Help Sizing A Multi-Zone Mini Split System - Minimum Capacity?

We're considering a multi-zone mini split system for an older home (built late 70s) in Massachusetts. With the inverter technology, my understanding is that the compressor can ramp up and down btw its rated minimum and maximum capacities. What about the indoor units?

For example, consider Mitsubishi - if we install a 3.5 ton outdoor unit paired with several indoor units, what happens if/when those indoor units are operating solo (for whatever reason) and they are below the outdoor unit's minimum capacity (9K indoor on a 12K outdoor which seems quite common for M's outdoor units).?

The way I understand is that is that indoor unit will not be realizing the benefits of inverter technology if it's ever running solo. I imagine that the indoor unit will only be able to output 9K of BTUs, what happens to the difference from 12K minimum? I think that I've seen mention how the remaining BTUs will get sent to the other zones so they might overheat/cool even though they're not calling for heat/cool?

Comments

-

Your math is fuzzy. You first mentioned a 3.5 ton outdoor unit (42K), then give an example of a 12K outdoor with a 9K indoor, which isn't a thing as far as I know.

Multiple indoor heads are matched to the outdoor unit by the manufacturer. Using your 3.5 ton, and 4 indoor heads of 12+12+9+9, a 9 can certainly run by itself and still "realize the benefits". The indoor units have thermistors to sense air and coil temperature. With manufacturers like Daikin and Fujitsu, put the fan on auto, and it will ramp, and correspond to the load. The refrigerant can be diverted to other heads on low loads, but its nothing that will be noticed in those spaces. All heads should always be on, anyway. Set the temperature, and leave it.

0 -

Sorry, when I mentioned 12K outdoor, I neglected to state minimum capacity there.

Basically, I'm just concerned about having too many units that are below the outdoor unit's minimum capacity (i.e, 9K indoor on some Multi-zone outdoor unit that has a minimum capacity of 12K, as an example). Trying to determine if that's something that I should worry about. I've seen people comment that it is but since the vendor lists them as valid, I wonder if it is OK.

0 -

-

I wish it were that simple, I've had some rotten luck with installers that presented well and then unfortunately, not so much. That's why I feel like I need to double check and understand these things like this.

So, in any case, is it a good idea to install indoor units that are below the minimum capacity of the outdoor unit?

0 -

-

So it sounds like you're saying that if Mitsubishi says that you can install a unit of a certain size (even if it's below the minimum capacity) that it'll work fine. But just so I understand, that unit will run at 100% of its rating and the outdoor unit will run at its minimum capacity as long as it's the only one calling, right?

0 -

Typically modulating heat pumps can go down to about 25% of capacity. So a 12K minimum output from a 3.5 ton unit sounds about right.

You're absolutely right that if you have a 9K head in this system, and it is the only head calling, something has to give. Different manufacturers have slightly different approaches, but that head is going to be full on, regardless of the actual load, and the extra capacity is somehow going to be shared among the other heads that aren't calling.

The practical limit to how many heads you can have on one compressor is when this behavior starts creating unacceptable comfort.

1 -

Thanks for confirming that… so should this be avoided if possible? Or am I making a bigger issue of it than it truly is?

Something else I am wondering - how much would this affect CoP and how much potential for short-cycling? An earlier installer proposed units that were were already larger than their heat loads (for example, a 7K for a 3.5K BTU load, a 12K for a 4.3K BTU load). Seems to me like that smallest one is pretty oversized and really below the 12K minimum capacity.

Those are probably not a good approach, right?

0 -

-

If your trying to go ALL Electric then multiple systems are a must. Too many computer controls and so few trained techs that understand them.

In Mass I strongly recommend keeping the Steam / Hot Water as a back up and for those cold windy nights.0 -

We have hot water baseboard as the existing heat and will be keeping that as a backup.

OK, so I guess it's just something that's just the way it is and while not ideal, just something that we all have to live with, right?

0 -

Again

Who’s installing these?

0 -

Of all the things to be concerned about with a multi head ductless system, that is way down at the bottom of the list. Its not even a concern. It just is what it is.

0 -

OK, this is seriously odd… I posted earlier that we don't have an installer yet, still getting proposals, and that Premier Energy Solutions was the only one so far with Mitsubishi… yet, the post doesn't seem to appear above… weird.

0 -

why do you keep posting a link.

who else have you con?0 -

What? "Who else have you con?" - what does that even mean?

You asked who was installing it so I told you… I guess I'm not supposed to do that?

0 -

Who else have you contacted?

0 -

There is a couple of limits with these. The outdoor unit still has a minimum capacity, generally that minimum capacity goes up as more indoor heads are added as well. Especially on these many small indoor head systems, the min modulation tends to be a above the load of a single head so the unit will have to run refrigerant through zones not on. This also means that the indoor heads never modulate, they are either fully on or off. This tends to create issues with humidity removal and comfort.

Unfortunately this info is not well documented and you won't know how it will run until installed.

On heating it gets even worse as the unit needs to flow refrigerant through all the heads. This tends to tank the COP of the unit when only a few heads are calling for heat. It also means that zones not on will also get heat which tends to create overheating issues.

Overall you want to stay away from multi zone units.

If you do go with multizone, the heads need to be sized very closely to load. There are very few bedrooms out there with above 3000BTU load, so this won't work for most houses as even the smallest head is about 2x or 3x oversized. The best setup for a multizone is a small number of large zones. Something like a pair of ducted air handlers feeding a bunch of rooms works pretty well.

It would really be great if these worked as there are no easy options for places with a lot of rooms.

0 -

This is exactly the sort of thing that I am concerned about. The manufacturer says that a given outdoor unit can support up to 8 and so an installer just thinks that they can add a unit to every room. All this without an consideration for how each individual unit will work solo.

0 -

if there not a match trouble codes go up.

all the equipment communicates with each other.0 -

-

Mitsubishi did a good job of putting it into plain English. start with a load calc, size the ODU based on the load, put multiple small load rooms on a ducted unit, add 1:1 units if needed. These are sentiments shared by the manufacturer I deal with as well.

"The outdoor unit should not be selected based on how many indoor units are desired. If the outdoor unit is oversized just to provide a certain number of indoor units for each of the zones, overheating, humidity issues, and higher than expected energy usage can occur"

1 -

This is awesome and exactly the sort of info that I was looking for. Thanks!

0 -

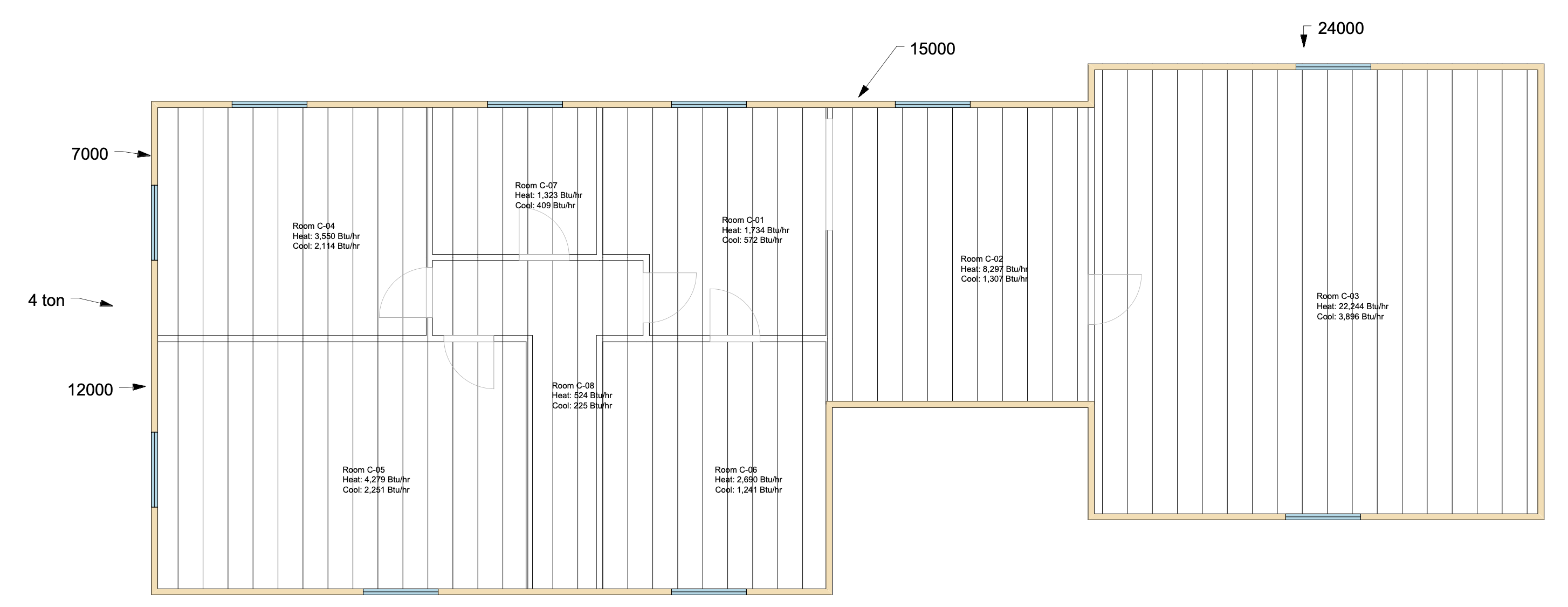

So here's a question - here's a sketch of the house upstairs

There are two thermostats that control the hot water baseboard are located in room C-05 just inside its door (controlling C-05, C-04, C-07 and C-06) and in room C-02 on the wall btw C-03 (controlling C-01, C-02 and C-03).

Rooms C-02 and C-03 represent an addition to the main house (C-01, C-04 → C-07). What's confusing is why C-01 is on the same baseboard zone as the addition. Must have been changed at some time and for whatever reason, C-06 wasn't changed as well.

In any case, this is just a background - the following is one option that we have been proposed

- Indoor units are installed in C-04 and C-05, I am told that they will be controlled by the single thermostat in C-05 (integrated controls)

- Indoor units are installed in C-01/C-02 and C-03, controlled by the single thermostat btw C-02/03

I'm trying to determine if C-06 being heated by baseboard via the C-05 thermostat, yet when using heat pumps, it'll be indirectly heated from C-01 via the C-02/03 thermostat.

Basically, it exists in two different heating zones, depending on baseboard vs heat pump.

It is what it is but what's the significance of it, if any?

0 -

so your running the HW at the same time as the heat pump(s)?

0 -

I see less then 1-Ton cooling total. Not going to work.

0 -

Not sure, I guess it depends on which strategy they use - cutover vs droop. I saw some Mitsubishi webinar where the instructor recommended to always use droop which I think runs the HP to the bone and then brings the baseboard on to supplement.

0 -

Mitsubishi heat pumps are rated down to -13F, no county in Massachusetts has a design temp below -3F so you should be able to heat entirely with a heat pump if you size it properly.

I'm not a fan of oil or gas backup of heat pumps, it's usually an excuse to undersize.

C03 can have it's own two ton head.

I'd be looking at something like this: https://ashp.neep.org/#!/product/34583/7/25000/95/7500/0///0

Your total heating load for all the rooms except for C03 is 22,397 BTU/hr, that unit produces 25,600 BTU/hr at -13F. It also modulates as low as 14,600 Btu/hr on cooling which is still more than your load but not terrible.

It's a compact ducted unit. The air handler is only 9-7/8" high. I think your best bet is to drop the ceiling in room C08 by a foot, put the air handler in the drop ceiling and run duct work to all of the adjoining rooms. For C02 you're going to have to put a soffit in either C01 or C06. I think that's going to give you the best comfort and probably cost about the same as three heads.

If you tell me your county, what you pay for electricity, what fuel you'd use for the baseboards and what you pay for it I can run some numbers on the economics of all-electric vs using a backup boiler.

0 -

I should have mentioned that "room" C-08 is actually the stairway from the ground floor (the base of the 'T') and the hallway for the upstairs (the top of the 'T'). So I don't think that you can do anything with the ceiling there. Having said that, the attic above the main house (C-01,04-08). Room C-02 has minimal access above the room as it's in the "attic" space above that 1st floor joining room to the garage (C-03 is loft area above garage).

We're in Bristol country, kWh rate with EverSource seems to be ~$0.33/34 and the backup heat is oil which average out to $3.8/gallon over the last year (approx 900 gallons - not clear as to boiler efficiency, installed 1999)

Thanks again

P.S.

Is it worth considering Mitsubishi Hyper Heat (-13F) vs "Standard" (-5F)? The design temp that I've seen so far has been around 6F.

0 -

do you have your room settings input properly so loopcad knows the space below is conditioned space? it will change your load dramatically if it thinks the space below a suspended room is unconditioned.

0 -

OK, the analysis is here:

I'm in Rhode Island but I can literally see Bristol County out my window right now. I used the weather station at New Bedford, other options for Bristol are Plymouth, Block Island, Martha's Vineyard or TF Green in Providence. For some reason Taunton isn't listed. Your design temperature is 12F and your average annual low is -1F.

For your energy prices, the break-even COP for a heat pump is 2.92. For the Mitsubishi unit I linked to above this occurs at 29F, so that's your break-even temperature. With a heating load of 22,397 BTU/hr you'd expect an annual heating bill of $1,730.88 if you heated just with oil, $1,735.98 if you heated only with the heat pump. If you switched from the heat pump to oil at 29F or below, you'd save $187.65 annually. The heat pump is capable of meeting 100% of your heating load. The details are in the "Analysis" tab of the spreadsheet.

This is about what I'd expect, both oil and electricity are expensive in New England compared to national averages and they're typically pretty competitive with each other.

Some notes:

First, this analysis is highly sensitive to the input conditions. I guessed at 80% for the boiler efficiency, changing it to 85% makes oil more advantageous and thus reduces the benefit from switching. On the other hand, I paid $4.11 at my last tank fill, at which price the break-even point drops to 26F and electricity has a slight edge. Choosing a different weather station would also have an impact.

Second, in the scheme of things there's not a big effect from going dual fuel. Yeah, two hundred bucks is two hundred bucks, but I paid more than that to have my boiler cleaned this year. If you can leave the boiler off and avoid cleaning then all-electric is cheaper. I point this out because a lot of guys in the business will say things like, "you need a backup with a heat pump." No, you don't.

For the curious, the process of modeling energy usage is explained in this post: https://www.greenbuildingadvisor.com/question/how-to-model-and-predict-electricity-usage-for-a-heat-pump

0 -

"Is it worth considering Mitsubishi Hyper Heat (-13F) vs "Standard" (-5F)? The design temp that I've seen so far has been around 6F."

The big difference between the hyper heat and standard units isn't the operating temperature, it's how much capacity they keep at low temperatures. The unit I linked to earlier is hyper heat, it's rated 34K BTU/hr at 47F and 32K BTU/hr at 5F — so it keeps almost all of its capacity.

This is a similarly-sized standard unit: https://ashp.neep.org/#!/product/214502/7/25000/95/7500/0///0

It's rated 40K at 47F and 20K at 5F.

When it comes to heat pumps, the nameplate capacity is meaningless. You're never going to need more heat at 47F than at 5F. What you care about is low temperature. That 40K unit is really a 20K unit.

My recommendation would be to only look at units that could satisfy your entire heating load at a temperature between your design temperature and your average annual minimum (-1F). When you're doing a new install there's no reason not to give yourself the ability to go all-electric in the future.

1 -

"the backup heat is oil which average out to $3.8/gallon over the last year (approx 900 gallons - not clear as to boiler efficiency, installed 1999)"

My analysis predicted 455 gallons of oil, but only for half of the upstairs. I assume that 900 gallons is for the whole house? That would lead me to suspect that the heat load calculations are too high. I get a whole house heating load of about 44K BTU/hr for 900 gallons of oil in your climate. Do you also use oil for hot water? That would further impact the estimate.

0 -

"I should have mentioned that "room" C-08 is actually the stairway from the ground floor (the base of the 'T') and the hallway for the upstairs (the top of the 'T'). So I don't think that you can do anything with the ceiling there."

I expected that was the case. Is there an architectural reason the ceiling can't be lower there? I don't know about where you are but usually code allows for 6'8" clearance over stairs. I assume there's a landing at the top, I'd put the air handler over the landing so that you can stand there for filter changes and maintenance.

0 -

And since the installer is recommending five tons, I have to pass this along:

0 -

This was done by an HVAC guy, not me. I have to trust that he did it right.

Thanks a lot for that calculation, I gave it a shot earlier on when I think you posted it in another thread. Will have to see how mine compares to what you provided.

Yes, the 900 gallons is for the entire house and hot water for July 24 to July 25.

She also keeps the house rather cold (approx 63F, I think?).

So you're saying that the heat load I mentioned above is too high since you feel that 44K BTU/hr is right for the entire house? The HVAC guy also has another 35K for the downstairs which basically mirrors the upstairs except for the loft area.

The ceiling above the stairs is actually really quite low already. I'm about 6'3 and I am quite close to the ceiling as I go up/down the stairs so they're probably the requisite 6'8" you mentioned.

Not quite sure why because there's just the attic above and as I recall, it's just flat up there.

1 -

If the boiler is also producing hot water you have to net that out. Obviously it depends on how much hot water you use, but let's say you use 40 gallons a day. That's about 5 million BTU/year or about 10% of the fuel bill. So knock 10% of the heating load estimate, 40K instead of 44K.

If the house was only being kept at 63F you'd have to adjust for that too. In the model I use 60F as the break-even temperature, the outside temperature where occupant activity balances the heating load and no heating is required. Lowering that to 53F I get a heating load of 59K for 900 gallons of fuel (or 54K for 810 gallons of fuel not used for heating domestic hot water). This is a little tricky though, the breakeven temperature is just a simplification and a guess. The more efficient a house is, the lower it's going to be. So you get into this tail-chasing where you say, "well, with a load of 54K the break-even is probably more like 5F below room temperature than 10F below room temperature," and around you go.

All that said, I think 85K for the whole house sounds about 50% too high. Have you added on to the house as part of this project?

0 -

There haven't been any additions to the main house since C-02 and C-03 were finished almost 25 years ago now.

0 -

OK, then based on your fuel usage I'd say the actual heating load is somewhere in the 45-55K range for the whole house. Maybe 16K for the loft, 16K for the rest of the upstairs, 20K for the downstairs, total of 52K?

0 -

Are you scaling that up from the 63F to 70F?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements