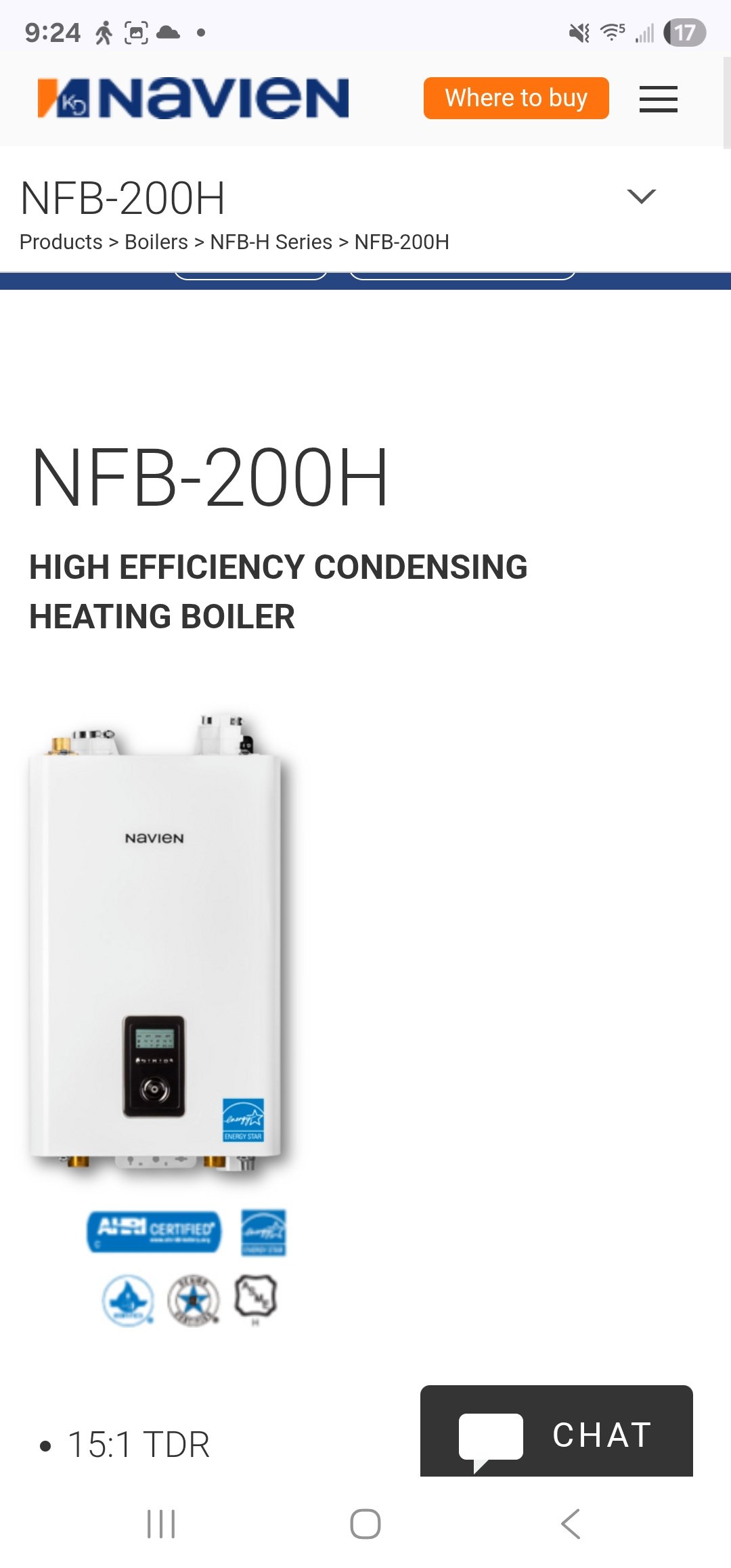

Cast iron boiler replacement with Navien High Efficiency Condensing Boiler NFB 200H

Hello!

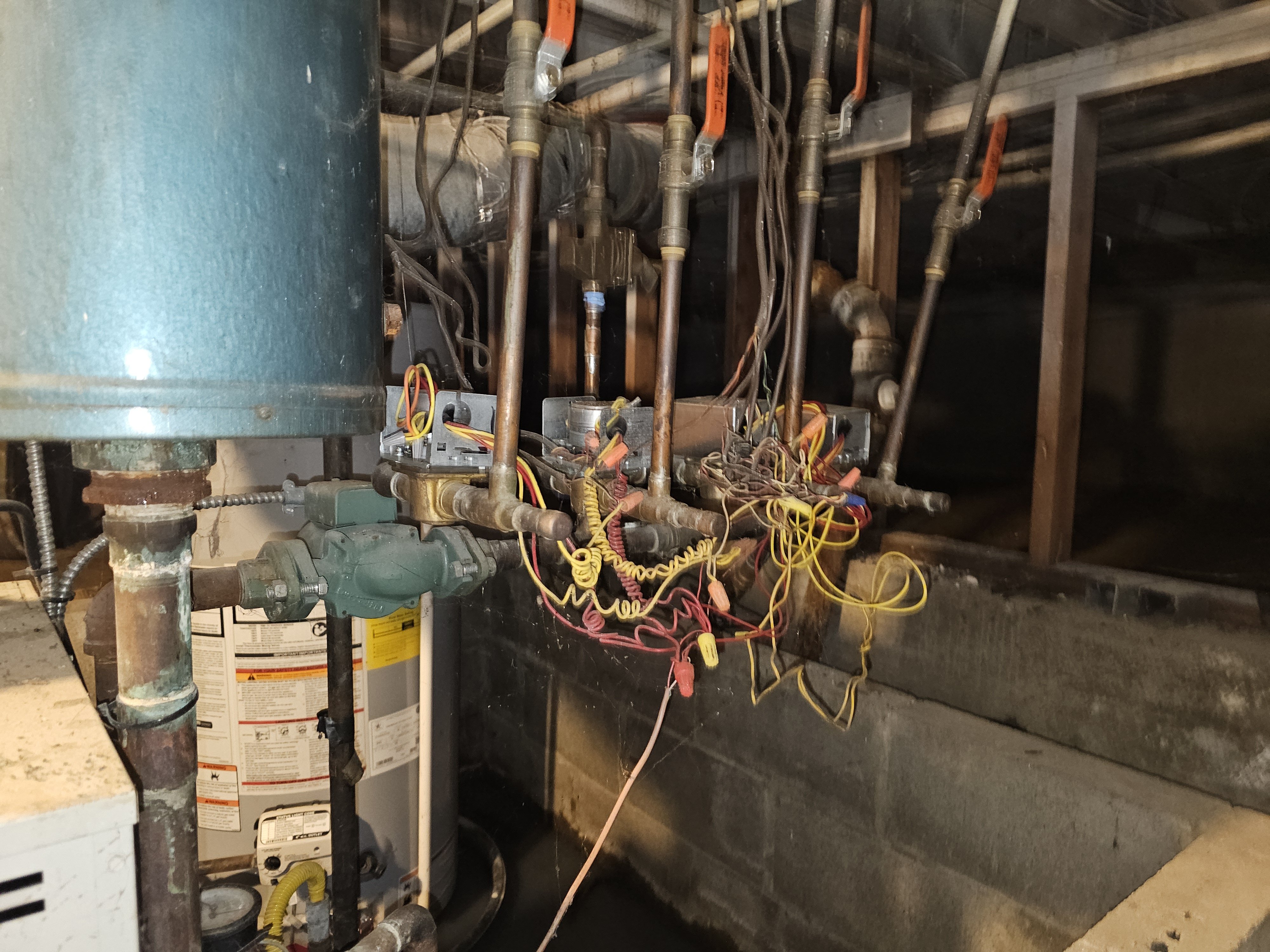

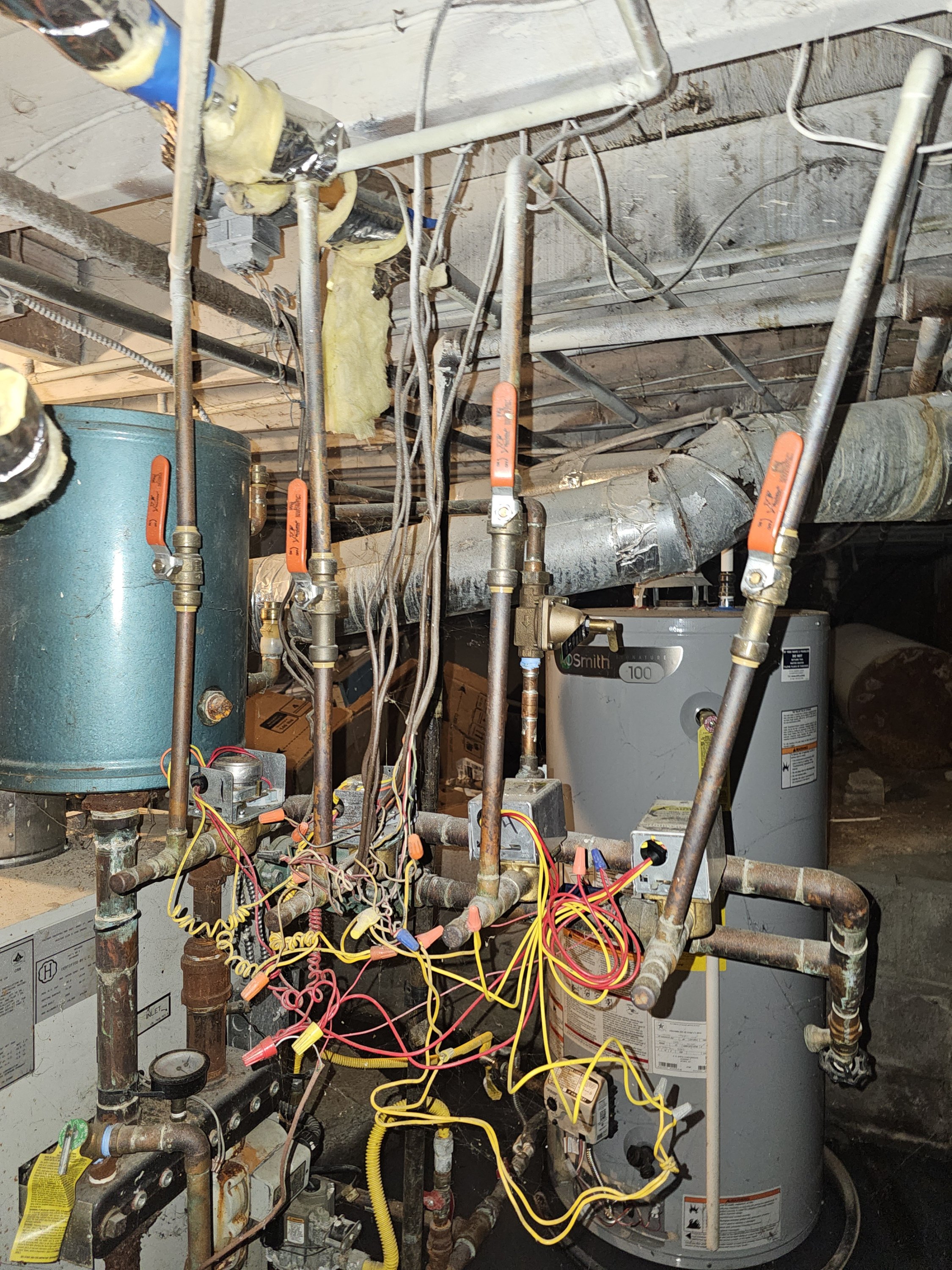

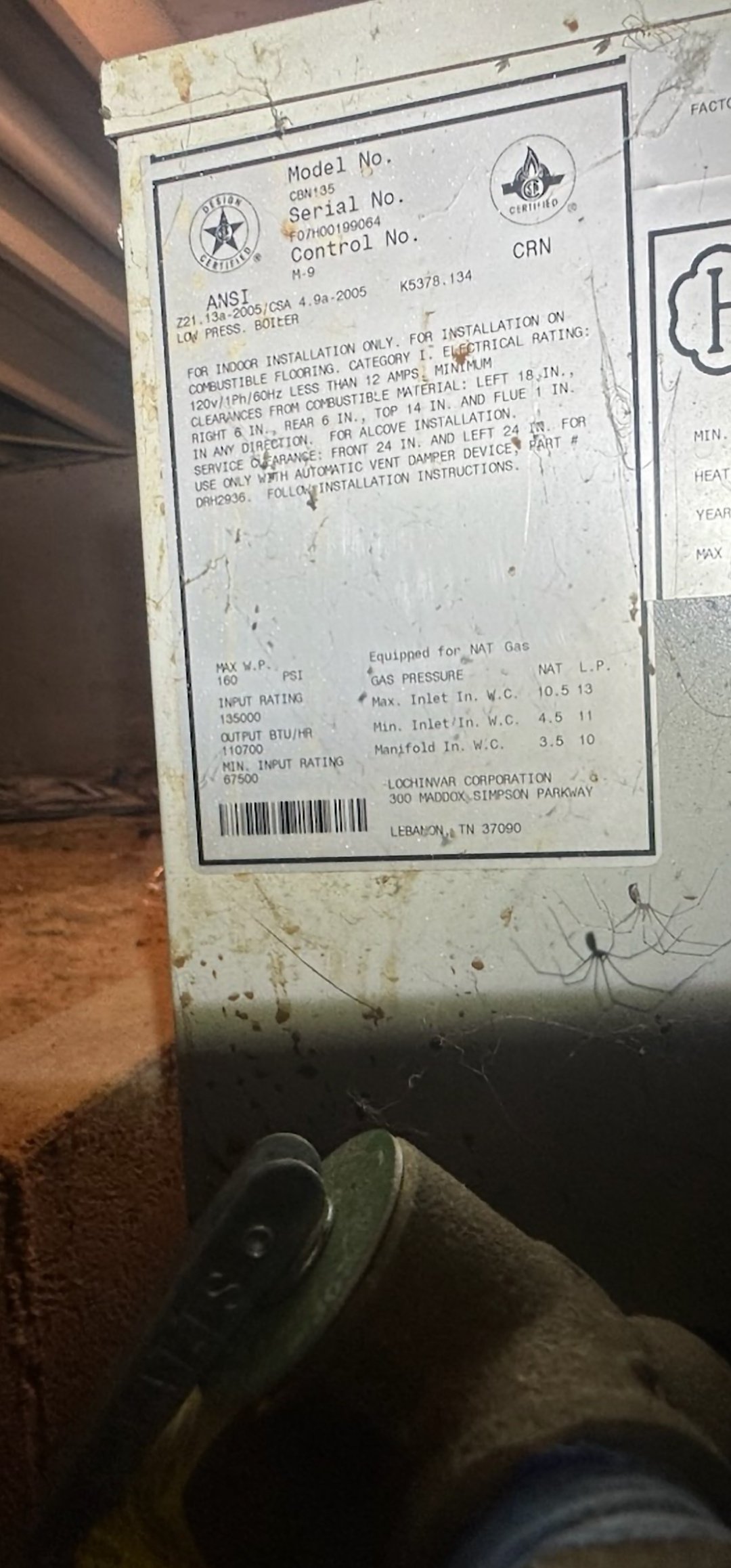

I am going to replace an old lochinvar solutions boiler with a new NHB 200H Navien Boiler. The existing system is piped as a series loop zone supply and return system. I am going to be converting it to a manifold system with individual supply and return runs. I need advice on what's the best way to do this. The original system has 4 zone valves. The boiler supplies 20 baseboard registers in a 4 apartment building. My setup with the new boiler will have 2 pumps, a 1558 pump on the return side of the boiler and a 2699 pump on the supply side of the boiler. Can I stick with the 4 zones and have each apartment ran off one single thermostat? I will install new t stats in each apartment if so with new wire. Also need some help on the wiring side of this. Zone valves to transformer? 4 Zone valves = 1.28 A with a single 24V Transformer? Control wire to boiler from transformer? Pumps wired into boiler? Any thoughts on the naviclean kit? New venting, new gas line connections. I will be installing two new non side arm water heaters as well. So this boiler replacement is only for baseboard heat.

Comments

-

EEEK. Is that poor boiler really sitting in a pit? Asking for trouble.

Step 1. Make sure you have the sizing right. Mod/cons are wonderful gadgets, but they do need to be sized correctly for the load. So… a building heat loss is in order.

I'm curious. Why two pumps in series like that? That makes no sense at all. You are going to be running primary/secondary, I hope, so two pumps will be needed — but not in series as you suggest.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

-

-

Assuming that a load calc has been done and that BTU range works for your load there's a few things to consider.

- Not a fan of Navien and their heat exchanger design. There are better boilers in the price range give or take $. Viessman , Burnham / Velocity Boiler Works are my go to. When compared to Navien it's a much better product. Both manufactures have similarly price ranged products. Might spend a few bucks more but it pays in the end. Choose a brand that's well repped in your area.

- I would flush the system prior to installing a modcon such as sentinel or similar product.

- Definitely install a mag filter when installing a new boiler to help further filter the system and protect the heat exchanger.

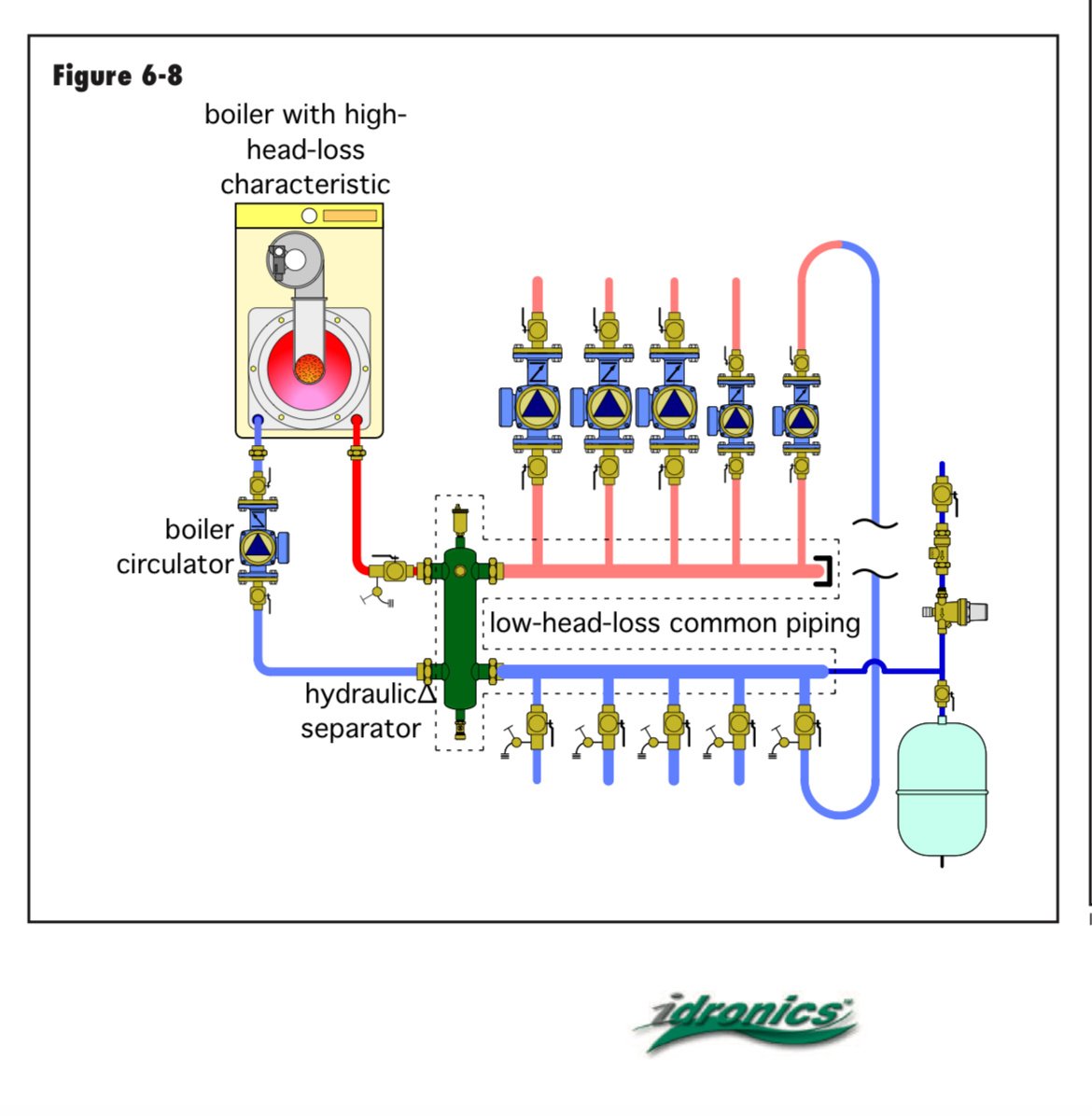

- Hydraulic separator makes easy work of primary /secondary piping. You can get one with a mag separator if you like.

- Get a zone control panel such as a Taco,Tekmar, etc. Cleans the wire up and makes troubleshooting much easier.

- If you stick with zone valves Taco sentry are a great upgrade from the honeywell and easy to override if needed.

- Follow and read the install instructions.

Owner of Grunaire Climate Solutions. Check us out under the locate a contractor section. Located in Detroit area.

1 -

This is how im planning on piping zone valves/pumps minus the side arm tees and domestic pump. This a triangle tube boiler i did a while back during the piping phase, almost completed.

0 -

Yes boiler is currently sitting down in the cinder blocked out pit. Im going to be adjusting / Framing a support wall for the new boiler to be hung

0 -

I believe the boiler wasn't properly sized, not pushing enough, so the client im working with has his mind set on the navien 200

0 -

-

-

At the very least count up the heat emitters in each unit

If you have 50’ of fin tube in each unit X 550 per foot you can only put 110,000 into the units

Even a 1 million btu/hr boiler would not add more heat The heat emitters are what you might size to, if they have been adequate in the past

Here is a multi function hydraulic separator, Sep 4

It does air, dirt, magnetic and hydraulic separation in one unit

This shows zone pumps, it could be one pump and 4 zone valves

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you I appreciate the insight! I will definitely take all of this into consideration moving forward

0 -

Can you elaborate on the low header loss common piping. Where the autofill connects

0 -

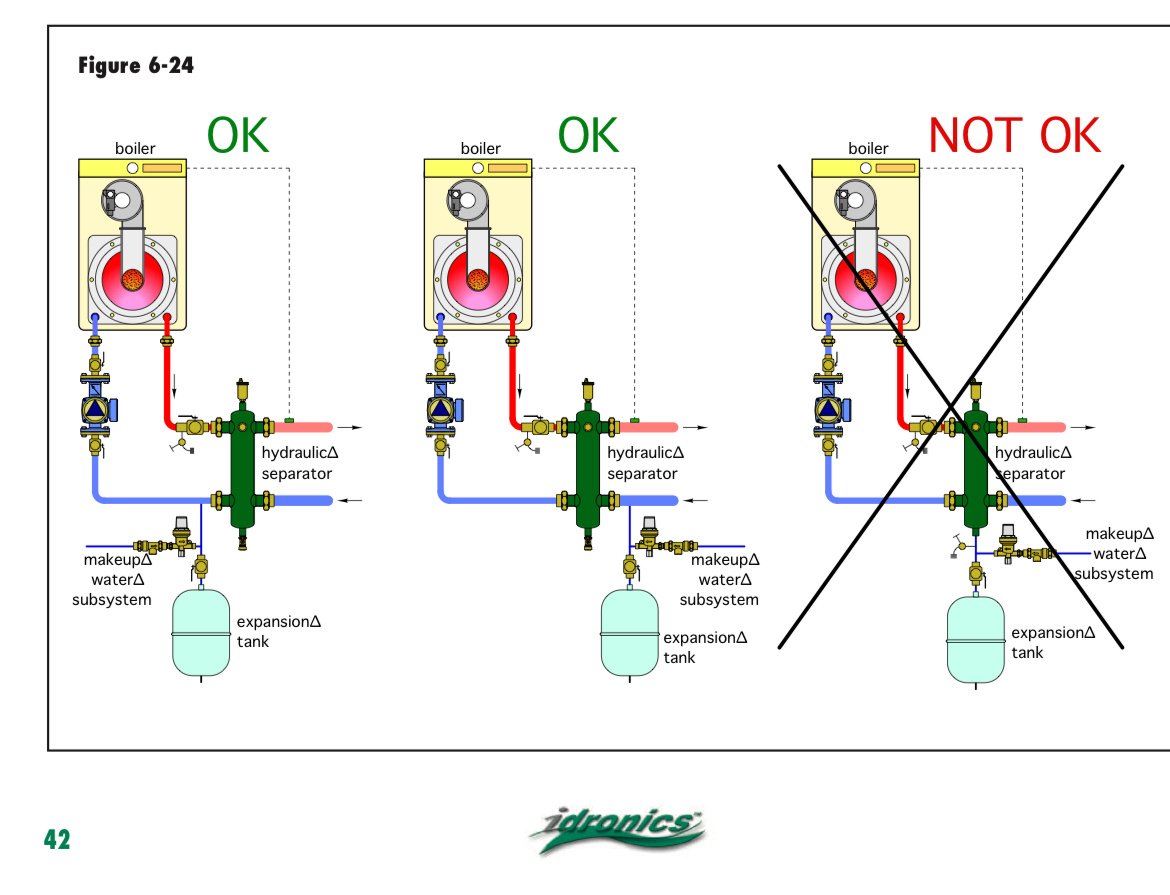

the expansion tank and fill could connect at any of the 4 connections

Most often at one of the bottom, return connections

But not right off the bottom as it collects debris from the dirt separator inside

pump and zone valves on red line, the upper right

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements