Pex sizing

Just trying to understand.

Wood boilers seem to be like 200,000+ BTU. Like a Central Boiler a buddy has claims up to 400,000 BTU.

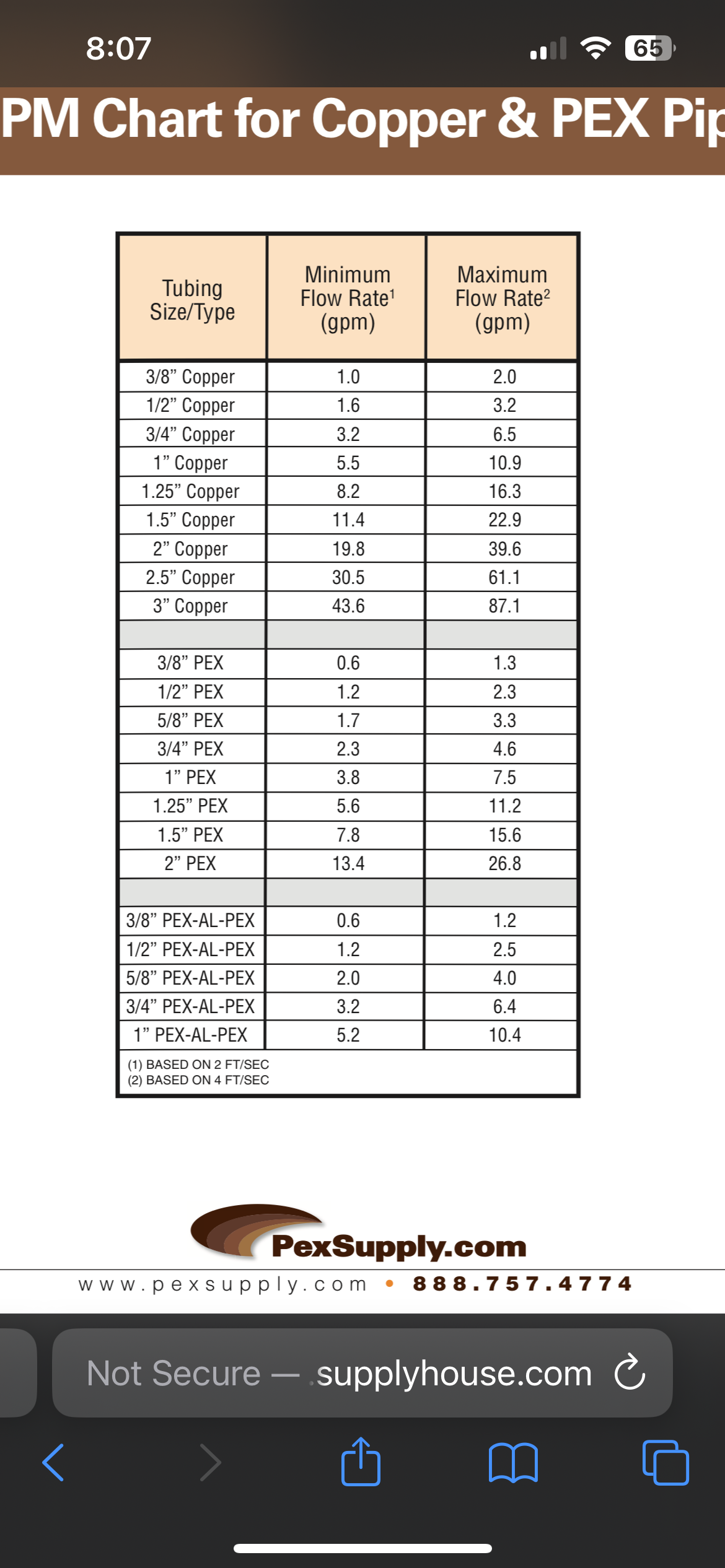

Why is the buried pex most commonly 3/4"? From what I can find, that can only do around 75,000-100,000 BTU/hr. (depending on pump flow)

I'm working on a setup to heat my place. It's a used oil boiler, but same idea of a wood boiler that it's out in another building and the heated water is piped in.

The used oil boiler is 160k BTU and has 1.25" piping. I'd think the pex running from a boiler of that size range would need to be at least 1.25". maybe even 1.5" if it's a long run?

Right now heating with a 120k btu gas mod con boiler. It uses 1" copper for primary loop, 3/4" for secondary and the floor pex is 1/2", each of the 4 loop flows about .4 GPM.

I had planned to use 1" for the used oil boiler and 3/4" pex for the insulated run, but now wondering if that'll be large enough? Anything over 1.25" for copper is harder to get and even that stuff is $$ and limited compared to 1"

Comments

-

3/4" pex can move more like 30,000 btu/hr at 4gpm at 20 f delta t

0 -

that mod con is modulating way down except for maybe when it is first heating the system up. that system is probably able to absorb maybe 40,000 btu/hr

note that 3/4" pex is significantly smaller than 3/4" copper pipe

0 -

Why would it be used on most wood boilers? Seems like it'd be WAY too small?

Whatever it outputs, it's enough to heat a 30x42x14 ft building at -30* with mediocre insulation and 2 10x13ft garage doors that are like r5

0 -

I see the most common insulated pex for OWF is 1”. 1-1/8” outside, .875 id

3/4 copper M is .811 id to get an idea of the flow capacity

There is some PAP pex al pex available that has a larger ID that is used with OWFs

It should be the job of the installer/ designer to know what size is required.

Leaving the tube size selection up to the OWF sales and marketing , often leads to expensive mistakes. There are plenty of online sources for sizing pipe and tube for hydronic applicationsThe pex manufacturers and their reps are happy to share sizing information also

If the oil boiler is a 160,000 input btu x 80% efficiency so you have more like 128,000, @12 gpm is all the flow you need to move its full output. 1-1/4 pex can do that flow.

These are conservative numbers based on 4 feet per second velocity

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

3/4" is used in MAYBE 5% of wood boiler applications. The most common by a landslide is 1", with 1-1/4" being next in line. OWB typically have a large volume of storage onboard and can tolerate a higher delta T due to mixing in the water jacket which allows a smaller diameter line, but realistically a 1" PEX loop at 200ft total and a 26-99 sized circ will flow about 7 GPM and with a 40* delta would supply 140,000 BTU. The 400k BTU Central you mentioned is a bit of a scam as they use their 400G of storage to create a 400k "first hour" delivery, while the actual continuous output is less than half of that. Most OWB using their full capacity are serving more than one building so the above example of a 200ft loop of 1" with an additional building using an additional 200ft loop of 1" to another building, we're approaching 300k capacity with only 1" PEX. Calculate your required BTU and flow rate, then you can size your lines and circ accordingly.

3 -

Thanks for the info, I'm learning this info and it's tough as there's so much bad info that's presented as correct! The place I talked to said that almost all they use is 3/4" and didn't understand why I was looking for anything bigger.

I was questioning this as why are std sized boilers, at least the main loop, are piped in 1-1.5" if 3/4" is plenty… and that loop is usually like 10feet or less.

Manual J that I'm coming up with is around 70k BTU needed, THOUGH I may expand the building later, and that would be closer to 120k BTU… if I'm understanding the manual J program right. I think I'd rather upsize the pex in case vs redoing it later. Cost of 3/4 over 1.25" isn't huge.

30x42 building, 14ft ceiling, 1 man door, 4 windows that are 15sq ft, 2 10x13ft garage doors 1.375" thick (maybe r7). Mediocre insulation (working on that though). Expansion would add another 900 sq ft and maybe 2 windows.

So 120k BTU would be like 12gpm at 20 delta T. And 8 at 30 delta T. So 1.25" would be ok… I think?

Was thinking of DIYing the buried "lineset". If I use foam insulation on the pex and set it in 6" SDR or ABS pipe, and then built a 2" foam "trench box" I'd be into it around $9/ft a foot.

The made for it insulated 1.25" line runs about $23 a foot factoring in the shipping. Like a 50ft length of 1.25" is a bit over $700 JUST in shipping. Plus the ~$500 for the line.

0 -

I am the designer and installer. It's all a DIY job. I get oil for free, so by installing this, I will have near free heat.

Insurance wouldn't cover the boiler inside the building, so I got a connex to put it in. It'll centrally located between the current shop and future how, so will have lines running to both. Future house and current shop have natural gas heating as well. In case the use oil goes down or can't keep up, the natural gas will work.

0 -

so 1260 square feet of shop?

70,000divided by 1260= 55 btu/ sq ft. That seems like an awfully high load number?

you get 2 btu / sq ft / degree difference. The difference between ambient air temperature and floor surface temperature.So if you maintain the shop at 65 degrees the floor temperature needs to be 92!

92-65x2 = 54 btu/ ft

If you want a 68 degree shop, my ideal work temperature, the floor needs to be 95 degrees!

95-68=27x2 54 BTU/ sq ft

That is almost too hot to stand on even in work boots. Your feet will be sweaty all day.

Low to mid 80s is a floor surface that is comfortable to be on.

Rarely do you need over 120-125 degrees supply temperature to heat a shop.

Maybe try another load calc program?

Here is what I settled on to run underground hydronic lines. It is an insulated pvc pipe, you glue the sections together, so it is water tight. wrap the seam with the blast hole liner that they use as the outer layer. A 45 on each end for the large diameter pex to enter/ exit

Now you can slide, even remove whatever tube you chose. Run a water line with the heat lines

They have different pipe size as well as insulation thickness

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I’ve been installing outdoor wood boilers for over 25 years and tried several methods of underground piping. I’ve found that using Rehau’s pre-fabricated piping is the best and most reliable.

The Insul Tube that Hot_rod mentioned is also a good system but doesn’t have any real flexibility, it’s pretty rigid.

I’ve also done a lot of fabricating my own using drain tile and wrapping the pipes with multiple layers of foam wrap. After having a couple of those leaking ground water in because the drain tile was defective, I abandoned that method.

The Rehau piping is well insulated with a very tough outer jacket.

If you p/m me, I’ll recommend a source where the price is well below $23 per foot.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Unless it's pure sand with a constant slope toward a basement for drainage, this is a bad idea. I see it at least 20 times every year that somebody is losing 30-40 degrees between their OWB and building due to saturation. Spending the extra couple hundred dollars on something like the Rehau Insulpex that Bob mentioned or a similar product like Thermopex or Rhinoflex (specific to Central Boiler and HeatMaster, but both come off the same machine and utilize Rehau Pex-A) and eliminating that possibility is worth every penny. The stuff is unbeatable for this type of application.

0 -

The main cost is the shipping.

Example from OutDoor Boiler.com, 1.25" pex line 02 barrier, is about $11 a foot. The shipping for 50ft just to WA is $420. Then shipping from WA to AK is another about $200.

I just did check on 100ft for grins, and that shipping is $505 (LTL shipping) and then around $300 to AK, so it's around $19 a foot vs the $25 for a 50ft length

0 -

That's why I was looking at running the pex in PVC/ABS/SDR pipe. It would keep it dry. Put foam insulation pipe wrap around the pex, slide it in the 4 or 6" pipe, glue it together. Can put 2" foam on the floor of the trench and build a "box" before backfilling too, though not sure if that'd just be a waste of $$?

Around here, frost depth is about 10ft so going below frost depth isn't overly practical. I'd probably go 5-6ft just to not need to worry about damage from running over it with a dumptruck or anything.

0 -

A local supply house might be able to order and ship it through their distribution chain for less.

0 -

Edit… for some reason it's not quoting correctly, but my post is replying to post #25,837 from hot_rod.

Yes, 30x42, 14ft ceiling.

I can't remember what my floor runs at in the dead of winter, but 90* sounds about right. Whatever temp it is, it's not uncomfortable at all.

The floor is 70-72* right now and it feels cool to my feet with socks on.

0 -

I'm not sure if anyone locally sells it anymore. I've not come up with anything online or calling the couple places I know of. There was an outdoor boiler outfit a while back (like 2010 area) that was selling it as part of installing the boilers and it was right around $15/foot back then, for 3/4". I remember it well because a friend put in a boiler and hadn't planned on the pex being so expensive. It ended up pushing the project a full year as he didn't have that kind of money… it was near 1/2 the cost of the boiler.

Outdoor wood boilers are mostly a thing of the past around here, so there's not much demand for the pex they need. Natural gas has come to more areas, and the ones that don't generally use diesel or have a wood stove in the house.

My buddy has a Central Boiler and he stopped using it 2 years ago. Heats the house with a wood stove inside and says it uses less than 1/2 the wood that the boiler did. I've heard the same from a few other folks.

0 -

try plumbing and heating supply houses. some of them should be rehau dealers and should be able to order it. Normally it would be shipped as part of a truckload to a distributor then a truckload would be shipped from the distributor to the supply house and the shipping would cost a lot less than having one item navigate the motor freight system.

0 -

Outdoorboiler.com is a scam and the owner of it has been sued a thousand times. The "best in the business" line he sells is literally somebody else's with a different label on it, and it sucks to boot. It's worth nothing just like everything else in a drain tile. Find a somewhat local wood boiler dealer and buy some of the foamed stuff mentioned above (1" is about $14-15/ft nationwide) and be done with it. You can thank me later.

0 -

There isn't anything available in state that I've found. This is likely a next year thing anyhow, ground is about to freeze up now, but still info is helpful. Something available near Tacoma would be ideal, then would have mostly just the WA to AK shipping.

Outdoor Boiler is just the site that comes up all over when I search for insulated PEX, but most the other stuff available is the same setup.

To me it doesn't seem like anything overly special that 2 pex lines with foam pipe insulation in an ABS/PVC pipe wouldn't have similar results.

0 -

The rehau product is foamed in place so that the foam is bonded to the pex so if there is flowing water in the ground the foam insulation is still effective.

0 -

Where in Alaska?

Keller, Pacific, Ferguson have locations in multiple cities. Seems they could bring in a coil on a truck load oth other pex if you gave them some notice?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Wasilla. I talked with Ferguson, Grainger, Pacific Plumbing, Keller, AK Goldstar, Meadow Lakes Supply, an old number that was on a Central wood boiler that I came across (disconnected).

It can be had, just nothing on hand, and it'd be ordered in no different than if I just buy it direct. Everyone said it's not something used much, generally is sold as a package with the boiler.

Where 1.25" 02 barrier pex, foam insulation and 4 or 6" ABS, SDR, etc is on hand and most anywhere.

0 -

Again, find a wood boiler dealer near you and buy the right stuff. According to a 2 second Google search, AK Fire and Flue sells Thermopex in Wasilla.

0 -

They are checking.

0 -

Only have 1" in state. 50ft is $1000, 100ft is $2000, 200 is $3000.

1.25" would need to be ordered in. Didn't have price on that, but would be more.

That's at Fire and Flue. Only place that I called that had it, of the places that either answered or got back with me. I suppose there could be a huge dealer of the stuff that just is hiding too.

0 -

Having done underground pex runs numerous times, here are a few opinions. Nothing wrong with running schedule 40 pipe and then pushing your insulated pex thru it. Just make sure there are no sharp bends and the pvc is big enough. One small downside to that method vs the ones that are a solid pex-foamed-in-pipe unit, is that the pex will expand many inches out each end as it heats. You need to install so that expansion does not make a problem at each end. I would go with the manufactured unit IF available.

0 -

The manufactured unit is about 2x as much as a DIY one though.

0 -

Join a wood boiler forum or group and you will see literally thousands of people who have had problems with DIY or drain tile type underground lines. Every single one of them is problematic in some way or another. There is no excuse not to just buy the good stuff right away because you WILL end up buying it down the road anyway and have to dig your yard up a second time.

1 -

I'm not seeing any of these posts, I spent a few hours yesterday looking. Actually just the opposite, where many people saying their DIY setup is working great. Have any links?

Found posts of people saying the Thermopex is trash, it soaks in water, so I dunno.

0 -

Where did you look for "several hours" and not find any of this? Literally zero people have seen Thermopex absorb water, it's not even physically possible. There are a dozen groups on Facebook where this topic is discussed almost daily and the consensus is always the same. There are a few who brag about their homemade stuff that just hasn't started leaking YET, but it is easily 100:1 on the good lines. Go ahead and try to build your own, but you WILL regret it at some point or another. I along with several thousand other guys have learned this lesson the hard way, and I assure you that you are not an anomaly.

0 -

Did you try woodheat.org

The Hearth is where wood boiler folks hang out.

At this point you know what you need to do to move the various heat loads from spot to spot

Sounds like getting your hands on the product is the issue now?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It's just needing a waterproof channel to run in and some insulation. Lots of folks have done what I was thinking and good results.

Not really different then setting a water line or sewer line. If done right those don't leak for many many years.

I'll decide when it's time to source how I want to go… either spend $500 or $1500+. The oil is free so not worried about 1* heat loss or 5*… of course don't want the boiler running 24x7 barely keeping up either because of the piping.

0 -

Yeah, would be special order unless I use 1". Which maybe is fine. I talked to a guy I knew from the old stove shop and he said that's mostly all they sold for outdoor boilers. Not sure why if the book #s don't work that it should work.

0 -

You could always lay two runs of 1" and header them together if you find a bargin on small diameter.

There is no secret to heat transfer, flow rates, velocities, heat loss. The numbers and calculations are well documented and industry accepted.

True, some salespeople tend to tweak the numbers to fit their narrative.

Take the advice from whomever you chose. Actual hands on tradespeople here with engineering tables, proven experience.

Or the used car salesman, or woman :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

Have you considered using a much smaller coal stoker boiler to heat your shop and future home??

They are small enough that they can be placed in a shed or a lean too attached to your garage. The AHS Coal Gun Boiler will burn western Sub Bituminous and you will have much less ash and work to do to maintain it. The western Sub Bituminous Coal smokes a little but not much, The Alaskan lignite coal smokes more when burned.

If you are anywhere near the Usibelli Coal Mine at Healy, Alaska you will save a great deal of money on fuel.

0 -

I would have to buy coal. Oil is free and easy to source locally. Usibelli is around a 7hr round trip. Also still a fair amount of work dealing with coal.

Not sure how insurance would be with it. They mostly want a no maintenance, no constant tending to setup.

Putting the used oil not in the building is partially due to the building also currently being my house. BUT if just a shop, it would need to be UL rated for that purpose and they would need to do a different policy that would be similar to if I had a commercial shop instead of just a building storing my tools and junk (so $$$ I'd imagine). From what I've read, lot of insurance outfits won't even consider it at all… some for the fire, but some for the potential spill issues. Even just fuel oil heat some won't touch. My folks ran into that when then were shopping around some years ago.

My old place I mainly heated with a Blaze King and it had to be put as "comfort fires" or something like that for insurance, had to had a no maintenance automatic on heat source (boiler, furnace, etc). I had a real tough time finding an outfit that would even insure an place in AK

I have natural gas. It's certainty.. supply and cost is rocky. It's not crazy expensive right now, but still far more than free…. Last year it cost me about $1300 to heat the shop, so figure if this works without too much headache, it would pay for itself pretty quickly and after be a cost saver.

Adding a house and heating that, I wouldn't doubt that to end up being $2k + a year between the two.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements