More efficient control for slightly archaic multifamily hydronic system

I'm part of a 20-unit multifamily building with a hydronic system built in 2000, and I'm trying to figure out how to reduce our gas bills. For example, we spent $3300 for 1050 therms for space heating between Jan 15 and Feb 15, despite having well-insulated townhouse-style homes that get a fair bit of solar gain and mild weather (rarely colder than 40F). Interested in thoughts on my wacky researched-it-myself ideas before I try to find somebody who might be willing to work with me on implementing them.

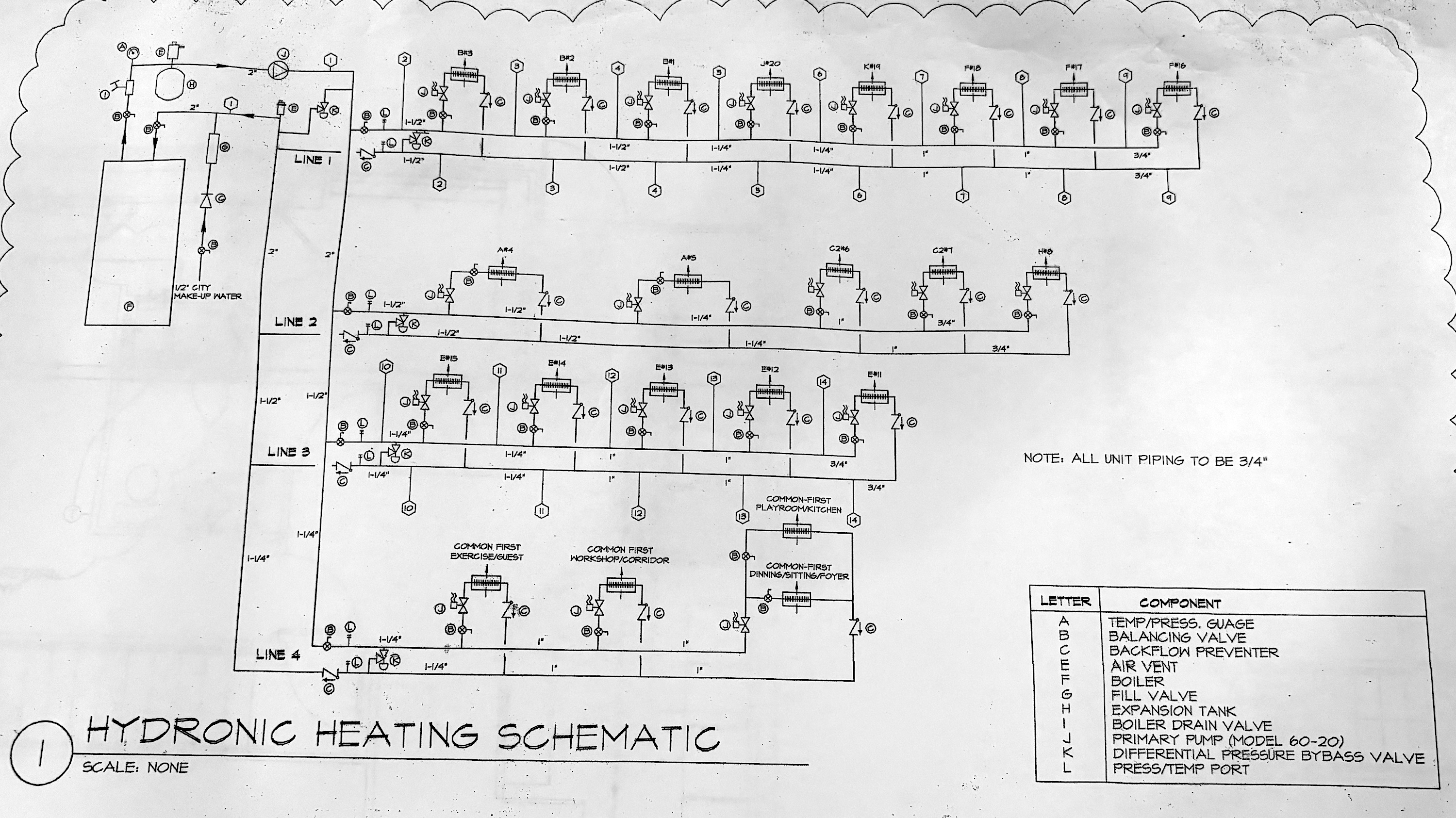

Context: We have a conventional gas boiler (SuperHot AAE-960), a fixed-speed circulator that runs continuously, and 23 zones. We have a Tekmar 256 outdoor reset controller configured to provide a permanent demand to the boiler, set to minimum boiler temperature 140F (minimum necessary for conventional boiler), on auto-differential.

The system seems to have an inefficient concept of operations: the controller has no knowledge about whether any zones are calling for heat. If the weather is below the warm-weather shutdown temperature, the Tekmar tells the boiler to keep the water at least at 140F, whether or not anyone needs it. So the circulator keeps circulating the water, the water cools along the way, and the boiler reheats it, just in case anyone needs heat. Maybe nobody does!

Unfortunately, it does not seem feasible to wire all the zone valves to connect them to a boiler controller - too much distance, too many walls and floors. It'd probably help to replace the circulator with a variable-speed one, but this one is only 2.5 years old, so we're hoping to get more years out of it before we replace it. Interested in other options in the meantime.

I'm planning to add a timer switch (Tekmar 033 or equivalent) to enable the Tekmar 256 to at least have "unoccupied" setback temperatures at hours that typically have low demand, such as 2-4 am and 2-4 pm.

Here's my question: could it make sense to try to find somebody to put in a flow switch that triggers based on whether zone valves are open, configured so that the boiler only turns on if at least one zone valve is open? I haven't seen examples of systems like this, so I'm wondering if I'm missing something in my research or if this is a bad idea. Thank you!

Comments

-

keep the heat in!

Tighting the envelope has the highest return on investment.

properly sized and set up boiler is next.0 -

They make ultrasonic flow detectors that just clamp onto a pipe, the Tekmar 256 has a Demand input which in your case may presently be jumpered. The challenge is the control logic to occasionally run the circulator to see if there is a zone calling for heat. If so continue with the circulator and tell the Tekmar 256 there is demand. Once the demand is satisfied shut it all down until another trial is scheduled.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Seems like with 20 units there will be demand nearly all of the time in at least one unit. Wouldn't the people that are there during the periods you propose to turn off the boiler be very unhappy during those periods? Beyond making sure the piping and building are insulated and air sealed I don't see where there is a lot you can do, the heating system is just producing what the building is losing.

1 -

hopefully!

Is it sized properly?

Set up properly?

0 -

Unfortunately, it does not seem feasible to wire all the zone valves to connect them to a boiler controller - too much distance, too many walls and floors.

Possible to do this wirelessly?

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

The units are already relatively tight. I turned off the thermostat in my unit on March 24 and haven't needed to turn it back on since then to stay above 68F.

The boiler is vastly oversized, but I don't see much I can do about that until it comes time to replace it.

I'd be interested in any specific suggestions for an ultrasonic flow detector that somebody has used successfully. I haven't been able to find any that seem less expensive and more reliable than hiring a person to install a flow switch.

The Tekmar is configured for permanent boiler demand, and the circulator (B&G e615S) runs continuously. I don't think this circulator would be happy getting turned on and off often - seems better to leave it running and stick to controlling the boiler.

The timer idea is kind of a stop gap. My goal with the flow switch idea is to enable units to call for heat when they want to. For example, most units warm up during the afternoon due to solar gain, so they tend not to need any heat that evening, even when the outdoor temperature drops below the WWSD temperature. But if somebody left their windows open and suddenly got chilly, that's fine, they should be able to run their heat.

0 -

most of the heat loss will be in the units on the outside. units in the middle aren't a good indication of what the heating demand is.

a buffer tank could increase the cycle time of the boiler. constantly heating the system then letting it cool isn't going to change your standby losses much.

0 -

I haven't found any existing products that could get 20 or more zone valves to communicate wirelessly with a boiler controller, while allowing people to continue to use their preferred thermostats. I'd be interested if anyone knows of one!

That's why I'm wondering if we could use the change in flow of water as the communication signal. Just seems a bit tricky to calibrate.

0 -

" the circulator (B&G e615S) runs continuously. I don't think this circulator would be happy getting turned on and off often - seems better to leave it running and stick to controlling the boiler. "

Seem like a waste to me having a circulator running with all the zone valves closed. May not be good for the circulator, although it has lasted this long. Does it run all Summer too ?

You certainly can just monitor the flow and control the Tekmar 256 Demand input.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Its getting into the 'Roll Your Own' territory. You could have a low cost RF transmitter in parallel with each zone valve. If anything is received at the boiler (would not need data or even addressing) there is demand.

No call for heat, no power to the zone valve, no RF from that zone.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Curious, does each unit have its own 24 VAC transformer for the thermostat and zone valves.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

What is wired across the boiler input terminals? That would be the spot for the flow switch. Flow switches can be wonky so there may be a more Modern alternative to prove flow.

0 -

I'm assuming there is more than one circ here. Typically this would be done with primary secondary piping to so the flow rate in the primary loop will not change with zones cycling.

Usually local ordonnances dictates that you must provide heat up until a certain date, so shutting down the boiler is not really an option.

The usage is quite low, on average that works out to about 9000btu/unit. Not going to get much better than that. There is not much you can do improving the existing setup. Provided those pipes and boiler are in conditioned space, those standby losses go to heat the building anyways, so shutting down the boiler won't save much fuel.

If you want better, when the boiler comes up to replacement, you can look at a condensing unit which will allow you to run a much more aggressive outdoor reset curve so you won't need to circulate 140F when it is warm outside.

0 -

One circulator! Attached a diagram for you. Fun fact: line 4 is never used, because the common spaces have sufficient solar gain to warm them up.

This is in the San Francisco Bay Area with a mild Mediterranean climate. My unit rarely needs more than an hour of heat even on cold days.

I agree that it's wasteful to circulate water when not needed, but I'm not sure there's a better option until we can replace the circulator with something more modern. For example, we had a power outage the other day, so I went and switched off the boiler and circulator so that I could monitor restart. When I switched the circulator back on, it had some weird chk chk chk type noises along with the usual noises for a while. It's a big circulator. Seems less risky to just let it run.

Yes, each unit has its own 24 VAC transformer for its thermostat and zone valve.

I don't want to roll-your-own for anything integral to the system. I set up DIY monitoring to log and track boiler cycles, but that's non-invasive and non-essential.

0 -

Here's an example of 24 hours of the life of our poor boiler and pump that work hard to send heat to people who don't need it, annotated to show my understanding of what's happening:

0 -

Also, the space above the mechanical room gets uncomfortably warm, so I've been trying to improve insulation for those supply and return pipes to reduce unwanted heat. I suspect the boiler sends a fair bit of standby heat loss into the earth via the basement walls, and into the atmosphere via the mechanical room's extra-large combustion air vents. The circulation loops go through some unconditioned spaces, like the parking garage (they have insulation - not in amazing shape though, working on it). And I figure at least 20% of the gas bill goes up the flue. Lots of reasons to want to try to reduce how much this thing fires when not necessary.

0 -

-

Get rid of the Tekmar 256, its as bare bones as a control as you can get. Install a Tekmar 360 and you can add a three way floating control valve so you lower the supply temperatures to the heating system emitters. Then you can set the aquastat on the boiler to what ever temperature you want, but normally 180. The Tekmar floating control will maintain the target temperature by mixing the cooler return temperature with injecting the 180 from the boiler into the loop. the boiler loop is always hot enough to protect the boiler but also lower the system temperature to save money.

Obviously the initial investment will cost some money but with a building with 23 units there should be a payback. Is your boiler 1-stage or 2-stage?

0 -

We have a 21-Unit multi-family building with a hydronic heating system built in 1997. We have high-mass PEX in Gypcrete in-floor heating so Unit temperatures are very stable. We installed a Taco SR-506 near the Boiler and hard-wired it to the thermostats in 6 Units. Selected the 6 highest Heat Demand Units due to orientation or residency. The Taco SR-506 provides the Heat Demand to the Mod-Con Boiler and one ECM Pump when any one Unit calls for heat. Do Not need all 21 Units providing the Heat Demand to the Boiler - that is redundant. The rest of the Units heating fall in sync with the weather and the 6 highest Heat Demand Units. Works like a charm - been doing it this way for 20 years - no problems. Very Simple - Meets everyone's needs - Big Cost Savings. Doug

1 -

Thanks @pedmec, that's an interesting idea! I'll look into this. This is the boiler manual - it says ours (AAE-960-N-E-M) is a two-stage high/low fire model. I don't know whether it's been configured to force it to stay on low fire.

@Doug_7, that's a nice solution to wire in just a few of the highest-demand thermostats! I don't think even that would be feasible with our building layout, but I like the practicality.

0 -

A couple of thoughts:

First, what was considered well-insulated in 2000 would be considered marginal in new construction today.

Notwithstanding the foregoing, as the lawyers say, I would assume that a 2000 building has an insulated basement. So all the heat you're producing is staying within the insulated building envelope and it isn't really wasted, it's heating the building. Unless parts of the building are uncomfortably warm there's really nothing to fix.

I agree with @Kaos that the overall level of usage isn't that high. The reason it seems expensive is that your gas is expensive.

0 -

Seems more effective to try to improve efficiency rather than trying to reduce the price of gas. :)

I'm working on the straightforward parts like sealing gaps in insulation in pipe runs in unconditioned spaces. But I figure that if I'm lucky, this might conserve enough BTUs to extend the nobody-calling-for-heat cycle time from 18 minutes to 19 or 20 minutes. The spaces above the mechanical room are uncomfortably warm.

So that's why I'm trying to figure out how to match boiler output to actual demand (zone valves open).

0 -

That main circ is probably about 1.5kW running 24/7. I think replacing that with an ECM unit is an easy cost save that is not intrusive.

The boiler is definitely short cycling, a buffer tank would help just not sure if it would save enough money to justify the work.

I really like @Doug_7 solution. Simple and effective.

0 -

Where are the zone valves? To control a circulator you don't need to run a wire to the thermostats, just to the zone valves.

0 -

And, what model are the zone valves?

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

Each unit has a Honeywell V8043F1093 zone valve close to its thermostat, within the unit.

The label on the circulator seems to say 0.55kW:

Since we have solar panels, and since we turn off the whole hydronic system for at least half the year, the cost of electricity for running the circulator 24/7 is not significant. To justify replacing it with an ECM circulator, I'd need to make the case mostly based on projected savings in natural gas bills.

Agree on a buffer tank possibly being helpful but unclear whether it'd justify the cost - I ran an estimate based on the formula in this Idronics issue, and it seems like we'd need a lot of buffer tank to make much difference.

0 -

This

That main circ is probably about 1.5kW running 24/7. I think replacing that with an ECM unit is an easy cost save that is not intrusive.

Miss Hall's School service mechanic, greenhouse manager, teacher, dog walker and designated driver

0 -

Is your Domestic Hot Water made using gas? and is that included as part of your monthly bill?

0 -

You could put a flow switch on each heating loop branch after the differential bypass valve (marked K on the drawing). The flow switch would only now activate if there is a zone on that branch is calling for heat. This would get you a demand signal.

The other option is to use the return water temp as a demand signal. You can generate this by puting an aquastat and delay timer on the return water. The idea here is to set the aquastat a bit above the temperature you expect when there are zones calling for heat. If the zones shut off, the return temperature rises triggering the aquastat. This now starts a timer that keeps the boiler off for say 2h. This is pretty simple to install and set up and should see pretty quick return.

The nice part about this is that it will force the zones to synchronize as more zones will eventually be calling during the off period but since there is no heat, they will stay on together. This extra load at the same time will also reduce the short cycling during the shoulder season. Thinking about this, you might want to have a programmed off period even in the winter just to do this.

If your emitters are also as oversized as the boiler you can also adjust the reset curve. There is no reason to make 180F water when cold if 150F will heat the place.

0 -

@Grallert Am I reading the circulator label wrong? It says 0.55kw.

@GGross We have heat pumps for domestic hot water. When the boiler is off during the summer, we only use 1-2 therms a day (cooking and clothes drying).

@Kaos Thanks, that’s a helpful way to think about using the temperature as a demand signal! I like that it would be relatively simple, just a aquastat and a timer. The delay timer is the key part I wasn’t thinking of.

I’ve already set the Tekmar to relatively low settings to try to reduce the curve - 68F target indoor temp, 150F boiler design temp, 140F boiler minimum, auto-differential. It doesn’t support increasing the outdoor design temp above 32F, even though our actual outdoor design temp is 40F.

The weird part is that even if the boiler is starting back up after a whole day of WWSD (with water around 65F), it runs for 90 seconds a few times, instead of running for 2-3 minutes. Seems like the Tekmar is trying not to overshoot. But the boiler has been short cycling for 25 years as far as I can tell, so I guess that hasn’t hurt it yet.

1 -

Just to sanity-check:

I'm going to assume a townhouse-style unit is roughly 1500 square feet, so 20 of them is 30,000 square feet. Let's say a 2000-vintage building with a 40F design temperature has a design load of 10 BTU/hr/sf, that's 300,000 BTU/hr as the design load. At 40F you're 25F below 65F, so that's 12,000 BTU per degree-hour or 288,000 BTU per degree-day.

According to degreedays.net, San Francisco had 390 cooling degree-days in January, which would require 112 million BTU's. A therm is 100,000 BTU's, so that would be 1120 therms.

Actual observed usage is 1050 therms.

So just at first blush that doesn't seem that bad. Obviously all of the assumptions can be questioned and refined, but the energy usage isn't way outside of what would be expected.

I'll throw in that if you have heat pump water heaters, in the winter the heat for them is coming from the heating system. I would expect each unit to use about 20,000 Btu per day for hot water (50 gallons per unit) which comes out to 12 million BTU for the whole building per month.

0 -

@DCContrarian Ah, a bit smaller than that - we have 19.5K square feet of heated space. Our closest weather station had 407 heating degree days in January, according to degreedays.net. The domestic water heat pumps are outside the building, so I don't expect they're grabbing heat from the hydronic system.

I agree overall that our usage isn't bad, and the coldest months have higher gas prices than the shoulder seasons. But it's worth trying to make it more efficient, because any dollars we save on gas bills will help us save up for an ECM circulator and eventually replacing the boiler. And it's fun - I've learned a lot about hydronics by trying to puzzle this out!

0 -

Setting it up primary secondary and setting up odr on the building loop will likely solve a lot of your problems, it will reduce the standby losses substantially and it will mean the units get decent run times instead of very short infrequent cycles and it will stop the whole building form overshooting possibly just from the standby losses.

In this climate replacing the boiler with an air to water hp might be feasible in the long run.

1 -

I would figure out what is causing the boiler to short fire when staring up from WWSD. Maybe a setting on the boiler is off or on the Tekmar. That should not happen and besides wear and tear, it hurts efficiecny. There is a good chance that you have similar issues under low load so getting that fixed will also reduce your fuel use.

Setting the boiler on low fire only, if not already there, is definitely a good thing as well.

0 -

@mattmia2 Thanks! Yes, hoping to replace the boiler with an air-to-water heat pump or two someday. That's part of my motivation for reducing standby losses: if we can get the same comfort on fewer BTUs, we can get smaller AWHPs - less expensive and less noisy.

@Kaos Agree, this behavior doesn't seem right. Planning to get a professional to check whether the boiler is on low fire and even see if the gas input can be safely adjusted down a little, so they can check my Tekmar settings too.

In summary, here's what I'm thinking for boiler control - curious if I misinterpreted anything.

Low investment, low reliability: use return temperature as demand signal

Seems like this could be done with non-invasive methods that would be easy to undo if not working as expected, so I could probably roll my own:

- Configure the Tekmar "unoccupied" setback as low as it can go.

- Set up a pipe-mounted temperature controller on the return pipe.

- Determine the return temperature when all the zone valves are closed (nobody is calling for heat), and determine the return temperature when at least one unit has a zone valve open and is absorbing some heat. (Not necessarily easy, would need some monitoring and adjustment.)

- When the return temperature is above the threshold, the temperature controller would activate a timer relay, which would then activate the "unoccupied" setback state on the Tekmar for a certain amount of time (try 1 hour, see if we can extend that without compromising comfort).

- When the setback expires, the boiler heats up to check for demand. If no demand, the process activates again.

Higher investment, higher reliability: separate the supply temp from the boiler temp

This would be a longer-term plan that requires professional analysis and installation, probably suitable to consider when we're ready to replace the circulator. Currently the boiler has to heat water to 140F or more and send it to the radiators, even if 120F could do the job. So we could look at separating that primary circuit (which has to stay at 140F+) from a secondary circuit capable of providing a lower temperature to the radiators, and configure outdoor reset on the secondary circuit. Could do this with the help of a mixing valve and a Tekmar 360, possibly with a hydraulic separator between the circuits.

0 -

I think your assumption that you need no heat is incorrect, i think that most of the time the load is so low that the piping essentially acts as radiant heating to heat the building. i suspect the bottom of your odr curve is far lower than 120.

with no rwt protection on the boiler you have to fire the boiler enough to heat it and the water enough to keep it above the condensation point. when you are heating the mass of all the water in the system to that point you are adding more heat than you need to the system and it overshoots. i think it is very likely the system and boiler are very oversized.

your first option is essentially a complicated way of adding a delay timer that requires a certain off time to reduce short cycling. it may work or it may cause temp swings that are too great when it is colder out. the rw temp will fall over time regardless of if there is any heat calls or not, it will just fall faster if there are heat calls so unless you control does calculus measuring the rwt won't tell you anything other than you need to fire the boiler to keep the system hot.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements