Radiant flow not pushing fast enough

THis forum has helped me figure out alot of the problems I've had in my home since purchasing it 15 years ago. So here goes.

This past winter was doing reno in main part of the house including kitchen/lr/dr/den all one level ranch. Decided to run radiant heating 1/2" pex tubing, 5 loops all approximately 200 feet each loop.

Connection to boiler was completed and we had heated floors but not all the way through. I have a fireplace insert so was able to supplement the heating by burning wood until Spring 2025.

Fast forward to today, Winter is coming and I was thinking of upgrading the circulation pump that runs that zone to push more water through the loops.

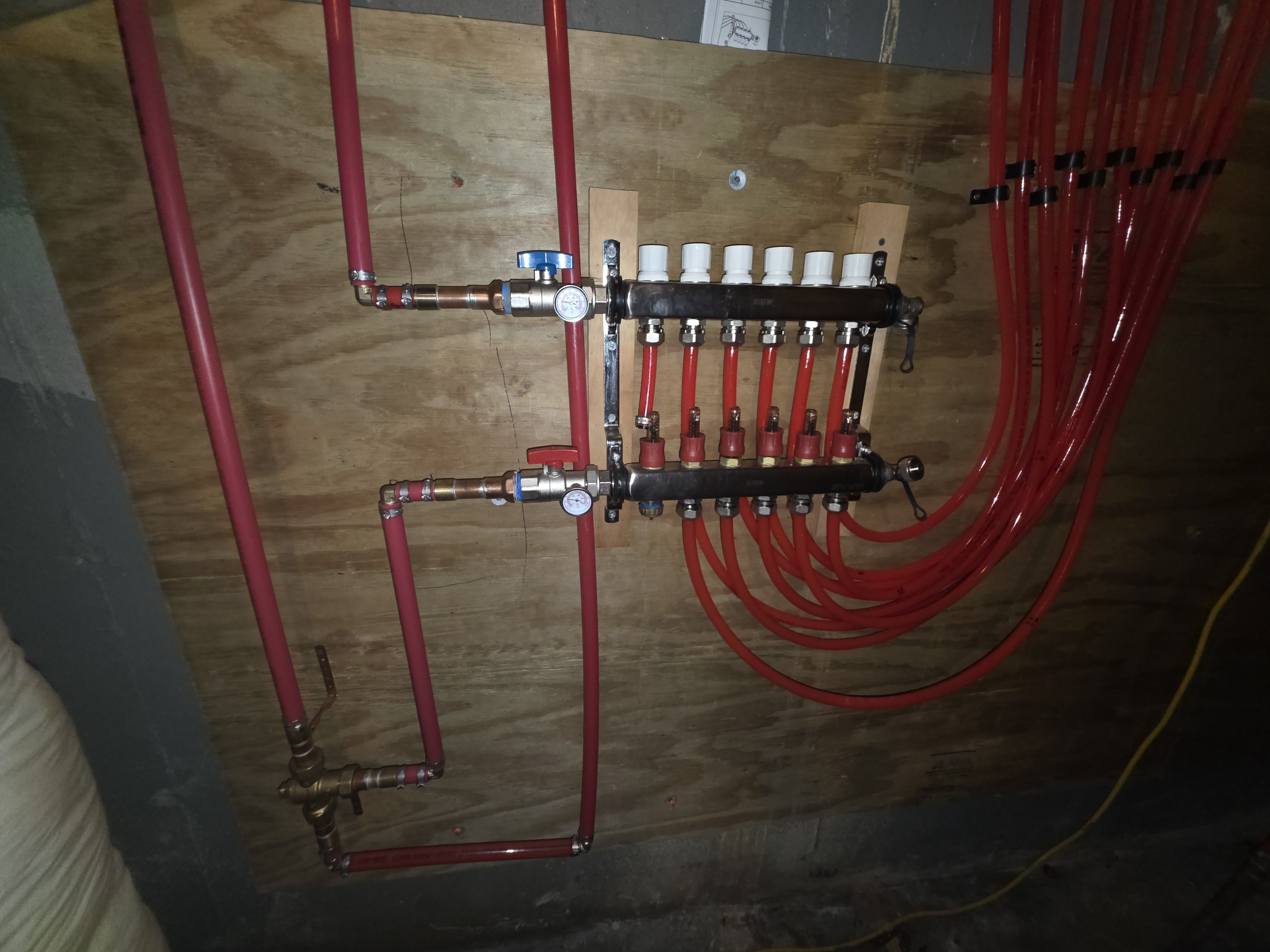

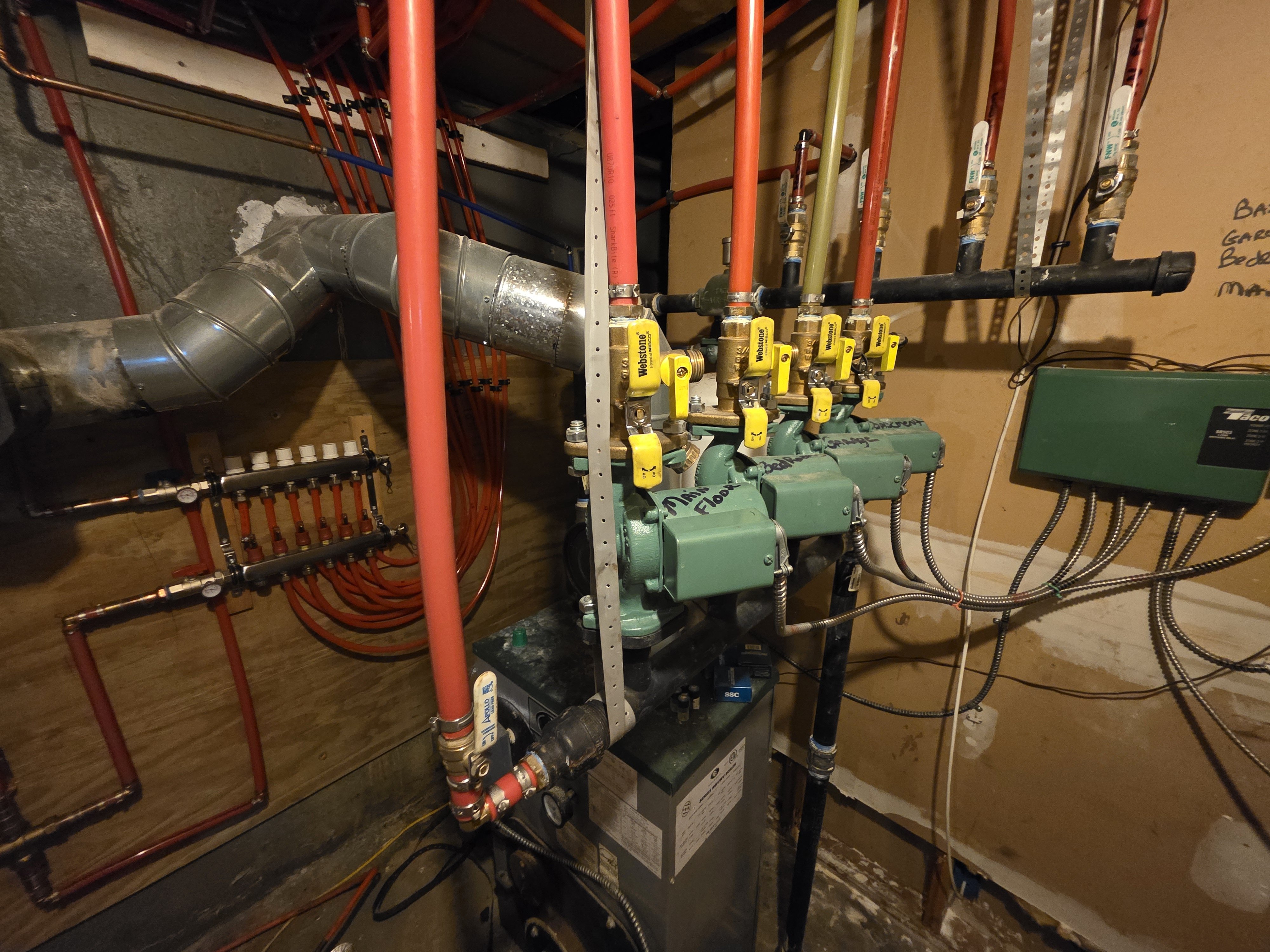

I post pictures of my setup. Running a manifold off the boiler with 4 zones total. Rest of house is baseboard heating. Hot water is separate oilfield burner.

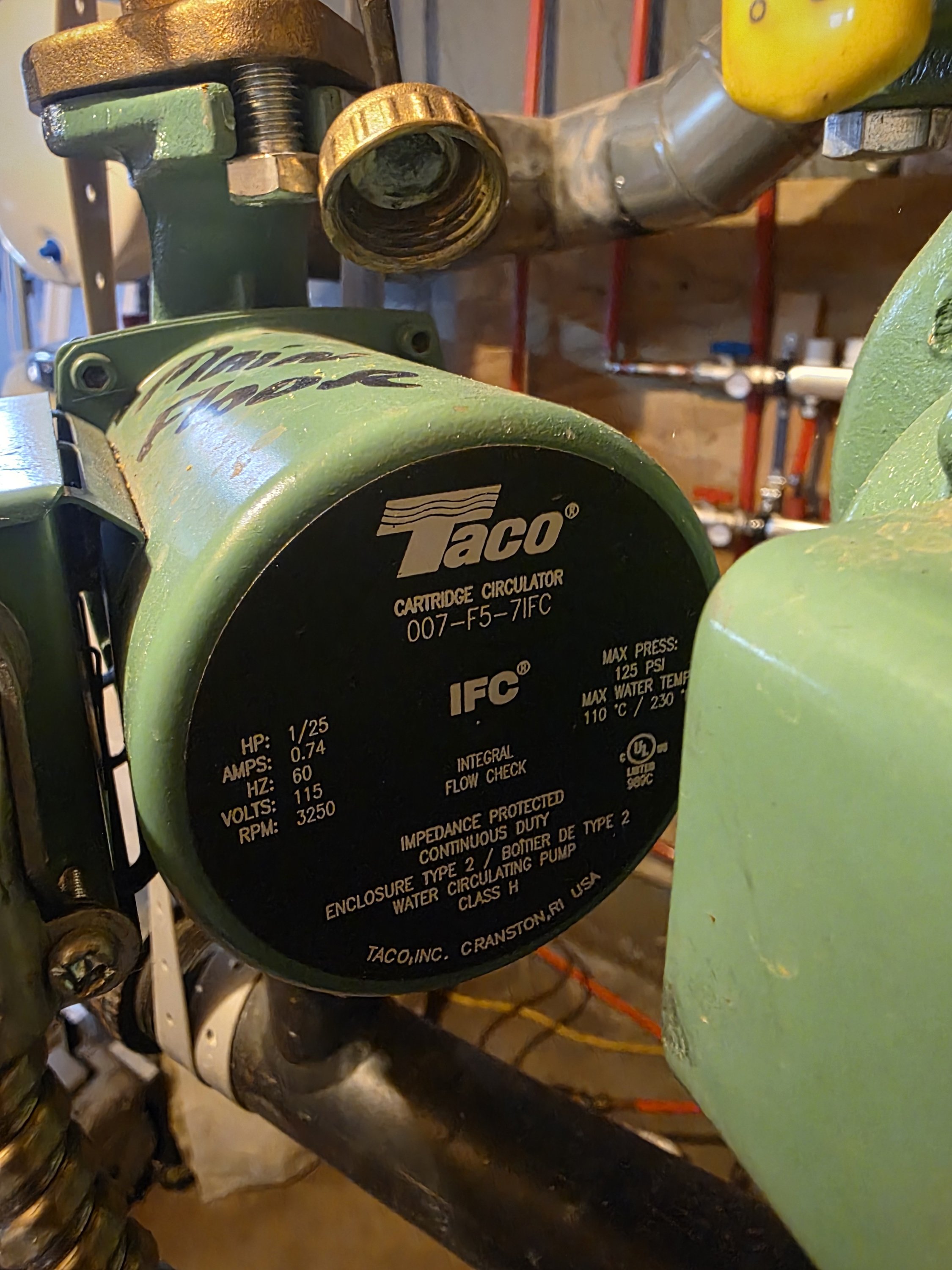

Current circulators are Taco 007 1/25 HP

1/2 pex is set in 2.5" of mud with tile on top

4 zones total. 1 of the zones going to radiant manifold.

Also have taco mixing value 86⁰ to 175⁰

Wanted to install Taco 009 1/8 HP.

How does that sound or will I blow my system up?

Thank you for your expertise in advance.

Comments

-

Though not impossible, I don't think your problem is the circulator.

What happens on a call for heat?

Does the heat call get satisfied?

Does the boiler cycle on high limit?

What is the supply and return water temp?

I'm not sure your circulator is in the right place in relation to the thermostatic mixing valve(in fact i think it isn't but i'm not an expert on that).

2 -

-

there will be a little circulation but it will stop when the mixing valve gets to setpoint, then that tube between the circulator and the mixing valve will cool and it will push that slug through, then it will stop again…

0 -

-

-

i'm guessing that is either modern hydronic heating or pumping away.

0 -

Thank you. To answer @mattmia2

On call for heat, for the first week of running water temp going into the manifold after mixing valve was reaching 120⁰ setpoint and coming back in the 80⁰ give or take.

Then just stopped pushing through and at that point I confirmed pump was hot to touch almost like a electrical short had occurred. This is what made me think that it was underpowered.

Call at first would get satisfied but after some time no. It's like system got tired of pushing water.

Boiler would reach limit and shut off.

It's hard to test now with outside temp still in low 70s. Im on Long island, NY

I thought maybe mixing valve malfunction or pump just died on me. Pump is fairly new maybe 3 years old.

0 -

-

Yes, with your pump getting very hot, it might be fried. Check the amp draw when it’s running. It should be .71-.76 amps. If it’s different, replace it with it relocated properly.

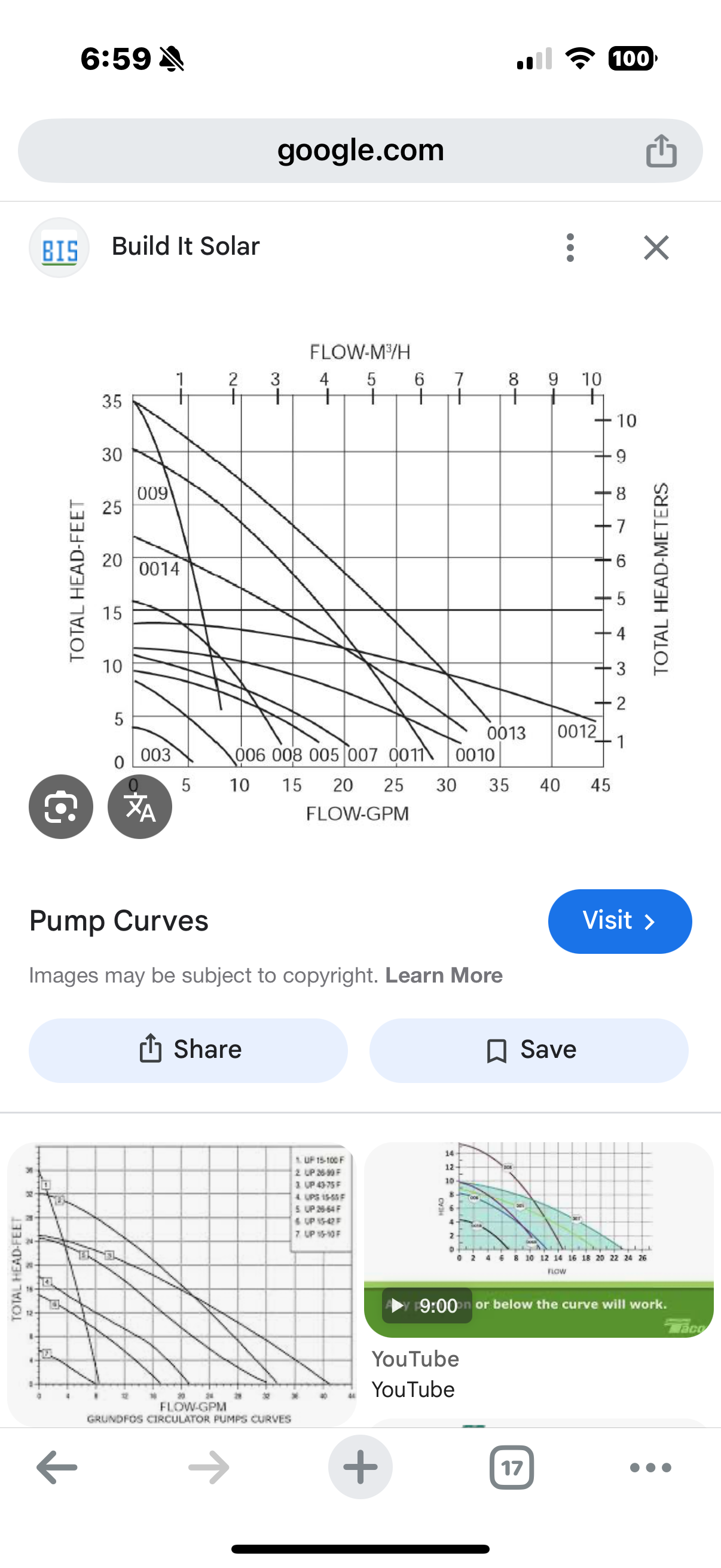

But don’t use a Taco 009. As you can see by the 009 performance curve, you won’t get any more GPM; you’ll get less if the pumping head is over 8'.8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

-

Since the circulator is pumping in to the hot port of the thermostatic valve, isn't the thermostatic valve going to close that port off and fully open the cold port when the outlet of the valve gets to the setpoint. Won't the valve get to the setpoint very quickly when they boiler is up to temp because it will be pushing water that is hotter than the mixing valve setpoint in to it? There will be essentially no flow in to the cold port because the circulator will pull the water that goes in to the loop back to the boiler through the return when the valve is open on the hot side and once it closes the hot side completely there will be no flow at all. I think the combination of hot boiler water and deadheading the circulator is making it hot. That will eventually damage it but it may still be ok now.

The valve does modulate between hot and cold but if the setpoint is like 120 f and there is 160 degree water being pumped in to it, it will go full to cold.

1 -

To be continued. Im gonna wait for a 50⁰ day and fire it up. Thank you all for your input.

0 -

Turn off the gas to the boiler or disconnect one side of t-t to the boiler so it doesn't heat or just let it fire to 100 degrees or so and then stop the boiler but keep the circulator running and see if the heat gets all through the loops.

0 -

I suppose it depends on the design of the valve, not all valves shut off the hot port 100%. ASSE listed scald protection valves can shut off the hot 100%.

You should pipe up a few demos and report back :)

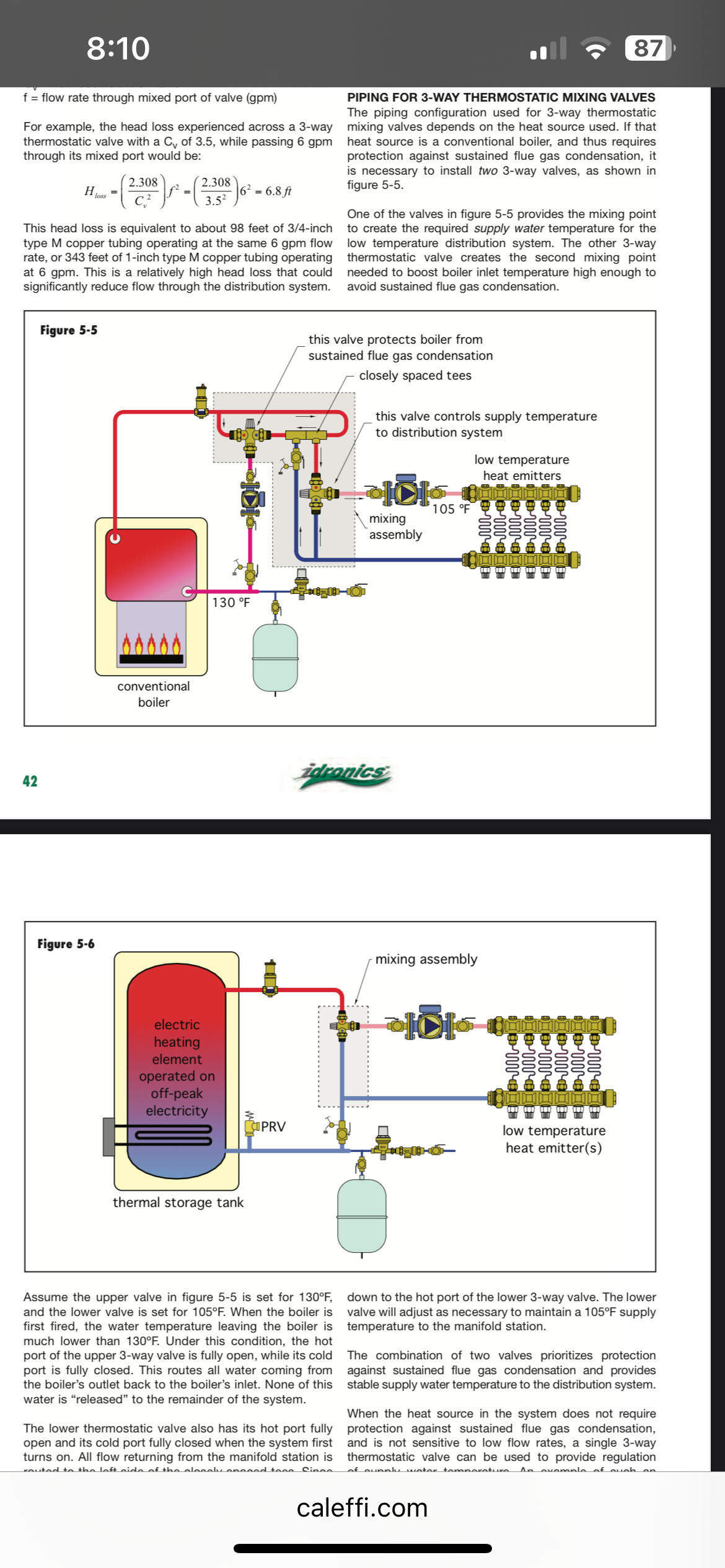

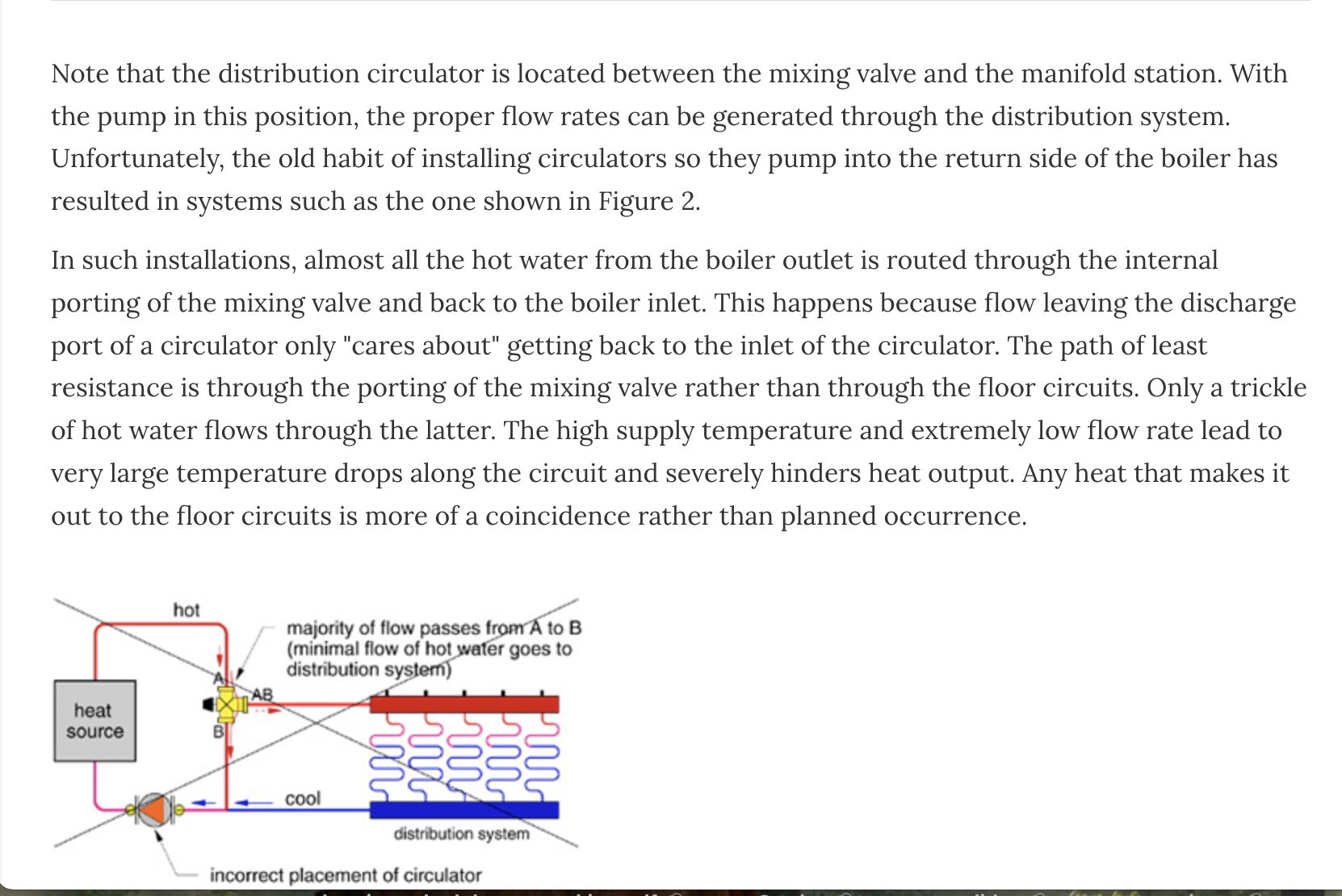

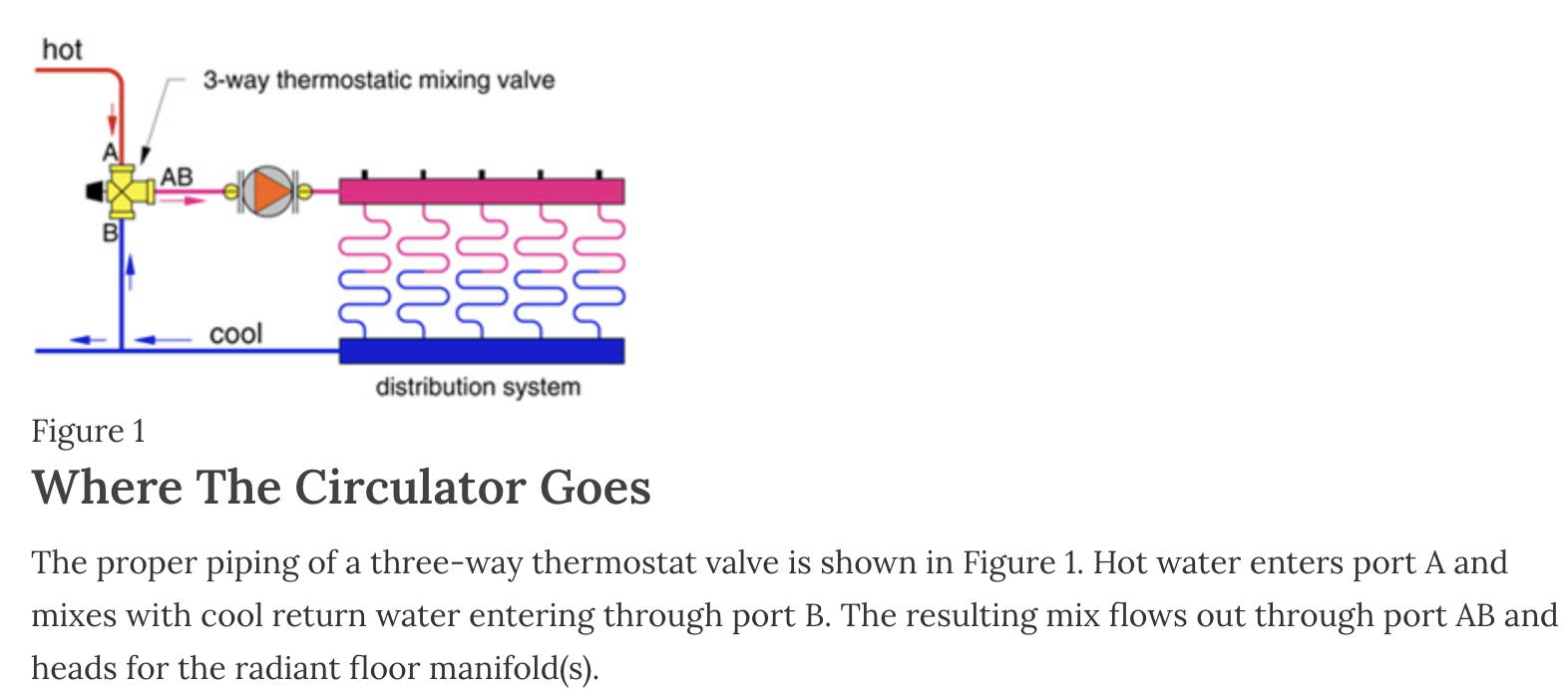

Regardless, this is how most if not all three way thermostatic manufacturers require a 3 way thermostatic to be piped, for hydronic mixing use. Piped this way it will work, piped in any other configuration you may not always get the results you expect.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

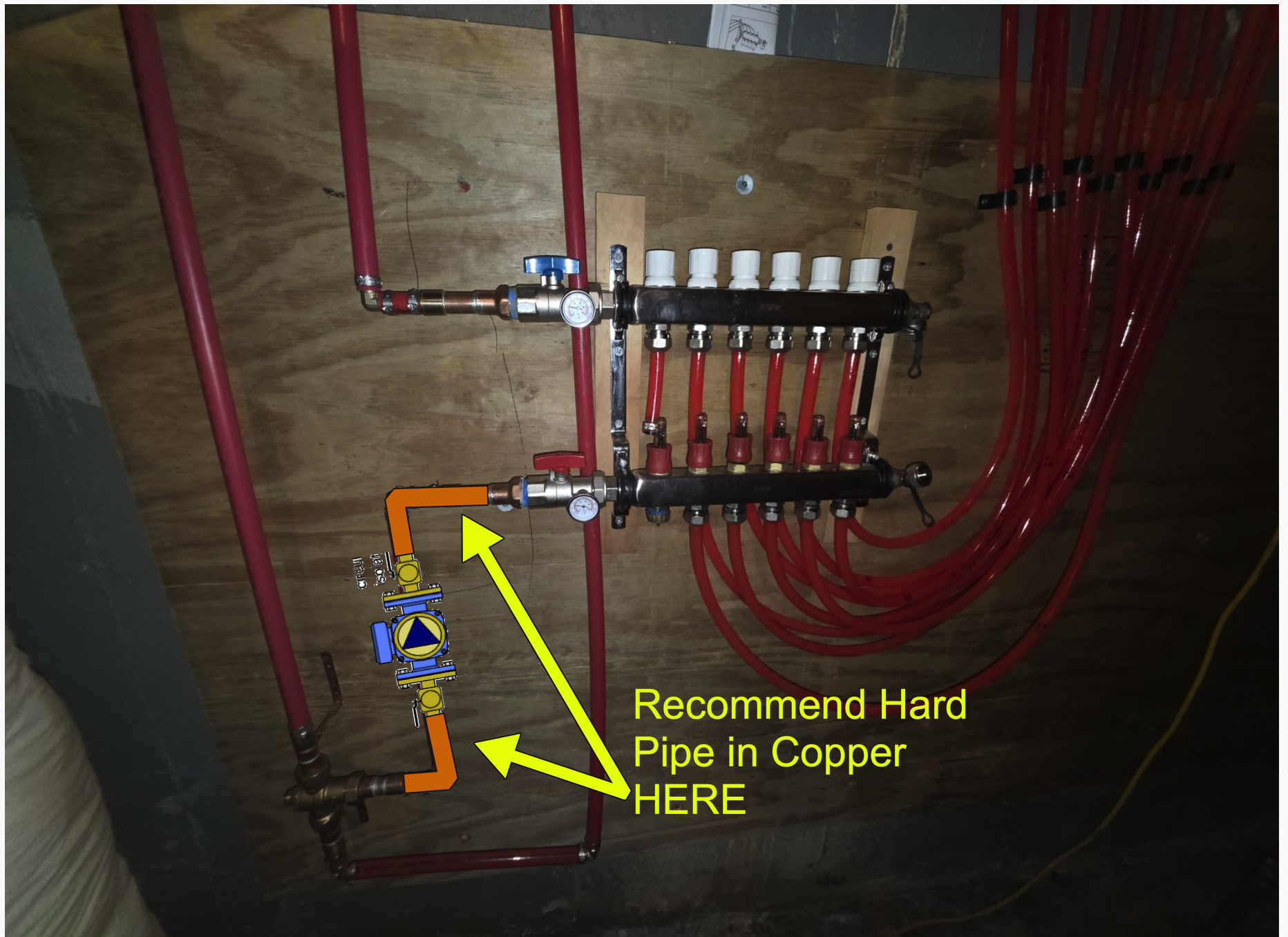

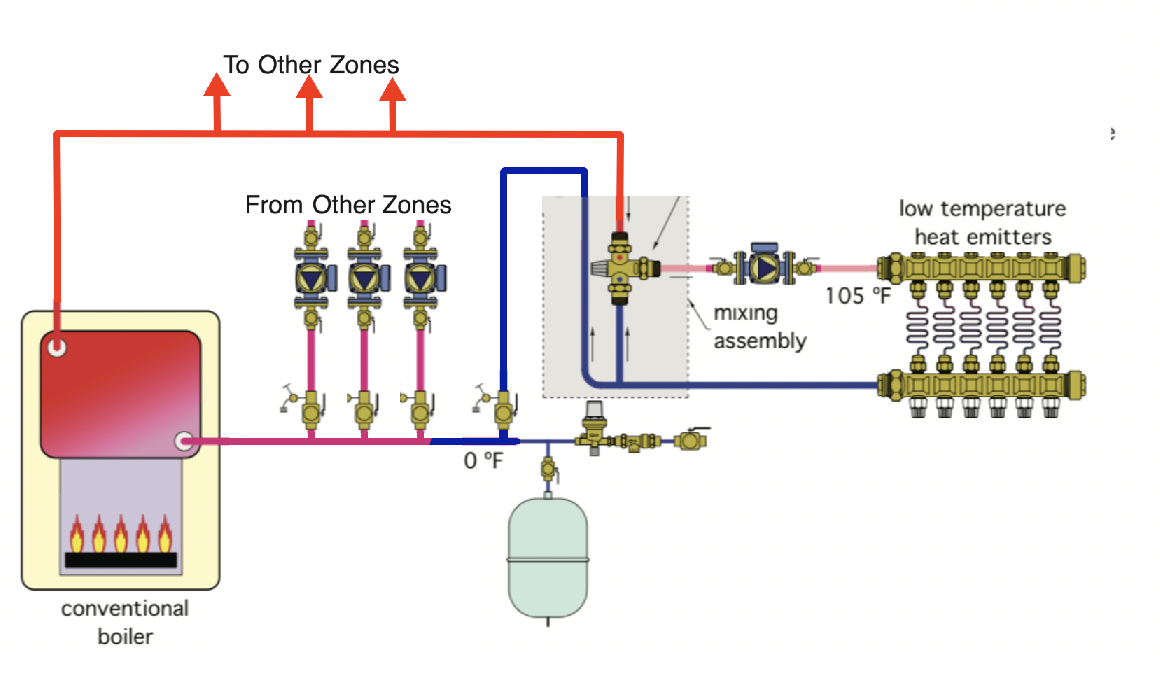

Where is the circulator for the Radiant floor zone located? It should be here (see Photo)

You may not need the circulator on the boiler side of the mixing valve as indicated by @hot_rod

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

In my first and only build sp far, we left the circulator where it was on the manifold just in front of the return manifold of the boiler. its labeled main in photos.

Thank you for your input on my situation.

0 -

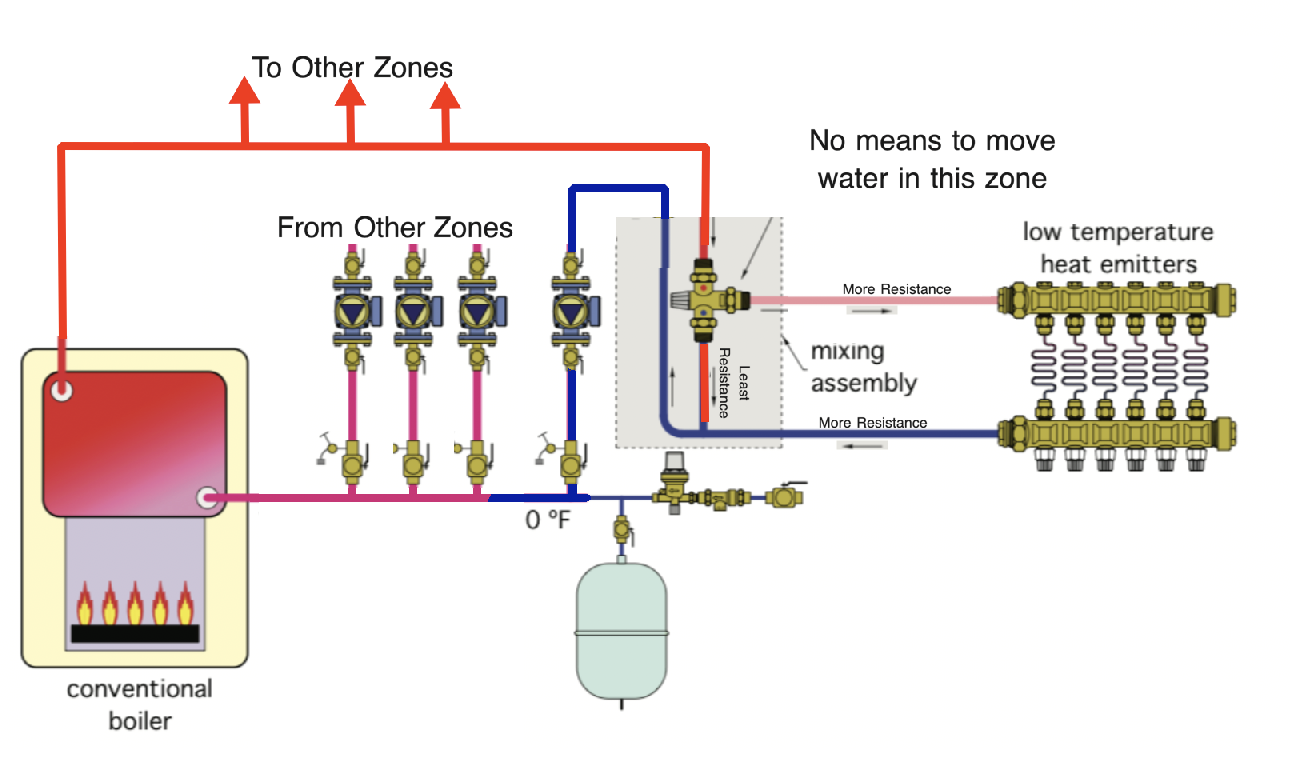

I see that circulator in your photo. This diagram is how your system might me piped:

You can see there is not a lot of pressure drop across the mixing valve when the MAIN pump is operating because is pulling equally on the cold inlet of the mixing valve and the return from the radiant floor loops. There is nothing to move the water into the cold side of the mixing valve, so all you get is what might pass thru the mix valve top the radiant loop and the rest of the flow may even go in the opposite direction on the mixing valve cold inlet port.

This next illustration indicates the circulator in the proper location.

The pump will pull water from both the hot and the cold ports to get the proper water temperature and move it thru the radiant floor tubes. I have also learned that you do not need the circulator pump where you actually have it located. That is because the mixing valve will pull the water from the boiler as needed to maintain the "MIX" temperature you set it for. If it needs more or less hot water that valve will compensate automatically.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

Thank you Again. I will report back.

0 -

(UPDATE) so the Winter is here. My brother helped me move the circulator pump just after the mixing value which was prescribed by the majority of responses. The floor is getting the necessary hot water to warm up the zone. I had to change the taco pump aswell. The old pump was pulling hot water through the manifold but didn't have the power to push all the loops, all the way through and back to the cold side of the manifold. The pump possibly got burnt up on the old setup before moving it. I now have 120⁰ going out and approximately 90⁰ coming back.

Thank you all, Happy Holidays

2 -

I'm baaack. So system worked great for 20 days or so, return temp were in the 90s . Now the return temp has dropped below 80 and to me seems that hot water is getting to the floor ( I can feel it) but not moving through and just stops about 30 feet in.. would it be best to add a 2nd pump on the return side back to the boiler to assist. Tia

0 -

I would purge air from the loops and add a halfway decent microbubble separator. You have short loops, and not many of them, the smallest pump should still be overkill, if its not flowing look to the system, you have no lack of pump on this system unless your loops are a whole lot longer than the mention 200'

3 -

-

-

cV 2.3

0 -

I will check for screens and possible debris.

Im gonna connect a grundfos 3 speed pump today. Purge and run it at a lower temp. 115⁰ instead of 130⁰ where It was.

Microbubble separator I definitely an option but I have taco air scoop installed on the whole system over on the manifold with 3 other radiator zones on it. Its all the same water. Do you think that scoop is sufficient?

Thank You and Merry Christmas.

0 -

Also will run the new pump at the slowest setting. Low and slow.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements