Baseboards only getting warm

Hello, I can’t seem to figure out what’s wrong with my heat.

I have a natural gas fired boiler delivering hot water to baseboards throughout my house (3 zones).

In one of the zones (top floor), the baseboards only get slightly warm.

The boiler itself is only 8 years old and it’s working great (a tech even just came out to test it). It quickly brings up the temperature of the water to almost 200 degrees F.

Because the baseboards get a bit warm, I know that hot water is reaching them. Just not enough of it!

In diagnosing this, I have the thermostats cranked way above the current temp, so there’s no issue with the system simply not remaining triggered for long enough. And other zones work great.

My first thought was air in the system. But I just spent an enormous amount of time trying to bleed out all the air with every possible combination of valves open/closed that I could think of. (Garden hose going into a bucket in the shower). It seems like there’s no air in there. Yet, the problem persists.

My second thought is the circulator pumps. But, like the boiler, they’re only 8 years old, and they seem to be working well (though I can’t be sure). The water immediately above the circulator pump is quite hot, so it’s at least pushing some hot water up – as far back as I can reach from the boiler before the copper disappears into the wall. Though I suppose that could be passive convection?

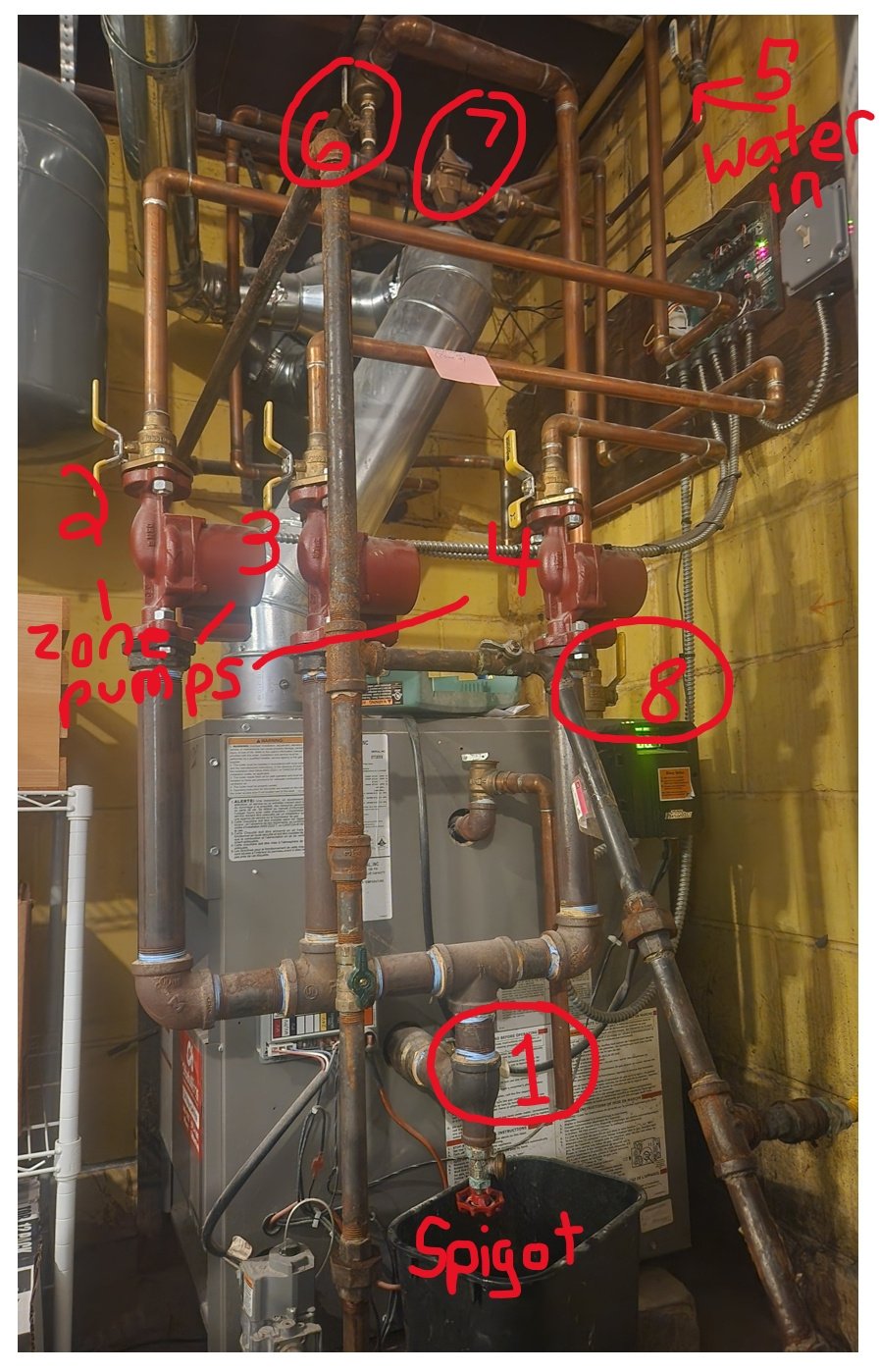

I’m guessing that I’m doing something wrong in bleeding the air out and that there’s some big air pockets in there that I’m just not able to get pushed through. If you agree that’s likely the problem, could you point me in the right direction as to what combination of valves I should have open/closed to ensure I’m pushing all the air out? I’ve labelled some in the attached picture for ease of identification.

Could a check valve within the circulator pump be preventing me from bleeding out the air correctly? If so, how do I deal with that?

Alternatively, if you think it’s the circulator pumps (or something else), I’d be eternally grateful for any advice there, too.

Many thanks!

Comments

-

what's the pressure in the boiler? post a picture of the gage,

and another picture of the entire boiler, a little wider shot, floor to ceiling, from a different angle

known to beat dead horses0 -

How many floors in the house? 15 psi is enough for 2 floors.

0 -

As long as they're not monoflo loops, close valve 8. If purging the top floor, close the valves at the circulators for the other 2 zones not being purged. Purge through spigot. Open ball valves when done. Its not exactly piped correctly. There might still be air in the boiler itself when done, but the Spirovent should make short work of it once there's flow.

FWIW, whoever did the gas piping should be ashamed of themselves.

0 -

Thank you for your help! Deeply appreciated.

Pressure is about 50 psi

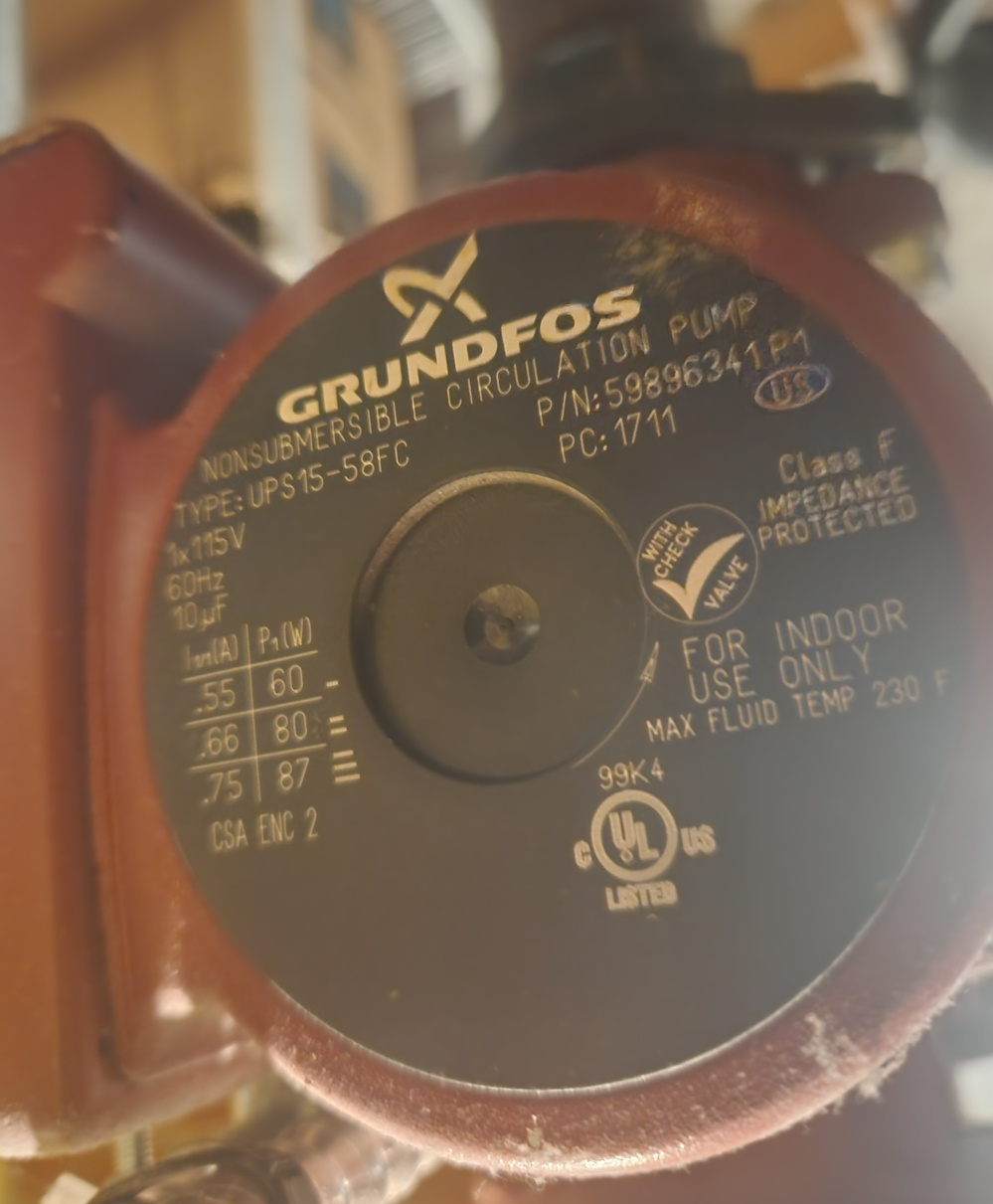

Well, I'm an idiot. It ocurred to me that I should put a multimeter on the leads for the problematic zone's pump. It is indeed getting voltage, but I can't feel the pump whirring at all even when it has voltage. (Whereas the others do slightly whirr when they have voltage). So, I guess it is the pump after all. It does make sense that this pump would fail first, since it's the one dealing with the most head. I'm just surprised that I'm getting any heat in the upstairs basebaords if the pump is completely dead. I guess convection can accomplish a good bit, though. Or perhaps the pump is just barely turning. Either way, I ordered a new pump. Installing that next week will be interesting.

Yeah that gas piping is horrible. My fault, though. After the plumbers installed it, I noticed an extremely minor natural gas leak. (Yes they should have dealt with that of course.) My temporary fix was simply rotating that whole assembly slightly clockwise, which tightened the problematic junction without the whole thing needing to be re-done. (Though I should get all that re-done asap!)

0 -

Do you have flow checks on the loops? If a boiler heats and the emitters don't, the problem is always flow. what stops flow?, air, restrictions, poor pumps, imbalances zones.

A specific job I took my time on engineering the problem was similar symptoms. Between first and second floors, heat was uneven. there turned out to be three problems. 1) the common manifold of three circulators on 3/4" pipe was 3/4". It had to sized to handle all three at once, 1 1/4". 2) The old flow check, " not a check valve" was not opening nor closing all the way. this made a room upstairs above the boiler overheat while an addition further out remained cold. 3) A great room on the first floor with cathedral ceiling had high heat loss and exposed pipe in crawl space which could be the problem but it was not. After replacing the flow check, changing the manifold, flow was restored. All were happy, reputation of contractor secured who said lets not add baseboard in the great room!

0 -

Just for starters, 50 psig in the heating system is too high. It needn't be more than 25 psig, even for a three story building. Which causes me to wonder what the expansion tank is set up for…

And the circulating head for all three zone pumps is likely to be about the same, regardless of which floor they are supplying.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

DOUBLE YUCK!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!, invest in three very well written books by Mr. Holohan, "PUMPING AWAY", "CLASSIC HYDRONICS" and "HOW COME"

Where is your air scoop/air purger?

If it was me I would cut that mess all out, make the home a single zone system, eliminate pumping into the boiler and replace the gas line mess.

Using one circulator with isolation flanges and gauge ports for pressure and vacuum gauges and use pumping away with a pump module and three zone valves would be simpler.

Seeing that exposed wiring above the gas valve is also troubling to me as a homeowner.

You need to move the shelving that is in front of the boiler as it hinders the quick access to the boiler burners.

A home plumbed as a single zone is so much simpler to deal with and live with.

0 -

I was thinking 50 was too high. I'm not sure how to reduce it though. Any pointers there? Thanks!

Interesting, I didn't realize head was the same regardless of the floor. Would that be due to the returning water helping to siphon up the water on its way TO the baseboards?

0 -

Yeah, it's all pretty gross unfortunately.

What you describe does sound simpler and better. Another thing I'll have to save up for!

All that wiring is only exposed because I removed some covers to try and do some diagnosis.

Shelving moved :-).

0 -

I'm not sure what a flow check is. There are check valves built into the pumps apparently, though. I wonder if the problematic zone simply has a stuck check valve? I suppose I should remove it and take a look inside. Then again, I suppose I'd feel some whirring when it's getting voltage even if that was the problem. And it seems to me that it isn't even doing that.

Does the fact that I have one of these thingamajiggers mean I don't have to worry about air in my lines? Or are these only good at getting rid of tiny bits of air, not big flow-restricting pockets?

0 -

The good news is that I finally found the rotting dead mouse that was causing the whole basement to stink and cause headaches just by being there! At least now I can work on the boiler without getting nausea

0 -

We hate MEECES,

The flow check in each circulator prevents ghost flow back through the circulator when it is off.

Does the bladder tank have an autofill vale on the top of it??

I would check the Schraeder valve by depressing it slightly to see if any water comes out of it, if water does come out of it the tank is bad.

0 -

I think you're reading 50 feet, and around 22 - 25 PSI, might be a little high for that low a temp,

did you change that circ yet?

known to beat dead horses0 -

Flo checks are used in forced hot water systems to prevent ghost flow such as when a boiler provides DHW in summer and to prevent multiple circulator zones from affecting other zones when those pumps are off. They use a weighted vertical check plate. They also have a manual open option in case of circulator failure to allow gravity circulation. We often mix old systems with new and sometimes people fail to get everything right. These flow checks are placed on the supply branches of each zone on the supply main. Since some pumps come with a check valve, which are removeable by choice, the question of allowing it to be in the pump with flow checks it is unknown to me how they would affect the system. But in my training double checking anything can cause a problem. A check valve will not stop gravity flow but only forced reverse flow. remember a gravity system works without any pumps at all. I share with you from John Siegenthaler's Do and Don'ts hydronic design :

"The following pointers are all "do's" that can stop gravity flow from carrying heat where it doesn't belong:

- Install a flow-check valve (or spring-loaded check valve) near the outlet of the heat source. Either type of valve stops hot water from sneaking out of the boiler until the circulator starts. A swing check is not an acceptable substitute since it offers no resistance to forward flow.

- In systems that combine space heating with indirect domestic water heating, layout piping between the boiler and indirect heat exchanger so heat can't migrate into space heating piping during warm weather. Customers get justifiably upset when they feel any warmth emanating from their radiators while their cooling system is on. Wouldn't you?

- Protect indirect DHW tanks from creating convective loops through their own heat exchanger and external piping after that piping has cooled off. A tank full of hot water with an adjacent piping loop is just begging Mother Nature to set up a convective loop. Install a flow-check valve to keep the heat where it belongs--in the tank.

- All secondary circuits connected to a primary circuit should have a flow-check valve or spring-load check valve on the supply, and one of the following options on the return: 1) another flow-check valve, 2) a swing check valve, or 3) an underslung thermal trap at least 18" deep. These options are shown in the schematic of Fig. 1.

It is always the odd arrangement of zones and timing that can create ghost flows. It can come and go. All flows for proper control need to be balanced for all on and as well as any one or more zone being on or off. A circulator being off will not always stop ghost flow. Gravity power is always greater the higher we drop. and buoyancy power increases the greater the difference in temperature. Hope this helps.

Lance

0 -

Well, yes, it's a vevor, yes, its ugly, yes, it's not aligned the same as the other pumps… but it's in, it works, it's not leaking, and I have heat!! It'll be interesting to see if a vevor pump lasts. I'll try to remember to post here if it fails. I appreciate all your help!

0 -

Look at the Gauge in the photo. the arrow is pointing to 50 Feet H

2O.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

My bad, I was mis-reading the gauge. So 50 feet h2o is an okay pressure?

0 -

50 feet h2o, 22 psi, at 80* may be a problem when you get back up to 180*,

that 180 will expand the water, and if your tank isn't ready for it, you'll be testing and exercising the 30# safety valve

known to beat dead horses0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements