Gravity compression tank connection

I have a steel compression tank for a 1930s gravity system with a 1950's american standard boiler. The connection for this was made in 1/2" copper. Before I bought this building, tweakers had stolen all of the exposed copper pipe including this connection. Should i redo this connection in the same size, or would it be better to make it in 3/4"? Also, there is only one connection on the compression tank with the other bung plugged. Is this a specific valve that allows the tank to be drained without draining the rest of the system or do i need to also have shutoff inline between the boiler and the tank? I know that normally there are 2 valves, one to isolate the tank from the system on the inlet of the tank and a second valve on the other bung to drain the tank periodically.

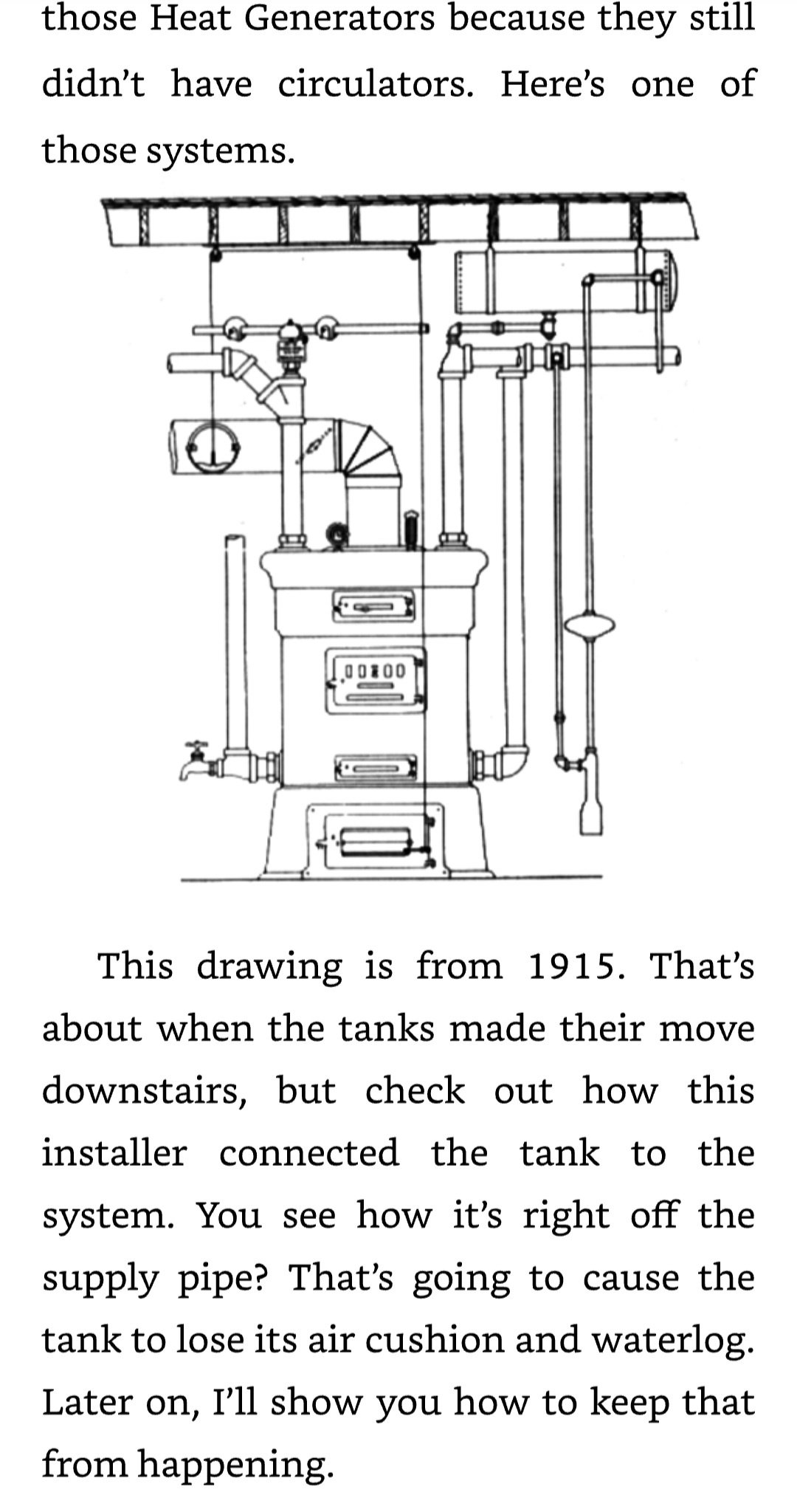

Comments

-

Disregard the shark bite and pex, that was only to test the system for leaks

0 -

That's a "tank drainer" and you don't need another drain or valve. There should be a small plug in the other side of that unit. You hook up a hose, open the valve to depressurize the tank, then remove the little plug to let air up into the tank so the water will drain.

1/2" pipe is fine in this instance.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

make sure it slopes up toward the tank so air goes to the tank. there should be some sort of air scoop or airtrol boiler fitting where it connects to the system if that part was stolen.

0 -

-

Wouldn't i need to plumb in an air separator somewhere in the 2-3" black supply pipes coming out of the boiler? I assume I would need something considerably larger than a 2 gallon membrane tank since it is replacing a 25-30 gallon steel tank.

0 -

typically a diaphragm tank will be 1/3 the size of the compression tank. Due to the captive air space.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Please provide more images of your boiler and its close plumbing and the plumbing connecting the compression tank to your boiler with the plumbing in the basement joists to the radiators.

Something in your statement about it being a "gravity compression tank" is wrong in your description.

0 -

Here is the dinosaur. It will be replaced sooner than later but first i want to make sure that the radiators a were placed actually heat the whole house comfortably. This heating system is installed on a ny style row house with the boiler located nearest to the street with the brick wall being parallel to the street.

From left to right: the piping coming of the boiler goes Return Supply Supply Return. The returns both come back to the same tapping on the far side on the boiler through a large tee. The pair of pipes on the left aregoing to the front of the house and feed 4 radiators. 3 with 1" connections, one, on the third floor with a 1.25" valve.

The 2 pipes on the right go straight back and feed additional radiators with dedicated 1" pipe teeing of for individual radiators and 1.25" pipe for 2 radiators that are subsequently plumbed with 1" After teeing at the ceiling of the floor below.

You can also see additional photos in my other thread reanimating Frankenstein, however, if you like, i can provide a photo of every radiator.

0 -

From the opposite side you can see the pressure relief valve attached to a tee with a 1/2" stub of copper i assume was previously connected to the steel tank. (Next to the red square label of the old pressure relief valve). The large tee at the bottom has both returns. Barely visible on the lower left is a 1" tapping that connects to the fill and the drain.

0 -

-

Would something like the watts etsx-60 work? Do i just hook it up to the existing stub by the pressure relief and set it on the ground, or should it connect somewhere higher?

0 -

May be easier to use multiple smaller ones. I use two number 30 with hangers on my large converted gravity system.

0 -

Is the compression tank broken? Or is it that your plumber can't figure out how it works? If it's not broken, and I can't imagine what might break it, drain it out, connect it up to the system, bring the pressure to where it needs to be, and be happy. Takes half an hour at most, unless fittings or valves are stuck.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

yeah, i didn't catch that it was a gravity system. they will have to manually bleed it no mater what, without a circulator it won't move the air out by itself no matter how you set it up. there is less benefit to a bladder tank on a gravity system.

you can make the compression tank less likely to circulate its water out and move its charge in to the system. without some sort of a trap the cooler water in the tank with more dissolved air will circulate out of the tank by gravity circulation and be replaced with hot boiler water with less dissolved air and the cooler water will be heated in the boiler and lose some of its dissolved air. The hotter water that circulated in to the compression tank will cool and absorb some of the air in the compression tank. Over time this will pull the air charge out of the tank unless it more or less moves from the boiler to the tank.

0 -

A B&G Airtrol fitting will prevent that. This is my preferred setup, since it eliminates the diaphragm or bladder which eventually fails, necessitating a completely new tank.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

You can save all the existing piping to feed your system "if you are not going to use circulators" it just needs some work done by someone that knows how a beautiful gravity hot water system like the one you have functions.

You have a simple clamp on external aquastat that was used to control the boilers water temperature which most likely can still be used.

This building had a either a hand fed coal boiler or a coal stoker boiler originally and it was replaced with a gas fired boiler.

The plumber that installed that boiler knew what he was doing and how to properly connect it to the existing piping with unions and gasketed flange piping.

If my memory is right about this type of gravity system, the radiator's in this home are used to create the point of no pressure change holding by holding an air charge to maintain the point of no pressure change by running the piping bottom to bottom on each radiator and avoided or eliminated using an open to air expansion tank due to the flat roof on this home.

If you have time your please upload pictures of your radiators on all the floors and any more heating piping.

The way the plumber installed the piping for this gas boiler will simplify replacing it as it all can be reused quickly due to the flange fittings and pipe unions he used to assemble it.

He used heavy schedule 80 pipe for most of it because the previous coal system had this weight of pipe and it is entirely possible much of this pipe was original to the coal boiler too.

Mr. Holohan or Mad Dog please correct me if I made mistakes about this

0 -

All correct. Thanks.

Retired and loving it.0 -

As far as i can tell there is nothing wrong with the steel tank. Others suggested a modern bladder tank and i was offered a used bladder tank (mentioned above) which should be suitable. I've read Dan Holohan's books and while he has a diagram of a gravity system with steel compression tank on page 36, he says the installation will inherently cause a waterlogged tank eventually, and i didn't see the correct way he alluded to later in the text. Since this is a large bladder tank that sits on the floor, I'm still not sure whether it should be connected at the top of the boiler where the old tank connected or if it is better to connect it higher, and whether it should be in the on a supply line or a return line.

0 -

As @Steamhead said, the compression tank should connect into the system at a high point near the boiler, and ideally an Airtrol fitting.

However, with a pure gravity system (no circulator pumps anywhere) it may sometimes lose its air charge — but that's not all that common. What you do need to watch out for is to not have any other air removal fittings anywhere! Yes, you need to bleed the radiators on startup, but once bled if the pressure is correct there should not be any need to bleed again.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

So, I'm going with the used 33 gallon standing diaphragm tank since it was avaliable. I actually had reservations on reusing the 30 gallon plain steel tank since i had no way of knowing if it was sized for only the first floor or all 3 floors. Per @hot_rod a diaphragm tank will can be 1/3 the size of a plain steel tank so I'm golden. My last question is whether the is any difference whether i attach the diaphragm tank to the supply (red) or return (blue) side of the boiler. Obviously, on a circulator application it would be on the supply right after the pump that pumps away from the boiler, but for all gravity systems, they usually hook the return to the attic tank. Since the return had slightly cooler water, I an currently planning on hooking up to the blue at the line drawn

0 -

Any trapped air in the system will not dissolve into the air volume of the tank if you use that bladder tank.

The air blanket in the steel compression tank holds the air in the system in place to create the point of no pressure change.

You need a plumber well versed in gravity systems to install an ATF-12 valve in place of the drain valve in the steel compression tank.

0 -

-

Ah… um… how do you propose to keep air out of the water side of that bladdery tank… ? pumped systems can use an air removal device, but the circulation in a gravity system is too slow for that be effective — and your bladder tank will gradually get air bound.

Make provision for this.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

and? that will just add to the compressible volume.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements