BOILER SHORT CYCLES

Hi,

We installed a 80% boiler with mfg outdoor reset (160 DEG) but it short cycles. There are 3 zones, but the loops are ½" instead of ¾". We are figuring that we will have to install a buffer tank with primary / secondary loops.

Just wondering which diagram you would recommend & why? Also would you recommend a variable speed delta T or delta P pump. I was thinking we could also add a taco outdoor reset that goes down to 140 deg also…

Would you also recommend only running the boiler pump when the burners are on?

2072 SQ FT HOUSE

70,000 BTU HEAT LOSS

OLD BOILER OUTPUT 84K

NEW BOILER OUTPUT 77K

ZONE 1 – BASEMENT- 60’ LOOP, 15’ BASEBOARD 9K

ZONE 2 - 130’ LOOP, 54’ BASEBOARD 32K

ZONE 3 - 80’ LOOP, 40’ BASEBOARD 24K

TOTAL BASEBOARD - 65K

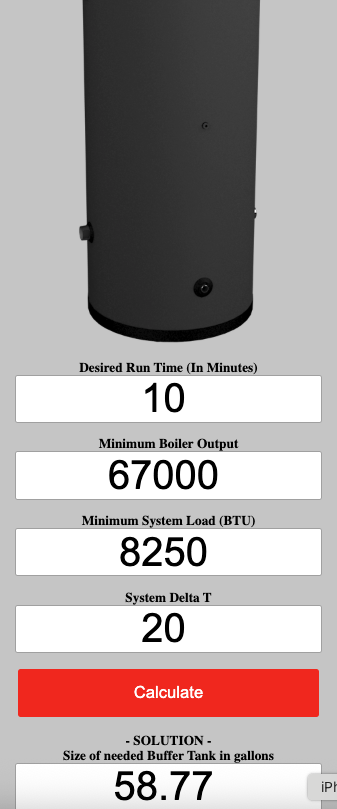

BUFFER TANK FORMULA:

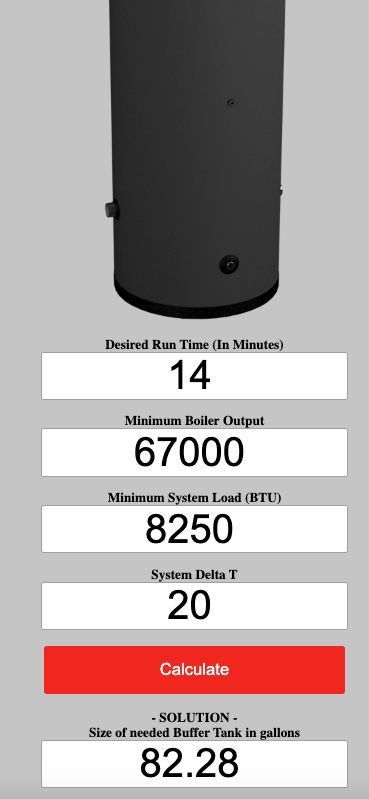

T= TIME (10 MIN)

Q= BOILER OUTPUT

q= SMALLEST ZONE BTU

DT= DELTA T (20)

V= T (Q-q) 10 (77K-9K) 10 x 68K 68000

500 X DT 500x20 10,000

V= 68 GAL

Any help would be appreciated…

Randy

Comments

-

smallest zone when it’s hot out

Not surprising it’s shore cycling.

0 -

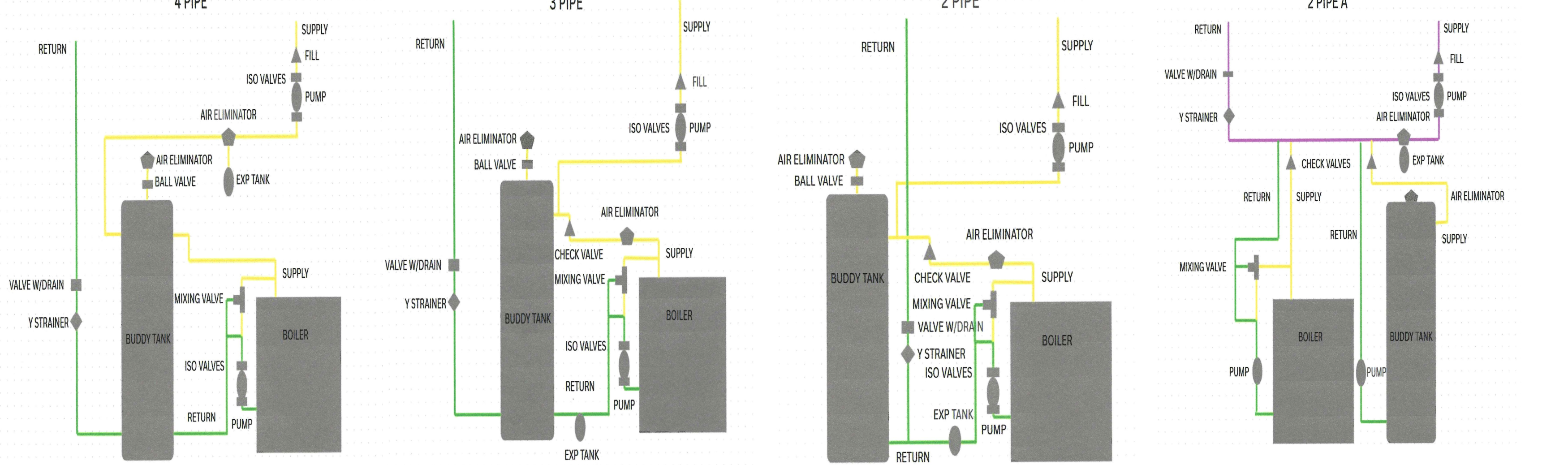

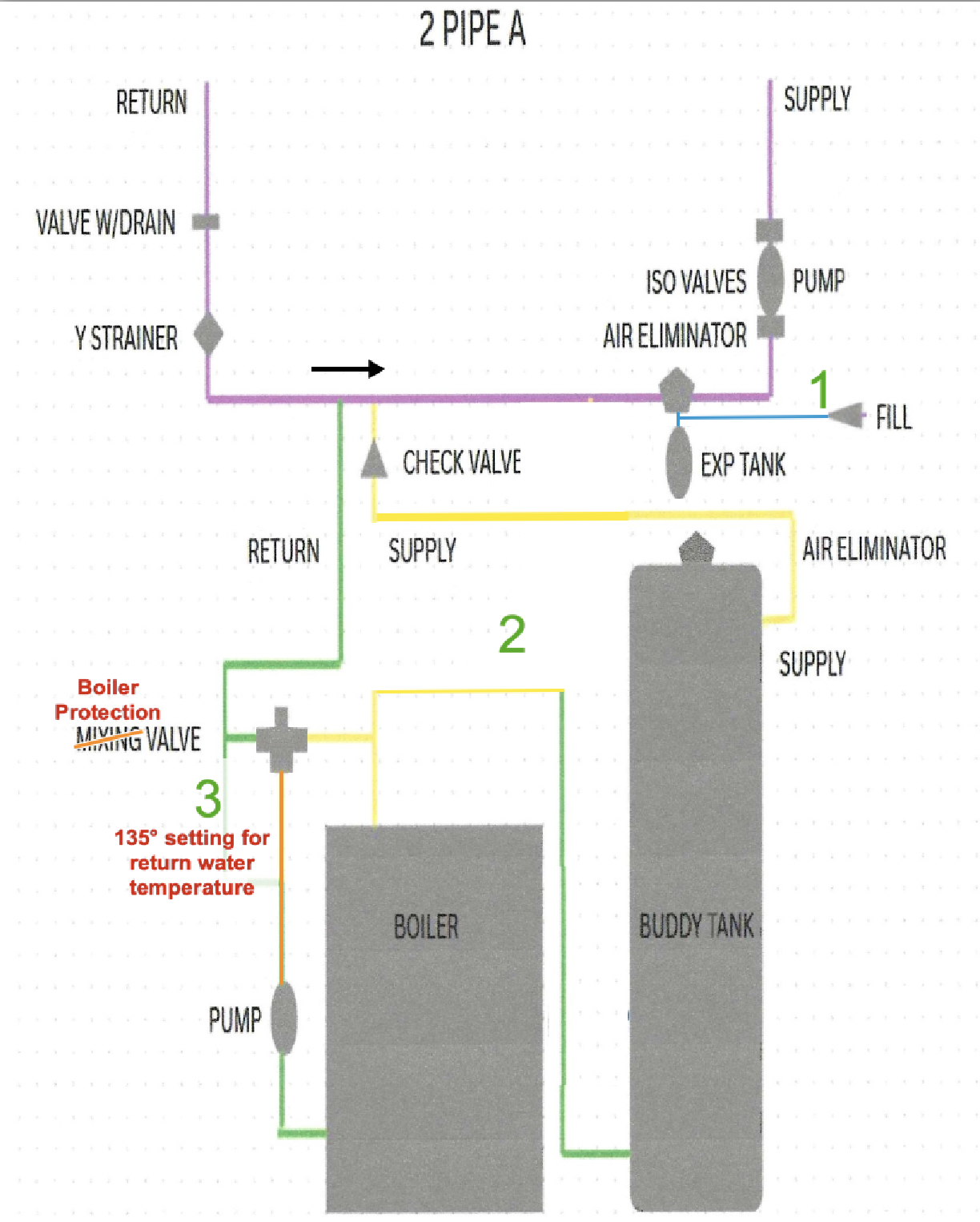

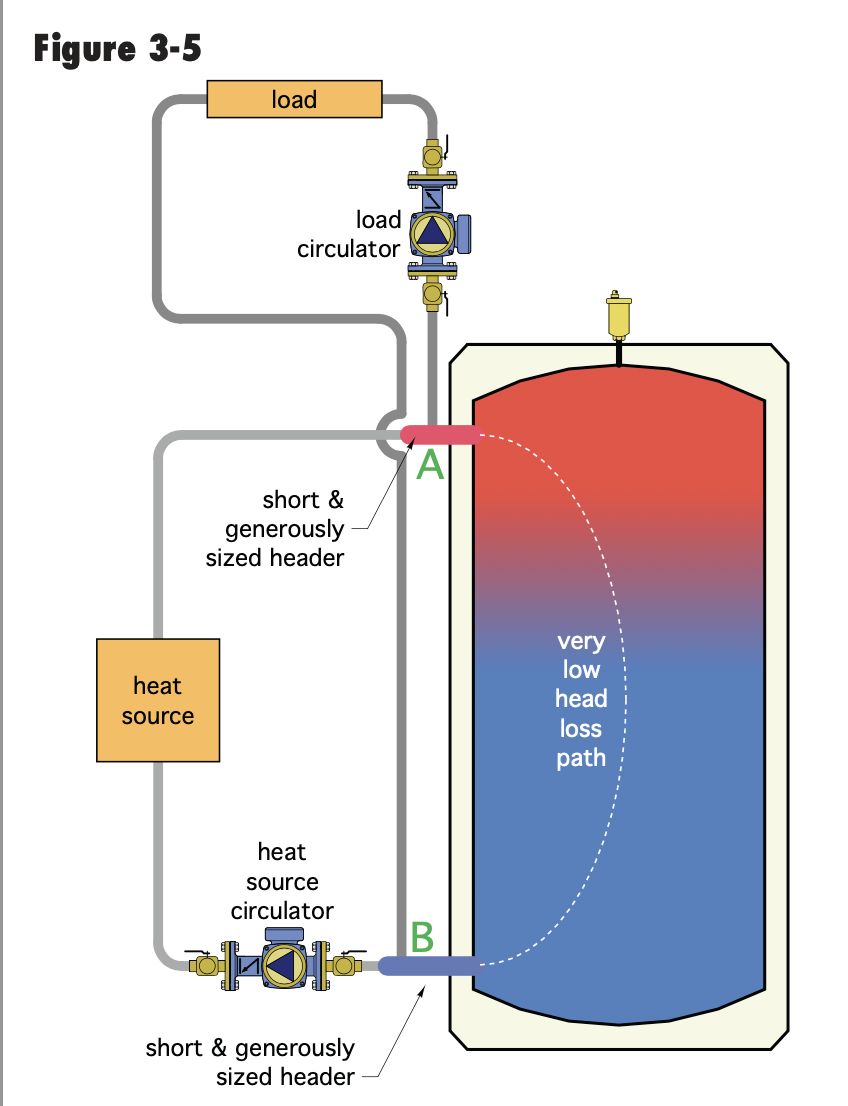

I looked close at your 4 different piping diagrams. I believe the 2 pipe A is the best choice.

I would make some minor changes though.

- I like to place the water feed valve at the same location as the point of no pressure change (PONPC) which is always at the expansion tank.

- I also don't believe that you need to have a separate circulator pump for the buffer tank if you pipe it in series. having another secondary loop just for the buffer tank is just adding unnecessary parts and pipes.

- Finally remove the return pipe bypass around the boiler protection (mixing) Valve. that bypass defeats the purpose of the boiler protection valve

Of course there is not really enough detail in your post to find a definitive "BEST" piping design. With a 15 foot of heating element zone and such a that might only deliver 6000 BTUh from a 77,000 output boiler (See Note1), you can be sure that the boiler will heat up very fast if that is the only zone calling for heat. There are others like @hot_rod who design this kind of stuff all the time and might suggest another piping arrangement with something called a Hydro Separator that will perform the job of the primary secondary piping design, add a little extra water volume like the buffer tank and have the function of boiler protection without the mixing valve, when designed properly. There is a lot of math involved that he has built in to the filing cabinet in his head. ( I would need to spend hours on the design to get it as good as he does in 5 minutes.)

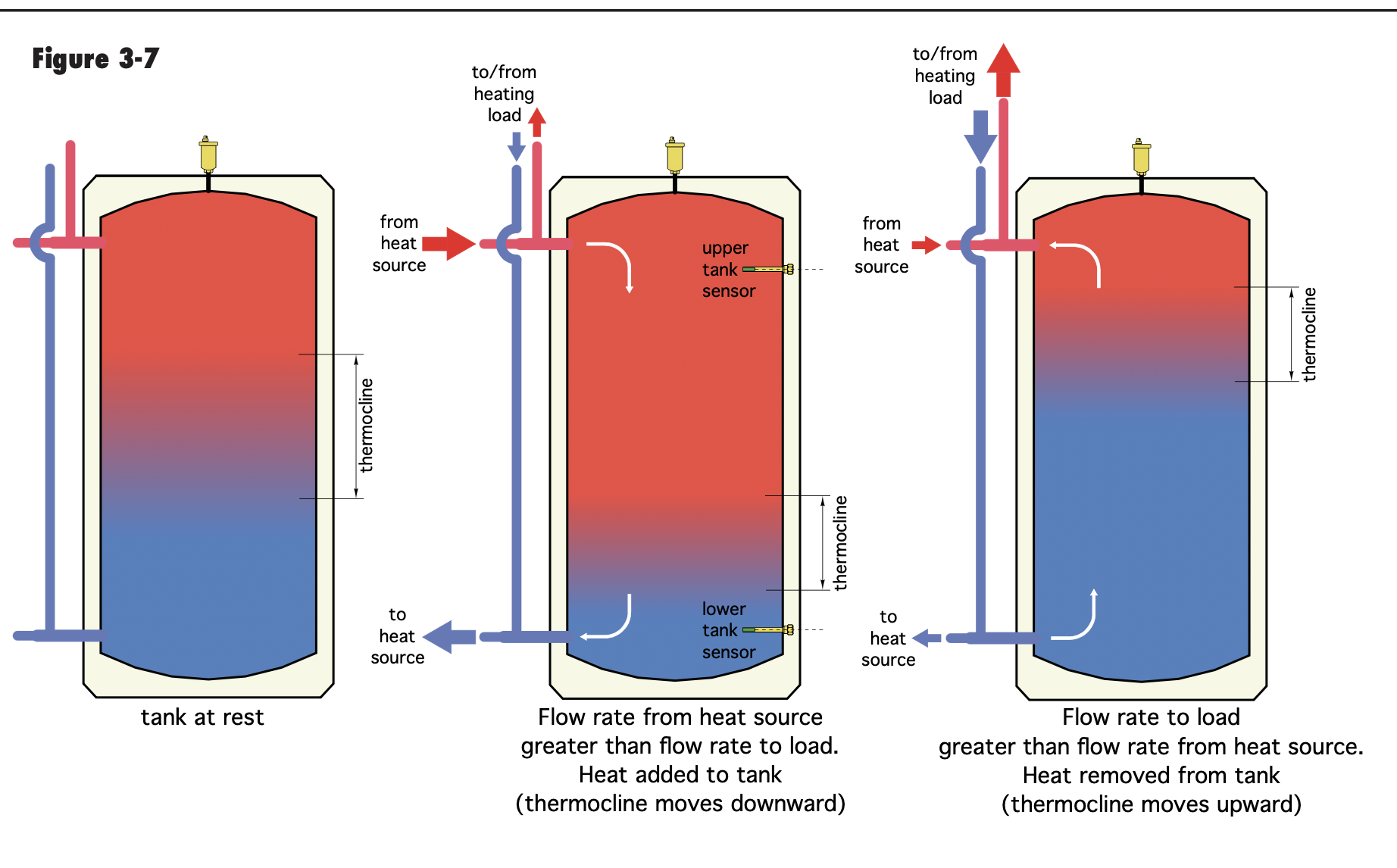

If your buffer tank is too big then you may be wasting a considerable amount of energy stored in that tank at 160° when the call for heat is over. Without "Thermal purge" that heated water will sit there and cool off if there is no additional call for heat for an extended period of time. With Thermal Purge your pump and zone valve would stay open to dissipate that heat from the boiler and the buffer tank so that energy is put in the rooms and not wasted in the boiler room.

Note1 Are you taking into account the piping and pickup factor that is in each boiler rating? there are 3 BTU numbers on each water boiler. A 94,000 BTUh Input boiler that is operating at about 82% AFUE might have an output of DOE Output of 77,000 BTUh with a AHRI NET of 67,000 BTUh. The smaller NET number is what the professionals use to compare the heat loss calculation to, not the DOE Output

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Zone 1 being 8250 BTU/ hr (550 btu/ ft X 15')

Call the boiler 67,000 out. 10 minute minimum run time. So a 60 gallon buffer fits nicely..

Lochinvar U for the Tank Simulator program.

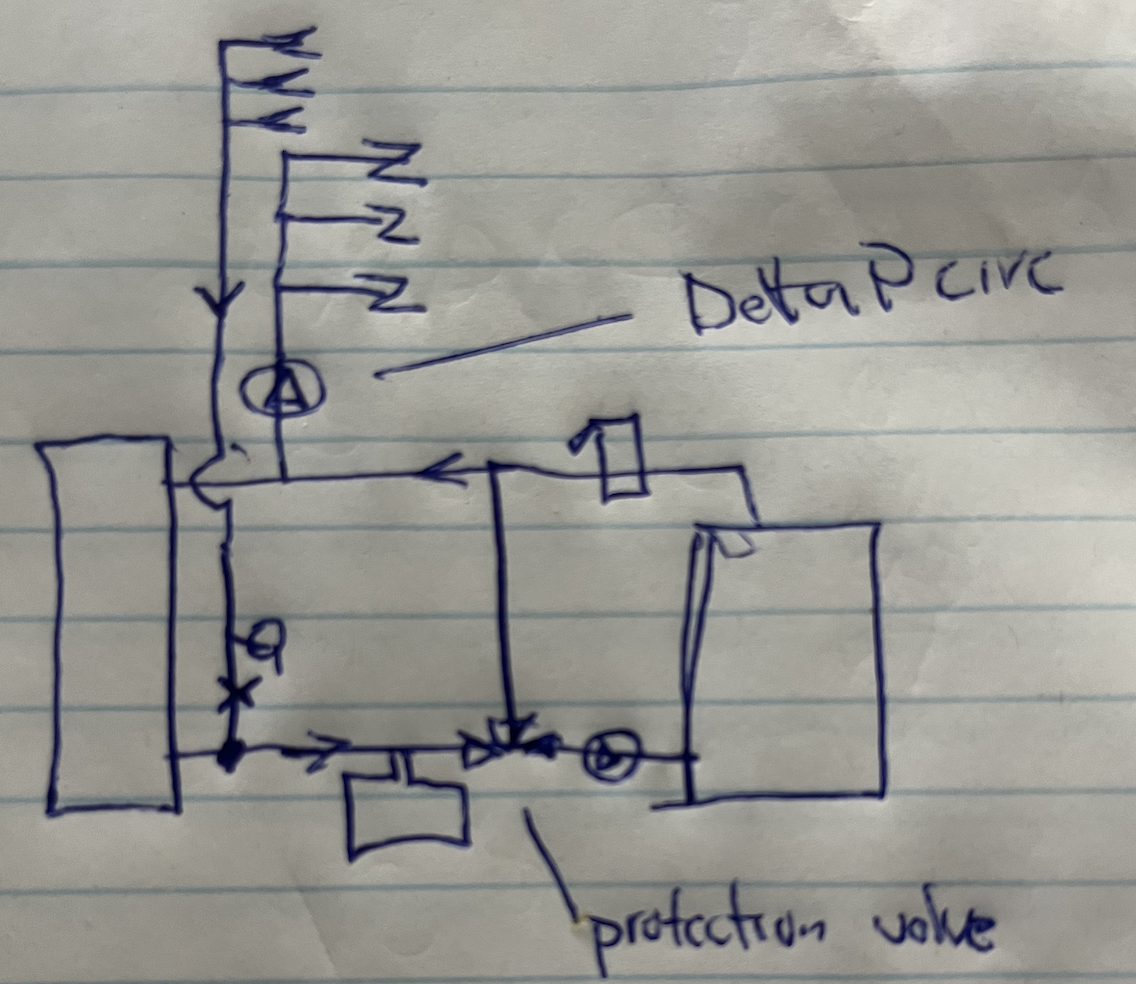

A 2 pipe buffer like this, 280 boiler return valve, delta P circ with 3 zone valves.

A well insulated buffer should not lose all that much heat, and it is inside the building anyways.

This is a direct to load buffer piping. When all zones call little if any flow through the tank. The large piping at the tank is your hydraulic separation function.

I have used electric HW tanks as buffers. Remove the elements and increase those 1" ports to 1-1/4" A 1" MIP X 1-1/4" copper adapter for example.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thanks so much for your opinions…

I'm having a hard time finding a 60 gallon buffer tank or electric water heater, they carry 50 or 80.

Randy

0 -

60 gallon is only a suggestion based upon a suggested 10 minute run time. 10 minutes was used as a guide, not a rule. So if you were to use an 80 gallon tank, the run time would be longer (not horrible) or if you used a 50 gallon, it would run a little shorter (again not horrible)

Dave Holdorf

Technical Training Manager - East

Taco, Inc

0 -

OK, THANKS…

0 -

80 gallon gets you about a 14 minute run time. If you go to the expense of installing the buffer, go with the 80. 50 gallons only gets you 8 minute run time.

There is no code or hard and fast rule for what a short cycle is defined as. 10 minute run time is generally an industry accepted number.

80 gallon plain steel 9Boiler Buddy) or glass lined steel will probably be the least $$.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements