Pressuretrols and Gauges

Good evening,

Below is a photo of my old boiler pressuretrol assembly. The boiler has since been replaced and all of the near boiler piping has been redone. As I am working through getting the new boiler up and running I have a couple of questions about the pressuretrol and gauge:

My old boiler had a Honeywell pressuretrol for cut in and cut out and another high limit pressuretrol with a manual reset. My new boiler has a Resideo that is identical to the Honeywell on the right for cut in and cut out. There is no second pressuretrol.

- Do I need/want to add the second pressuretrol high limit switch?

- If the answer is yes, is it advisable to use the one that came off of my old boiler?

For context, the old boiler was not installed correctly, maintained at all and our water is terrible. In fact, the entire assembly fell off one day when I bumped my head on a steam pipe. It was rusted through at the point of contact with the sight glass piping. That was a lot of weight on that one little connection.

For the gauge my question is sensitivity. The gauge that came with the unit is the same that was on the old one, 0-30 PSI. Since I have had my boiler up and running the gauge has not moved even a little bit. Should I get a lower pressure gauge? Is there a recommended brand/range? Part of me feels that I need to see something happening here to know that it is all working. Not very scientific, I know.

Comments

-

On the pressuretrols. On larger boilers two are required — one for control and one for safety — the latter having a manual reset. It does no harm to have two on any boiler.

On the pressure gauges. Code — and your insurance people — want one gauge which reads to twice the setting of the pressure relief valve. Not optional. However, also not of much use to seeing how the boiler is actually operating — so many people put another gauge, typically 0 to 3 or 0 to 5 psig — on. Very often smply teed off the pigtail carrying the control pressuretrol.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

that red button is the manual reset on that secondary pressuretrol

0 -

Usually, manual reset pressure control is installed on commercial jobs. In MA where I am they are required over 200,000btu.

If in doubt put it on the new boiler. It should be on its own pigtail not doubled up like on the old boiler.

No pressure on the gauge is a good thing not a bad thing. Put a LP gauge on if you want. You have to keep the 0-30 gauge and I would put a petcock on the LP gauge only. Keep it off when not checking pressure.

3 -

Are the pressuretrols pretty durable? Given that the system was not in great operating order would re-using the old one be a problem?

0 -

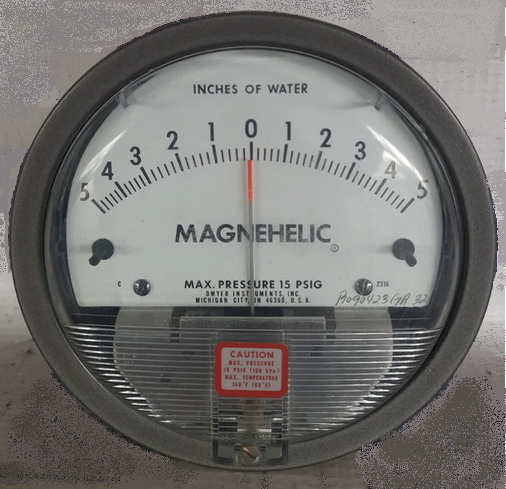

I too like to see the actual working pressure. I like this type of gauge (Dwyer Magnehelic), many on eBay, but you really need to know what pressure your system runs at since that would determine the type of gauge you purchase. They come in many pressure varieties.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System2 -

Yes the pressure controls are durable. Just make sure the pipe connection is clean.

0 -

In a pinch you can make a water manometer from some vinyl tubing and a hose barb. Attach the barb to your low drain hose (get a hose if you don't have one) then suspend a sufficient length of vinyl from a high point (preferably near the sight glass) and connect the two pieces of hose with the barb. Careful open the drain valve (preferably with the boiler cold initially) and the water level should fill the vinyl right up to the waterline in the sight glass. During boiler operation you can watch the pressure gradually climb as the level in the vinyl moves above that in the sight glass.

Voila! You now have a very sensitive pressure measurement in inches of WC. Just close off the boiler drain when you're done watching or if the boiler pressure is going to exceed the headspace you have. For most gravity systems this shouldn't be the case but you never know. You will also see clearly if you system is pushing water up in dry returns.

You can tap on that 30# gauge all day long and register nothing.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

1 -

I will build a rail and add the high limit pressure control on a separate pigtail. I will put a lower pressure (0-5 psi) gauge on the rail with a valve to close it off when not checking pressure. Am I worried about damaging that gauge that I should put it on a pigtail as well? I will put it on a petcock as mentioned by Ed.

Unrelated, and likely amateur, question: My boiler turns on and off frequently (I can count and time the frequency if that matters). But it does not stay on long enough to actually produce steam. My assumption is that it is keeping the water warm? If that is the case, what regulates that? Looking through the wiring diagram I do not see anything that appears to be monitoring temperature of the water in the boiler.

0 -

Is it cycling on and off when there is not call for heat? Is there a tankless coil in it for domestic hot water?

0 -

No tankless coil. Utica PEG150 EID is the boiler model. That would make sense if it had it, but it does not.

0 -

does it cycle on and off without a call for heat to keep the boiler hot(which is called "warm start")?

0 -

I did not answer the question. Yes, that is what seems to be happening. I may be missing it but I do not hear the click of the thermostat calling for heat. I will start paying closer attention to see if there is a call for heat or not.

0 -

If it is set up as warm start, there is probably an aquastat on it that keeps it at a minimum temp. You can turn that all the way down. Did it at one time provide dhw or heat a hot water heating loop? The aquastat would have been field installed so it won't be on the boiler's schematic. Can you show us pictures of the other sides and the piping above?

0 -

There is no field installed aquastat since I did not install one. This is the same project as the near boiler piping with the charred floor joists. I started a new thread assuming that is preferred when the topic changes. If that is not the case let me know.

Picture below. It is a brand new boiler install and has never provided DHW.

I have been tied up with work all day and have not had the chance to spend time with the boiler today. I am going to do more skimming tonight or tomorrow AM, I will pay attention to it.

0 -

That is an older (@week) photo. It has a valve on the copper water supply near the boiler now and the sight glass is a lot cleaner. It is still in need of skimming but much better than in the photo here

0 -

the psycho…er cycle gard will shut the boiler down every x minutes and verify the water level. the period depends on the model. what is under the front cover? i wouldn't expect it to be set up warm start from the factory.

it is probably better to keep it in the same thread if it is all the same boiler or at least link to the other thread

0 -

Is the LWCO simply shut it down due to surging ? That sight glass looks kind of contaminated.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

measure t-t or r-g or whatever the t-stat connection is with an ac voltmeter and see if it is 0 or not, if it is 0 the t-stat is calling. could put an led with the resistor for 12v there too so it lights when there is no call.

0 -

12v ?

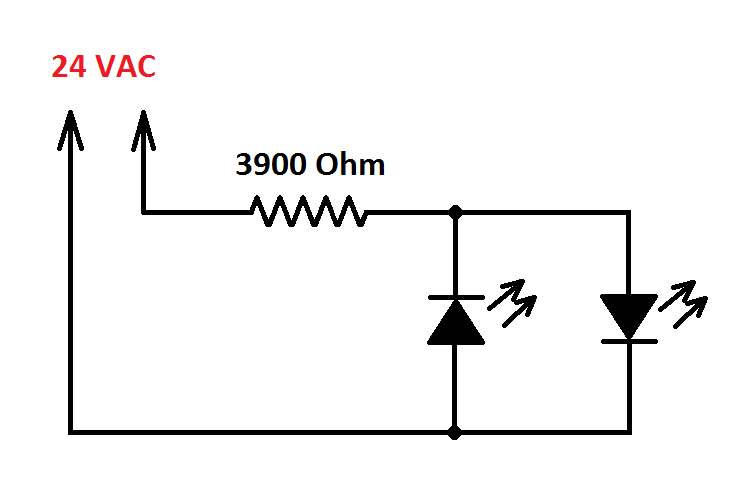

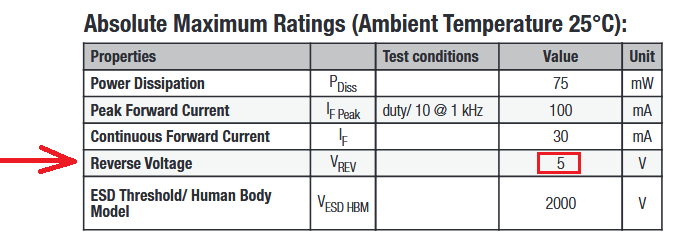

For a 24 VAC circuit two LEDs wired as shown below works well. If you only use one LED you still need a diode to protect the single LED from excessive PRV. With two LEDs they protect each other.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it is only half wave rectified so you only get 12 vrms. technically it is 12 / ((2^.5)/2) volts. you should have a reverse biased diode but at 12 v it is less of a concern.

0 -

@mattmia2, you better think about that for a bit. With only one LED when it is in conduction (forward biased), say the positive alternation you have the forward voltage drop across the LED (a few volts depending on the LED) the rest of the alternation's voltage is dropped across the current limiting resistor. With the negative alternation there is no current flow so all the voltage of the negative alternation is applied across the reverse biased LED. V peak is almost 34 volts with 24 VAC RMS.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Alright, I was in the basement for @25-30 minutes and the boiler cycled on 4 times. The first was for about a minute and the second was for about 2 minutes. Measuring the temp of the nipple coming out of the supply tapping point neither of the first two times got over 190 degrees (infrared thermometer, not perfect but close enough). On the 3rd time it cycled on for about 4 minutes and did climb to steam making temp before shutting down.

The fourth time was an actual heating cycle, it turned on and ran for 6 minutes or so before the LWCO check and then it turned back on again.

I am not sure what is going on. The only thing that could be causing it to cycle on, as far as I know, would be the thermostat. That really only makes sense though if the thermostat was also turning it off when it hit the set temp. Since the first two cycles did not make steam it could not have raised the temp enough to have the thermostat turn it off. The 3rd time it did reach temp but only for a about 4 minutes (since it had just recently cycled it it reached temp fast).

The 4th time it acted as it should. Call for heat, run, LWCO check to make sure everything is OK, run again and then turn off once the t stat was satisfied.

This is the original thermostat. I appreciate the advice on the LED and may make one but for the time being I just might splurge for a new thermostat. I will post once I do and have it running for a bit to see if that was it.

0 -

I codoubt ubt very much that it has anything to do with the thermostat. That said, you will need to observe it some more and find out what is turning it off. First villain would be the LWCO…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Test equipment like a multi-meter is the most common way to perform testing, but that is not the only way. If you can carefully disconnect one wire at the thermostat and see if the boiler starts, you may have to wait a while. While disconnecting the one wire look for dilapidated insulation causing the thermostat wires to touch and bypass the thermostat, it does not take much.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Just so I am clear it appears to erroneously fire the burner. Not erroneously interrupt a call for heat.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Yes

0 -

It is not turning off randomly it is turning on, as if there was a call for heat. That is why I am eyeing up the thermostat as the source. There is nothing else to make the call.

If it was turning off during a cycle then the LWCO would be more the culprit I presume based on your comment

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements