Caleffi manifolds EDIT: When you don't know what you don't know :)

I am building new with in slab pex, staple up, and an air handler for those few weeks of air conditioning. The air handler can also supplement the radiant heating.

The heat source is a GSHP from horizontal loops.

I have looked at several options for manifolds and loop valving and the Caleffi twistflow manifolds with the standard thermoelectric actuators seem to be a solid product.

Are there any other suggestions for that part of the hardware?

Comments

-

-

Thank you. I started out with the concept of zone = pump and then quickly got that out of my head. Too many zones. One idea I had was a dedicated towel warmer loop that would be the last thing to shut down as the weather warmed up. That one would have it's own small pump and timer system so you'd have warm towels in the morning and then it would mercifully stop heating the room.

I used the 'ironman' handle for CB radio for a brief moment in time in my youth. :)

0 -

-

-

Thanks I will clarify the rest of the install. Those are mixing units with the included pump: I have a low temperature Ground Source Heat Pump as a source and will not be mixing. The lower you can operate one of those, the more efficient the COP will be.

It is coming with a 14 gallon buffer tank and an air handling unit. I ran my own manual J on my house design a few years ago with CoolCalc at Lennox, then last year I paid for a professional asessment and design. The design proved out what I had planned to do with the ducting. It is only for my air conditioning, but the system will heat the house without the hydronics running.

The engineer I hired does not do hydronic design. I am doing that myself.

I installed all the ductwork trunks through my joists as I built. Now I am at the staple up point. I I will get that in, covered for an air gap, and insulated with a 4" batt. I will leave out where needed for plumbing.

I was hoping to run a small pump on a few hour's timer a day out of the buffer would not be too bad.

We're talking about those summer months that don't want any floor heat, specifically the shoulders where you are not running the AC. Once the AC comes on, to heck with warm towels!

I am in the exploration part of this phase and I really appreciate your inputs.

My plan is to heat the house via only hydronics as long as possible, and add some of that air handler heat on the worst few days.

THe manual J:

Total Heating Required Including Ventilation Air: 31

091 Btuh 31.091 MBH

Total Sensible Gain: 25

801 Btuh 94 %

Total Latent Gain: 1

642 Btuh 6 %

Total Cooling Required Including Ventilation Air: 27

443 Btuh 2.29 Tons (Based On Sensible + Latent)

I have a 4 ton inverter pump coming.

I over-looped with 3500' of horizontal loops that are home runs to the equipment room.

I can run half the field at a time and alternate on a schedule and keep those inlet loop temperatures as high as possible, until the real cold SHTF and I can run the whole thing if needed.

That may be impractical but I will figure that out with experience. I know that over-looped is a good place to be. My brother's system was under-looped and his temps got pretty cold in the winter.

0 -

I-joists are 16" OC and I will put up two runs per bay, using extruded aluminum shields and a narrow crown stapler.

I purchased 500' rolls of 1/2" legendflex tubing, and plan on splitting them into two loops. I'll adjust those lengths to work different areas, but right around 200' outbound is what I am shooting for.

As we work across the house I plan on insulating the transport part of the loop on the way out to the areas to be heated.

I came up with 20 loops, counting the 6 in the concrete.

@0.5 gpm per loop, that lines up with the 4 ton GSHP specs of 9~11GPM.

0 -

you would just want to run an odr curve that matched the load and run all of it instead of trying to zone parts of zones. ideally you get the swt temp to match the load and it just runs continuously, the thermostat is just to prevent overheating rather than the operating control.

hydroair coils have to be very big and air velocities low for forced air heating with low water temps. if you feel low temp air moving it will feel drafty and the energy transfer isn't great at a small delta t between the air and water so the coil needs a lot of surface area. unless you can make a sw close to traditional temps just for the hydroair I don't know that i would use that as a strategy for design day conditions.

4 -

Thank you Matt, that makes sense. Rather than valve control loops just throttle them down to get comfort where I need it?

The flooring is going to have an 85 F limitation, so I am aiming for 105F maximum supply water.

0 -

@mattmia2 I will wait for the hardware to get here sometime mid-June. I think all is there for implementing ODR control. I see heat set compensation in the documentation, but need to confirm it indeed has the outdoor sensor input required.

If not I will be looking for help with an external unit from supplyhouse.

0 -

When I don't know what I don't know:

Thanks Matt. I have done the deep dive on your post and it makes sense.

So much so that I can and may go with a larger air handler because I can. I had a 3.5 ton unit ordered, but I called and I can just about double the coil size by opting for the 6 ton unit. Incidentally it comes standard with auxilliary electric heating coils. I had no intention of backup heat but this might prove to be the best possible situation in a bitter cold snap.

The other thought was putting a mixing valve ahead of the hydronics, and turning up the SWT to a level where the air handler works as intended, only in the extreme end of the curve. You planted a lot of seed and I am grateful for all your knowledge.

Now I am looking at other manifolds based on feature set. They all seem to have provisions for adding a zone control actuator, but the Legend units have some easily manually operated valves on the return side that you can just turn.

That could come in handy on the south rooms that are going to bake. Go shut those loops off when you want to enjoy the insolation, and still keep some warm floors on the north side.

0 -

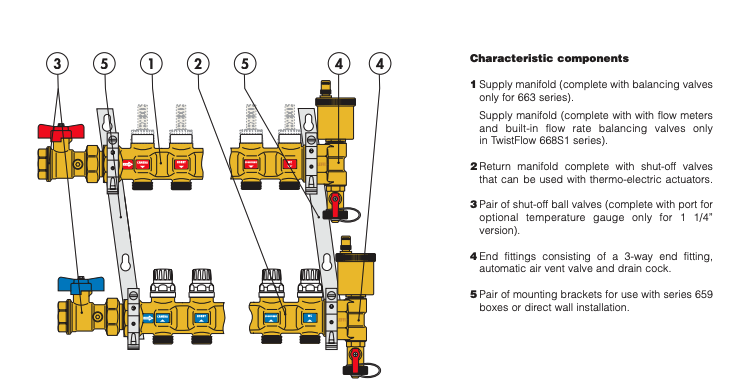

Pretty much any manifold that accepts actuators and also has flow meters give you two way to shut off, or balance flow.

On the actuator side you can adjust with the white plastic knob. Also on the flow indicators you twist them to adjust flow.

If you keep the fluid clear you can observe flow in the clear plastic indicators.

Some pics of the cut away to see those valves.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

Using the Legend Duo Heat transfer chart, I figure 2400 ft heated into ~32000 BTU = ~13.3 BTU per foot.

My wild arse guess for SWT was not far off. Much like a broken clock.

figure 15 BTU and the floor material is glue down LVP with a low R factor of < 0.2, I find an SWT of 105 and surface temp of ~77.

i was concerned about the maximum heat for the LVP and this is a safe buffer for that.

0 -

Add the R value of the subfloor wood also. 3/4ply or OSB .08, and the .2 for the flooring, more like R-1. But still well within the comfort range.

If 77° floor surface is the design day temperature, do not expect the floor to feel real warm. If skin temperature runs around 83°F. Floor surface temperatures below that will fell neutral, or a bit cool.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I will be playing with it for sure. That heat load and BTU/ft is based on heating the whole thing. The main floor is 1632 and the 2nd floor is 1088. We will live on the main for the most part, so I will tinker with turning down the upstairs and let it get heat passively when we don't have guests in the house upstairs. I would like a more perceptible heat but we are constrained by floor materials that top out at 86 or so.

I put electric heat under our bathroom tile at the current home and with it at 84 it feels nice.

I took measurements and subtracted a foot off each end, and also shortened it up under cabinet runs and the like. I have a good count for buying the extruded omega plates. Ironically the 3/8" joist trak is more than the 1/2". I think that 3/8" sounds like a better time all around.

I am the semi-retired equipment operator for a commercial plumbing company, and I recall seeing a PEX unspooler back there. They may get me a deal on the plates too.

0 -

-

Both systems will have glycol.

0 -

are you sure you want to have to maintain glycol?

0 -

It is called out for in the manual.

0 -

-

I'd like to go with 3/8 but the circuit lengths for the upstairs become a bit long. Each home run to the basement equipment room adds at least 35' of dead pipe load. My current thoughts are a manifold right below this floor. I have a really handy closet that I designed in with chase room in it, close to the equipment room below. I have plumbing, a 12" round duct, and the radiant piping coming through that. It is located right below the roll in shower.

it is my space to do as I wish, ingore that chase line. I can carve out as much as needed. So many designs just try to jam everything in wall cavities for the almighty square foot. I wanted a chase or two from the start.

It is 9' ceiling and I can put a hatch up there and drop the lid down to 7''6"~8' and have plenty of elbow room after everything is finished.

Bring 1" supply and return lines to a 6 Port or whatever works for the 2nd floor. I would think that purging would be easier on a level playfield, so to speak.

Perhaps I can throttle that down as a whole on the supply line when it is not occupied?

0 -

if you are using glycol you're going to need a pump cart to purge and fill it to get enough velocity to pull most of the air out. use a good microbubble air separator at the boiler because glycol holds on to small air bubbles better than water. probably want a makeup tank and pump since there will be small amounts of air coming out of that for a while until all the bubbles make it to the air separator.

1 -

-

Is this one that can route the fluid in different ways to either extract heat from the earth or put heat in to the earth so it is using valves in the water side to route the fluid to either the condenser or the evaporator depending on which way it is moving heat so the evaporator and the ground loop uses the same fluid as the indoor system? If that is the case it could be worth using a HX to avoid using glycol in the house especially since your radiant fluid temps are so low so you could get a decent delta t across the HX.

0 -

it is a standard split system with a buffer tank. no mingling of ground loop to house etc.

The house side has a primary pump to the buffer, and I'll install secondary pump out to the heating loops.

0 -

I have a 30% mixture of Fernox Alphi 11 in my A2WHP.

A HX just inside under the IDU. So the buffer and all the radiant is plain water. It cost you the HX and extra circ, but the glycol expense, transfer and pumping penalty and maintenance is worth the trade off.

Un less you get well bel;ow 0 for extended periods, 30- 35% of a quality brand glycol should be adequate. Glycol at these low temperatures in a cleaned system should last 20 years. The site glass gives you a good look at it's condition.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

what about another air sep at that 2nd floor manifold? That way I am not trying to push air down 15' of head change.

0 -

The air should be mostly small bubbles that flow with the fluid after you purge it. The microbubble separator if applied at the highest temp and lowest pressure point will deaerate the water so that it will tend to absorb air from larger pockets when they cool and bring it back to the air separator at the heat source where it will tend to come out of solution and be removed by the air separator.

Since the valve in the air separator tends to eventually get dirt in it or wear and leak, it is better to have it at the boiler where that will be noticed and it can be repaired or replaced.

1 -

A manifold on the 2nd floor will make bleeding much easier especially if the manifold is above the heat loop it serves. Try to get something with auto air vents as it will take a while to get all the air out. I have an air separator on my 3rd floor manifold and don't find that it does enough. The air still collects in the manifolds (which is fine with the auto air vents).

Sketch up the system diagram you are looking at including some of the rough flow rates you calculate. 1" pex can move a lot of BTU, unlikely you will need that much for the 2nd floor.

Think about which areas you actually need control on and which areas can be always on. For example, my bath and kitchen floor heat plus towel warmers are always on. No thermostat, just the outdoor reset of the heat pump.

When using water for cooling, you want to minimize the amount of piping that will run chilled water. I would try to place the FCU right on the primary loop. If it is big enough you don't even need to plumb it onto the buffer tank as it should be enough load on its own. You might need a 3 way valve to select it and disconnect the reset of the heat during the cooling season.

I would not try to run the FCU for supplemental heat unless it has a heat strip. Dual temp setup with heat pumps is never efficient, if you do run the FCU, it should take in whatever water your floor heat uses and boost it up to a reasonable temp with the strip heater.

1 -

I had a call with tech support at the vendor. That 40% glycol was a carryover from the A2WHP manual. I can run water on the inside so that is a big relief. Less pumps, less dinking around.

Now I can run a primary to the buffer and secondary out and be done with that. No HX, phew!

I will still need ~20% glycol in the ground loops. I have seen them below freezing in extreme conditions.

@Kaos that 2nd floor manifold is not above the loops but just about even with them. Still much better than 20' above the heat pump and buffer in the basement.

Another designer suggested a tee facing up as the return comes off the manifold with a valve. Put a sep on top of that and open the valve and bleed that air off on a schedule. That way I lock off a leak potential with a valve, and any air that goes up the leg I can deal with.

The upstairs as shown above is about 1030' of thermofin. I figure 200' more in the turns and 150' more in the returns.

If I draw it up as a 6 loop, the lengths are a little over 200' each. 7 loops are going to average 180'.

0.6 GPM per loop = ~4 GPM total. I was thinking I can send that up with a 3/4" PEX.

0.6 GPM with 100% water in 3/8 PEX.

2ft/sec velocity

6 PSI pressure drop

13.8 ft head loss

Add in the 20' of actual head to that and I'm shopping for a pump that is happy with 35' of head?

I did think that the buffer could be valved off for cooling and just use the primary pump straight to the air handler. That would lock off the heating loops during the cooling season. I have no interest in cooling with the loops

As far as zoning, you guys have me sold on ODR tweaking and running it all. The only exception is shutting off that top manifold completely and then having to have a second set of numbers to plug into the ODR curve for that condition. Towel warmers are just going on the adjacent loop without a control. Just let it eat. I will try to locate the warmers on the return if that keeps the floors better heated.

I want to use a variable speed secondary pump for that reason, so I can deal with that partial condition easily.

I have not drawn this stuff up before but I will do so soon and you can critique the selections if you wish.

0 -

i'm not sure where your head calculation came from but if your loops are in parallel you just have to cover the head of the longest path at the flow for all the loops.

0 -

That was a 200' run of 3/8 PEX in this calculator.

The other 20' was actual head from the basement floor to the elevation of the loops.

It's a two story house on a full basement.

0 -

-

Assuming you are using water in the radiant loops now?

.3 gpm for a 3/8" loop is the general recommendation, so 3.5' head in a 200' loop

.5 gpm in a 200' loop of 3/8" is around 9' head.

20% is a weak glycol mix, not much inhibitor in that %. There are alcohol based geo fluids available also.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

yes you have shown the performance reduction of glycol plus the cost and it sounds like a PITA in general with the bubbles etc.

do you use a distilled water for this?

I'll be doing 8" OC due to the framing. It looks like I can still convey the 15~20 BTU per foot OK.

If my layout pushes the tube length to ~220' would I be wise to add a 7th loop? I can just buy 200's to solve that, and wait to order up the manifold.

The first floor is 48' x 34' nominal and has longer return runs. I will go investigate adding a remote manifold there as well. I can put one in the joist space and put a hatch there in the sheet rock. It has to get covered per code.

6 loops to the equipment room

6 loops to a remote manifold at the opposite end of the house.

6 or 7 to the second floor.

Plus the (6) 1/2" loops in the basement slab.

0 -

Yet another question:

The heat pump has terminals to power the outside and inside pumps. I do not need to account for those.

Do I need only one more pump, the secondary coming out of the buffer tank?

I ask because I want to power all the hydronics out of the critical loads panel from my inverter. The inverter will pass through 47.5 amps, it will create 47.5 amps from either battery or the solar panels.

It will get wired with a 60 for main.

I don't want to land multiple pump breakers in that panel. If I had to have two secondary pumps for whatever reason I can't see, I would rather bring out a 15 to a pump control unit that could handle the necessary pumps.

I will not power the air handler out of there. The AC season is just too brief to worry about.

0 -

your circulators will be under 100w each unless they are something massive, one circuit will power all of them or you could get a 240v circulator and power it off the heat pump circuit. Control xfmrs with 240v primaries are common to power the controls off of 240v refrigeration or electric heating circuits are common as well. Could also use 120v circualtors and controls if the equipment requires 120/240v or you run 120/240v to power the accessories.

There are treatment cartridges for filling hydronic systems, i wouldn't go beyond that, not worth dealing with distilled water.

1 -

Thanks Matt. I was looking at the Taco 008 variable speed Delta T at ~100 watts. It might be a little short on the curve though.

It got me thinking, if I do that once I figure out what the Delta T will actually be, would that be a good parameter for secondary pumping? I can see problems when the flows do not work and the pump is just beating on a high induced head. I'd have to work my way up to a Delta T that works for my conditions.

0 -

Don't get hung up on a fixed ∆T. Choose a ∆ for the design 10- 15° typically for residential radiant floors. Then size the pump, piping, etc to supply that. The actual operating ∆ will move around a bit from the design number based on the load on the system at any point. ODR and constrained ∆ are at odds with one another.

Distilled water is expensive and hard to come by in quantity. True distilled water is made by boiling to steam, collecting the condensate as it runs across a stainless plate, so expensive and slow.

RO or DI is fine this comes from either a membrane, RO, or through a media, DI.

For just a one time system, Axiom has a few disposable cartridges for generating DI water on site.

With a two pipe buffer, single temperature system you should only need a boiler pump, and the distribution pump. A 3rd if you run an indirect. With a zoned system an ECM delta P circ is my suggestion.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

"ODR and constrained ∆ are at odds with one another"

I was seeing that developing. Thank you Bob.

If I plan on closing that upstairs manifold when not needed, The Pressure regulated secondary is the ticket?

I may do that with the basement loops as well, just stopping them for a big chunk of the year and making that first floor the only hydronics going.

Our heating seasons in thermally efficient houses are really odd. There are huge shoulders where we do not run our split minis at all in this house, for an example. I'd still want warm floors and open a window as needed :-)

0 -

Where are you getting 20 btu/sqft? That is above what I see in air tight uninsulated doubled brick in zone 5. Anything new build should be around 10btu and easily bellow that with a bit of effort. The issue generaly with most new builds is the floor is not actually hot enough as the loads are so low. One way around it is to only heat high traffic areas so these can now run closer to max temp and only run the rest in the deep freeze.

The flow rate for each zone should be set based on the load to the zones, not what the pipe can do. Generally you would have more flow to zones with more load like two outside walls or ones with large windows.

You want an ECM delta P circ as it works the best with zone manifolds. I use a plug in corded pump and a switched outlet. Turn it on in the winter, off in the summer. Pump runs 24/7 during heating season.

Delta T seems like it should work but the controls on the ones I've tried are not the best. They do vary flow but it is more of on at max for a bit then run at min flow the rest of the time, never at a nice steady state.

Make sure the secondary is not over pumped, this is why you need to figure out actual flow rates you need. For best efficiency, the secondary flow rate has to be bellow the primary off your heat pump.

No zone control can work as long as the house loads track through the day. If you have any room with large west or south facing windows, you will probably want TRVs or zone valves on those to avoid overheating.

P.S. I would put the bath fan outside the shower, I prefer over the throne. A bath fan in the shower generally causes cold drafts plus it is rough on the fan due to condensation. Modern construction surfaces are warm enough that condensation on walls is not an issue.

2

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 428 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements