Cost to clean a heat exchanger?

I just had my annual fall inspection on my Lenox boiler (Hot water) and the technician says my heat exchanger needs cleaned. Boiler was installed October of 2022 and has not had the heat exchanger cleaned since install. Tech did a combustion test and carbon monoxide levels are elevated. He is saying the heat exchanger needs cleaned which is probably true. Cost is $$$ which includes 2 hours of his labor and he has to "buy a few brushes" for this job. Cost seems high to me, but what do I know. Boiler is a Lenox model GWB84-120E-01

Questions I have: 1. Is this a reasonable price to clean a heat exchanger on a relatively new boiler?

2. How often should this be performed?

Comments

-

-

Natural gas shouldn't be sooty unless something else is wrong. I've cleaned mine myself. You'd need flueway brushes but honestly a long cleaning brush for fridge coils works fine and lasts longer. Be sure to cover the burner tubes with a piece of cardboard to keep falling crud from plugging the gas ports. It'll be easier to vacuum up too.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

1 -

Also the sooting is generally the result of overly rich combustion, not the cause. I'd have that looked into.

Steward to 1923 Spanish revival near Chicago - 2 pipe steam 650 EDR shiny new Peerless 63-06

0 -

-

-

-

or it is lacking combustion air or it is massively underfiring for some reason like inadequate gas supply or a problem with the gas regulator or something clogging the burners.

0 -

Did the tech. say what the CO level was? 50? 100? or more?

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

the condition of the HX us related to the life it has lived, as @Alan (California Radiant) Forbes suggested

A site visit and some troubleshooting is required to know the answer

Maybe get a second opinion, now that you have some tips on what to ask the service person

It is certainly possible to plug or foul a HX in a years time or less if the equipment was not installed and set up properly

It is on gas not LP, correct?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

@Alan (California Radiant) Forbes CO was 408 PPM, CO2 was 2.47 , O2 was 16.58

It burns Natural Gas

0 -

Those numbers are not necessarily indicative of a dirty exchanger. Did anybody run a CA when it was installed? Also pricing is not to be discussed here, but yes that does seem pretty high for a 45 minute job. Would it be safe to assume that this was a big name company with a whole bunch of trucks and fancy lettering?

0 -

-

Maybe @captainco will chime in. He knows his stuff when it comes to combustion.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

Combustion is way off. I don't see a HX getting dirty with those #s but anything is possible.

CO needs to be below 100 below 50 is better and it should be a lot lower than that like 10

Co2 should be more like 9

O2 maybe 5-6

So your way off I am surprised it ran

But check the service manual for what the combustion #s should be mine are just a reasonable guess.

Something is way off and I suspect they never combustion tested it at start up.

1 -

@EBEBRATT-Ed I will check my manual tonight. Thanks for the help on this. I would guess they did not do a combustion test at start up. My next question would be how do we rectify this? I am in a small town in Ohio and only so many folks work on hydronic heat here. I am hesitant to call the person who installed it if the combustion is way off. Maybe this is an easy fix though?

0 -

They don't make a more simple boiler. That's an open draft hood, so I hope the tech got the probe up over the top of the block. With those numbers, it seems the techs sampling was diluted. Atmospheric oxygen at sea level is about 21%, so getting 16.58% during a combustion test means the tech didn't stick the probe where it needs to be stuck.

@Evan0307 , did you see for yourself the dirty flue passages in the boiler? Dollars to donuts its clean as a whistle.

3 -

The tech put his probe in the wrong place, which means he has no clue how to use a combustion analyzer. What was the flue temperature?

If the boiler is sooted you will find soot on the floor below the drafthood and in the drafthood.

Just because it is producing CO doesn't mean it has soot. I have measured many pieces of equipment with CO over 1000 ppm and there was no soot,

What part of Ohio

3 -

-

@EBEBRATT-Ed said: "But check the service manual for what the combustion #s should be mine are just a reasonable guess."

I can guarantee you that the manual does not have any specification for combustion numbers. This is an atmospheric burner in a cast iron boiler. The manual does not even reference combustion testing at all. Not like an oil fired boiler or a ModCon would have in their "Start Up" portion of the manual

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@captainco I do not know what the flue temp was. I was not present when he ran the combustion test, just got those numbers after the fact. I do know he drilled a small hole into the venting piece that goes into chimney for his test, then plugged it after he was done. I did not physically see anything dirty, but again I am only seeing the exterior of the boiler. Southern Ohio, Chillicothe.

So would you recommend I get a different provider to run another combustion test?

0 -

@HVACNUT I was not present during the combustion test so did not see inside of anything. I got the numbers after the fact. The tech drilled a small hole in the metal venting piece that goes into the chimney and then plugged that after he was done. Would you recommend I call a different servicer and run another combustion test? I do want to make sure everything is safe. I dont know if the first guy was trying to upsell me or if something is truly off?….

0 -

@captainco @HVACNUT After you mentioned draft hood I got to thinking and I am not sure if there is a draft hood?… I am including a photo here. Little red plug is where he drilled and stuck his probe in. If there is no draft hood could that be contributing to the wacky numbers?

1 -

I would get it checked by another tech only because of the CO readings. It's probably BS, but better to be sure.

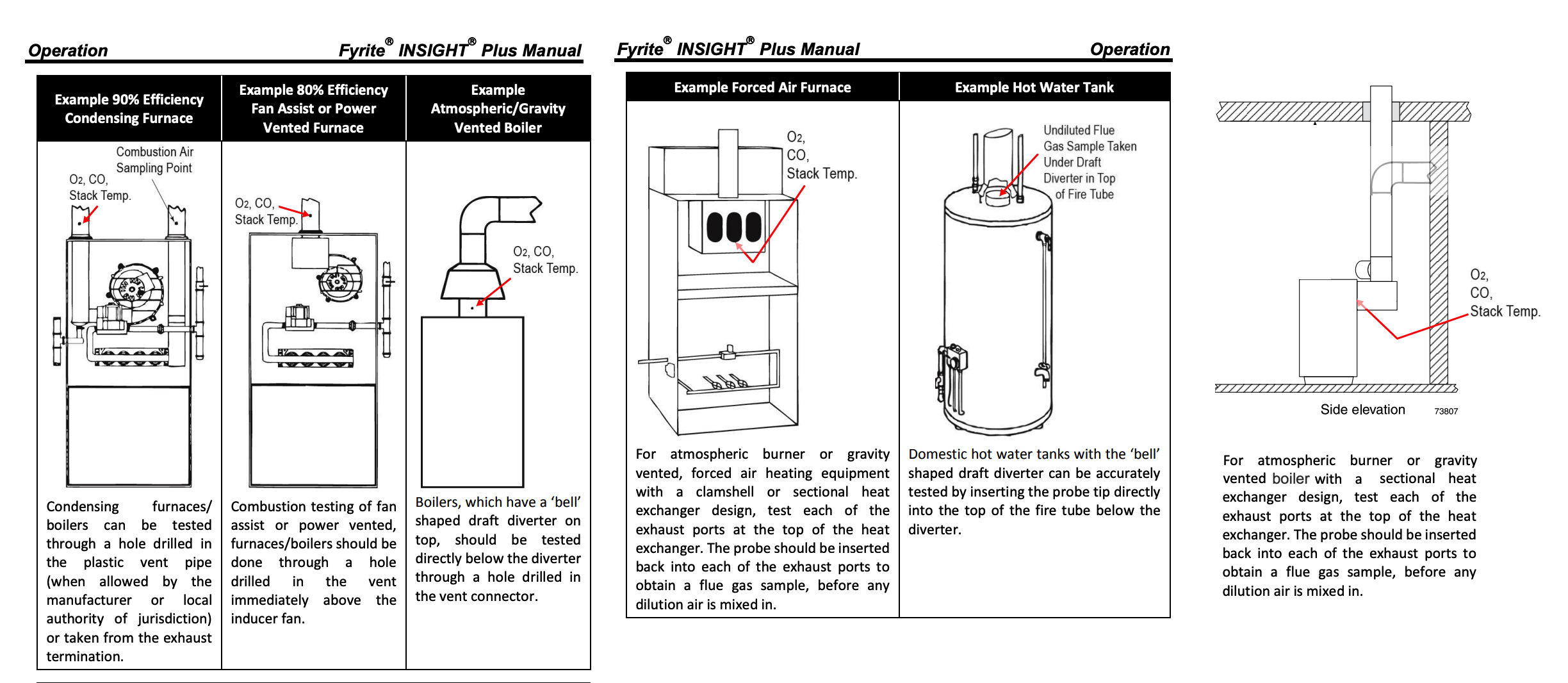

Drilling a hole in the flue pipe is NOT where the combustion analyzer probe goes on your particular boiler. The box that the flue connects to at the back of the boiler is open at the bottom. The probe needs to go up through that box to reach the undiluted flue gasses directly coming from the boiler block.

You mentioned this was part of your annual fall inspection. Have you been using the same company? Is it the same company that installed the boiler 3 years ago? Ask for a senior tech, and a copy of the combustion report. At no charge of course.

1 -

don t post to often but i will state in 40 years plus i have only seen 1 or 2 sooted gasfied hot water boiler . 1 lack of combustion air 2 bad gas valve

Its very rare that atmospheric gas fired boiler gets sooted not for nothing i know things are slow every where and the bigger a company is, the more over head the more they feed off of unknowing home owners and every service call must produce x revenue plain and simple .It,s sicking. Combustion testing in the wrong spot is the first indication of the wrong company wrong guy wrong training . I believe that if they aint doing oil fired equipment service then they aint to familar w combustion testing at least w old timers . I say this from experience and working in the phvac field for close to 40 years ,my experience is most of all the plumbers i have worked w would not even know how to do nor cough up for a combustion analyzer unless for free and or where forced at gun point to buy one or by law . i say this because i worked for some who did service and did not even own a electrical meter **** brought one a fluke meter and case for him zero thank you too ,i know this as one of buddha four noble truths . This is not to put all of them in one bunch there are a few but in the grand sense most say there s no need . lol Remember in the father land plumbers do waste and vent thats thats and heating are heating tech different animal and there heating tech make us look silly for sure .

Personally the bigger the company the more the eye is off the ball and detail are forgotten and workers are a number and profit is king there are exception but be sure that it will cost $.

PS get a half way decent co detector plug in battery back up ,it may only alarm at 40 to 50 ppm but its better then waking up stupid or dead ,basement boiler room area ,bed rooms

peace and good luck clammy

R.A. Calmbacher L.L.C. HVAC

NJ Master HVAC Lic.

Mahwah, NJ

Specializing in steam and hydronic heating0 -

@HVACNUT The company doing the fall inspection is not the company that installed the boiler. My thought was to call the original installer and ask them to do a combustion test and Im not even going to mention the results of the first test and see what the 2nd test gets. That will inform my decision to move forward.

1 -

@HVACNUT @captainco Photos looking up into the box at back of boiler than connects to flue pipe. Some soot but I dont know that this is excessively dirty?… No soot on the ground under box or around boiler.

0 -

-

can you look inside the boiler? you are looking up the draft hood up the vent. the collector box on top of the boiler connects in to the side of that box, can you look in there? there is some soot there which shouldn't be there. not enough to affect operation, at least here, but something is happening to make it.

you can also take the front cover off and take some pictures around the burner and up the bottom of the heat exchanger.

turn the switch off before you start sticking your hand and face inside so it doesn't accidentally fire with you in it.

0 -

-

Would you recommend a Harley, or an Indian, or are the foreign motorcycles like Honda OK? The passenger side mirror on my MiniVan says "OBJECTS IN THE MIRROR ARE LARGER THAN THEY APPEAR". Will that one work too?

But seriously: As other's have explained you do have a draft hood and the combustion test was taken from the wrong location. here are 5 diagrams from the instructions of a combustion analyzer that show the different types of gas heating appliances, and I have put Red Arrows to indicate the test location. If you look at the 4th diagram of a furnace with a similar draft hood to your boiler's draft hood you can clearly see that you need to place the probe inside the furnace from the underside of the box type draft hood. In that illustration there are 3 openings to that draft hood box where you need to take readings.

I have added one more illustration that depicts your boiler's draft hood, and the arrow showing the test location for CO, CO

2, O2, and stack temperature from each separate section. this may reveal that the boiler is operating perfectly in all the sections but one. then you can look at the burner that feeds the one problem section.Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

@mattmia2 @Alan (California Radiant) Forbes @EdTheHeaterMan @hot_rod@captainco @HVACNUT

Looking down into the heat exchanger with top cover off. I'm not sure if this is how a typical heat exchanger should look? You all have been very helpful and I appreciate all the advice given thus far. This site is a wonderful resource for homeowners!

0 -

Certainly some black soot there. If that is the top? how does it look from the bottom with a mirror?

I'm not sure about the yellow color, @captainco will know.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

What kind of emitters is this connected to? Is it fin tube baseboard or cast iron radiators or what? What is the aquastat set to?

0 -

@hot_rod There was very little room going from underneath to see anything but from what I could tell the bottom of the heat exchanger was a little sooty like the top. I did not notice the yellow color on the bottom but again I didnt want to take everything apart to get a better look.

0 -

it is probably caused by lack of return water temp protection, the boiler is probably staying too cold and is condensing. it needs to have a thermostatic bypass or at least a manual bypass to keep the boiler temp up with all the mass in that system. is it a gravity conversion, are the original mains huge?

2 -

I'm not liking the soot although it is very minor. The problem with soot is that the little coating can build up almost unnoticed for weeks or even months, but all of a sudden there is a point where things turn really bad within hours. then you have a house full of soot and no one can explain why it happened.

You may have a negative pressure happening inside your home from time to time. There may be a tree growing higher than your chimney, there are many reasons for back drafting through a boiler like yours. It could be a rare occurrence but just enough to screw up the combustion process for a minute or two and then you get “incomplete combustion”aka "SOOT". You may never find the cause, but it is important to keep an eye on this condition. At the end of each heating season, you should open up your boiler like you just did here. Inspect the heat exchanger and brush off anything that may have built up over the past heating season.

I have found that placing a piece of cardboard or newspaper at the bottom of the combustion chamber after removing the burners from the combustion chamber. Use the brush to clean out the HX and you can pull that paper out with all the soot and debris to discard before placing the burners back in place. You can also clean out the burner tubes while you have that burner assembly out of the boiler.

The white/yellow build up is less of a concern. That is just some calcification that happens during the combustion process and it sticks to HX. You can try to brush it away with a soft fiber brush. That is all you really need to clean the soot away. You may need a wire brush to do the white stuff but it is not a priority.

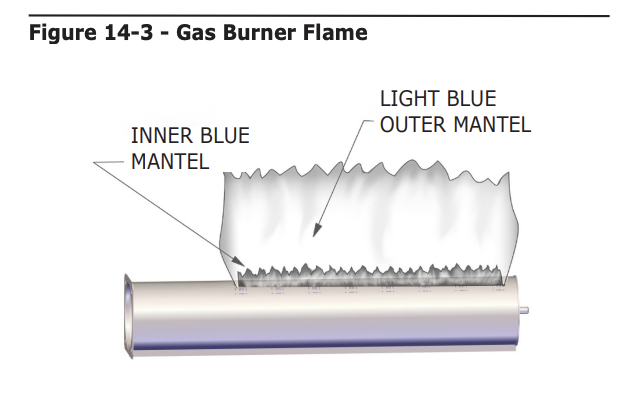

This atmospheric burner does not have any air shutter adjustments because the manufacturer feels there is no need for adjusting the combustion air. All the adjustments are done by eye and adjusting the gas pressure so there is no yellow in the flame only blue "according to the service manual." Many pros on this site will disagree with "Adjusting by eye" but there is no mention about combustion testing in the I/O or Service manual(s). But I have the combustion testing tools, so I would check yours if I saw that soot during one of my maintenance or service visits.

This assumes that the boiler room has sufficient air for combustion. If you have installed the boiler in a “confined space” or have done renovations that cause the previously acceptable boiler room into a confined space, then you will need to make provisions for the right amount of combustion air for your boiler. Ask me about that if you need more information about what is considered a confined space.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements

![IMG_4879[1].JPG](https://us.v-cdn.net/5021738/uploads/Q5KS7PC7FANL/img-4879-5b1-5d-jpg.jpg)

![IMG_4878[1].JPG](https://us.v-cdn.net/5021738/uploads/WPGS4ZMITWW7/img-4878-5b1-5d-jpg.jpg)

![IMG_4889[1].JPG](https://us.v-cdn.net/5021738/uploads/9KFC8FFMFT9A/img-4889-5b1-5d-jpg.jpg)

![IMG_4890[1].JPG](https://us.v-cdn.net/5021738/uploads/UYE90LRCNGMX/img-4890-5b1-5d-jpg.jpg)

![IMG_4892[1].JPG](https://us.v-cdn.net/5021738/uploads/3NX2CN31WCW6/img-4892-5b1-5d-jpg.jpg)

![IMG_4896[1].JPG](https://us.v-cdn.net/5021738/uploads/I2HGSKL6602B/img-4896-5b1-5d-jpg.jpg)