Air Vent at boiler. Necessary with Air Sep?

Hi everyone,

I noticed my boiler (CG8 hydronic) has been operating for years with the boiler vent pipe capped (no auto-air vent). If I install a Air Separator at the supply of the boiler above the expansion tank (I will be pumping away), should I also add an auto air-vent on the boiler? Thanks for your advice!

Comments

-

-

That will depend on the type of compression tank you're using. (expansion tank). If you have a tank that has some type of membrane that separates the air from the water side of the system, then of course you should have an automatic air vent somewhere.

If however you have the older technology steel compression tank where the air and the water are in contact with each other, then you may want to make sure that the tank is equipped with the AirTrol® tank fitting, and use the top of the air scoop to vent air into the compression tank.

Can you explain the reason you feel you need the air separator? Are you experiencing air problems?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thank you @EdTheHeaterMan . I have a EX60 membrane-type tank. Reasoning for adding an air-seperator is to help prolong the life of this old, cast iron boiler. Ive always had issues with bleeding the fin-tubbed heat emitters on the top floor. Hoping this conversion to pumping away will help, as well as air sep and/or automatic air vent at the boiler. Am I off track?

0 -

Depends on the circulator location. If you have the air sep on the supply (HOT) side of the boiler piping and the circ is pumping away from the air sep, AND you attach the Ex-60 expansion tank and boiler fill valve at that same point, you will actually eliminate the air problem. It all has something to do with the Physics of Water and Boyle's Law of dissolved gasses. Long story short… Hot water and low pressure will release dissolved air. Put a vent there and all the air in the system will get absorbed in the water and released at the air sep. (ask me how I know this)

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

what is the static cold fill pressure and how high above the boiler are the problem emitters? you might need a little higher cold fill pressure to keep adequate pressure at the top.

0 -

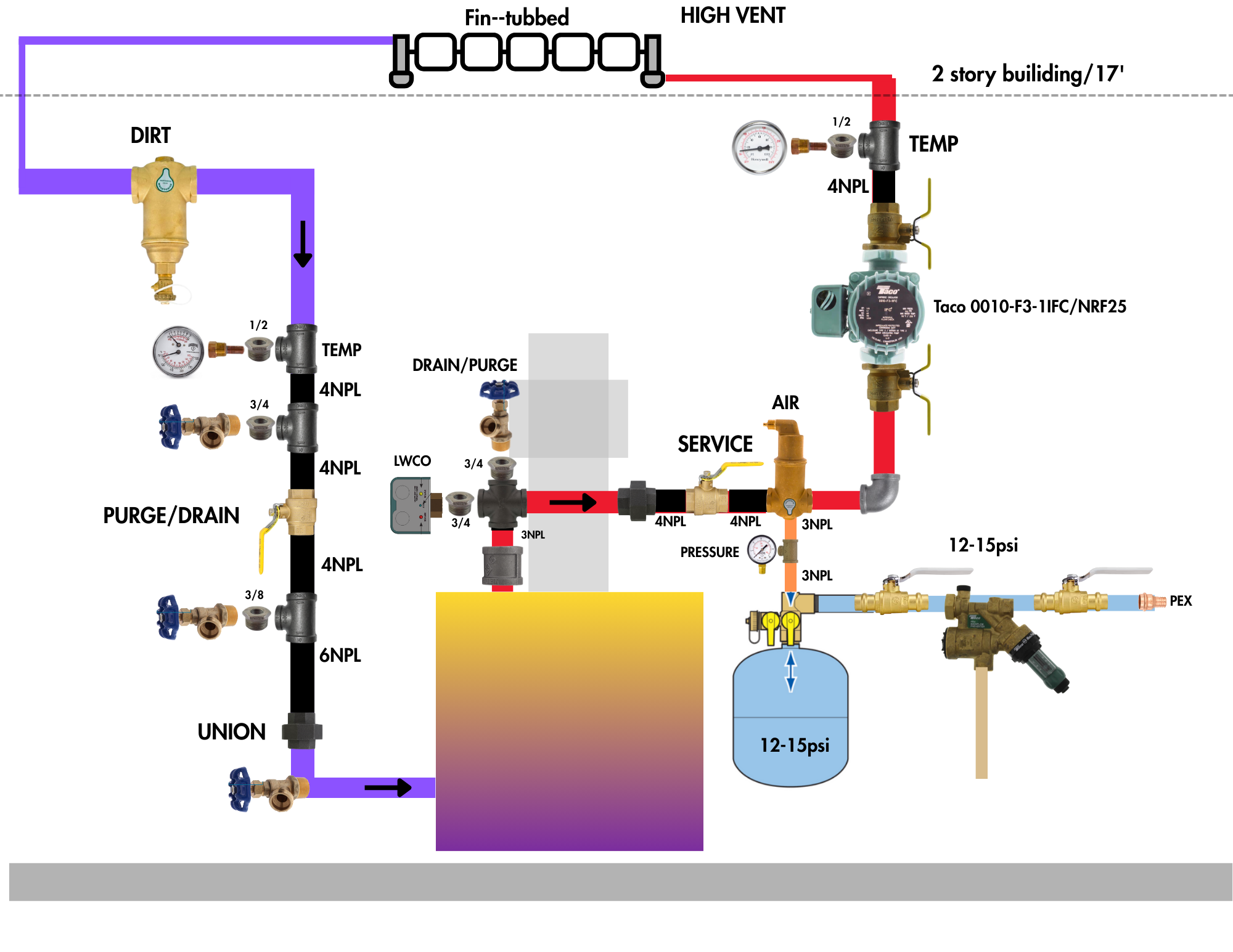

Thank you @EdTheHeaterMan and @mattmia2 . Yes, on the supply side: boiler - expansion/airsep-circ.

circ to top radiator is roughly 17feet.202,000 output boiler.

Once a gravity system.

1 -

-

-

Thanks @pecmsg. 1937 4-family apartment building. (2bed 1 bath). About 4000 sq/ft.

Brick. Cincinnati, OH.

0 -

17 feet above the circulator pump that may be about 3 feet above the boiler pressure gauge indicates that you need about 8.9 PSI of static pressure to get the system filled. add a little extra for a buffer and you can operate at 12 PSI for that system. So 15 PSI at the boiler gauge is more than adequate without going overboard. Set the air charge in the expansion tank to 15 PSI when the expansion tank os not connected to the boiler water pressure. That would mean with the boiler pressure below 12 PSI if you want to check it without disconnecting it. Then set your auto fill pressure to 14.5 PSI to 15 PSI so not to add more water to the 15 PSI expansion tank at cold startup. You should be good to go with pumping away from the expansion tank!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

-

I still think you have a lot of families in the 4000 sq ft building

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Ha! Well its just 4 (actually just 8 people).

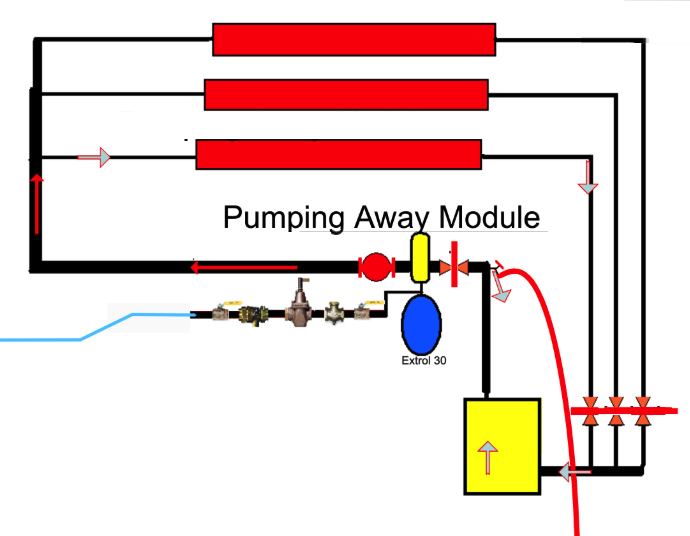

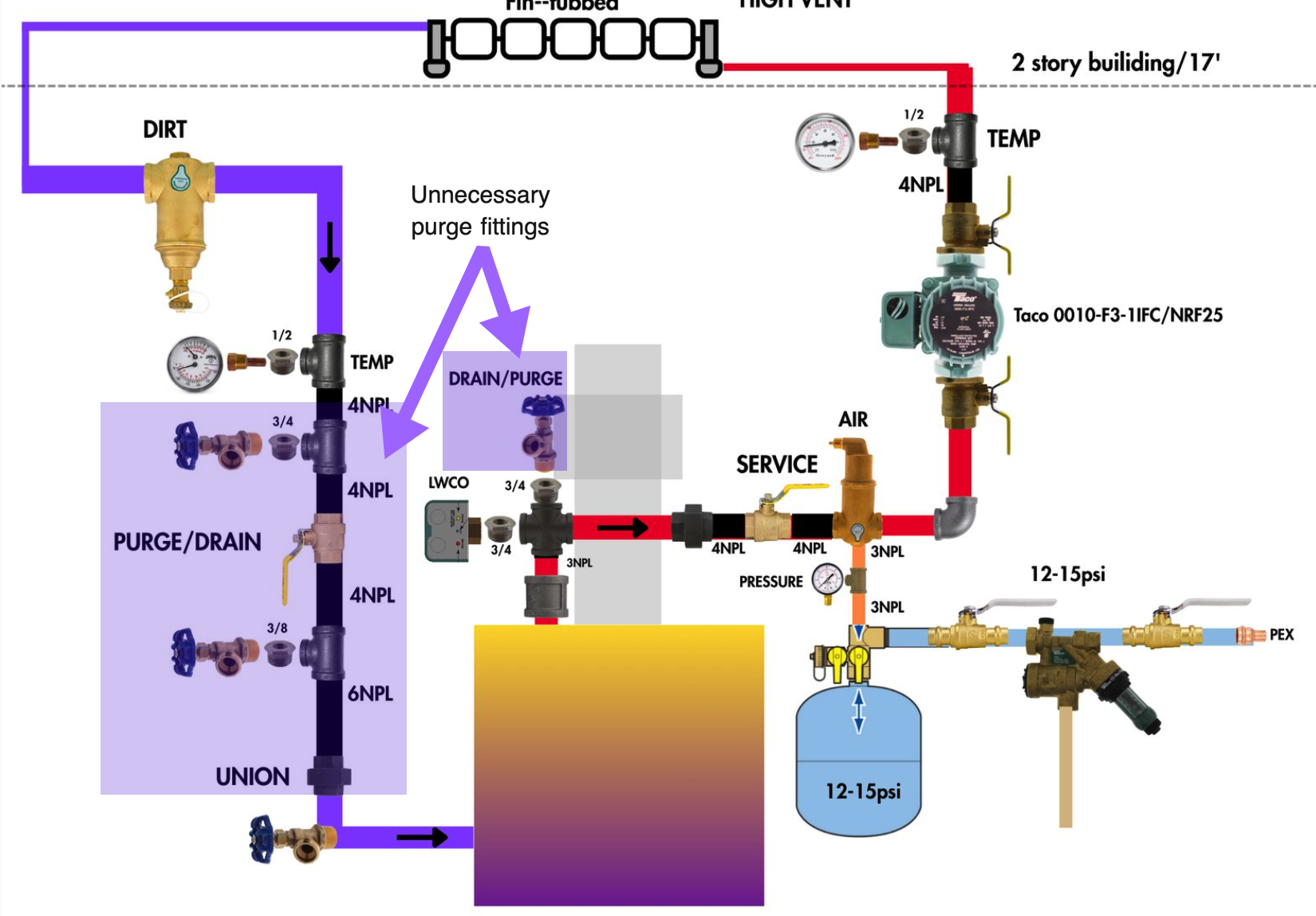

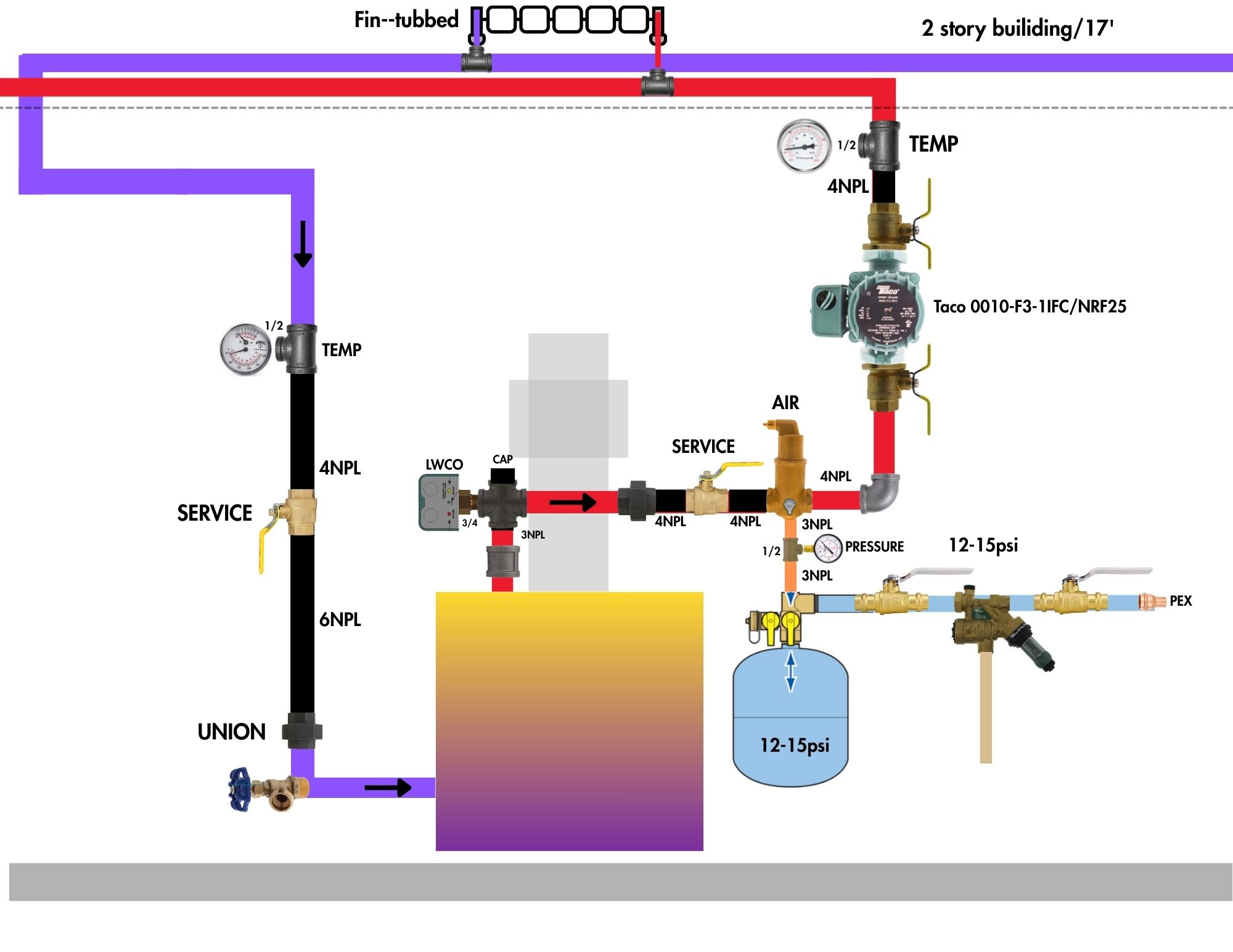

How does this look?

0 -

Just curious,

but have you tried simply turning up the high limit temperature of the boiler for a few hours to force the air bubbles to a new larger automatic air vent? that is the easy way to remove trapped air slugs.

You can simply install the new air vent with a reducing bell, pipe nipple, ball valve, pipe nipple and coupler the size of the automatic air vent.

The use of a ball valve lets you change the air vent by simply shutting the valve off when it starts leaking.

The one inch male thread air vent in the attachment is just one model size offered by Mcmaster-Carr.

1 -

Thank you, @leonz! I have not tried this. Excellent idea. Are you suggesting the boiler vent port (which is currently capped?)

0 -

Yes, that is what I am suggesting to you as long as you have enough space overhead to install one of the air vents from Mcmaster Carr using a pipe coupler, pipe nipple, ball valve and then the air vent in that order.

A long enough pipe nipple clears the elbow and lets you safely tighten the pipe coupler, pipe nipple and air vent in one operation-if you have a big plumbing supply house nearby they may have a one inch air vent in their inventory and they may very well put the whole thing together for you leaving you to remove the cap after you drain the boiler and use pipe dope for the male threads on the pipe nipple. Do not paint the last thread of the pipe nipple with pipe dope or teflon tape as it will end up in the boiler water and you do not want that to happen as it can cause problems.

1 -

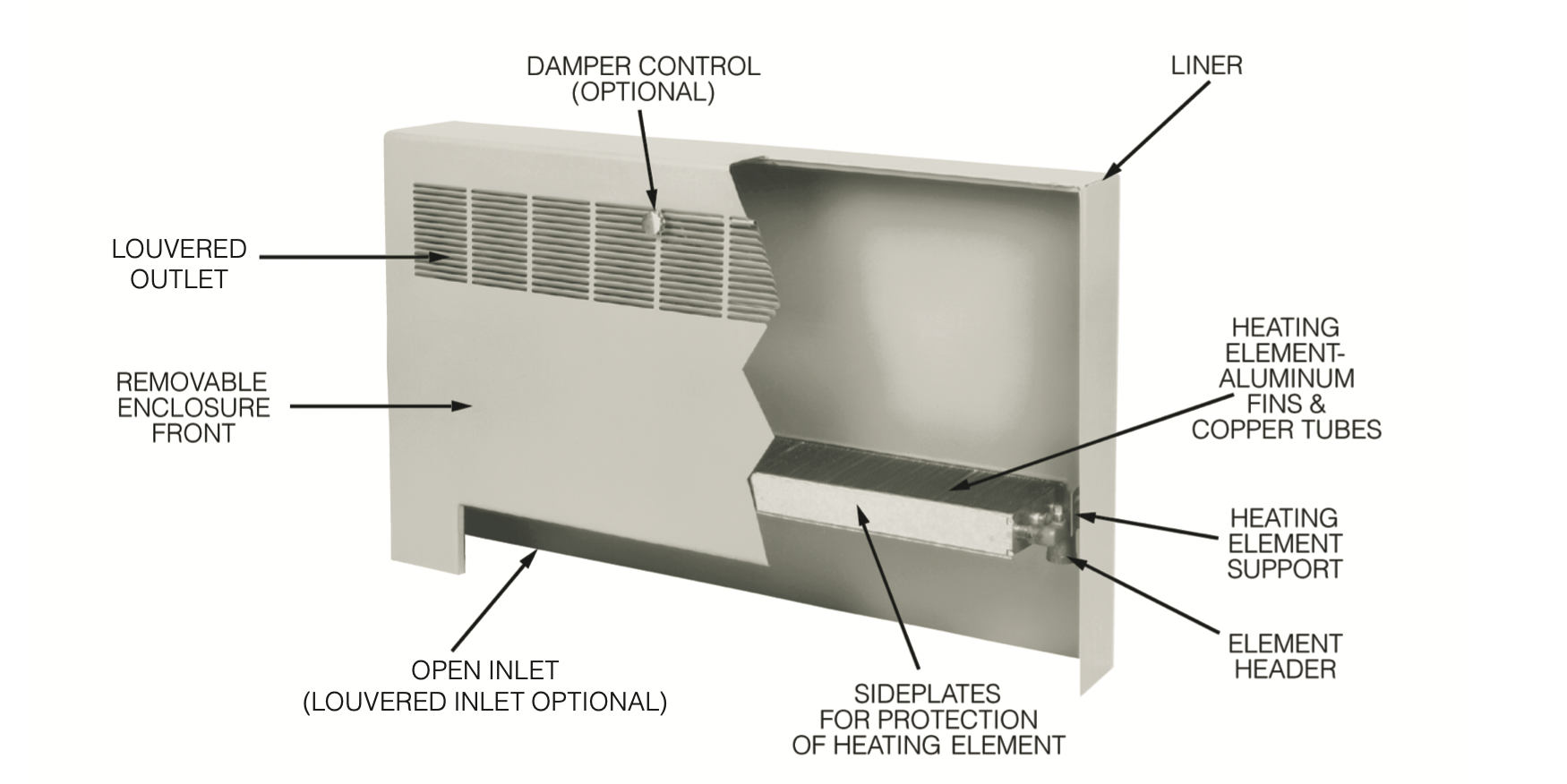

That looks great! I am wondering how all the rest of the radiators are connected? Obvioulsy you have more than one radiator or Fin Tubbed.

Are they all in one series loop of baseboard

or are they all convectors with fin tubes inside a cabinet?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

thanks @EdTheHeaterMan !

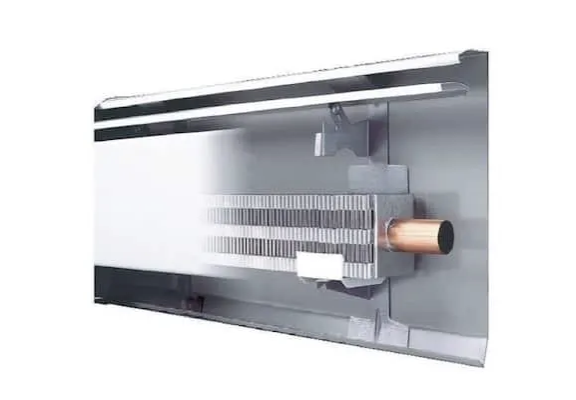

All are convectors with fin tubes inside a recessed cabinet. Photo below.

I have roughly 6 30” sections of convectors per apartment (so a total of 24 convectors).The basement supply and return pipes are not insulated which seems to be intentional in order to heat the basement also.

From what I can tell this is a 2-pipe system.Not sure if it is a direct or reverse return.1 1/2” supply/return in basement.. 3/4” risers to second floor. 1/2” piping to first floor.

0 -

Then as you may already know, Purging air from the system is not going to work. You must vent the air at each radiator to get the system started. so the highlighted valves and fittings are probably a waste of $$$

Purging only works where there are no Tee fittings involved and since your have a parallel piped system with 2 tee fittings for every radiator, purging is not an option, Venting is the only way to get the system filled with water.

Once the system is operating, then you can use the pumping away design to remove any air that may have found its way into high spots. That will happen over a short time (about a week or less) depending on the amount of air stuck in the system. Pumping away uses Physics of water (Boyle's Law) to remove air on a molecular level and vent it on a molecular level at the air vent just above the expansion tank.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@EdTheHeaterMan this is incredibly helpful!

I have so much to learn! Is there any benefit to keeping the return ball valve? Also, with this new information regarding how the system is piped, is using a automatic air vent on the boiler beneficial in addition to using the vent above the expansion tank?

0 -

The capped tapping on the Weil McLain boiler is designed to be uses with the old style expansion tank that do not have a membrane between the air and the water. There is really no benefit to using that as a vent when you have the MicroBubble style air separator like a Spirovent or a Caleffi Discal. Those vents are like air vents on steroids. The other vents are just something that will eventually leak and need replacing.

Here is something I just told another member about the difference between the two different types of expansion tanks:

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Like.

This will remove air from the system as the system operates with the help of the laws of Physics. But each radiator convector must have at least some water in it so that water can flow and can absorb the air into the water and carry it to the hottest, lowest pressure location where there is an air separator.

I like your diagram

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

One last question, @EdTheHeaterMan. If I ever needed to add a cleaning/inhibitor chemical or a system "flush", would the purge valve section on the return be useful? Or is this not common with a 2-pipe system like mine?

0 -

@AlwaysLearning2024 for the most part once you fill the system with water, and that water tests fine, that is the last time you need to do anything with the water. That water should stay in there forever (unless you need to remove it for a repair) because it will become inert in a very short time. That means that all the things that are dissolved in the water like dissolved air or oxygen, will rust a little bit of the metal, then it is done. No more oxygen will be left in the water to make more rust. So that closed system's water will get a gray coloring and will no longer have harmful agents dissolved to make problems.

If for some reason your system develops a leak and the auto water feed keeps adding fresh water to replace the leaking water, then you will find that the new fresh water has new dissolved oxygen and other agents that will corrode away the inners of the cast iron and steel parts. Keeping the system free from leaks and keeping the existing water in there will reduce or eliminate the need for adding chemicals or other treatments.

The drain valve at the bottom of the system is just fine for adding chemicals and water treatments if needed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements