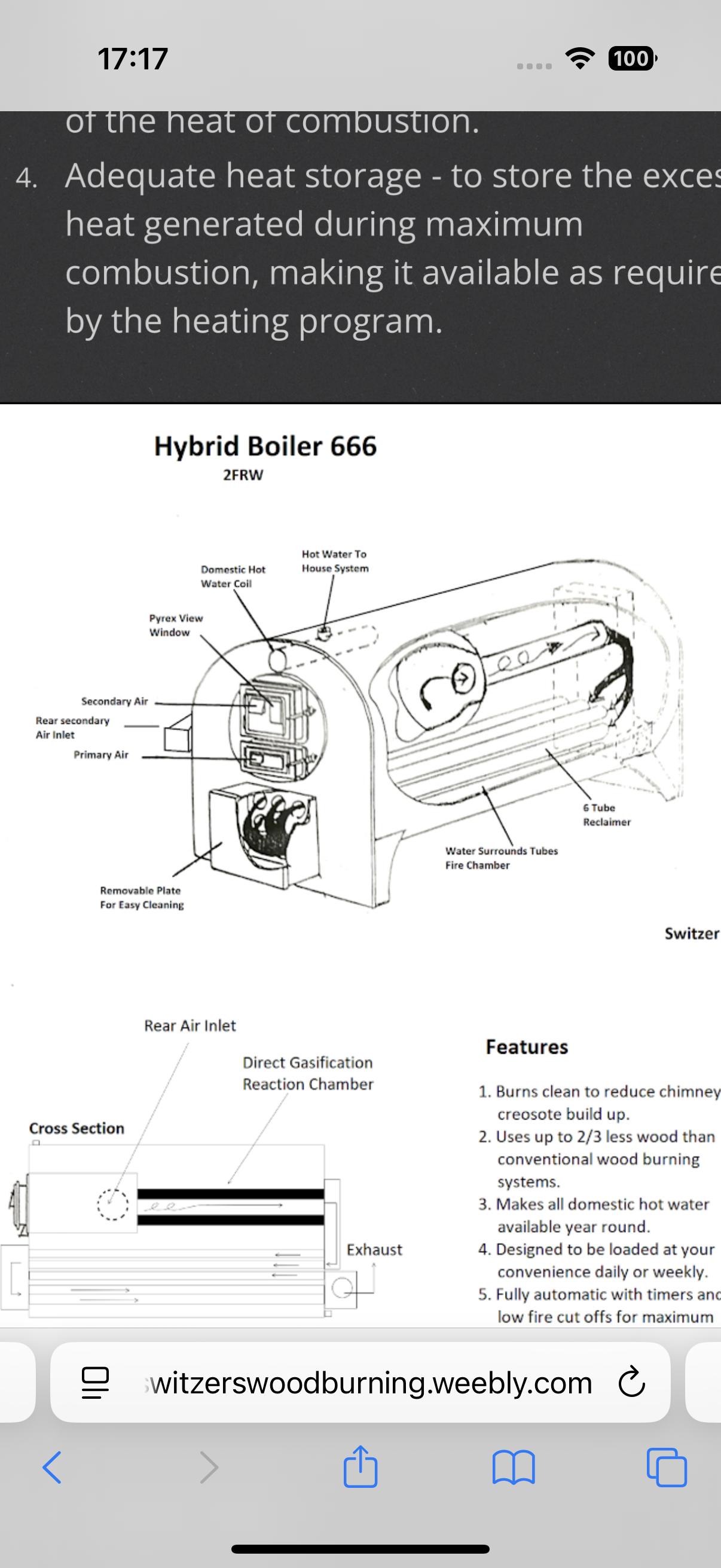

I ordered this Switzer wood boiler years ago and was finally ready to install it six years later. It’s a 1750 gallon wood gasification boiler and it provides DHW and radiant floor heat. The wood boiler is connected to the system across the room by 2x 1 1/4” pex supply and return lines for the radiant heat, and 2x 3/4” pex lines for DHW.

The heating system is designed to utilize the wood boiler until water drops below 120 degrees at which point it kicks over to the propane boiler. I am on well water and water quality has been a concern. The Bosch propane boiler has a leaking heat exchanger that needs replaced - the system wasn’t holding pressure. I had a 5 micron filter installed between the well and the house / heating system. At that time I asked them to check the water quality and ph- it tested neutral at 7.3.

Right now I have all 1750 gallons of the wood boiler connected directly to the heating system and thus the pex lines that run through the floor. The heating design calls for Fernox f1 for water treatment. Heating that amount of water with Fernox is costly. I was considering a plate heat exchanger between the wood boiler and the 1 1/4” pex lines that bring hot water over to the other corner of the room and the heating system. That way I could treat the wood boiler with less expensive treatment and only treat the water going through the floors and propane boiler with the Fernox.

It looks like I lose about 20 degrees of efficiency if I do this.

Couple questions - are there plate heat exchanger manufacturers to avoid ? I want to say the system is designed for about 160k btu/hr. I was looking at a 225 btu/hr exchanger but in the remarks it said 180 boiler side, 160 return.

The wood boiler heats the water to about 220 under 30psi pressure. I don’t understand the 180/160 numbers. Anyone see any good reason not to install a plate heat exchanger between the two? Recommendations on what to purchase ?

Thanks in advance

Comments

-

that is a common approach to use a plate Hx

A simple oxygen scavenger in the wood boiler. Most wood boiler dealers have that in 5 gallon buckets

There are free HX sizing software online if you want an exact answer

Most HX info is just one configuration which may or may not match your needs

Bigger is usually better

Stay away from the very cheapest brands Find a name brand on bay, etc.

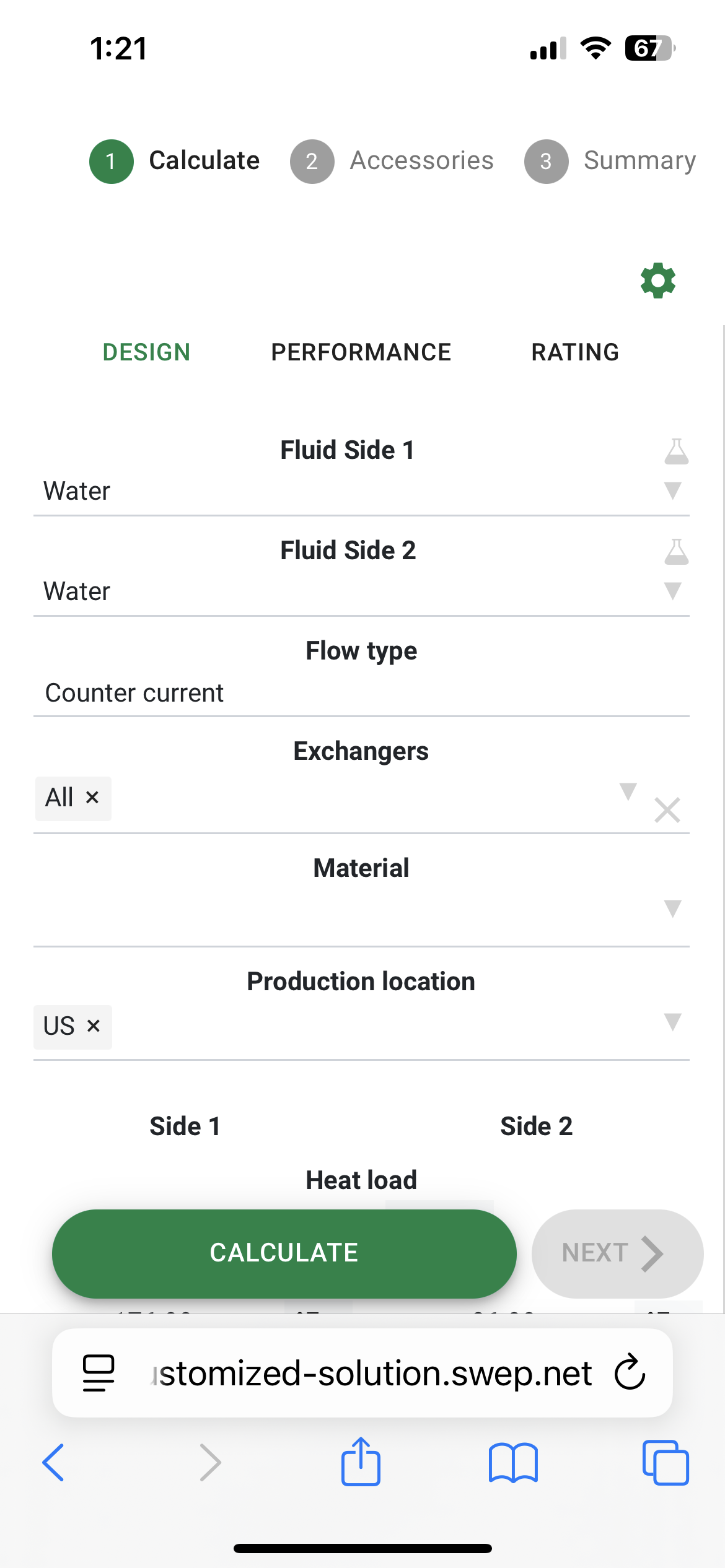

https://customized-solution.swep.net/singlephase?c=13748f2b-3ab1-48bf-90c5-be4958b8e7aa

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks! @hot_rod

0 -

I agree with everything that Hot Rod said, except for the brand thing. Obviously the super cheap ones from China might not be a good choice, but I can't even count how many big dollar exchangers from Xylem and Swep that I've found leaking between plates. I have been installing exchangers from Badger Insulated Pipe in Wisconsin for more than a decade (which are no-name, probably from China) and have several hundred in service without a leak (yet… Knock on wood) or failure of any kind. Obviously the DHW will need its own exchanger (20 plate 5x12 from Badger has both 1" and 3/4" ports to make DHW easy) but for 160k of radiant floor, you have the buffer of being able to have a large delta meaning a smaller exchanger is sufficient. I'd put that in 30 plate territory based on past experience but oversizing doesn't really hurt anything. I personally have a 70 plate from them on my wood boiler that serves 2 buildings with high temp but 1 of them has a radiant floor on a mixing valve and the other has a 20 plate for DHW as well as a small 20 plate 3x8 for a little snowmelt in my sidewalk. Everything running together is about 280,000 BTU and will drag the return temp down to about 70*, but that 70 plate will bring it right back up to within 10* of where the wood boiler is which is usually 160-170 range. The weird part is that 70 plate is supposedly rated at 280k with 24.5 GPM. I am only running about 9-10 GPM on the wood boiler and can keep it within 10 degrees, so maybe that rating is trying to match temps? Either way, if the required output temp was only 100* instead of 150*, that same 280k rated exchanger could easily move 500k or more.

0 -

I appreciate the information -

Switzer has a domestic hot water coil in his boiler so I don’t need a heat exchanger for that. Right now I have the ability with valves to bring the water from the well and run it through his boiler and either preheat a domestic hot water tank , or bring the heated water directly into the house from his boiler. I’ve had the propane boiler turned off for over a week or so. I fired the Switzer boiler up on Saturday and got the temp up to 200. I left on a military trip on Sunday and returned home yesterday. Since Saturday, the temp had dropped from 200 to 170 on the boiler and the family has been using DHW throughout that time. I do have a recirc pump that I can utilize that constantly keeps the water running through his boiler coil so hot water is on demand and available within a couple seconds. I’ve had that unplugged to keep the temp up on Gary’s boiler, though. I’ve found that bringing cold water from the well and directly into the house after making a trip through his DHW coil is plenty hot to take showers with.

I’ll take a look at those plate exchangers you recommended. I’m on the Wisconsin border north of Rockford so they are local.

I’m trying to figure out the calculator that hotrod sent. Not sure what co flow and counter flow means. And why are there two inlet and two outlet settings?

I have a max temperature of 220 water on the wood boiler. Max temp water required in one of the 11 zones is around 120 water. So I probably only need to bring 160 or so through the pex tubing and over to the floor system to mix with the return water. I think when I only had the propane boiler in use for radiant heat I had the dial set to fire up to about 140.

The only other concern I have - the wood boiler is set up so that if it over fires - temp more than 220 - it automatically opens up the valve to the garage floor for a heat dump. Hopefully the installation of a heat exchanger wouldn’t inhibit that safety feature for heat dump? I also have a taco three way mixing valve with dip switch settings that I’ve now set so it doesn’t limit the temperature it sends to the floors. Not sure that was the correct decision either but I didn’t want to keep the excess hot water trapped on the primary side by a taco valve - so I set the settings to not limit water temp at all for the garage floors.

Hindsight I should have run copper over to the wood boiler vs the 1 1/4” pex, but admittedly I’ve already overfired the wood boiler once - temp exceeded 220 on the boiler by a bit, the heat dump valve opened and 220 water ran through the 1 1/4” pex across the room over to the copper pipes. I went to the back of wood boiler and manually opened a valve to let hot water escape but I was concerned to keep it pressurized so I didn’t have boiling water in my pex lines.Definitely some learning required with a system like this, but looking forward to not seeing the propane man show up in his truck as often.

0 -

If you are seeing a 220 degree water temperature without the relief popping off, you need a much better American made gauge from Marsh instruments or Dwyer instruments.

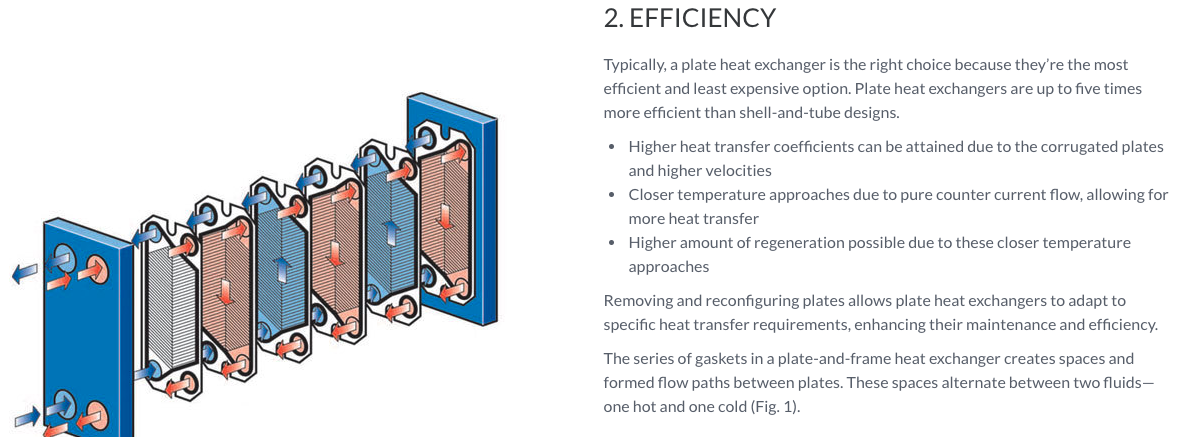

You should look at shell and tube heat exchangers before you make a purchasing decision.

If you do not have a dump zone to get rid of excess water temperature you need to have one installed.

You can use the garage as a dump zone using a Zurn garage heater with a separate circulator and single aquastat to power a separate circulator and the garage heater.

You never want to see your water temperature rise to 220 degrees, you need to buy an American Made temperature gauge with a 4 inch round dial or square face.

I had one of Garys CWW100 boilers for 33 years until I switched to a keystoker coal stoker, the keystoker boiler was a mistake from the get go as well as the clowns I had to hire to install it.

I never had a bit of trouble with the CWW100 except for the left kalamazoo coal grate popping out of the weldments holding it in place.

1 -

There’s a thermostatic mixing valve on the back of Gary’s boiler to control temp leaving the boiler - but my understanding is that 220 degree water at 30 psi is max performing the boiler. Until I get a bit more practice learning how much wood to put in, I’m going to be shooting for 200 degrees at 25psi.

To clarify : Gary has the dump zone to the garage floors set up, hopefully I’ll never be having to use that again. It was an afterthought on my part to adjust the dip switch settings on the three way taco valves. Otherwise I don’t think the hot water would make it into the secondary and to the manifolds.

I’ve dialed the thermostatic mixing valve back so even when there is a need to dump heat, I shouldn’t be seeing 220 degree water exit the boiler. I’m not sure what temp to shoot for there, particularly if a plate heat exchanger is installed as an after thought. I’m wondering if a plate heat exchanger would inhibit the existing heat dump zone to work properly. I guess if a heat exchanger is installed at the back of Gary’s boiler before it hits the 1 1/4” pex lines, I could open that thermostatic mixing valve all the way up so that even at 220 degree water the most I’d see in the pex lines would be 200…

Although I don’t need that hot of water for normal operation by any means

0 -

can you limit the boiler operating temperature to 180 dump at 195.At 220 if pressure drops you are flashing to steam a very powerful force to recon with.

Pex can go above 180, dependent on pressure, it gets very soft at those elevated temperatures and pulls in O2 at a higher rate. I worry about fittings coming apart when the tube softens.

Boilers typically have pressure only relief valves. Although some do have a T&P also, Aquatherm had both, 30 psi relief and a 210f/150 psi t&p

Most all the plate HX manufacturers and reps will help you properly size a heat exchanger. There are terms used that are unique to that technology

The folks at Swep did a phone call tutorial with me. Ill bet there are you tube videos that walk you through the sizing

Long hand sizing if you are good at math

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If the Switzer WB has a DHW HX built in, why do you want another HX on the WB boiler?

Take cold through the WB intergral HX and on to the EK system. Simple no pumps or controls required.

I think the WB is already tied to the heating system somehow?

However your ultra high operating temperatures frighten me. Potentially you could send 200° preheated water into the dhw system.

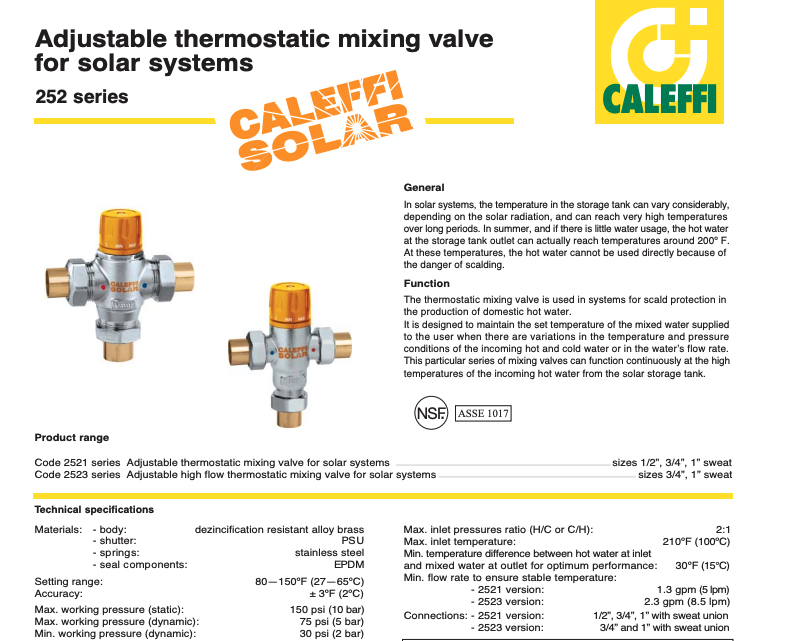

Somewhere you want a listed 3 way thermostatic. Ideally one rated for 200° plus. Generally solar mixing valves have that high temperature rating, but not over 210°F for obvious reasons :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I used 150 for the low limit, 170 for the high limit with 190 for the dump zone temperature.

With the amount of thermal mass you have you will be making plenty of hot water at the lower temperatures I used.

If you split your firewood thinly like I did you will have plenty of fuel to heat up all that hot water in batch burns with less work.

1 -

It may have to do with the designs gasification operation, high efficiency burns, that the designer wants the 200° + operating temperature. With that amount of fluid, plenty of btu stored at 180- 190.

This particular wood boiler has been discussed for years over at The Hearth. The high temperature is a common concern among owners. Especially pex users. Posts dating back to 2017.

I think I see this OP footprints over at the hearth?

I believe a mower parked in a shop with wood heat, and fossil fueled appliance is a big no no, as far as codes go :( Cozy set up, however.

Around here you cannot have an overhead door on a building with a wood fired appliance.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

When I was discussing with Gary, he didn’t mention anything like that as an option. In the back of the boiler there is are 3/4” supply and return lines for the domestic hot water coil. There are separate lines for radiant heat purposes, 1 1/4” lines.

There is a thermostatic mixing valve both for the DHW lines and one on top for the radiant heat. The dump could be set for 190 but I’m losing quite a bit of efficiency I would think- in that I’m heating significant sf and getting DHW. I would think that the 120 degrees where it kicks to propane would come quite a bit sooner?

Gary doesn’t think the heat exchanger is necessary. He says with the proper ph water- his boilers have lasted 40 years with no water treatment at all. My concern is the cost over time of treating 1800+ gallons with fernox f1 or sentinel 100- like my radiant heat design calls for.

I reviewed my plans and it looks like it’s a bit less btu/hr than I thought. It’s about 130k btu/hr - assuming the calculations that dsdesign accomplished is accurate.I have posted on hearth about this as well, there are a couple people with Switzer boilers there.

0 -

Re: lawn mower; I’ve since built a wall around the boiler , heavily insulated and fire protected. The lawnmower was there temporarily - that was before we even fired the boiler up for the first time. Garage door mainly for getting wood into the boiler area.

I think I might build a bench in there and use it as a sauna room- it gets warm. That’s how I can justify this entire thing to wife.

0 -

I agree that that you should not put the wood boiler water through your high efficiency mod con that I see in the pic. Is it a Triangle Yibe brand?

The HX allows you to run that system as the manufacturer suggests with a conditioner. Besides a small heat transfer efficiency penalty, not much downside.

Plate Hx don’t plug up often if they are sized and pumped properly. You get high channel velocity which scrubs the plates clean

I would put a mag sep on the wood boiler side for sure, lots of ferrous metal to oxidize.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

the propane boiler is a Bosch FS-151 greenstar.

Already replacing the heat exchanger after about two years of use.

perhaps I’ll call badger next week and see if they can help me properly size a plate heat exchanger ; I think I’m convinced that’s the way to go.0 -

yeah, aluminum block boilers really need careful fluid monitoring. You know that from the I &O manual. It may be the most sensitive of all the boiler metals.

I think some brands include a bottle of aluminum friendly inhibitor in the box

The info for sizing at Badger is basically rule of thumb, X amount of plates for X amount of BTUs. I’d guess there is a fudge factor thrown in They sell enough of them to have a goid idea of what works.

But a lot of variables in burning wood anyways. Moisture content and type of wood has a lot to do with output, you may never see the actual rated output, so another fudge in the HX sizing

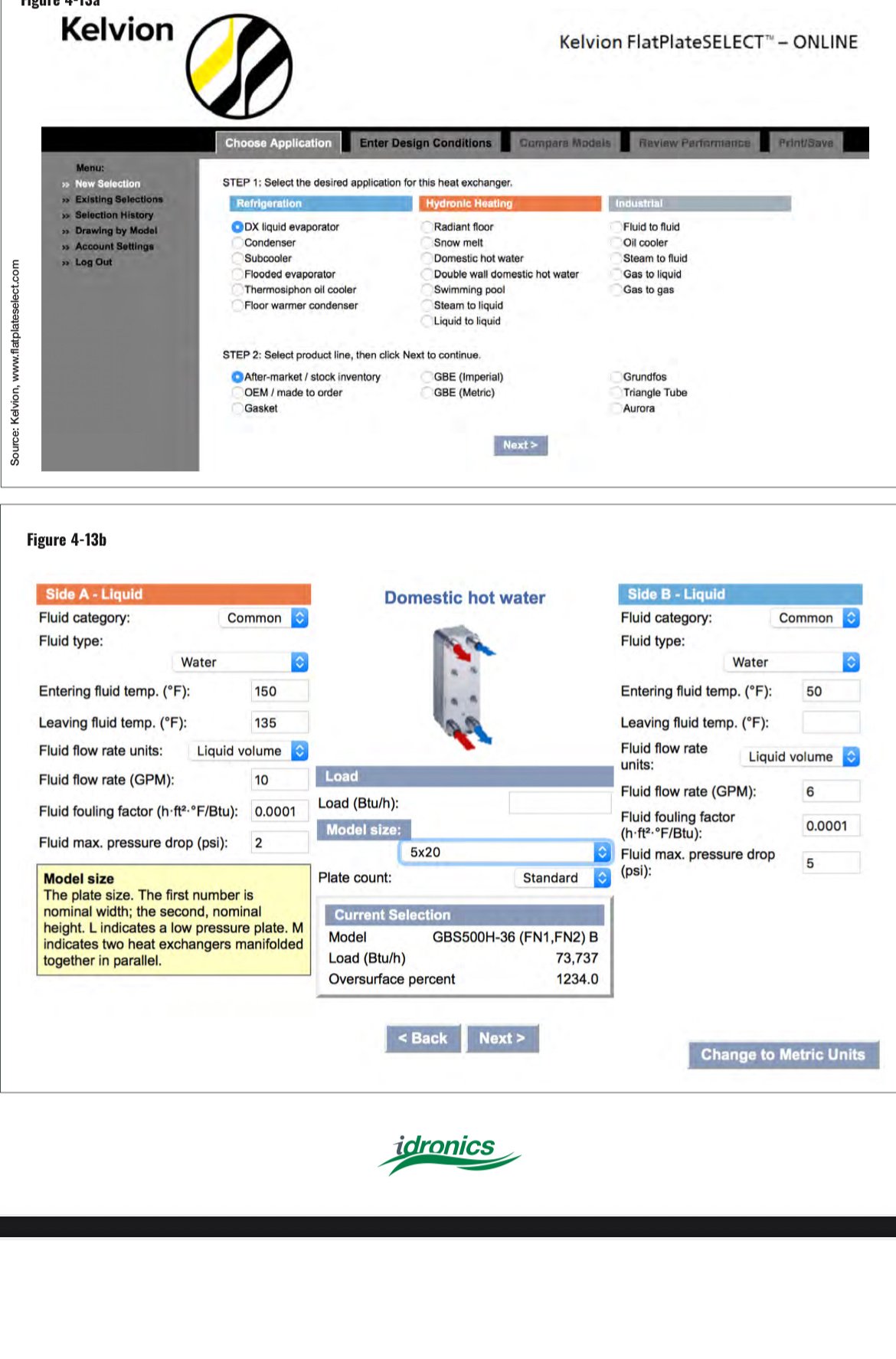

Four inputs in the sizing, 3 temperatures and flow This shows 50 degree water being heated at a 6 gpm flow, 10 gpm of 150 on the boiler side 5x10 -36 plates

Here is a graphic showing counter flow piping

A good practice to install unions on all four connectors, should you need to replace ir service

Its dhw hx that need occasional descaling due to the constant minerals going through them. Hydronic, not so much.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Since the buffer is on the wood boiler, you only need to size the heat exchanger for your space heat load not the burner size. That should be much less than the wood boiler size. Never hurts to go oversized exchanger but no need for big pumps and high flow rate.

Also watch how you plumb and configure your setup, you want to get every last BTU out of the wood boiler and you only want the modcon to run enough to make up for the missing heat.

1 -

I spoke with Rick up at Badger and he said I’d at least want 70 plate if I’m occasionally letting the wood boiler drop to 120. I ended up just getting their largest 100 plate exchanger. Hoping this works out ok.

0 -

-

Rick told me they’d have it on the 10AM truck if ordered today. I might be able to return it?

What are the advantages of what you’re recommending ?

0 -

My apologies , I had forgotten you had recommended those in an earlier post.

0 -

-

I called Badger and asked. Rick highly discouraged doing so. He said shell and tube exchangers are for pools. He said he often hears people say you can get a lot higher btu/hr for the $ with those exchangers, but said they are not designed for the higher temps ie 220 degrees on a Switzer boiler.

would you disagree?0 -

Plate type HX are more efficient and less $$ compared to shell and tube.

More size availability also.

I could suggest some simple union fitting options to get to copper, pex or threaded pipe. Plate HX usually have nipples with a nice flat surface to take a fiber washer and union nut.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

I would have used a copper coil in a steel tube for domestic hot water. My switzer CWW100 had one for 33 years and I had no issues. Gary would probably remember who he bought them from for the cww boilers

.

0 -

The major difference is the coil in the boiler is pretty much in still water, or barely moving water.

whereas the plates are in high turbulence condition always, they require two moving flows to even work at all.

Physical size and cost are a selling feature for fogs.

However copper wins hands down for heat transfer efficiency.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Theoretically a shell and tube can be set up for thermosyphon saving you a pump. Exact BTU and efficiency is not easy to figure out as the pressure is very small and flow depends a great deal on piping.

For size/cost you can't beat a plate HX. It does mean a pump on the wood boiler side but that is a cheap circ.

0 -

To clarify, the heat exchanger to be used is for radiant heat purposes only. I have a separate DHW loop that runs through the DHW coil in Gary’s boiler. When I spoke to Gary on the phone about the plate heat exchanger he said that I should be able to use the existing pump on the back of his boiler if I plumb it properly. He’s sending me a diagram of how to do so. Ideally I’d like the exchanger installed so that with a max temp of 220 wood boiler water, with 20 degree loss only a max of 200 water is hitting the 1 1/4” pex lines - although he seems very confident in the pex ability to withstand high water temps under pressure. My other concern was if I overtemp the boiler (greater than 220), the ability for the dump zone to work properly through the heat exchanger. I intend to wire it so that the heat dump opens more valves to more zones, instead of just the garage floor, so there is more volume available for the excess heat to distribute to. I don’t intend on over firing the boiler, but it is a learning curve of how much wood I can put in based on type/condition of the wood I’m burning .

The DHW was designed so that cold water from the well would run through the wood boiler coil and be preheated on the way to a DHW tank, and then be topped off by the propane boiler. We installed a couple valves, however, that allow us to bypass the DHW tank and bring well water through his boiler and directly into the house. I haven’t had the propane boiler on for a couple weeks now and have found that water making one trip through that wood boiler coil is plenty hot as it is. I have a recirc pump available that keeps the water flowing through the boiler and hot water lines, but I’ve just been waiting 30 seconds or so for the hot water to reach the shower head for now. I intend to put a timer on that recirc pump for times of higher water usage, eventually.

0 -

I borrowed my buddy’s copper press tool and am about to plumb in this 100 plate heat exchanger. Gary has advised me of the way to hook it up, which involves taking the current 1 1/4” supply line and capping it off, and using a 3/4” line that has hot supply water that t’s off prior to his expansion tank and runs through a recirc pump. This would allow me to use the existing pump behind Gary’s boiler by installing a relay to circulate water through the heat exchanger when there is a call for heat ; rather than that pump only running when his boiler is fired up. I like his thought on this , but I have concern about reducing the supply down to 3/4” pipe, only to expand back to 1 1/4” to go into the heat exchanger ports. I bought all the fittings to do it this way, but wanted to check here in case anyone sees any problems with reducing diameter and using 3/4” supply lines for portions of this plumbing ? Picture attached annotated to show the cap. Green is the pipe I’ll use for supply after it t’s off and after it runs through the pump.

0 -

Yes the pipe reduction will add some pressure drop to that circuit. With 3/4 connections on the FPHX you don't have any options.

If the boiler manufacturer has a specific way to pipe the HX, they should know what works best.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

the connections on the heat exchanger are 1 1/4”. Im reducing down to 3/4” to utilize the line to the hot supply line to the expansion tank which t’s off - and use the current pump. Then eventually going back to 1 1/4” pex to go across the room and into the heating system where the propane boiler is.

I’d need another pump to create all the loops with 1 1/4”, but after further inspection it looks like Gary already has the return line reduced down to 1” copper behind his boiler.

The way he’s having me do it is the least amount of work and parts; and I don’t need an extra pump. I was just concerned about the reduction. They are short loops, I guess …0 -

This is the difference between and off the shelf HX and one that is built and sized to the exact application. The connection can be a variety of sizes and locations in a factory built HX.

If you have 3/4 male threads on the HX, make the increase with as short a fitting as possible.

A 1-1/4 X 3/4 black steel bell reducer for example.

There are 1-1/4 X 3/4 female copper adapters also, but $$.

If it were me I would have unions on all 4 connections.

1-1/4 black unions, bush the one end to 3/4 fip and adapt copper to the other side, with a press adapter perhaps.

A press union 3/4 fipx 1-1/4" copper would be ideal, but I've never seen such an animal.

You may be find an 1-1/4" version like this and reduce the fip threaded side with a brass bushing, again the more custom the fitting the more $$

Basically when flow hits that smaller opening you get a velocity increase in that section, basically it's an orifice.

Go with the flow, transition as you wish and keep moving.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you, I got started today and should be finished up tomorrow.

0 -

-

the HX connections are 1 1/4” threaded. This is my concern. We are taking the boiler supply lines which were 1 1/4” (and matched the hex ports) and forcing all boiler supply through a 3/4” copper line that T’d off and went to the expansion tank and T’d off prior to the expansion tank to run through the recirc pump.

After Gary explained the way to be plumbed and I processed it overnight , I sent an email expressing concern over the reduction but haven’t received a reply.

im sort of committed at this point.

I’ve just got so much invested in this that I hope we don’t lose a bunch of efficiency.

I had expressed interest to Gary before the install about a HX between his boiler and my other one and the water running through the floors. Miscommunication, I thought he had one installed on the radiant heat portion of his boiler as well. Now I’m redoing all his work and hoping it’s going to work out.

I believe he was against the HX idea in the first place.0 -

Sorry , I misunderstood the port size of the HX

The amount of gpm, heat, you can move is dependent in the tube size, flow rate

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

3/4 is good for about 5GPM. Assuming 20f delta, that is about 50k BTU of heat. If your space heat load is less than that then the pipe size is fine. You can also run with higher delta and get even more.

The extra big HX just gets you closer approach temperature which is always a good thing.

0 -

my total heat load to heat this SF is approximately 130k btu/hr according to the designs.

as I plumb this in I have more concerns - maybe unwarranted.

the Return water from the house comes over in 1 1/4” pex lines. The way Gary had it plumbed before it ran into a 1” Tee and either went back up to the thermostatic mixing valve to be mixed with 1 1/4” boiler supply water, or go down through the 1” T and enter a 1 1/4” line to go back into the wood boiler to be heated.

the way I have it now is that 1 1/4” line hits that 1” T and either goes up to the thermostatic mixing valve and the 1 1/4” supply pex line to the house (after being mixed with the hot boiler water), or it can go down into a 3/4” line with two 90 degree elbows which eventually leads to the new heat exchanger. The water’s path of least resistance would be to travel up the 1” line and into the 1 1/4” supply line. Will any water make it through the 3/4” lines to the heat exchanger like this ???

thanks for your replies. I hope this isn’t a huge mistake.0 -

1 1/4” was spec’d by the designer from the wood boiler over to the primary side of the system with propane boiler.

designer didn’t have a heat exchanger in the system, that was an after thought when I saw the price of fernox f1 and the cost of treating 1800 gallons vs 50. Plus, I was a little concerned about 220 degree water running through 1 1/4” pex. Hindsight I should have ran copper across the entire room and really pushed for Gary to add a heat exchanger when he was plumbing it in.0 -

If you want to run a wide delta, maybe 30 instead of the common 20° To move 130,000 requires about 8.6 gpm

The math looks like this

GPM = btu/ hr ÷ 500 X delta T

130,000 ÷ 1500 = 8.6 gpm

At a 40° ∆ you need 6.5 gpm

I'd like to see it work at a 20∆, widening the ∆ is a work around. At this point, money spent, piping installed, see if it does the job. The test will be at design conditions when all zones run and you need the full 130K. Generally 80% of the heating season you are below that design requirement, so it may be workable.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements