Riello pump over pressure no flow help

Hi all, thanks for letting me join.

I have a problem with my Riello boiler, the unit will start up but not fire up, it tries to ignite and the cuts out, I fitted a pressure gauge and no matter where I have the adjuster the gauge max's out at the needle stop, so its running at over 15 bar if I disconnect the pressure outlet pf the pump I get no flow at all, the pump is primed and on my work bench with a header tank above the pump, I hear the solenoid operate and the terminals get 27 volts dc the coil read 112 ohms when tested off the pump

Why am I not getting any flow out the pump, I have had the pump apart today and can find nothing that would indicate a problem

Any suggestions would be grateful

Comments

-

Can you drain the system down (with any automatic feed off) and get the pressure down?

I'm very suspicious of the gauge. 15 bar is around 220 psig — which is absurd. If your system really is at that pressure, the pressure relief valve should have opened long since, and it's a wonder that some pipe or joint somewhere hasn't gone boom…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Hi Jamie, this is the boiler fuel pump pressure not the water system pressure,

0 -

Ah. That's a little more plausible… I'm not a burner guy, so others will chime in.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Just because there's voltage at the solenoid coil doesn't mean its opening. Resistance should be 100 Ohms (+-5) on the 40 series burner. Not sure what model you have.

What application is it with such high pump pressure?We dont see many over 12.4 bar in residential.

0 -

You could have a plugged nozzle for not firing , high Riello pump pressure indicates to me to check for a plugged return line . Where are you connecting the gauge ?

There was an error rendering this rich post.

0 -

Hi, my gauge connection is top right as you look at the pump, I have the the nozzle supply pipe disconnected from pump and no flow,

I fitted a new pump today, fully bled and when unit starts I don't get the needle to stop problem but it is very intermittent to get flow to nozzle, I'm suspecting there is a problem with the solenoid, even though the solenoid itself measures 110 ohms across the terminals, I'm at a loss to what the problem is, guessing its solenoid or control box

0 -

Can you post some pics? We have no idea of what model burner, or what "top right" is.

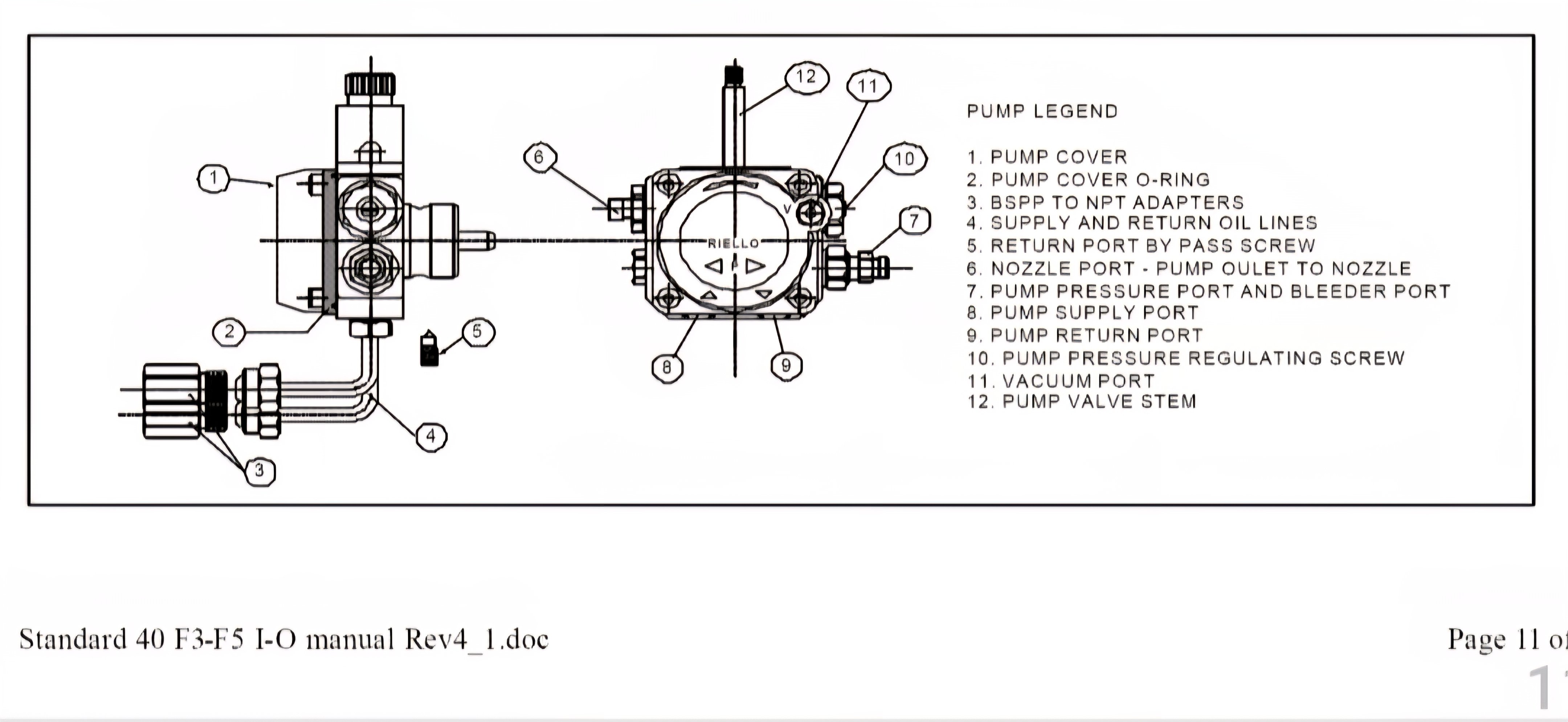

This is from the 40 Series F3,F5 manual. Bottom right is where pump pressure readings are taken. And how good is your ohm meter? 110 Ohms isn't 100 (+-5).

Put everything back together, including the nozzle assembly. Prime the pump. Put the pressure gauge in the correct port and start the burner. There will be 5.5 to 6.9 bar during prepurge, then increase to the rated pressure for your application when the solenoid opens. If pressure doesn't increase, its the solenoid.

FWIW, you shouldn't be doing any of this if you don't have a combustion analyzer and smoke tester.

0 -

Did you check the piston (pump valve stem)? Two screws under the solenoid coil take those out to free the piston. Shake the piston it should rattle if not replace the piston.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements