One pipe steam system advice

Good afternoon guys,

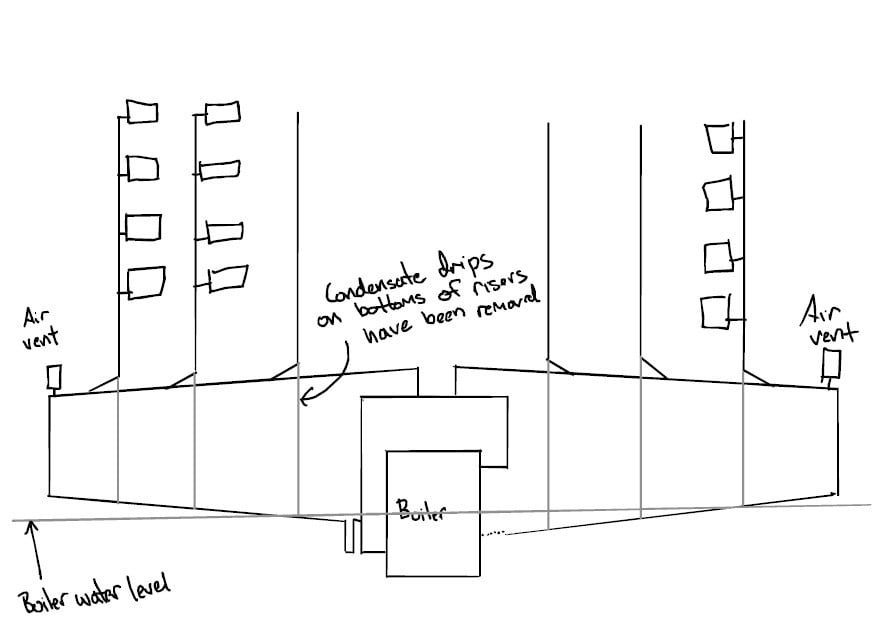

Quick question. See drawing of system I am dealing with. Someone in the past removed the condensate drips off the bottoms of the one pipe steam risers. The are all capped off. I am thinking that someone installed the boiler with a much lower water line and those sloped wet returns became half dry and half wet and water hammer started. I am not 100% sure.

We installed a new boiler (like for like replacement Weil McLain LGB-9 verified total EDR first). Had to cut open and unclog one of the completely clogged returns. The whole thing is going to get repiped. Fixed the header piping. Both mains had a single 1/8" radiator air vent on them. They now have (4) Gorton #2s each. Previous boiler was operating at 7 psi setpoint. We installed a vaporstat on the new one and it is currently operating at 0.5 - 1.5 psi.

Building is heating fine. Still getting a lot of dirt back from it despite two days of constant flushing. One return goes down under a hallway then comes back up and it is either trapping a lot of dirt or leaking under the slab. We are going to be replacing this.

No water hammer.

My main concern is the riser drips. Should we look into re-installing the riser drips and creating a false water line? Or maybe do loop seals on each one?

Comments

-

Unless you are getting a hammer problem in those long steam mains I wouldn't bother to do either one. However, bigger main vents where vents are shown are definitely going to help keep things even.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

- I agree with @Jamie Hall , if it isn't broke, don't fix it.

- If for some reason you are replacing the mains, make sure they are sized to carry all of the condensate from all of the risers in addition to the steam in parallel flow. They may have added the drips as a way to use smaller mains.

0 -

My system is like half of what you sketched. I suspect the original boiler had a higher water line. I compared (for curiosity sake only) the present water line with a hose water level and I believe about half of my pitched wet return is now dry. I have never had a problem with it. The present boiler is about 50 years old the piping is approaching 100 years old.

I suspect the steam never propagates past the main vent so it never gets into the return piping to cause an issue. Trapped air in the now dry part of the 'wet return'.

So yes, I also agree, if it isn't broke, don't fix it.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it wouldn't be a problem with a single return at the end. if there are additional drips connected in those would form a path for air to get out and steam to get in if they now connect above the water line.

0 -

The reasons to drip the risers:

1 Horizontal take off is very long

2. doesn't have enough pitch

3. or is pitched down

According to the Burnham Heating Helper

1" riser 25EDR horizontal 8' max if riser not dripped, if over 10' go up 1 size, if sloped down and dripped go down 1 size

1 1/4 riser 55EDR

1 1/2 riser 85 EDR

2' riser 150 EDR

Regardless of if it heats and no noise leave it

So, for example, a 1" horizontal riser can do 25 EDR if not over 8', if over 10' go up to 1 1/4"

If pitched down and dripped, you could use 3/4" pipe

0 -

I'd use the numbers from @DanHolohan 's book "The Lost Art of Steam Heating".

To do so, we'd need to know how much radiation is on each riser, as well as the pipe sizes of the risers and runouts, and how long the runouts are.

Also, have any radiators been removed from the risers?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

@Steamhead I have all the radiators / EDR written down for everything. Most radiators are still existing. But most have been covered with enclosures. Before I do anything with steam systems I always meet with the building and discuss issues they have.

They only had one complaint - one half of the building barely got any heat and the other half got so hot they were all opening the windows. A company from NYC called Runwise sold them a Runwise controller and put space sensors all throughout the building and told them this would fix the problem. They complained that they spent money on that and it didn't fix anything.

Turns out one steam main had a single 1/8" radiator vent at the end and the other had a single Hoffman 75. The side with the single 1/8 radiator vent was the side that was always cold. I did some calculations out of the book and we ended up installing (4) Gorton #2 vents on the end of each main on a tree.

While going through the crawl spaces and flushing return lines is when we found all the riser drips had been removed and capped off. I told them lets see how the system does now with clear return lines and proper air venting. So far no complaints. Then if there are still issues we can look in to a fix for the drips that were removed.

There is one other thing I need to look in to more. The boiler floods from time to time. And despite multiple flushes after a few days the water is dark brown again. We cut in full 2" sized drain valves on each return so they could be thoroughly flushed via steam pressure and with hoses. We flushed for nearly 2 days until they ran clear. But they are back to dirty again. One of the two return lines goes under concrete so we are going to be replacing that one. After that is replaced I was going to determine whether we need to add some water capacity to the system or not by adding a reservoir.

Never stop learning.0 -

Every time you flush and fill with fresh water, you are introducing oxygenated water that will immediately attack the iron and create brown, rusty water. You can add some 8-way to clean boiler water and it will dramatically reduce corrosion/brown water creation.

I'm not sure what that has to do with your reported boiler flooding. What do you mean it floods?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements