hydraulic separator piping

Comments

-

I like to try it different ways and honestly it's worked well each way I've tried it.

Steve Minnich0 -

Really not much difference. Wherever you connect the entire sep becomes the PONPC.

On the multi boiler system with the large floor mount tanks, the expansion is connected at the end of the large headers off the sep.

Avoid putting the tank directly below the bottom port of a separator as dirt and crud may settle onto the diaphragm in the expansion tank and cause wear.

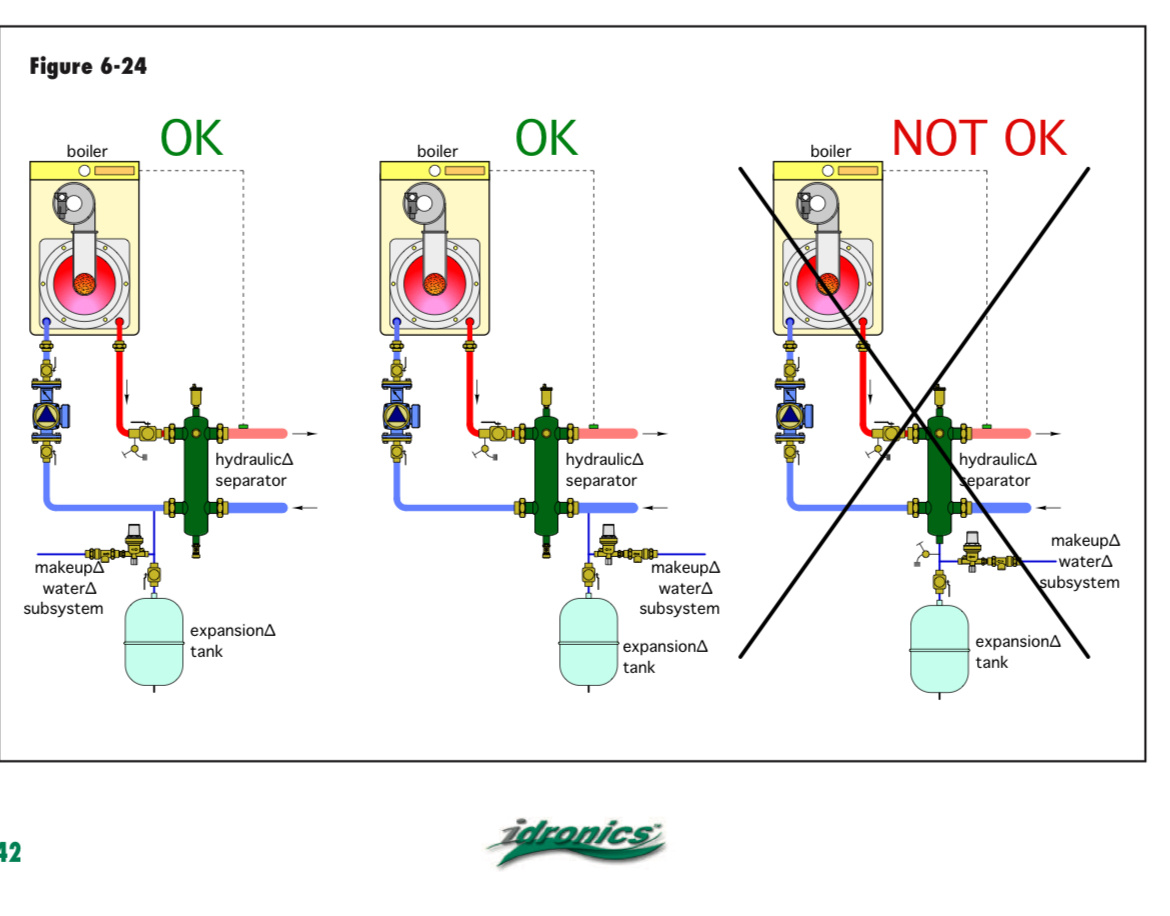

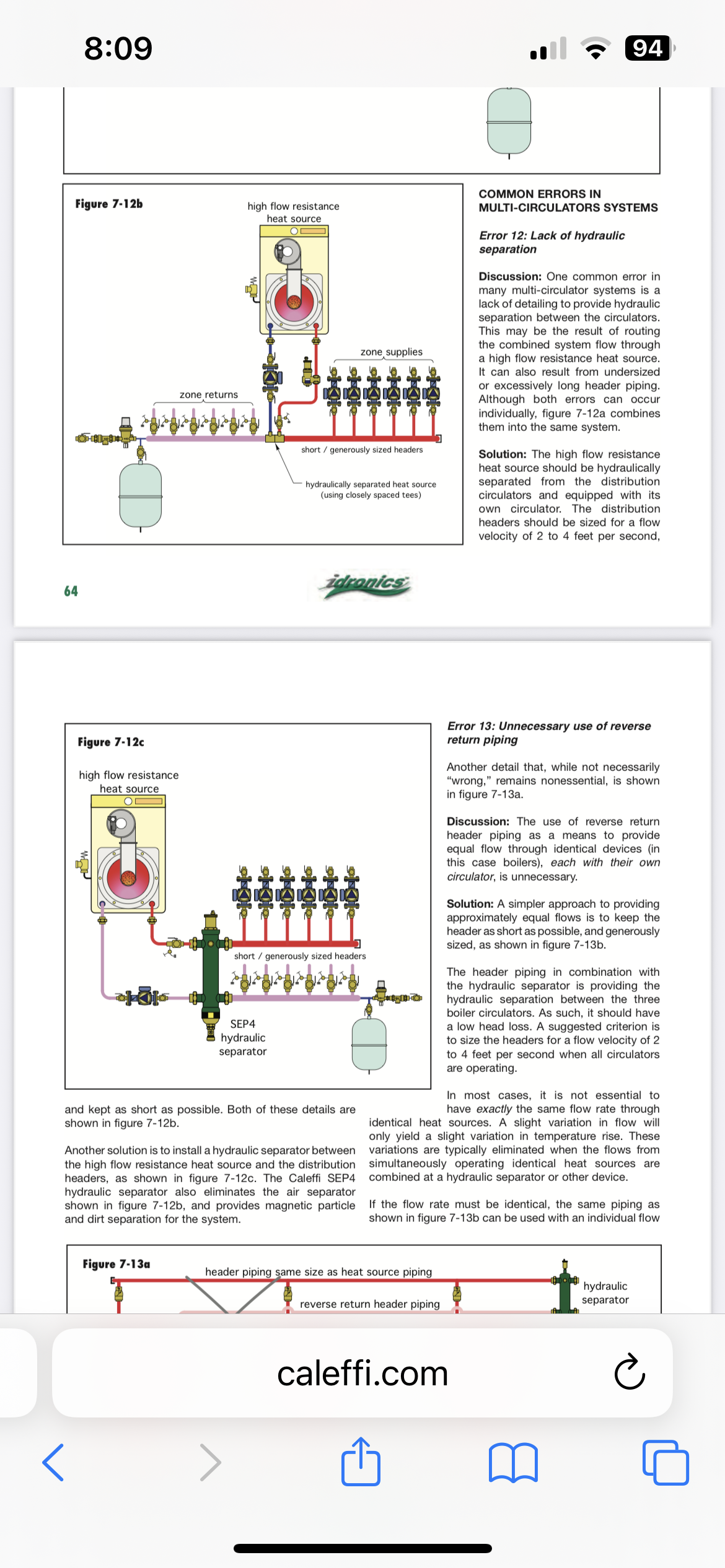

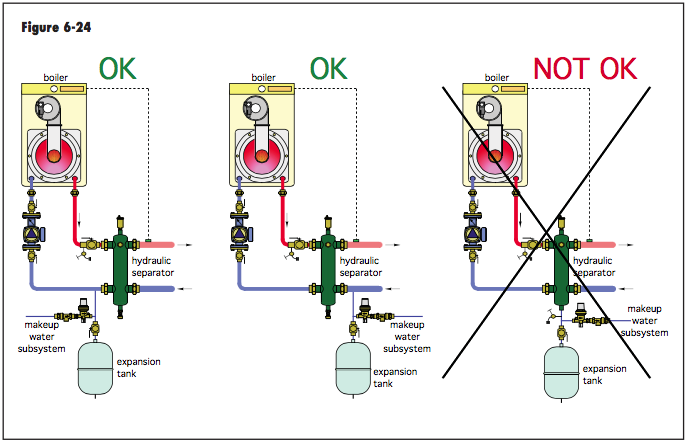

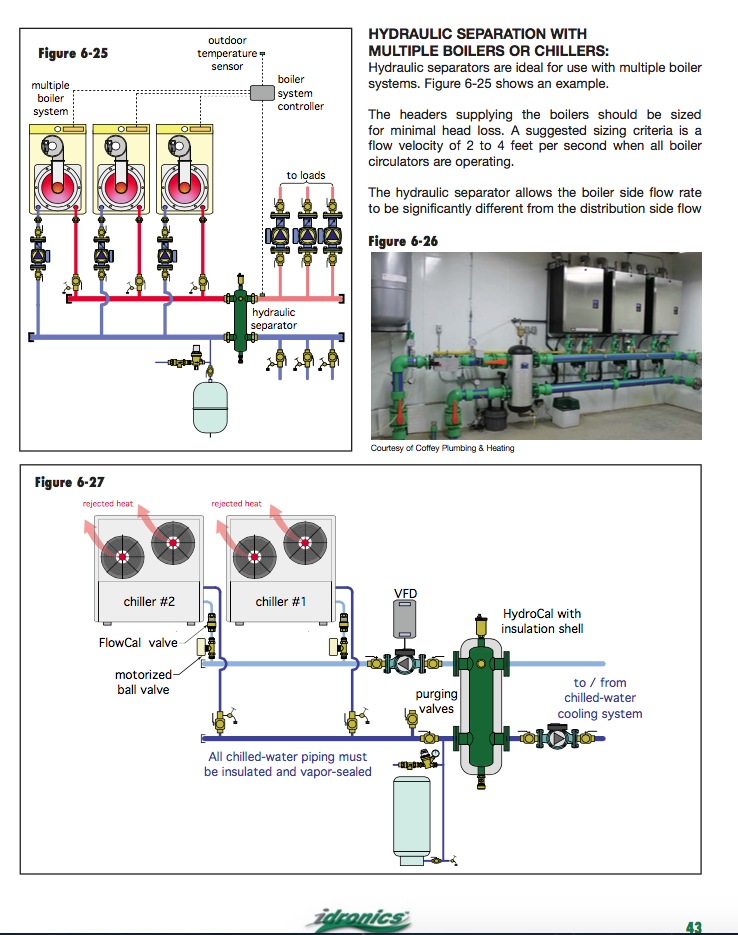

Here are some examples from Idronics 15.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

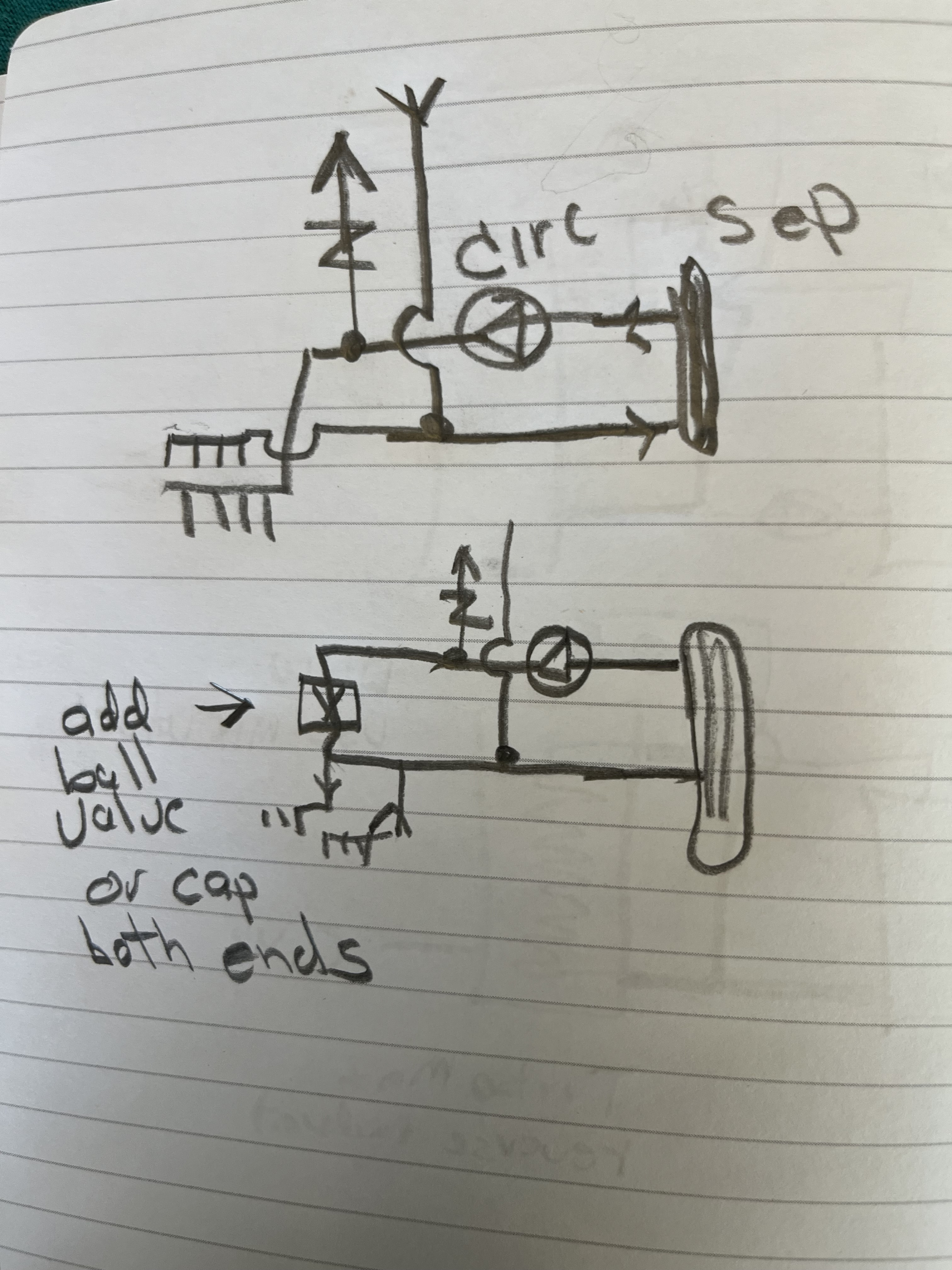

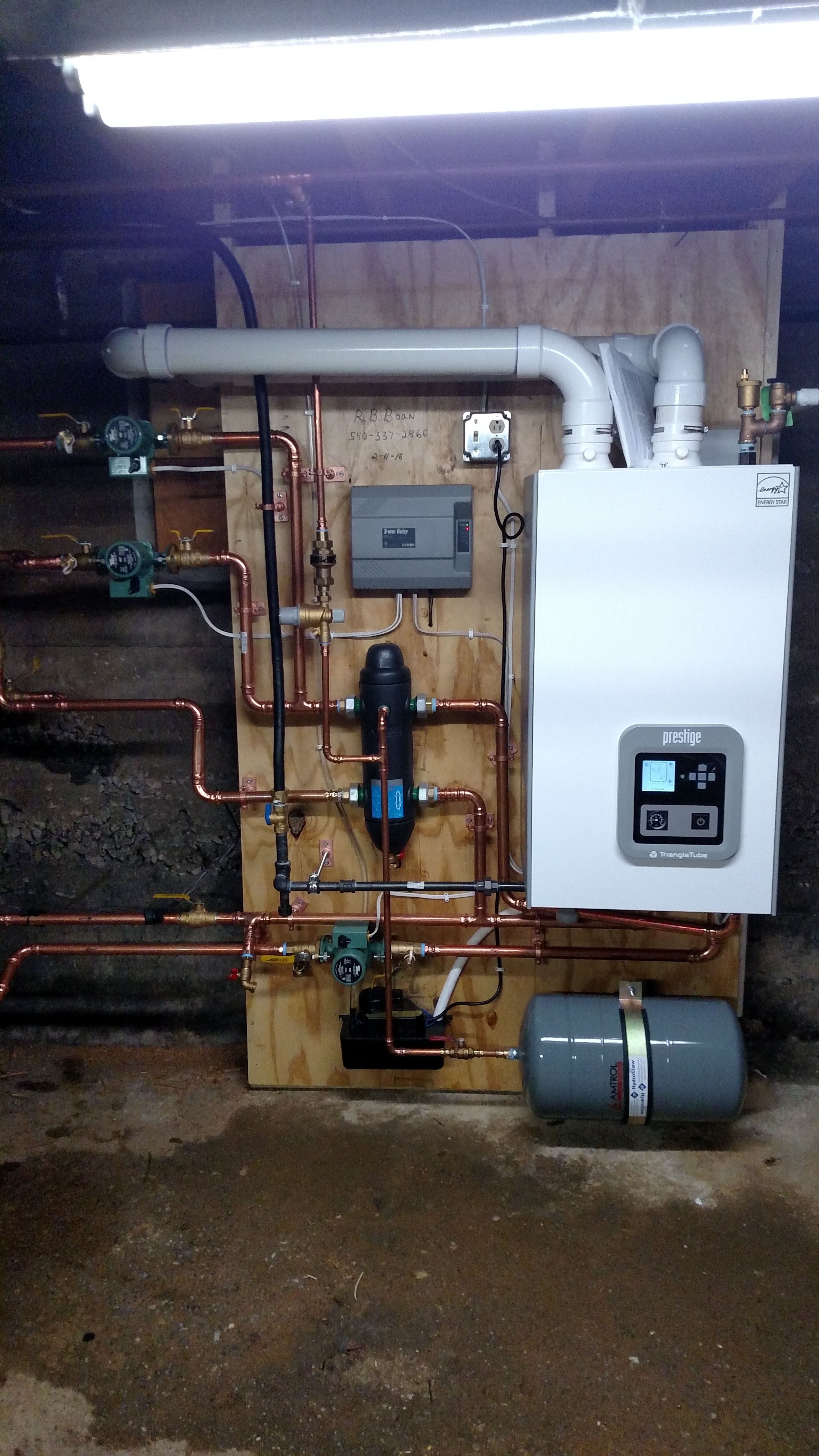

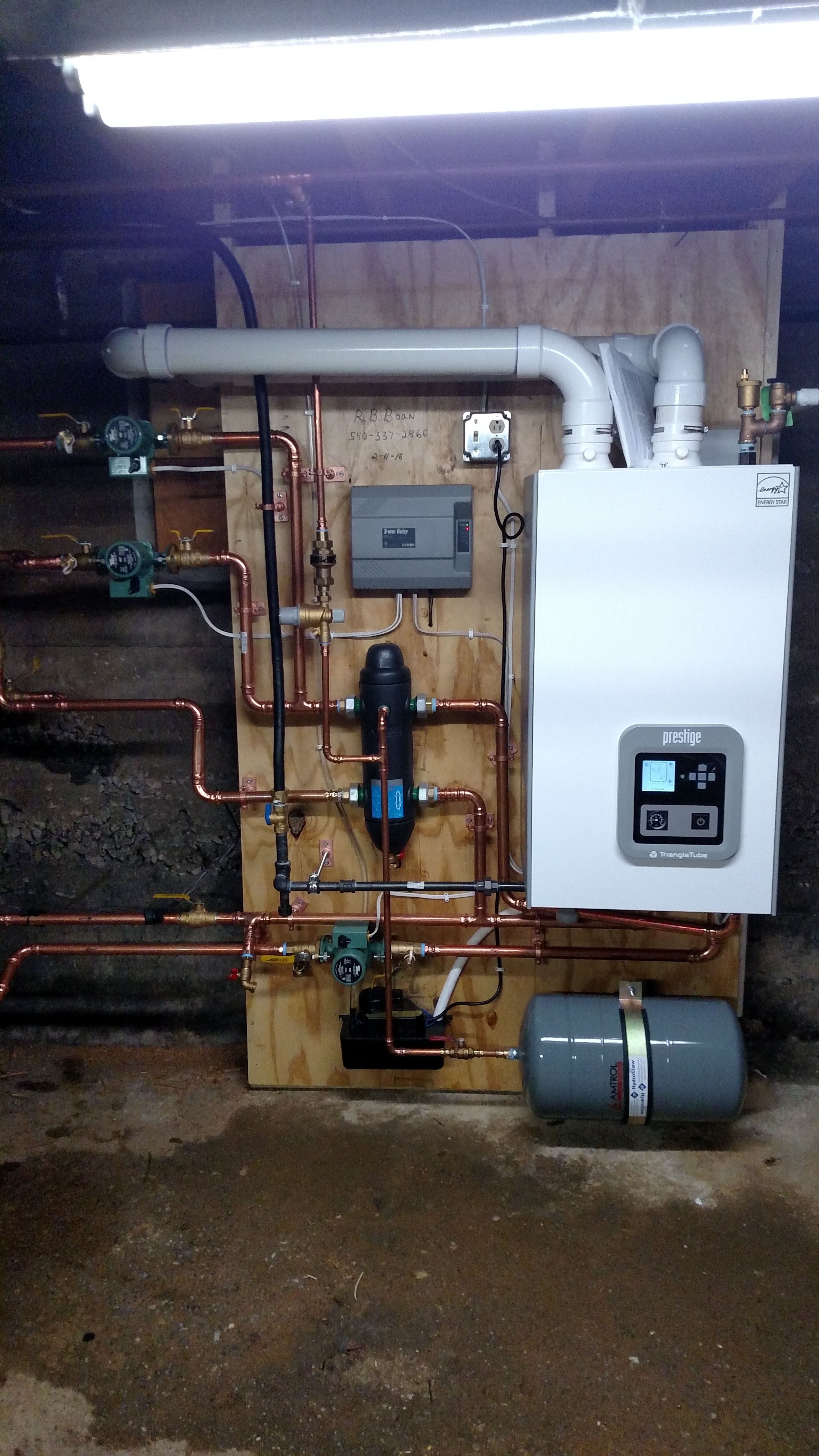

Or, you can do it like this:

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.3 -

Nice, creative. I like the exp tank mounted horizontal with that sturdy bracket. Hydro-Claw?

You have the backflow correct also. They can only be vertical if flow is down.

viIronman said:Or, you can do it like this:

Bob "hot rod" Rohr

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes, HydroClaw.

I've heard some folks say that you're not supposed to mount the expansion tank that way, but I've never had a problem with it and can't find any documentation to say otherwise. Mark Eatherton says it's okay. That's good enough for me.

If you think about it, a floor tank has the connection at the bottom, not the top.Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Page B3-5 in the Amtrol book indicates approved horizontal mount, if ever you get called out on it, or an inspector challenges you.Ironman said:Yes, HydroClaw.

I've heard some folks say that you're not supposed to mount the expansion tank that way, but I've never had a problem with it and can't find any documentation to say otherwise. Mark Eatherton says it's okay. That's good enough for me.

If you think about it, a floor tank has the connection at the bottom, not the top.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Thanks, Stephen!hot rod said:

Page B3-5 in the Amtrol book indicates approved horizontal mount, if ever you get called out on it, or an inspector challenges you.Ironman said:Yes, HydroClaw.

I've heard some folks say that you're not supposed to mount the expansion tank that way, but I've never had a problem with it and can't find any documentation to say otherwise. Mark Eatherton says it's okay. That's good enough for me.

If you think about it, a floor tank has the connection at the bottom, not the top.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

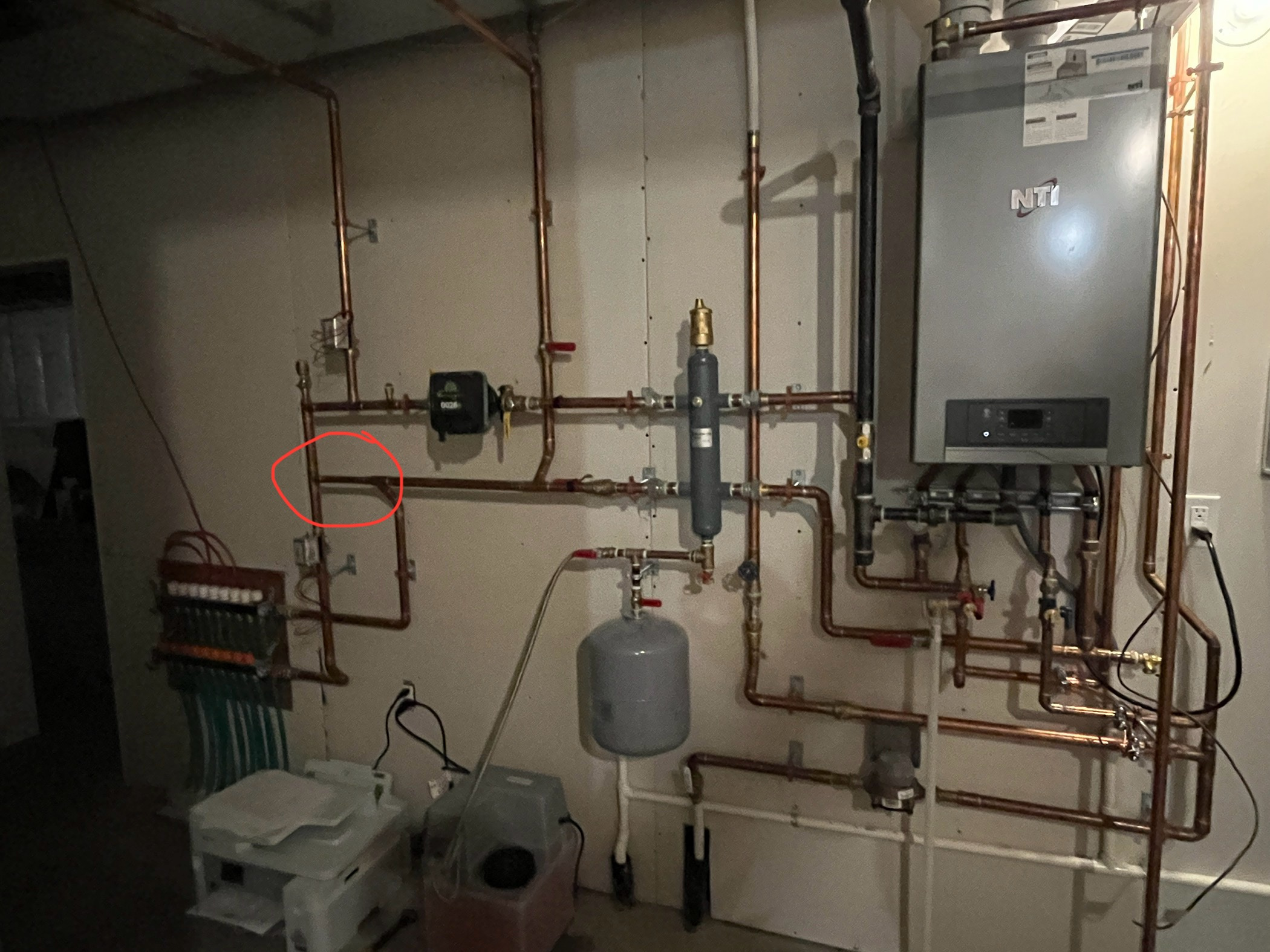

hey guys,

Thanks for the diagrams! Was helpful to confirm my configuration. One question, I can’t understand why they’ve installed a pipe connecting the supply and return to the floor heating. Is this correct?

0 -

I would say no if the circ is off when the zone valves are closed. If the circ runs all the time it should have a bypass valve installed in that pipe. Looks like they are using the small pipe for a pressure control.

0 -

that is not correct

The supply from and return to the sep should not connect

Install a valve or cut and cap. Take the handle off the valve after you turn it off!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks gentlemen! How about the pressure tank connection into the hydraulic separator? In the Calefacto CB100 connection diagram, nowhere does it show connecting into the bottom like that. Is it connected wrong?

0 -

manufacturers of low loss headers will always tell you not to hook the tank there. The concern being that debris tends to settle in that spot and can settle in the tank and over time possibly disconnect the tank from the system, and can make flushing the debris out more difficult. In this case they did build a little dirt leg of sorts there, it's probably OK but I would prefer it on the return pipe (colder pipe) on the boiler side of the low loss header, not attached to the LLH directly. I will also add that there are many many installed like that in my area, it was really common and I was even taught to do it this way originally, a conversation with our local caleffi rep right around the time we picked up their LLH with magnetic dirt separation changed my mind. I even took the white out to my diagram and changed it right then! I've also seen them piped in sensor/gauge wells like what you have near the top of the LLH, that's a bit better than the bottom but that thread is usually not NPT, and why not just put a gauge there if taking the plug out?

also im sure your pic is from service, but make sure that service valve to the exp tank is always open

1 -

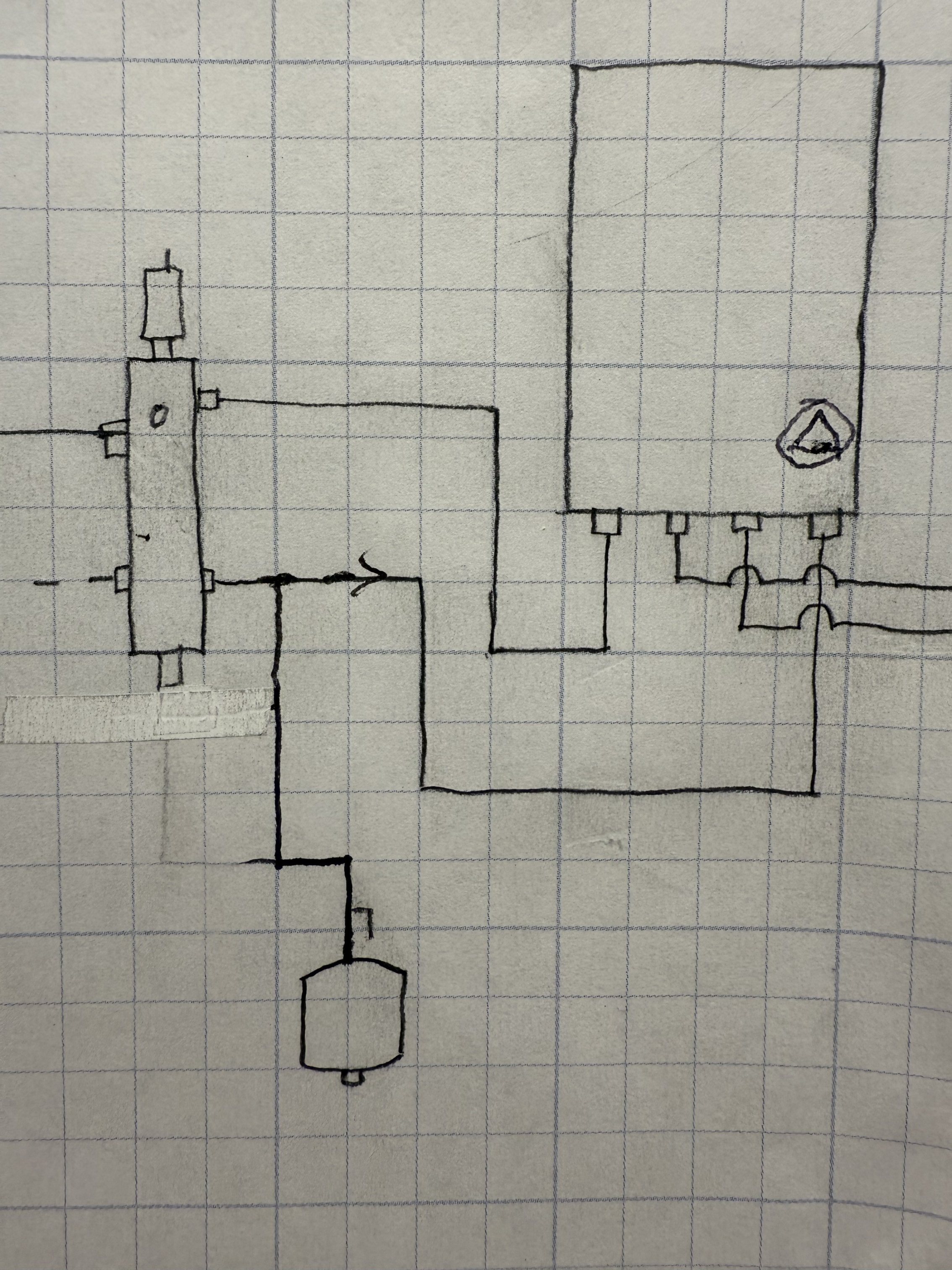

here are some piping options for an expansion tank on a sep

While yours is not pic perfect, they did offset with a tee, so it is not directly below.

I suppose it depends on how much debris will filter out and fall down to that connection

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements