Rinnai i150s Circulator Pump Question

Hello All,

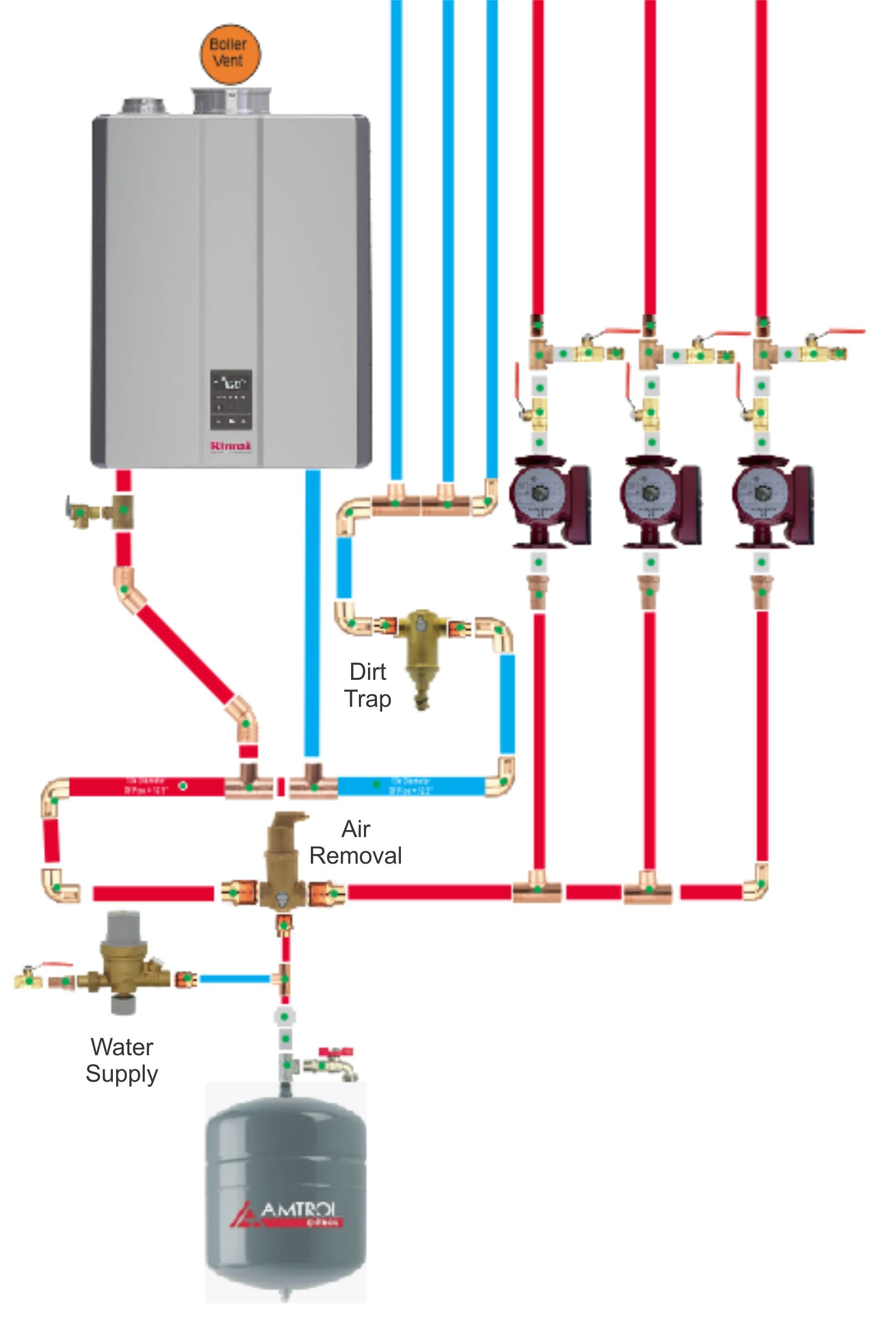

I Am Replacing An Old Cast Iron Natural Gas Boiler ( 35 Years Old ) With A New Rinnai Non-Combo Boiler, With Closely Spaced Tees For Hydraulic Separation.

The Previous System Has Three Zones Each With A Separate Circulator Pump.

My Question…

Do I Need An Additional Circulator Pump For The Rinnai Internal Loop?

Some Installations Show Separate Internal Loop Circulator… Some Do Not.

Thanks.

Comments

-

Probably. But check the Rinnai installation manual…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

i don't know what an internal loop is. In primary secondary piping both the primary and the secondary need, at a minimum, their own circulator. the close spaced tees hydraulically separate the 2 loops, the goal being that flow from one won't flow through the other.

Some boilers have a circulator built into them (mod-con combis for example) in those installations the internal pump is the pump for the boiler loop.

in your example each zone has a circulator, and the boiler is separated from those zones via close spaced tees. so yes there needs to be a pump on the loop with the boiler. if there is a pump built into the boiler then you are all set, if not you will need to install one.

0 -

Thanks.

0 -

Here Is A Drawing Of The Proposed System…

0 -

I would double check, but I think only the combi comes with internal pump, so you have to add an external pump to the primary loop. You also want some purge valves on the primary loop to help with air removal.

0 -

if there is no built in circ I recommend putting the external circulator on the return pipe flowing into the boiler (blue vertical line under boiler) and yes you will want some drains and valves. webstone makes pump flanges with and without drains that are nice, they also make ball valves with drains built in.

1 -

some other minor notes. I like to have a valve to shut off the auto feed, that way know there is a leak, taking on fresh water is typically not good for closed loop boiler systems, alternatively you could look into building a filling unit with an autofeed and an extra expansion tank that way you could control the makeup fluid. there are also pre-built systems for this. webstone makes an expansion tank service valve that will take the place of several fittings at your expansion tank and autofill setup . you also may be required by code to install an external low water cutoff device if there is not a flow switch safety built in to this. many have a pressure sensor safety that is sometimes accepted by local inspectors and sometimes not.

0 -

Thanks very much for sharing your knowlege.

Your generosity is very much appreciated.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements