Need help with new install of radiant with Buderus cast iron boiler

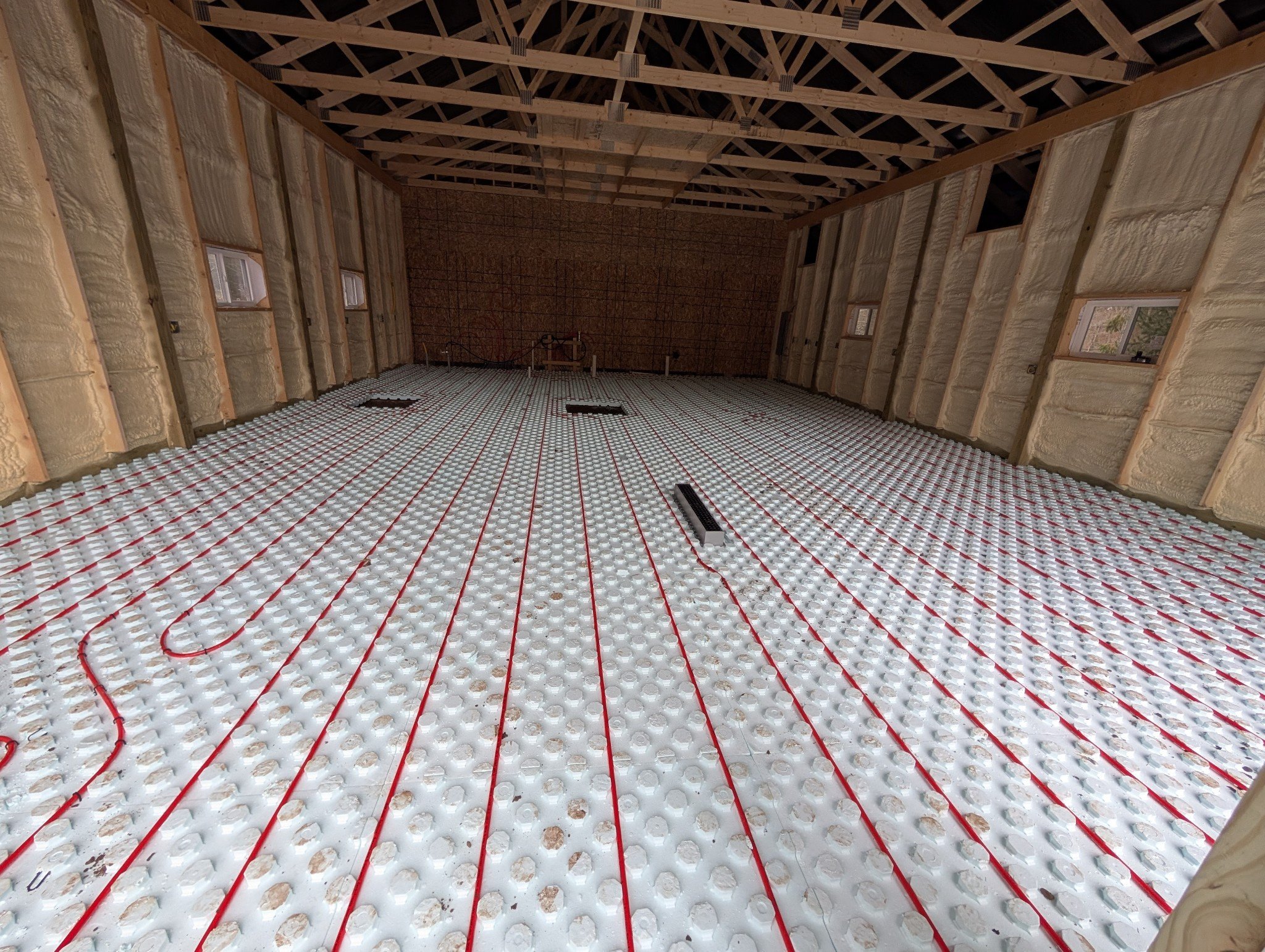

We are working on a new barndominum type building, 1 story 40x66 with radiant in the slab under all of it. Planned to go with a new mod/con combi boiler but budget got tight and my brother was replacing the system in his house and gave me his old system which was a perfect running and well maintained buderus G124x gas boiler and indirect tank.

There will be one 1200sq ft radiant zone for the shop, 1 zone for the 800sq ft living area and a 3rd circulator for the indirect DHW.

I plan on doing the install myself, I'm a handy guy but don't have much/any experience in this field. It's been difficult to find much information online about hooking and old school cast iron boiler to radiant. I know I need a mixing valve to lower the water temp to the boiler. Where I'm getting lost is I see that I also need to bring the return temp back up and am not sure how to go about this. Another mixing valve? Aside from the switching relay I'd like to keep the rest of the system mechanical.

The manifolds are the only thing I've purchased so far and just ran the pex to.

I have tried to find schematics but like I said there isn't much available for exactly what I'm doing. Just trying to figure out correct placement of the circulator pumps and whatever mixing valves I'll need.

Can anyone point me in the right direction or maybe throw out a quick sketch? Here are some pictures of the setup so far.

Comments

-

0

-

I believe you are going to need a buffer tank to prevent the boiler from condensing when the radiant is calling for heat. You can heat the buffer tank to a safe temperature to prevent condensation and use the mixing valve to lower the temperature to the radiant. Perhaps you can use the indirect tank as a reverse indirect. I'm just throwing some ideas out there. I'd look into some Caleffi Idronics articles for piping schematics and more ideas.

0 -

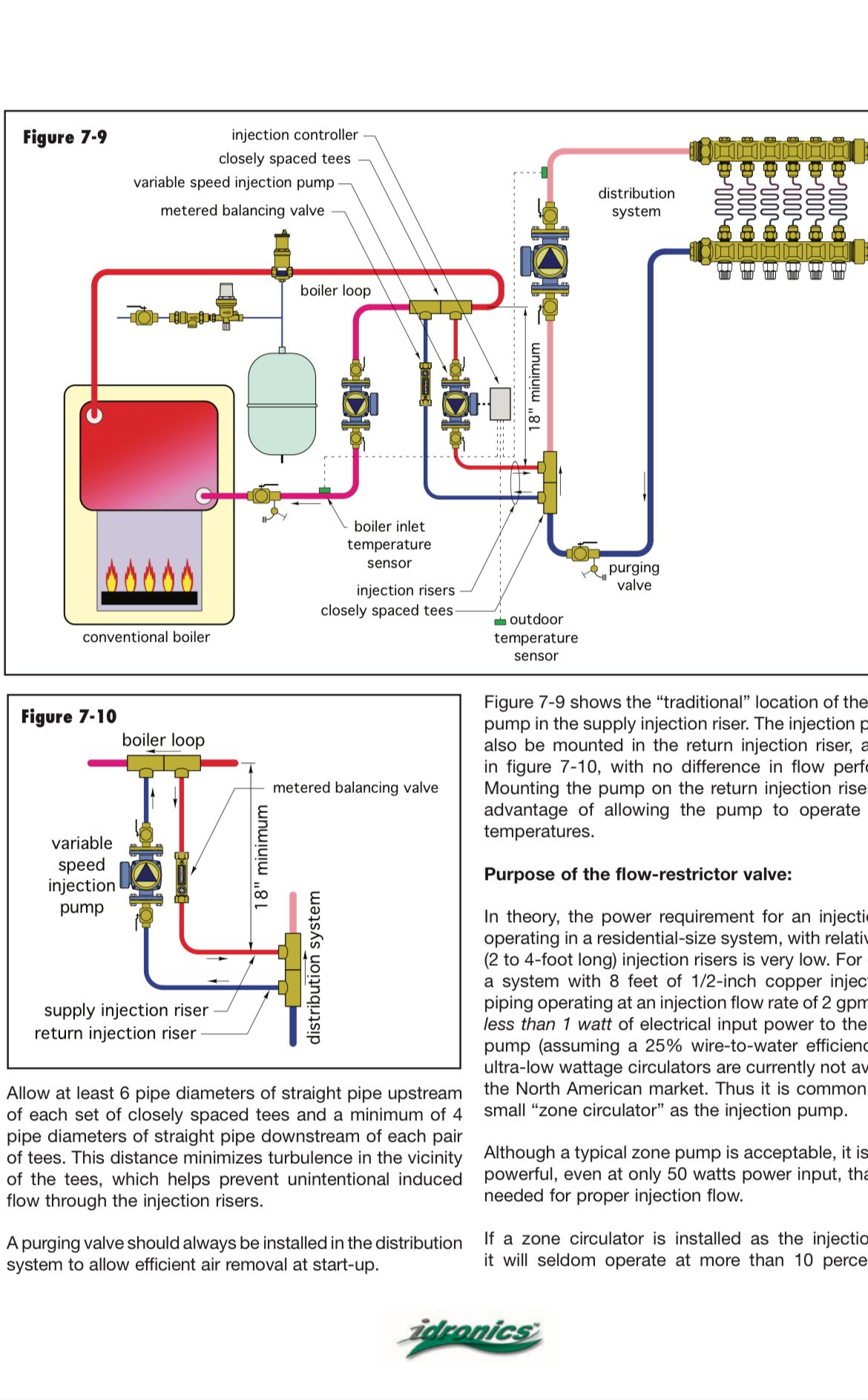

Variable speed injection mixing is the best option. Go to Tekmar’s website and look up their essay on it for complete details.

On thing that you need to aware of is the slab over heating due to its high mass. It’s called the flywheel effect. VSIM will prevent this as well as protect the boiler from cool return water temperatures.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

As they say there is no free lunch. The free boiler will cost you more than getting the right unit.

The issue is all the bits you need to make this work properly will be near the cost of a new modcon. If your fuel source is expensive like propane, the operating cost delta is not worth the effort (properly set up modcon will use about 25% to 30% less fuel with radiant).

1 -

Your first concern is boiler protection from low return temperatures. The guys will chime in shortly with various ways to do that. Mad Dog

0 -

Thats the primary reason for my post. Would love to pick some of the knowledgable brains on here and get ideas.

As mentioned by Supertech I would be open to utilizing the indirect tank for the heating system and maybe just adding a traditional tank type water heater later. Heat is the priority right now.

I'm on natural gas which is cheap in my area.

0 -

The more I think about this the more I like it.

Ok so thinking aloud, if I had the indirect tied into the heating loop, the boiler heating the indirect to say 180, and the radiant pulling from the indirect, instead of the boiler, with a mixing valve down to 120ish. Seems pretty simple no?

0 -

We won't even have septic until next year so I have no immediate need for DHW and am willing incorporate the indirect into the heating loop if it's a viable solution.

0 -

You can’t run a slab at 120*, that’s too hot. You probably won’t need more than 100* SWT on the coldest night of the year. And you don’t need a buffer tank: the high mass of the slab is more than enough buffer.

Again, I would encourage you to read Tekmar’s essay on injection mixing. It will give the answers to your questions and also provide the info that you need but are not considering.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

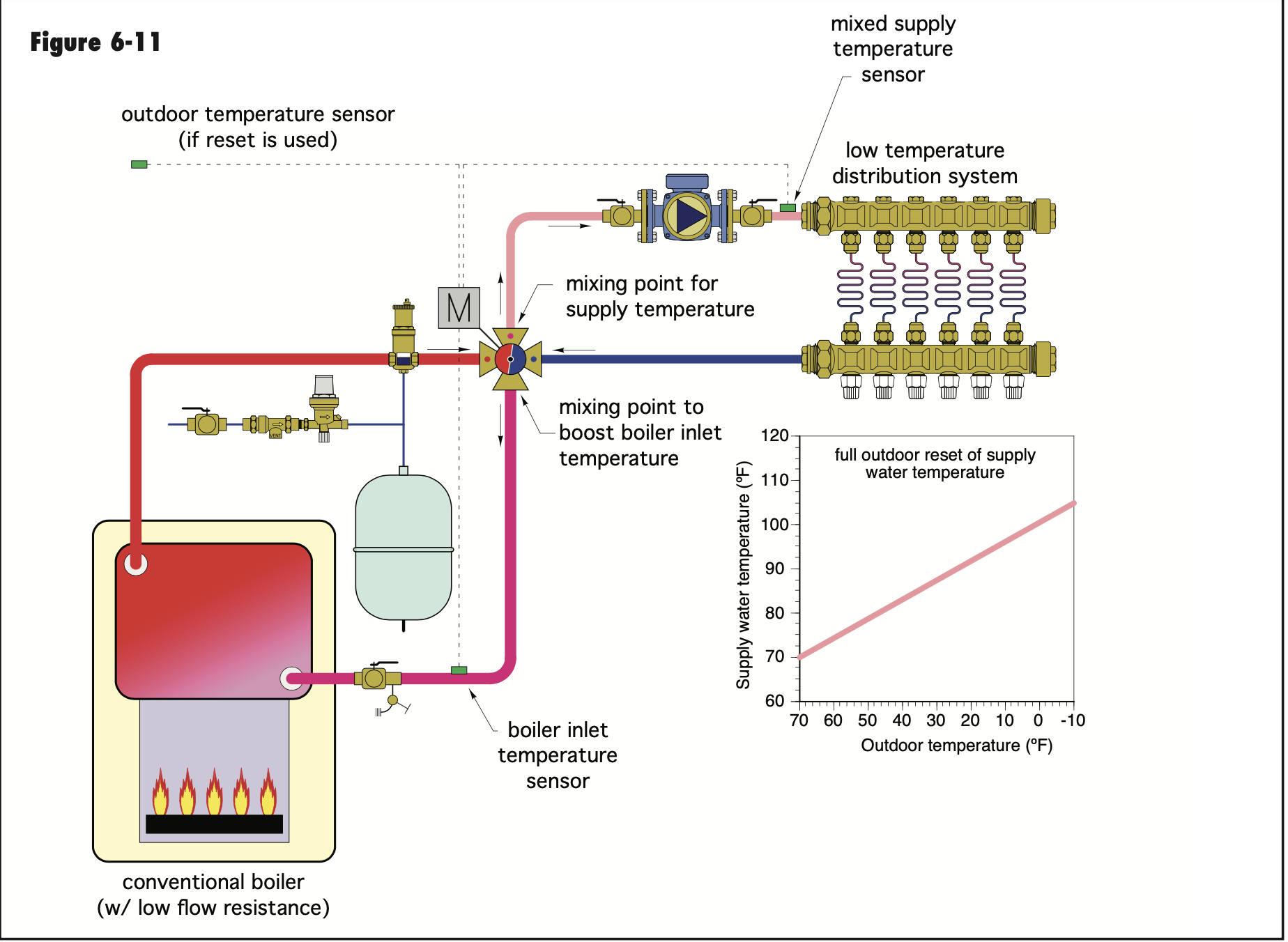

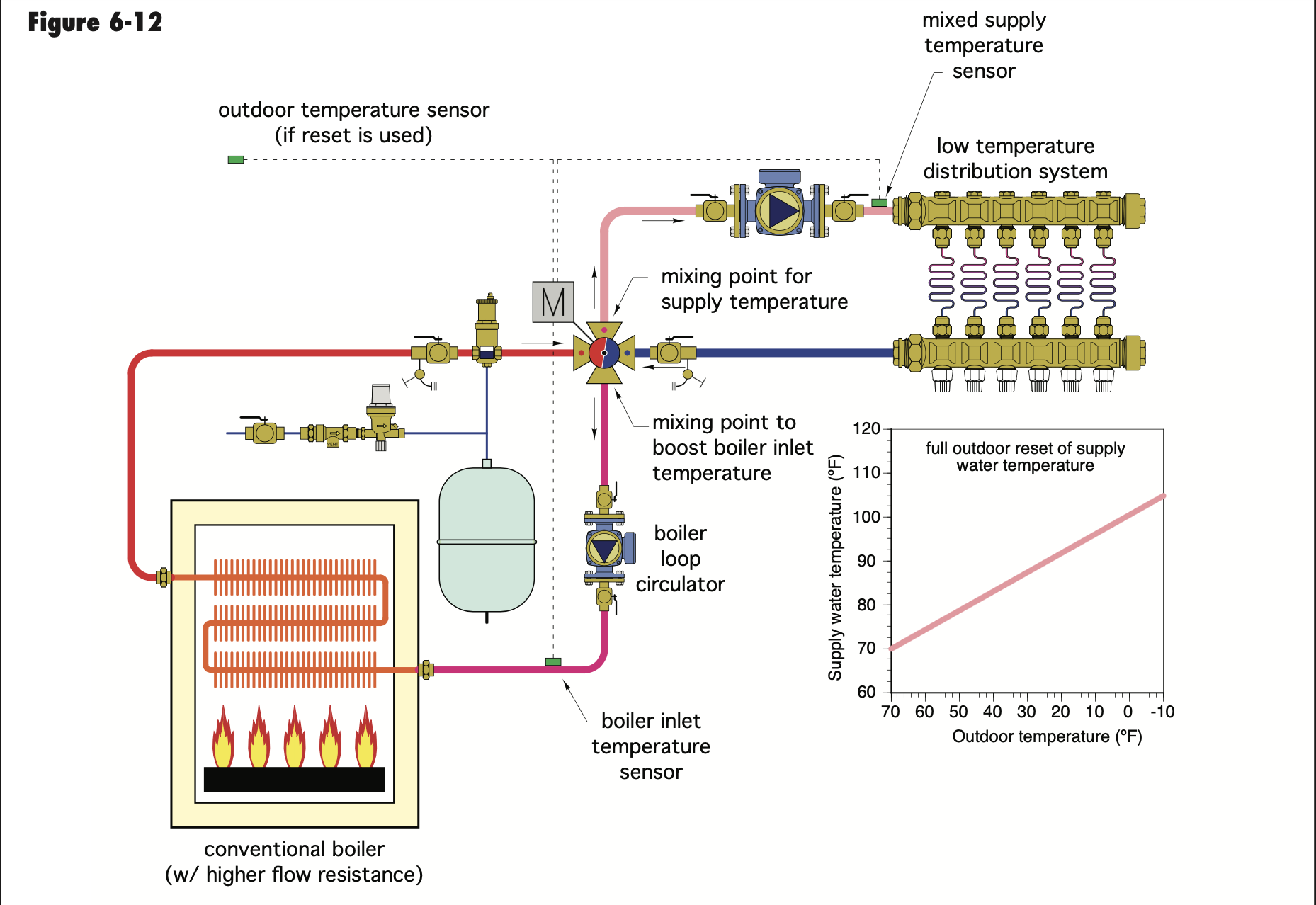

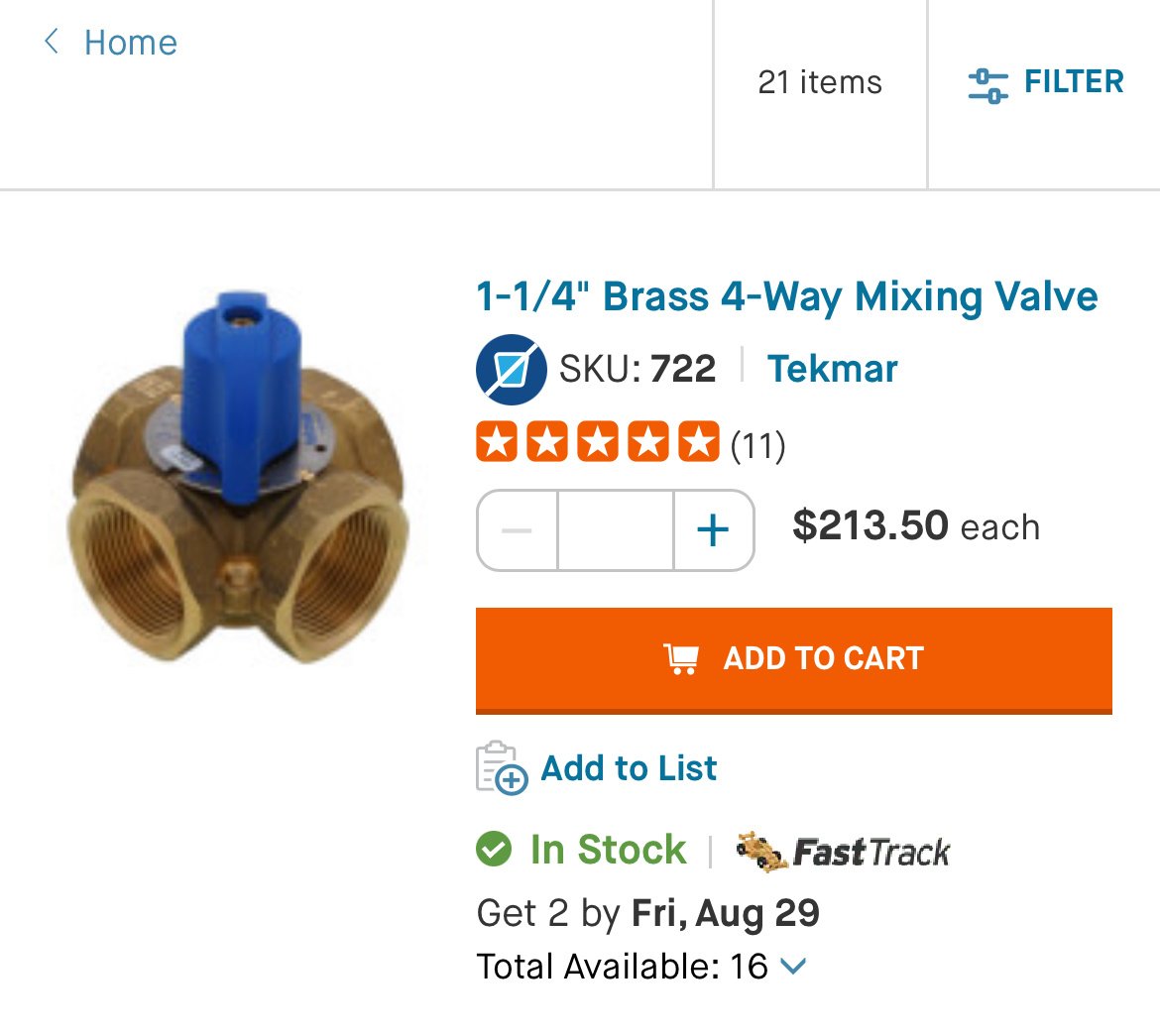

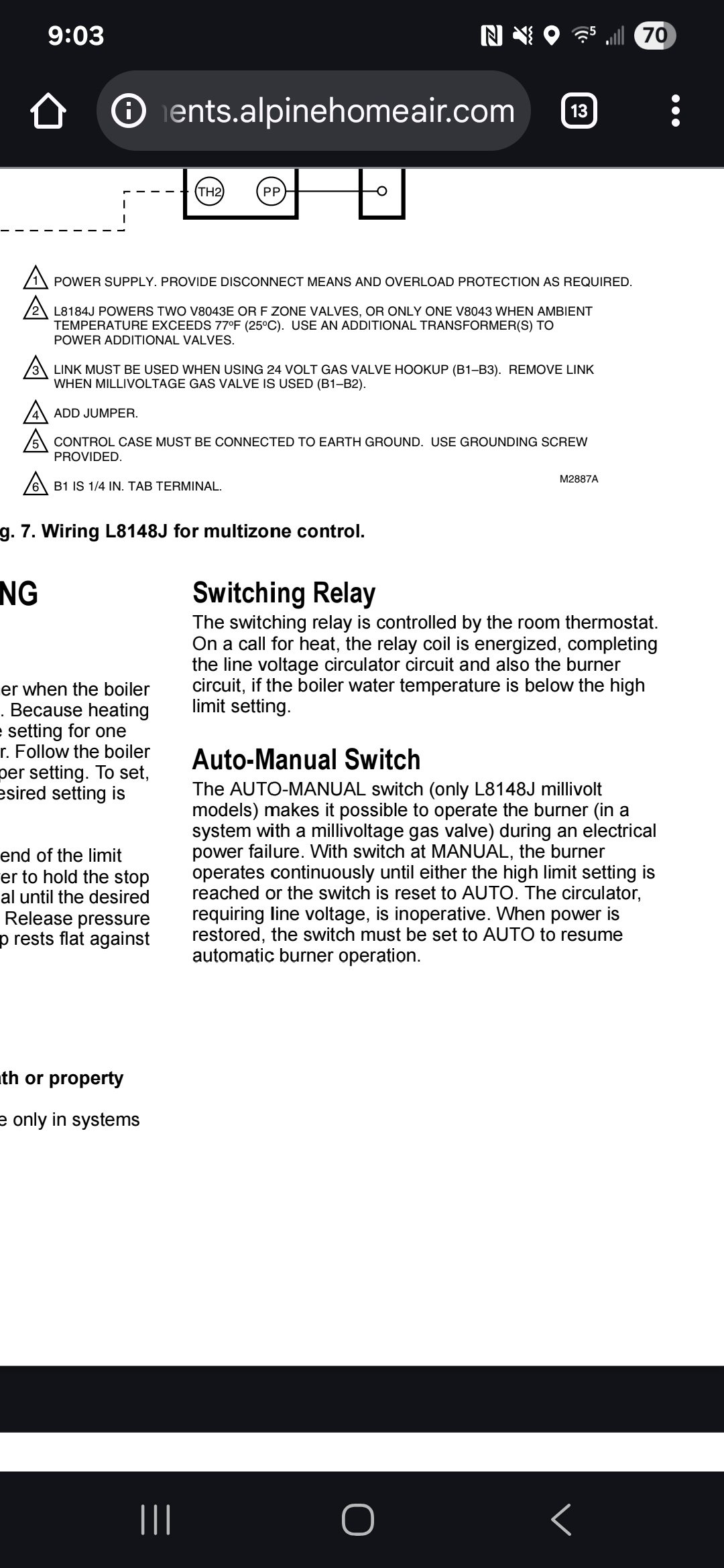

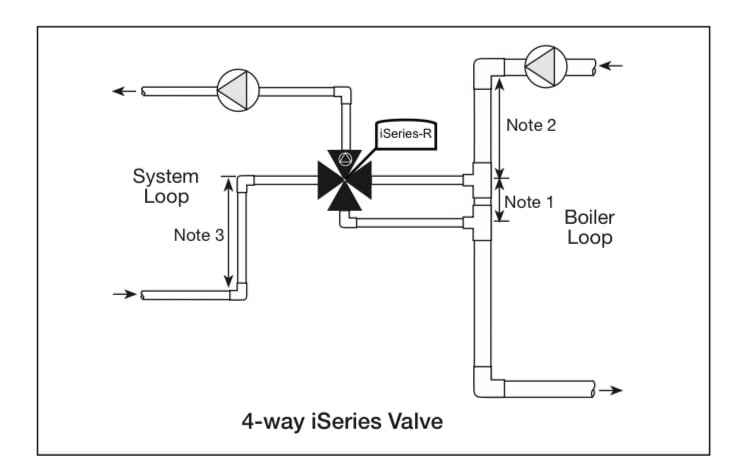

Back in the day, before mod cons, CI boilers were commonly piped with 4 way motorized mix valves.

This valve both protects the boiler from low return, and provides the mix down temperature. Many of the Euro boilers offered this assembly. Tekmar, HBX are a few that still offer the valve, actuator, and controller.

\If return drops below acceptable temperature the valve modulates to protect it as priority.

Possibly a single circ will; work, depending on the loop requirements, gpm and head.

If not a two pump system was used with either a high pressure drop boiler, or high pressure drop radiant.

Buderus used to promote that "flexible cast iron" as being able to accept low return without damage? But flue gas condensation needs to be considered.

Price it with the components to use that boiler, or a combi.

Many here rave about simplicity and long life, inexpensive maintenance and parts of CI boilers.

The 4 way also provides outdoor reset.

Caleffi Idronics #7 talks about numerous mixing options for projects like yours. Hard to beat a 4 way.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

Generally a high mass radiant coupled to a CI boiler does not need a buffer tank. No harm in adding one with $$ in mind

Just parallel the indirect, good chance the tekmar boi

ler control would do the mixing, return protection and indirect priority. Maybe the boiler control has DHW priority?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I have downloaded and studied the Tekmar injection essay. It's actually alot less complicated than I thought once I really read into it.

From what I gather the only extra components that would add significant cost are the controller, a circulator for the primary, and another variable speed pump for the injection. Is that correct or is there anything else I'm missing? Seems like pretty solid setup.

0 -

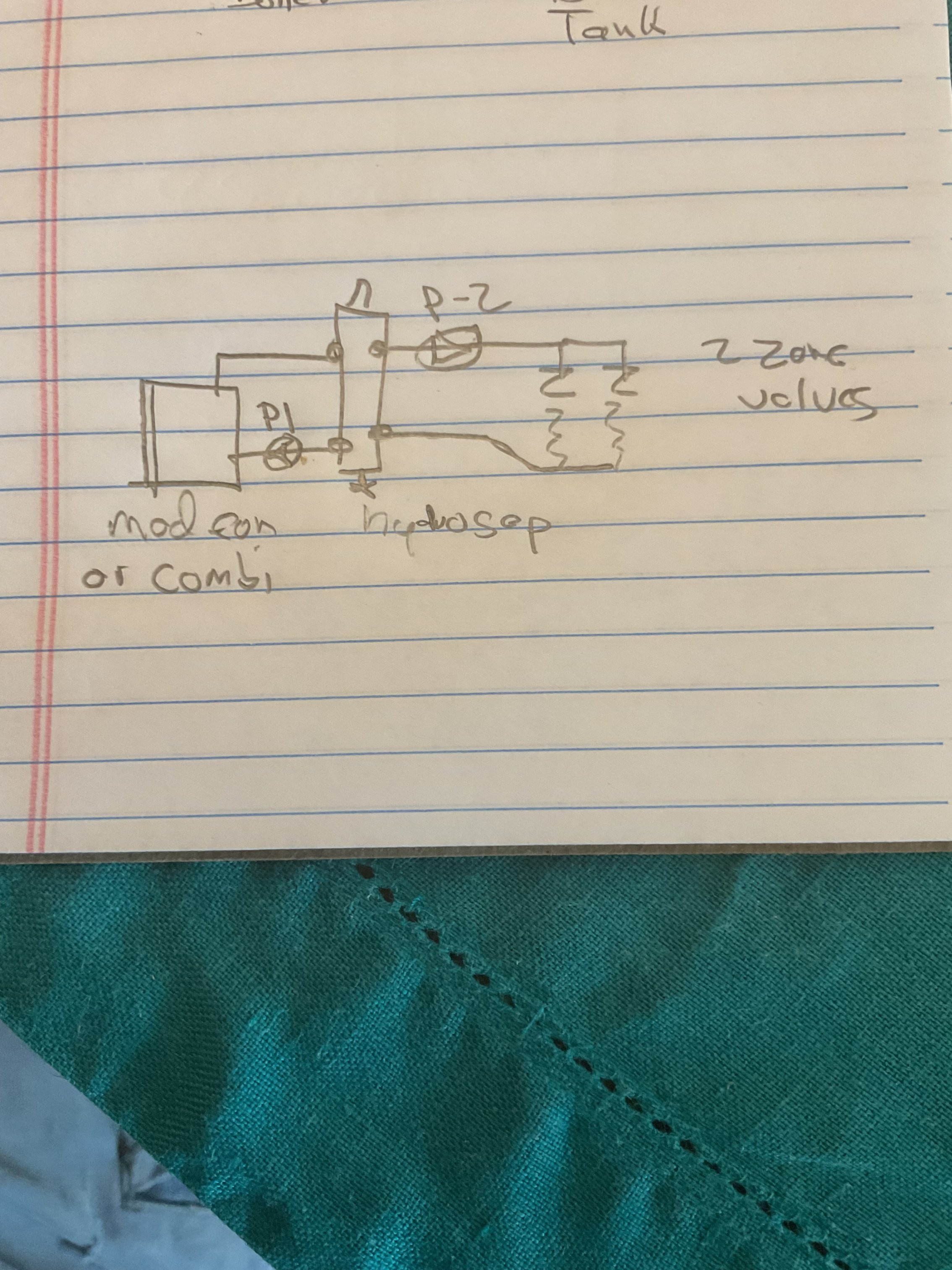

injection mixing will cost you 3 circs, 4 if you add an indirect. I think you could do it with a single and 2 zone valves

One issue we had with injection mixing was finding a small enough circ for the injection pump. Do the math, it may be 1 gpm or less. Often those injection pumps would stick up and not start when run on very low speed control

I believe tekmar changed their control logic control so the injection pump starts at 100% then ramped back

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

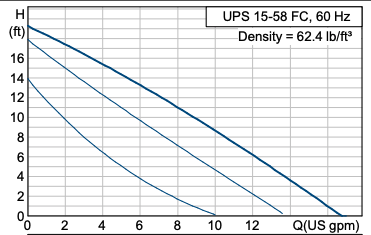

A standard circulator, like a Grundfos UPS15-58, is what’s used for the injection pump. The mixing control (usually a Tekmar’s 356) controls the speed of the pump.

With the return sensor added, the control provides boiler protection as well as ODR.

As hot_rod mentioned, Buderus boilers are made from a specially formulated cast iron that’s actually flexible. They can withstand return water temperatures as low as 106* without damage from thermal shock. However, you don’t want to continually run it that low because of flue gas condensation. A constant temp of 140* should be sufficient. You don’t need 180* unless it’s being vented into an over sized masonry chimney or when the indirect needs quick recovery.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

I’ve done quite a few VSIM systems and never had any problems. As Bob mentioned, it does require 3 circulators and the control. Still, You should be under a grand. Also, follow the instructions for sizing the injection bridge and installing the globe valve for balancing the flow.

One of the main advantages is that the boiler loop and the radiant loop will maintain the required separate flow rates in in each one. In other words, there’s hydraulic separation between the loops. This can help keep the floor a more even temperature a prevent possible freezing near the perimeter or an open garage door if the system is not protected with glycol.

With a mixing valve, the flow slows or stops in one loop as it’s transferred to the other loop. Either method will work. Your choice.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Ok so to clarify, my original plan was to use a circulator for each zone and one for the indirect, so 3 total circulators.

So in reality I am just adding 1 more circulator and the control correct? And a couple globe valves.

0 -

The loops I see indicate you need about 4.5 gpm at design? So to do that with 4- 78W circs will be 300W. Lots of electricity to move a very small heat load :)

One pump and two zone valves less that 100W.

Pumps with flanges, iso valves, relays X 5 is what you need to VBS injection.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Guessing a 40,000 load, boiler running 160-180, radiant 110- 90°

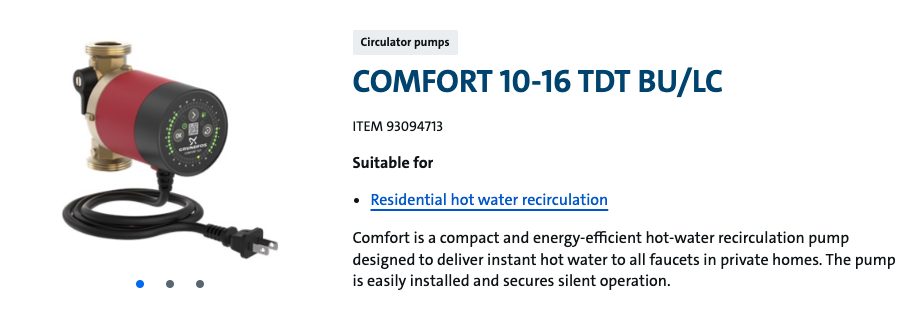

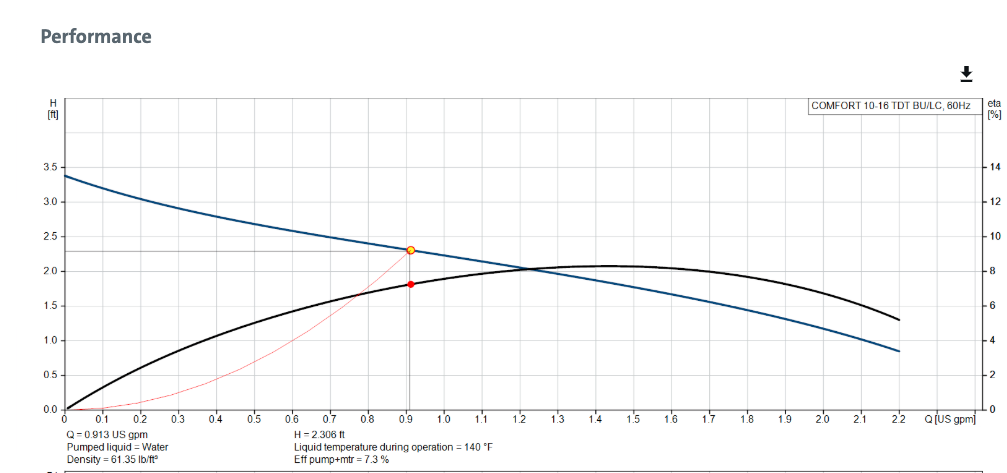

you need .91 gpm injection. A 15-58 is running well off it's curve at .91 gpm. SAo speed 1 with a balance valve choked way down. Not an ideal place to run. Ideally you run mid 1/3 of the curve.

A 10-16 DHW recirc pump fits nicely, but $$.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok first off thanks for all of the information! I've learned A LOT in the last few days and am still studying...

I've come across the Taco I-Series mixing valve. This is a modulating mixing valve that has the control built right in, can regulate supply temperature, boiler return protection, as well as outdoor reset option. So far this is looking like the easiest option that gives me everything I'd need with the least amount of components.

Would there be any downsides to going this route? I mean it ain't cheap, like 700 bucks for the ODR version, but if it gives me everything I need I don't think I can do much better than that going any other direction.

Also they offer 2, 3 and 4 way. Would the 3 way work or do I need a 4 way? That gets closer to a grand 🤦♂️

0 -

Let’s backup for a moment and get some basic info.

Was a Manual J load calculation done to determine the heat loss? If so, what are the results?

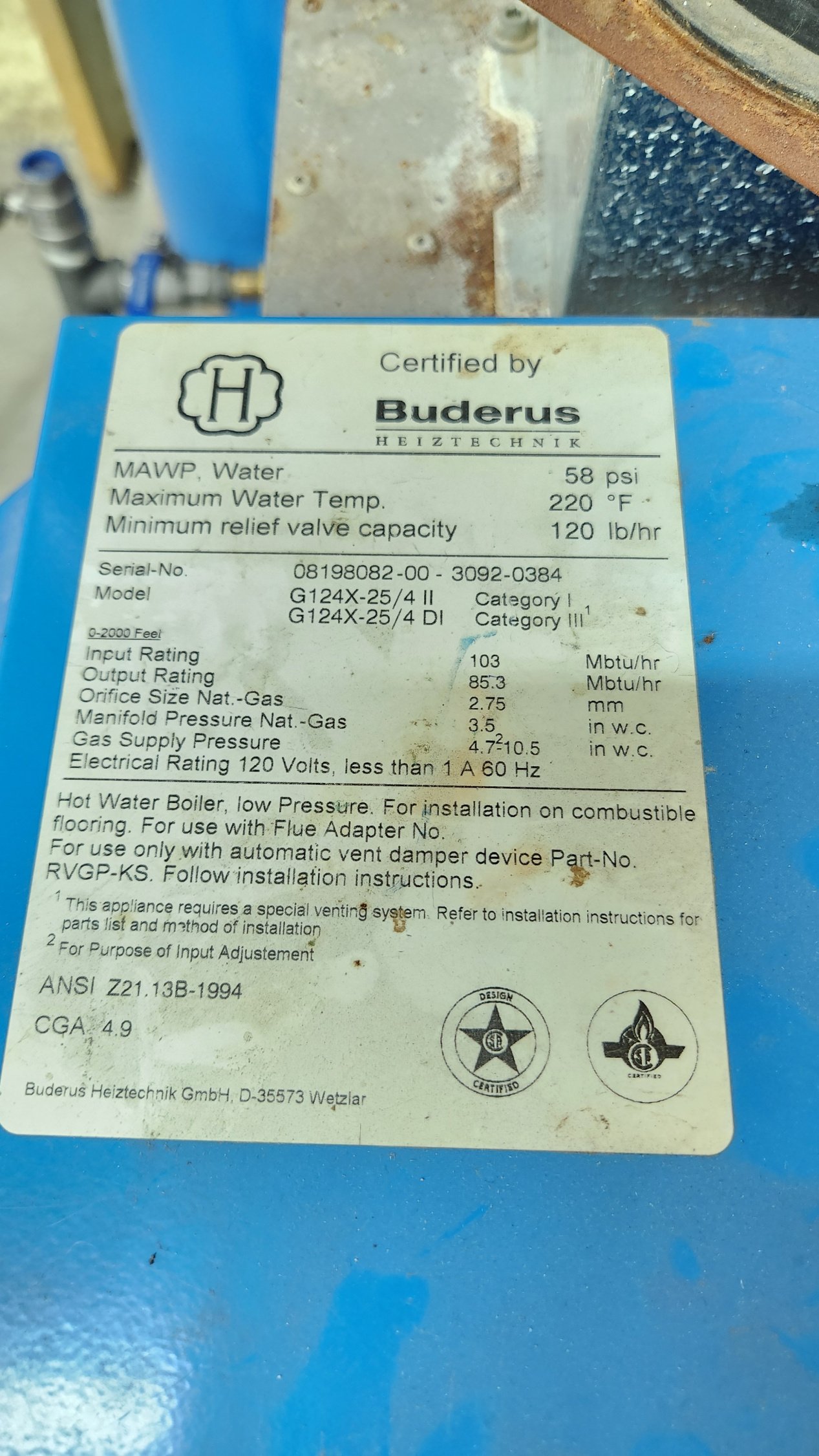

What size is the boiler?

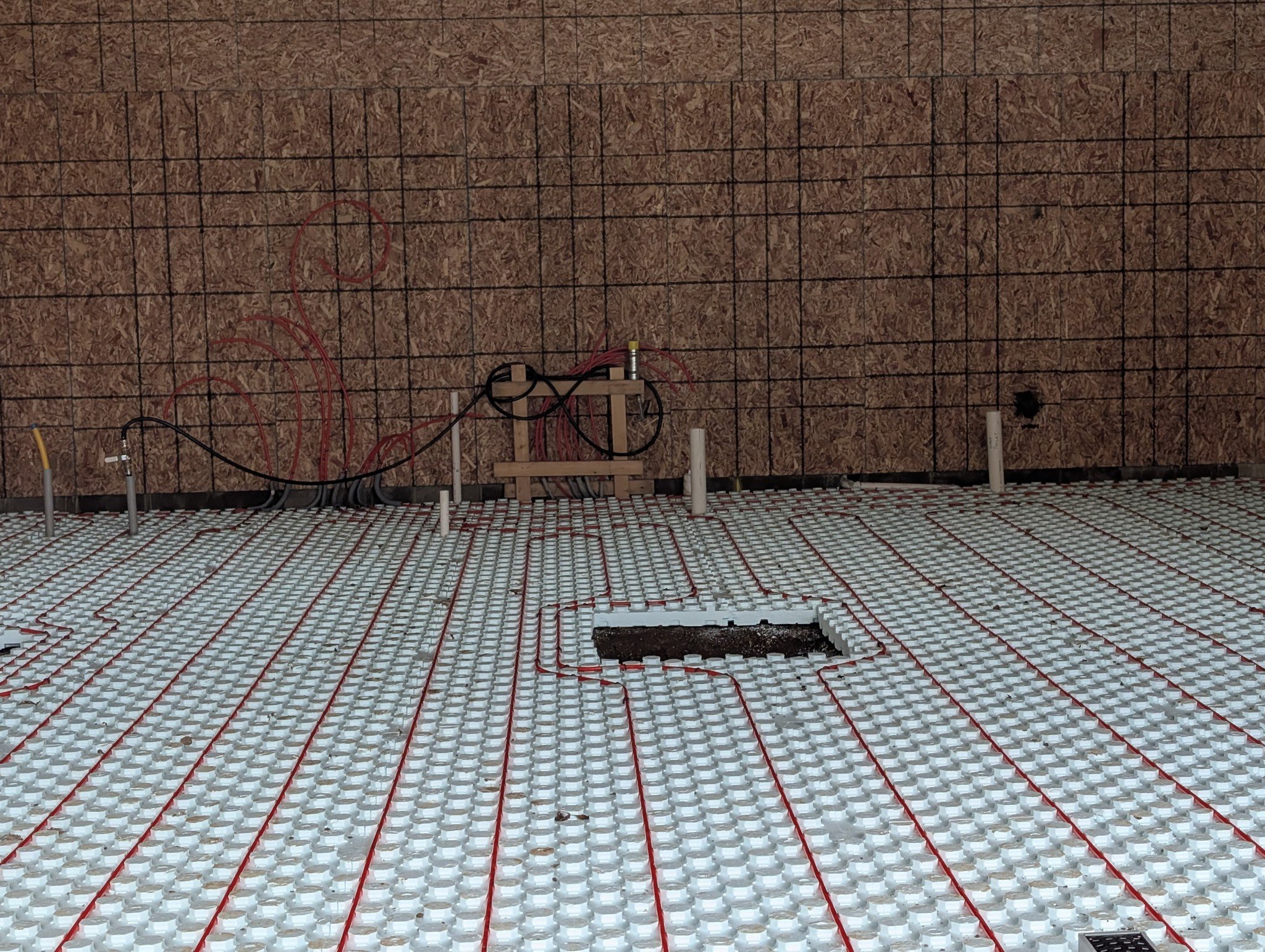

I see 4 loops on one manifold and 3 on the other. What are the tube sizes, the spacing and their lengths on average?

The reason that I’m asking is that unless you’re in a mild climate, it looks like that you may be under-radiated, in which case you’d need some supplemental emitters. If so, that would change the approach.

I apologize for not asking these questions first, but I went directly to addressing your questions without noticing the number of loops.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

If there were calculations done I was not involved in it. My contractor said he's done "1000" radiant floors so I took his word for what he was doing.

The 3 loop manifold is for the 800sq living space, the 4 loop is for the 1,200sq ft shop. 1/2" pex, I can't recall lengths or the exact spacing but maybe you can get an idea from these pictures. This would be the shop, and the living space is beyond the back wall. I'm in Western NY. R22 on the walls, r40 in the finished ceiling. 12ft walls.

0 -

my guess would be 3- 300’ loops

4-300’loops, so tube is 12” oc approximately

Tube length is usually printed on the tube

The shop looks well insulated. Not much glass. A load calc and design would answer some questions, I suspect you are covered

As for mix valve, the tekmar requires 3 pieces, valve, actuator and control, probably 1200 or so based on supplyhouse prices

The tekmar 360 control has more functions and would control the boilers operation. It is programmable with the digital display readout. Sometimes called a PLC, programmable logic control. So you would need to learn how to program and drive it.

Looks like the Taco uses dip switches for choices,Like buying anything, how many features do you need or want?

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Tekmar-360-install.pdf

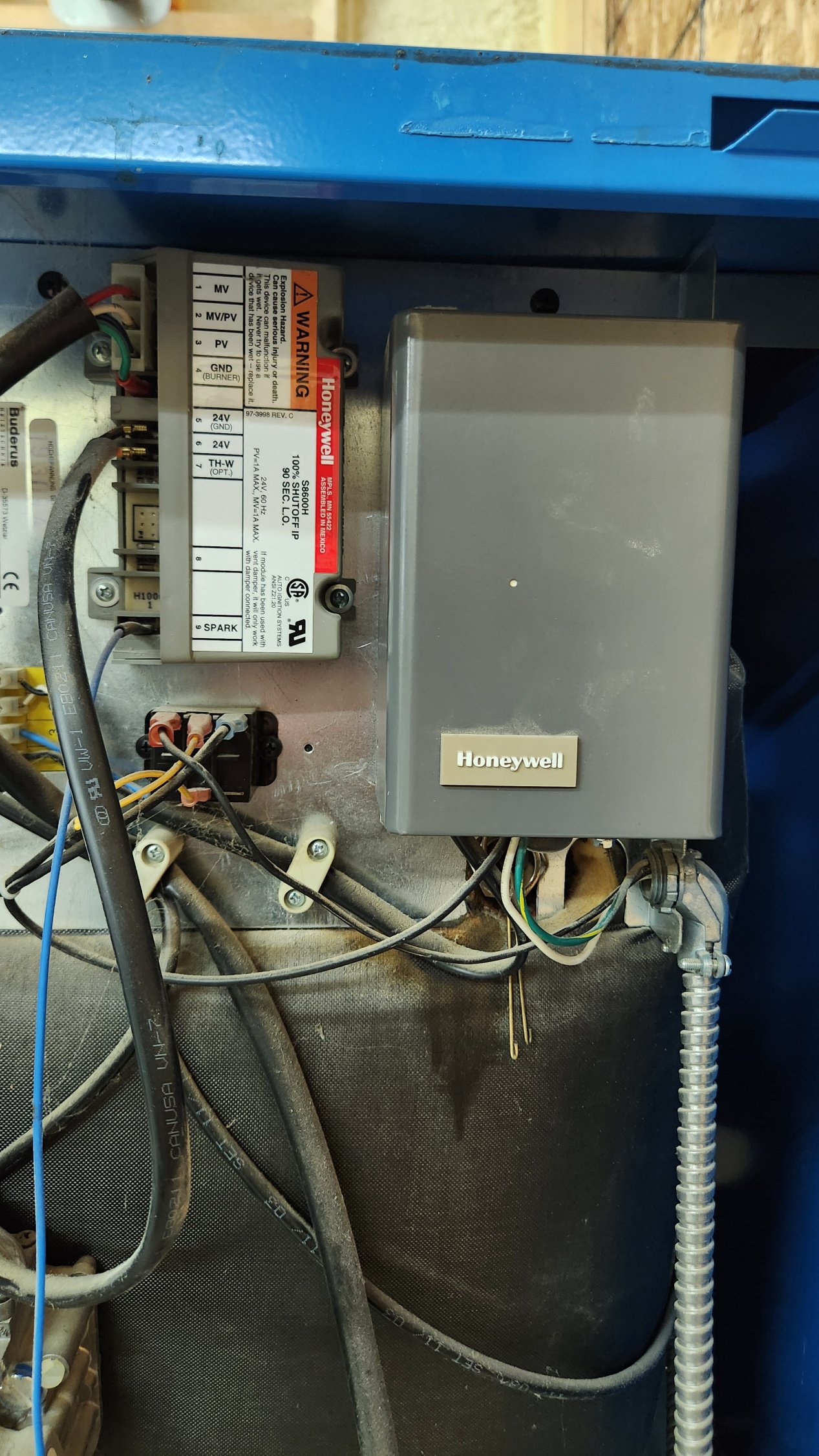

What control is on the boiler? It may have some of the functions you need?

Another option, put in the tekmar without the actuator or control. Manually adjust the valve at design condition. If the boiler has a control with ODR, no need to have two ODR functions

A control could be added later if you want more control

That boiler is fairly radiant friendly as it is

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

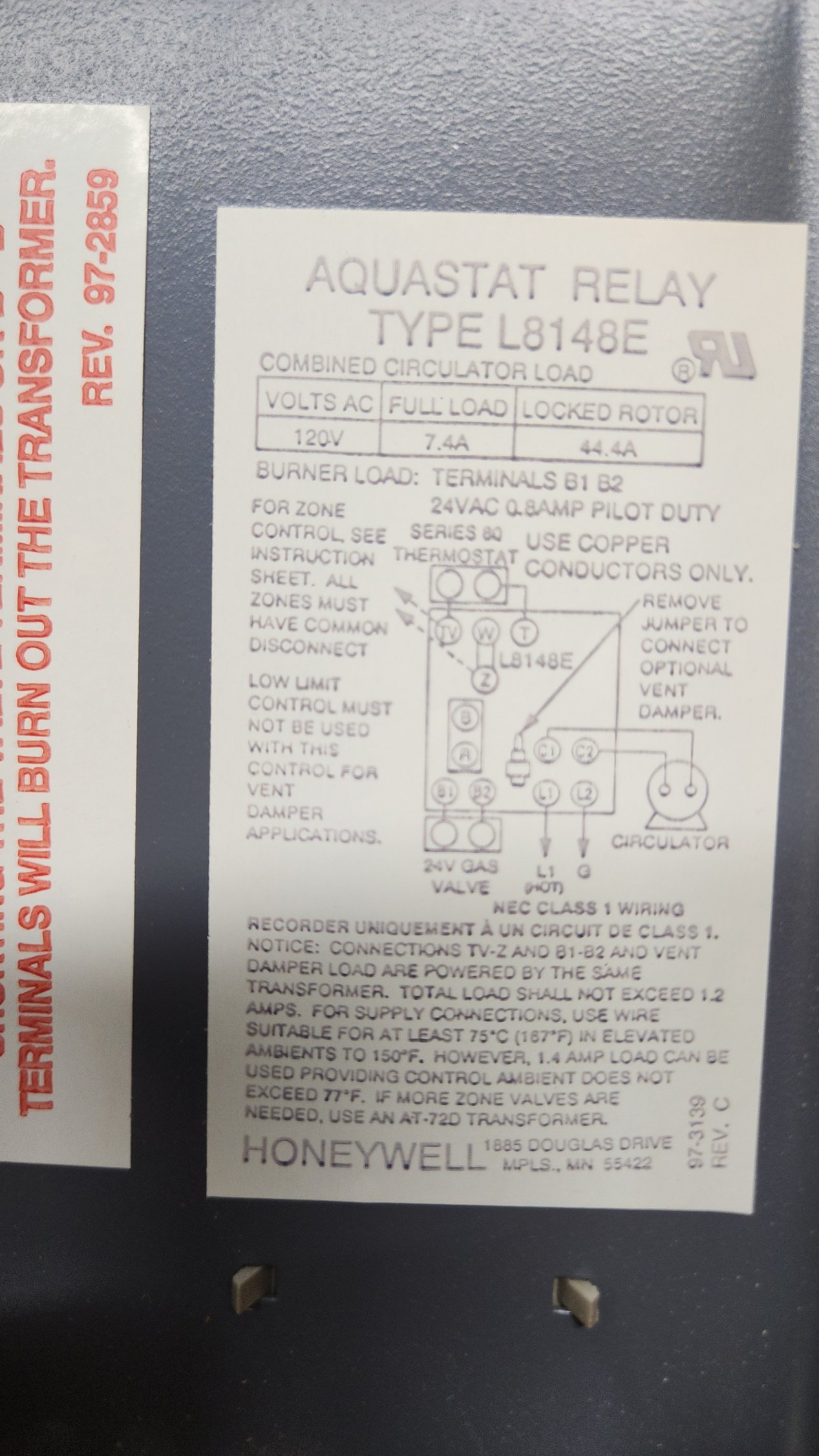

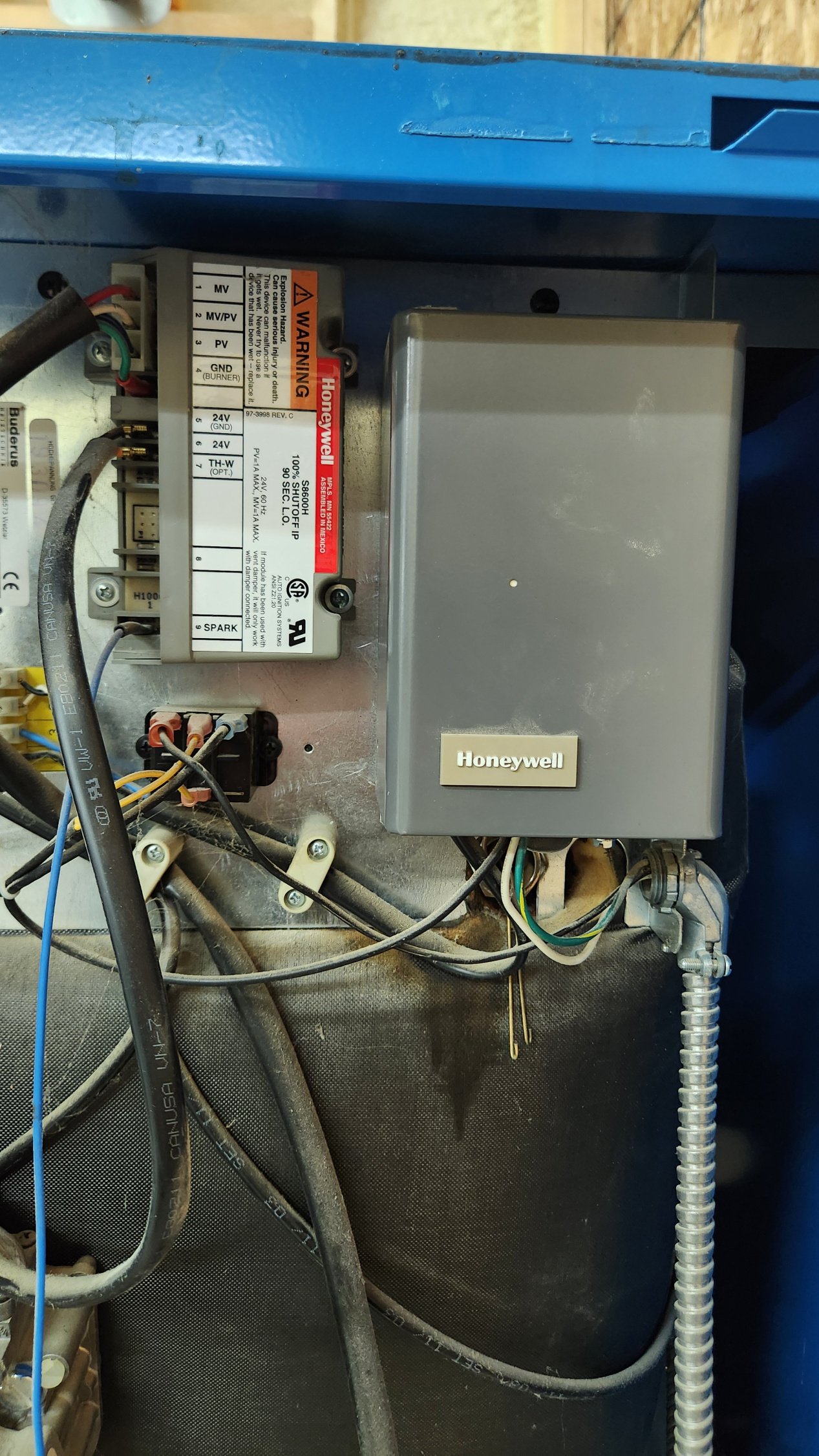

The boiler is 103k BTU. I didn't get any sort of external control with it and this is all I see under the panel.

0 -

I am intrigued by the idea of just a manual 4 way for now and adding a control later. Can you elaborate on that?

0 -

I live in the southern finger lakes and I am speaking to you as a homeowner. I heat my home and domestic hot water with a coal stoker boiler.

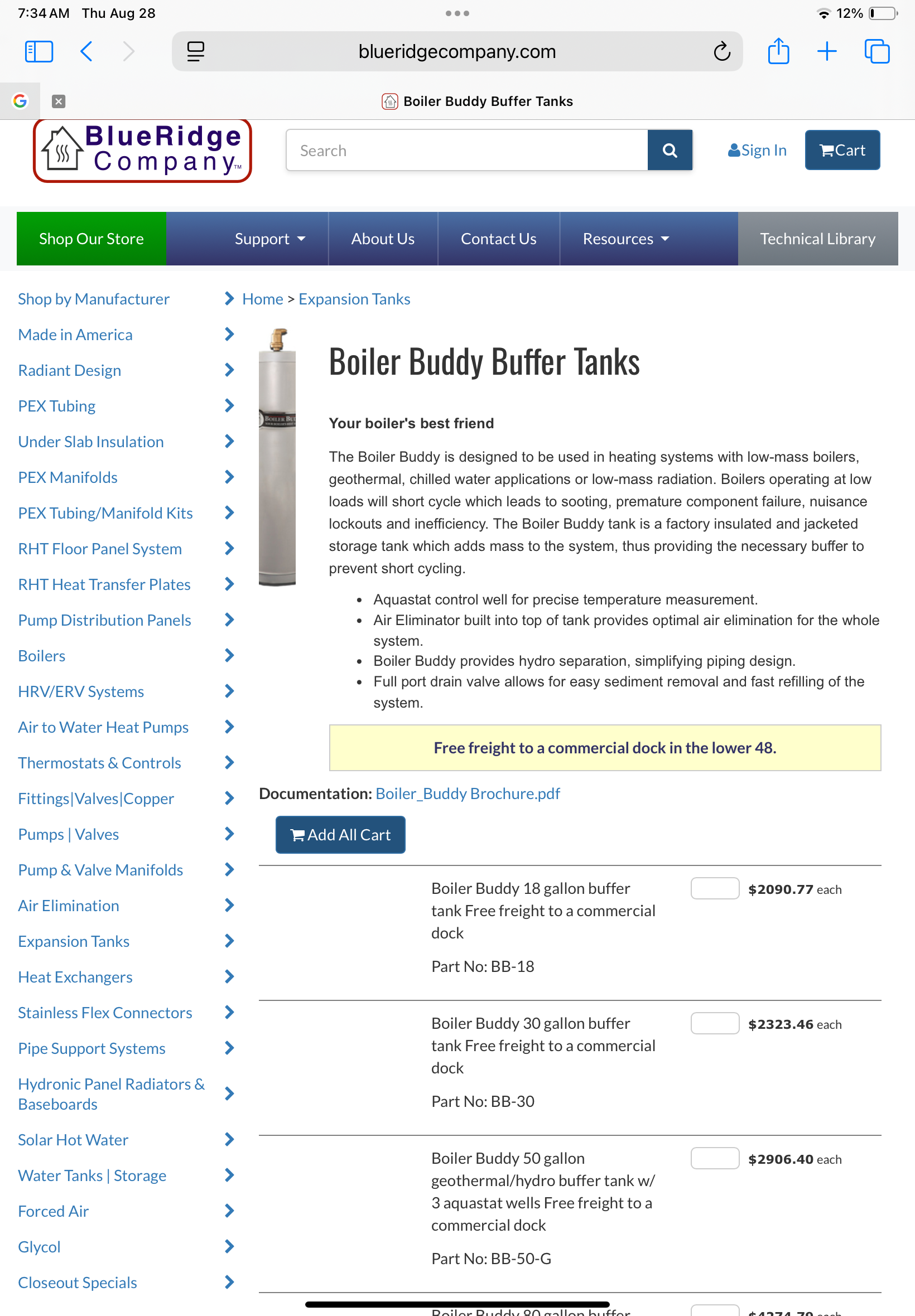

I am glad a buffer tank was mentioned as that is the first thing I was going to say to you, you need a great deal of buffer storage.

As you appear to have a great deal of room I want to suggest to you that you invest in a surplus bulk milk tank for your hot water buffer tank. Having a large buffer tank is no different than having money in the bank but in this case it is hot water in the hot water bank.

You can purchase a surplus bulk milk tank from the farm surplus company Wengers of Myerstown, Pennsylvania.

By using a buffer tank you have the benefit of a huge amount of thermal mass to heat with and the cooler return water will take less energy to reheat to heat your building.

The engineering tool box home page has a great deal of information about water.

1 -

use the output number of the boiler, so you have 85,000 btu available.

If I were a betting man I would guess a total load of both spaces of 30,000 btu/ hr. Maybe less.

Here is a link to a free demo heat load software if you want to try and pin down a better heat load number

But at this point the heat available to the space is determined by the amount of tube you have installed already. With 7 loops flowing a typical .65 gpm per loop, you could easily cover a 30- 40,000 btu load.

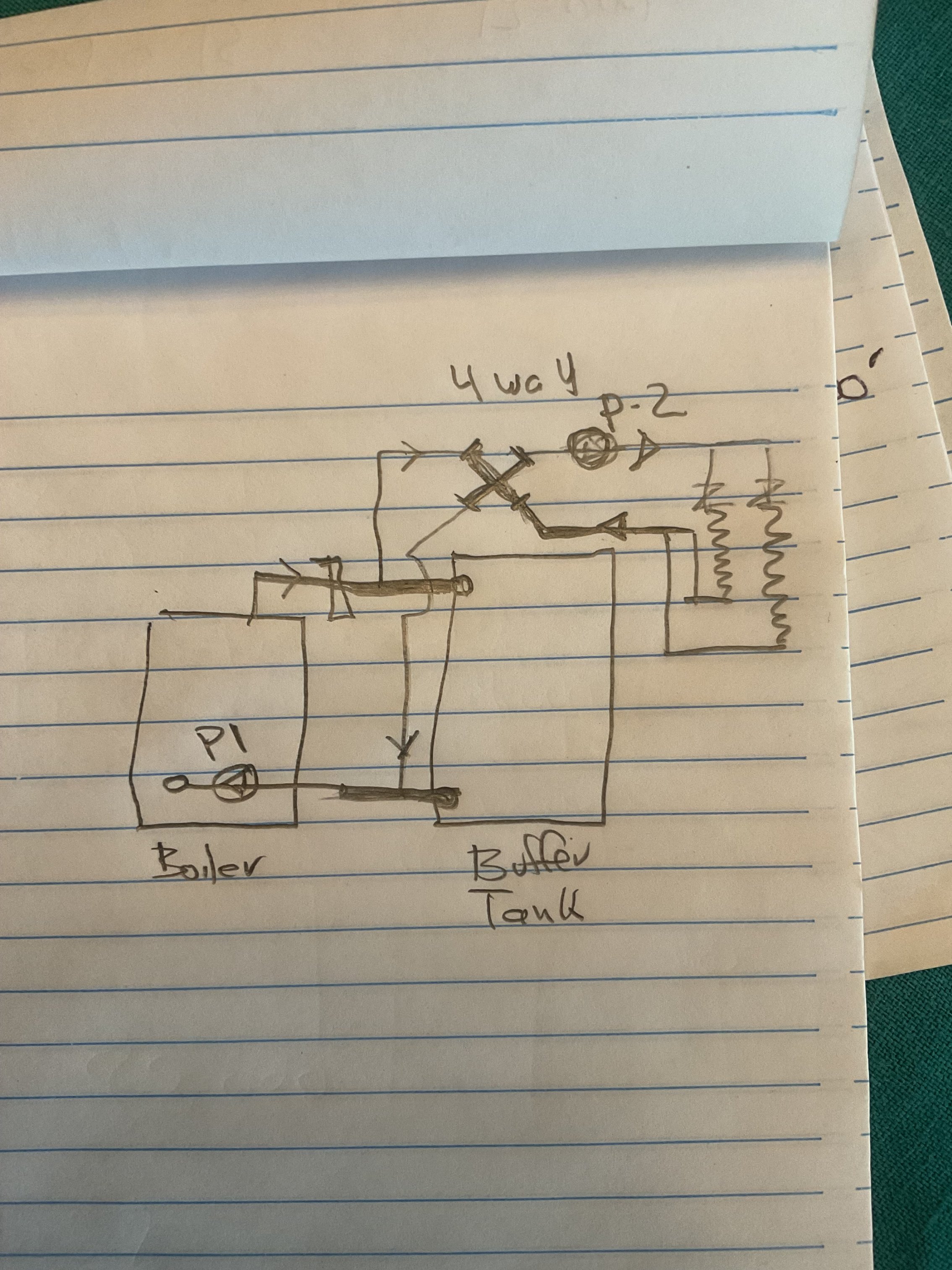

On to the boiler, it is twice, maybe even 3 times the output you probably need. So what will happen is the boiler will turn off and on frequently. More so as the buildings heat load drop during mild weather. The high mass of the slabs, cast iron boiler and system fluid content will buffer that to some degree. Consider just the 800/sq ft space is calling for heat. Perhaps it is a 10-12,000 load. You have a boiler that is one speed, always, 85,000 btu/ hr. See the mismatch in horsepower versus the load?

A buffer tank could be added, or run the system a winter and observe the cycling. Anything less than a 10 minute run time every time it fires is considered a “short cycle” That is hard on equipment and drives down the boilers efficiency.

I think when you add parts and labor to the system to make that Buderus work you may consider a mod con combi instead. Adding a boiler control and a mixing device, and a buffer will cost more than buying a new combi. A lot more if you buy a ready made buffer tank ie Boiler Buddy

A mod con or combi:1 it will modulate down to 8,000 - 10,000 btu/ hr depend on size. An 80,000 would be plenty, maybe even a 55,000

2 it will run 90% plus efficiency at those temperature requirements

3 it has a lot of control features including outdoor reset, some even have zoning control built in, now.

4 it is sealed combustion, exhaust goes out, intake air comes via plastic venting. That Buderus will need an outdoor air grill, always open allowing cold air in!

5 efficient DHW comes along, endless DHW at 3 gpm.

6 Piping is much, much simpler

7 a small wall hung package

Free advice from a born and raised Orchard Park boy☺️

Sketch of boiler, buffer, 4 port

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

No kidding, I'm down in Cuba, like an hour south of Orchard Park.

Are you taking DHW into account for the heat load? I planned to use the indirect for that.

Last year when I had deeper pockets I had the local HVAC company build me a quote for a modcon combi boiler setup, and based on all of my specs they recommended/quoted a 115k BTU unit. So I figured I'd be in the ballpark with the output of the Buderus.

My wife was unexpectedly unemployed for 7 months. We have 2 kids in college. She is back to work now but we are still playing catch up with tuition payments hence the low budget.

1 -

we used to take our hydroplane boats down to Cuba lake.

Well the least expensive option IMO would be a manual 4 way valve with that boiler.

You have the indirect already, so it just needs a circulator.

It is not ideal due to the probable size mismatch between boiler and load. You are tweaking a high temperature boiler to behave on a very low temperature requirement system. But we did this all through the early 90 before mod cons became available. So the concept is sound.

The mix valve could be updated later for better control. A buffer tank could be added also if the boiler cycles excessively, which it will.

A buffer and basic mix valve will cost more than a common mod con however plus a lot more piping.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

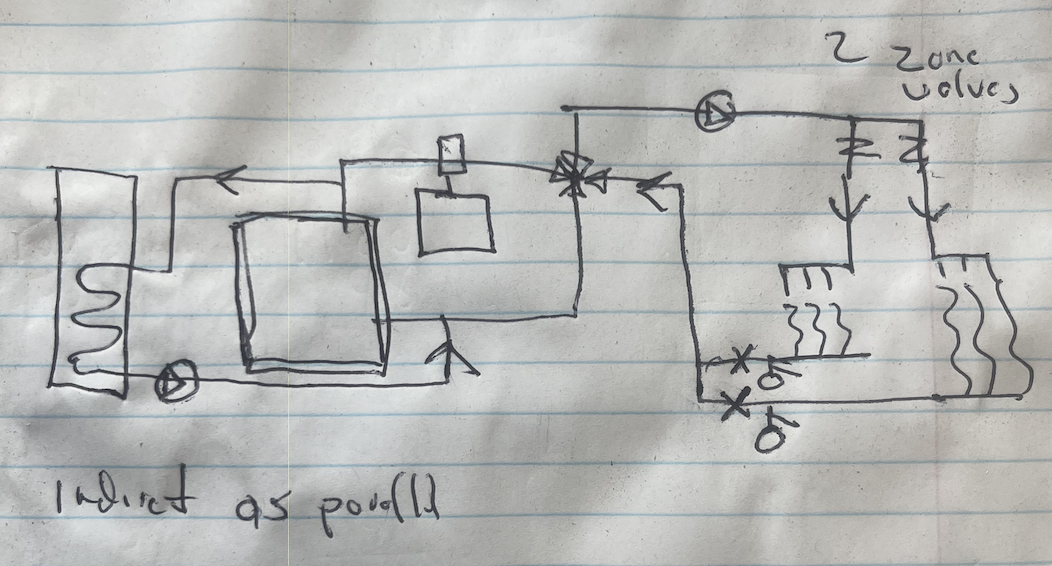

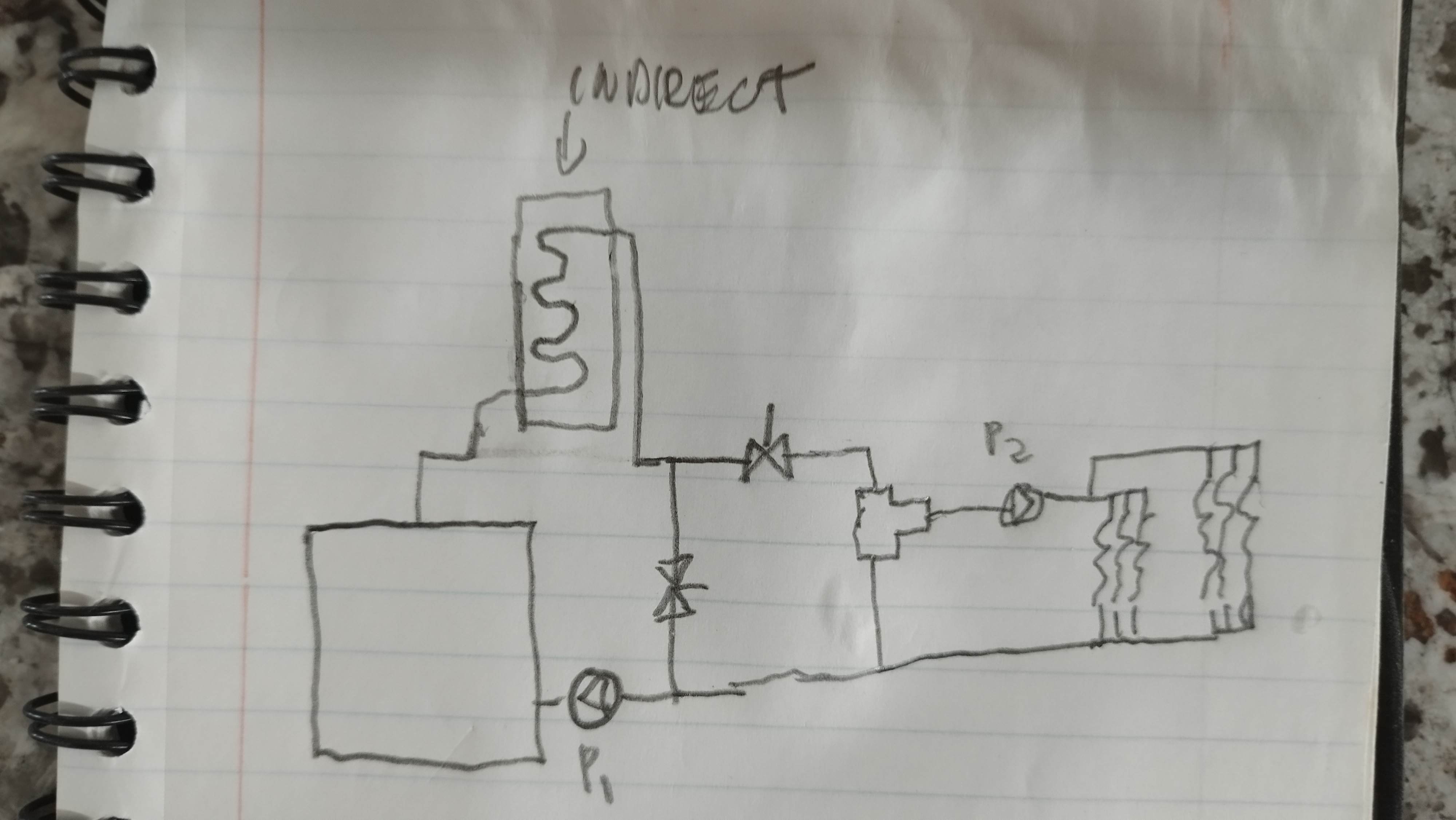

How about this as a cost optimized setup.

Fixed bypass and hold off on P1 for boiler temperature protection. Thermostatic mix valve for floor heat. No zoning to limit short cycling.

The indirect is always on the heat loop, when the boiler runs, indirect is always heated. When only indirect needs to run, only P1 is turned. Will need a valve before P2 that can be closed in the summer to stop flow through the floor heat.

The indirect does double duty as a buffer to reduce cycling.

2 -

-

The one issue that I do see is that using a thermostatic mixing valve will not address the flywheel effect of the slab. Without some form of ODR, the 2,000 square foot rock will continue to give off heat once the thermostat is satisfied and will overheat the building.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Wow Kaos now that is the solution I'm looking for! It does NOT need to be the most efficient or ideal, just cheap and reliable. This will likely just be a temporary solution to get us through a winter or two until we finish the rest of the build and can afford a modcon system.

Ironman I'm pretty sure I saw Tekmar had a thermostat control that had an outdoor reset function for an on/off boiler system. Could that work?

Also, isn't it possible to lower the upper limit of the boiler temperature via the aquastat? Would that help with short cycling? I don't need 180 degree water for anything.

And in reality it could certainly all be 1 zone for now, the living space is just for a guest house and is only framed in at this point. I'm never not going to be running heat on both sides for freeze protection. I could just put in a couple ball valves to throttle one side if I need to. That's actually all I use for zoning in my house with FWH and an old CI boiler.

0 -

If you purchase a large used bulk mil tank it is fully insulated and will hold the heat for you for a very long time and provide the existing boiler with a greater amount of warmer water that will require less fule to heat it to the desired temperature.

0 -

Well I think my pictures make it look like a bigger space than it is. Don't really have the space for a big tank like that. Shop is 30x40. None of those were current pictures, it fills up quick! And there will also be an automotive lift going in.

I'll be building my boiler room/bathroom in the corner where the boiler is now which will be about 6x15 so I need everything to be able to fit in there.

0 -

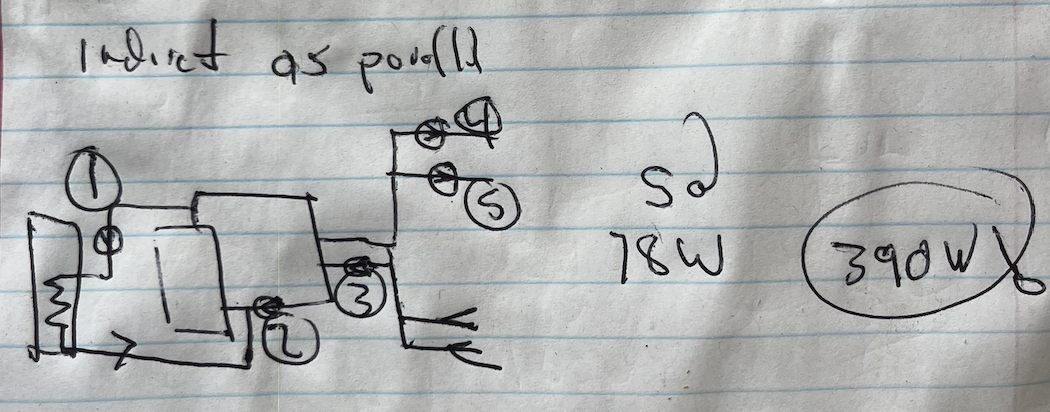

Here's a sketch with how my components are currently be oriented.

Questions:

Would the way I have the radiant manifolds piped with a tee inline between them work or should there be a tee further away with individual legs going to/from them? In reality the manifolds are about 7ft apart.

Also, where could an expansion tank go? I read they need to be on the auction side of the pump so could we move P1 up to the top for the same effect? Or put the exp tank elsewhere?

0 -

make your wish list and assign priorities

Odr is nice to have with a high mass slab in an area with frequent weather and load changes.

You are bumping up against a common question for low load buildings, that being a high mass radiant is not a great match.Much of the season, internal gains heat the space.

A radiant slab that requires you to open and close windows to maintain indoor temperature control is a bit silly.

I second @Ironman suggestion that ODR makes or breaks a high mass radiant on a low load building.

A 3 way thermostatic piped as Kaos shows will require flow through the boiler and tank always. The indirect is a dual purpise heat exchanger.

Two pumps running. So some additional heatloss up the boiler flue when it is not fired.

So pros and cons to all suggestions.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

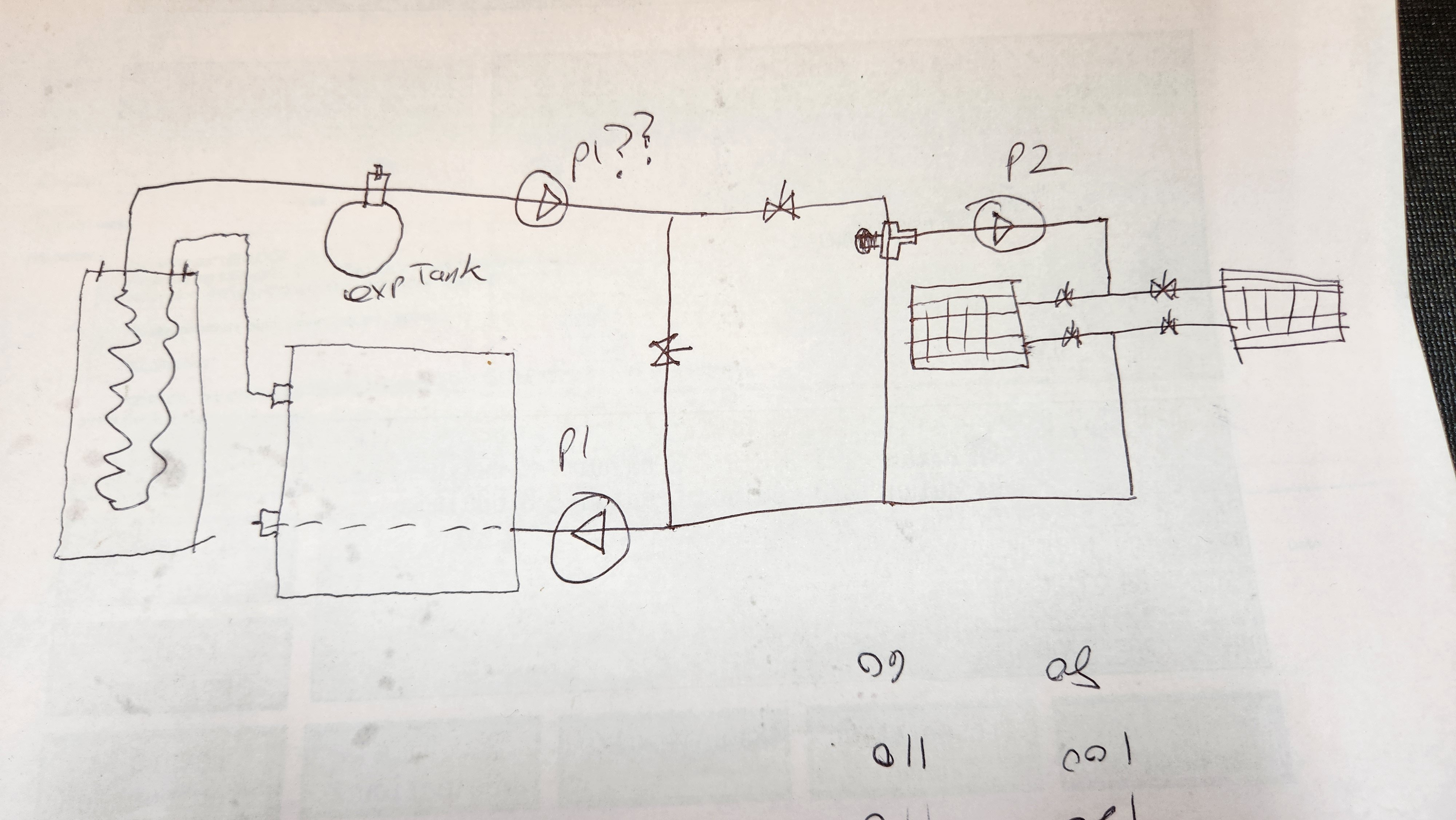

The setup will be higher pressure loss, so the better spot for P1 is on the boiler outlet. So boiler out→airsep+expansion tank→ p1→ indirect→ heating loop. Try to make the pump not be the highest point so easier to prime.

The benefit of modcons is all the fancy controls you get for free, the problem with your setup is adding any of those adds too much cost. I would keep in simple. If your boiler built in controls allow for pump hold off use that, if not an aquastat on boiler out for P1 to keep it off until boiler is hot. P2 runs during thermostat calls after the boiler is up to temp (that is, P1 is running).

0 -

Ok Sounds good Kaos. How do I know of the boiler has the pump hold off? There's no external control, just the aquastat. Here's what's under the hood.

0 -

Looks like the circulator just comes on with the thermostat. How can I add the hold off function?

0 -

A Tekmar 256 will provide ODR for the boiler. Using the manual 4way valve that hot_rod posted will allow you to mix down for the radiant.

Set the ODR at 130-160* to begin and adjust the 4 way to achieve 75-100* going to the radiant. In other words, a parallel shift. This is a suggested starting point, some tweaking may be necessary.

Leave the indirect in the boiler loop, but you should add a domestic tempering valve to prevent scalding. You won’t need to hold the pump off on the boiler side if you let the indirect’s aquastat call the boiler on. Let your room thermostat control the radiant pump.

Pipe like this:

The indirect would be piped after (down stream) of the boiler pump, but before the closely spaced Tees. The expansion tank should be before (upstream) the boiler pump. This is also where you want your air eliminator (MBR).

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements