Literature on Geothermal

Comments

-

-

-

If you are looking for information on cost savings of a geothermal vs a standard forced air system, let me tell you about 2 neighbors of mine. They both replaced the geothermal systems that were 20 years old with a Lennox high efficiency gas furnace and a high efficiency A/C system. They are both very pleased with the results. They claim to be saving money on the cost of operation, both summer and winter, and have less service costs. Their geothermal systems consisted of coils of black plastic pipe buried 6' underground. I have no specifications on the geothermal systems installation. They are located in south western Pa.

1 -

-

Fracking really killed the cost benefit of ground source heating. I think a vertical well with closed loop would be much better than coils at 6' but still I couldn't show an operating cost difference between mine and natural gas forced air.

Of course I got very efficient summer cooling also for no additional up-front cost, and I loved how nice the heat pump was.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

HI!

New ground source heat pump guy here. I'll be checking on those books, thank you.

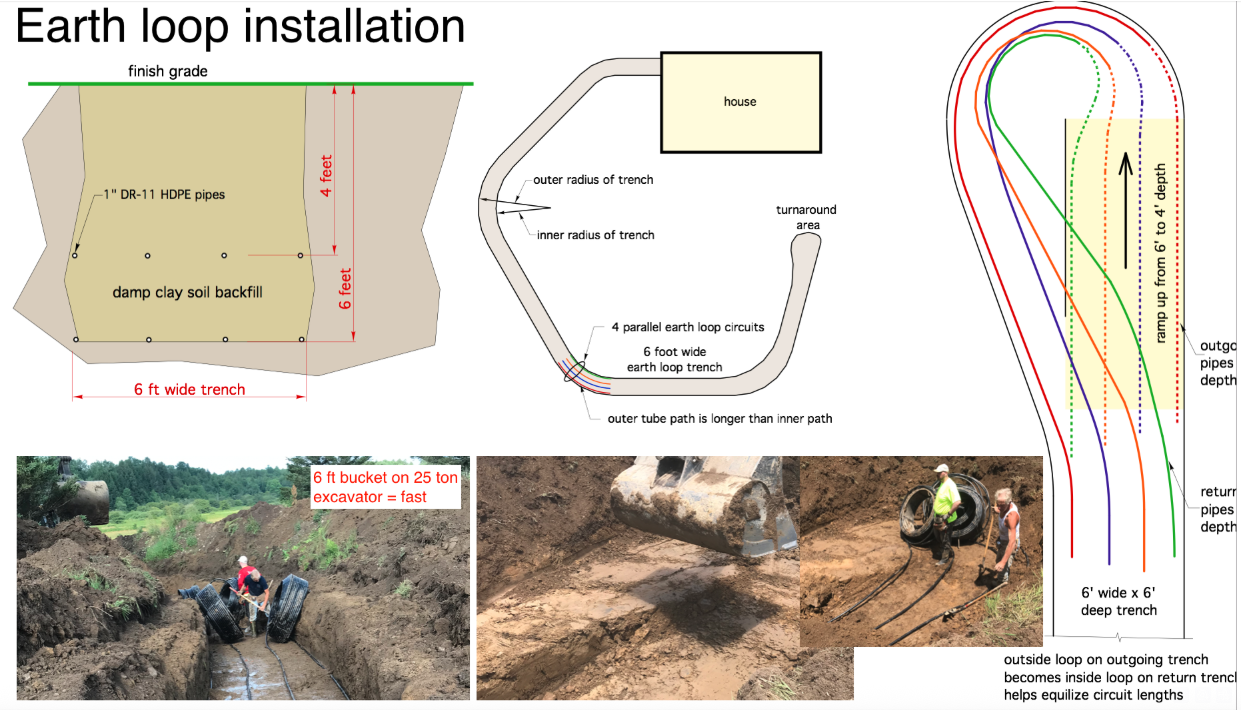

I have 6 of 7 500' loops in for the new construction. Primary heat is hydronic staple up that we are starting next week. The basement slab is done with 1/2" pex in heat sheet R10.

0 -

What type of soil are the pipe runs buried in?

Do the 7 loops of pipe consist of individual 500 foot long rolls/reels of High Density Polyethylene pipe with no butt fused pipe connections except at the header pipes?

What is the depth that the tubing loops are buried in?

Were the loops buried below the frost line if that applies here?

What is the separation distance between in feet between each pipe run?

What machinery is/was used to excavate the trenches?

Was the pipe pushed to one side edge of the trench and dirt piled on it every 10 or 20 feet to hold the HDPE in place prior to thier burial?

Was the rock in the trench dirt separated from the soil before the burial of the pipe?

0 -

Lots of questions.

All home run no fused pipe in the dirt.

It is clay with few rocks to speak of. We put it in pretty wet due to the time of the year.

I also added perforated pipe about 3' above the loops and will run downspout water and also irrigation water to keep the mass at closer to optimum moisture content. Wet clay has better numbers than dry clay by a large margin.

The bulk of it was pretty wet several feet down, but I will leave nothing to chance there.

Frost design depth for construction here is only 12".

Loops have 6' plus of cover. They are mostly in 8 or 10 pass wide trenches with 1' spacing. Each trench has a 2' buffer to the next, and one 10' gap for utilities.

We located and pinned the tubing down at the 1' spacing with "babies" of wet clay. We giggled a lot during the clay lump process. : "I need another baby here!" " Oh that's a BIG baby!"

here my brothers and nephew are raking the clay over and watching for any rocks as I push the clay over.

The equipment is a 12 ton excavator and a large compactor to get great compaction and contact with the clay. It was easily 95% compaction in lifts. This is the work I do for a living and that is the company excavator.

The edges of the field area will get a 4' retaining wall, the maximum I can do without engineering.

The excavator sank in about 6" in the clay and I schmoozed it out as I backed off that fill in February. Now it has skinned over rock hard and the machine won't leave a mark in it.

Because they are home runs I plan on using only half the loops at a time and alternating between the sets to see if I can get some recovery. It will be fun playing with return temperatures and seeing what we can do to maximize the loop temps and minimize the differential. The heating COP is directly related to that differential.

0 -

I wish those were deeper

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

We are good here Paul. It is a world of difference compared to NJ or even east of the Cascades in Washington. It gets wicked cold there.

Take a look at the design standards and Manual J information. It is just mild. I have never observed over 100 or below 23 myself.

We could get by with good shades and fans and no AC but we are wimps.

I did my own Manual J with Lennox Design pros Cool Calc.

I came up with 25018 BTUH heating and 21002 cooling, and a little less than 1000 CFM

Then I paid an engineer to go through it with me, do his own Manual J and design a system for me.

He came up with 31091 heating and 27443 cooling and ~1100 CFM, a little more conservative.

I had already set my sights on a Bosch 3 ton unit with an air handler for cooling.

I went with a 4 ton inverter that should be loafing, and gave it almost 6 ton equivalent of loops.

That said, I am going to call them and opt for a 6 ton AHU that includes 2x5KW strip heaters and about double the coil capacity. I think it will be a better match for my planned 105 SWT on design heat day and I can kick in the strips to take the edge off quickly if ever needed.

1 -

great job with all that engineering and sizing work.

Don’t oversized it and waste all that effort!

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

The 3 ton Bosch became unavailable, unfortunately. It was not a DC inverter unit like the 4 ton, and therefore was not a good match with my11.4Kw inverter. It had big Locked Rotor Amps (LRA), where this 4 ton is quite gentle on the uptake.

I had not planned on having the heat pump on the critical loads panel but now I can. The heat will work, the lights, and the fridge during a power outage. That covers all the main bases.

0 -

I’m missing something- aren’t those loops too close to the surface?

0 -

It is all down 6' +. I moved 300 tons of clay several times back and forth in different motions, the goal being to not disturb all the grass up there.

Here you can see the loops as they arrive at the house, 6' + down. If they are located down the hill, they are dug down an appropriate amount. It is just hard to visualize it so I marked the corners of the loops with 8' boards. That big ridge on the right is just stored there to backfill the house when I can. The flattish surface is the first time I could visualize grade.

I need to add some retaining walls and more dirt on the loop to the right. That was the hardest digging on the site there.

The back yard will never be flat. It will get stepped retaining walls to make a flat-ish spot with what I have.

It's come a long way since the rough Ex in September.

0 -

ahh I see you typed that above. Sorry! 6 feet should do the job! Looks good. What are you hoping for with ewt?

entering water tempNo Bosch? Waterfurnace is one week out, the rep tells me (we have a job coming up in a month or so)

0 -

-

We got the last loop in today. This one is not like the others, more of the classical 6' deep 9' wide gaw with a 10 pass loop.

We are trying to water it in, but it does not want to take the water, LOL.

We dug out along the first loop piping to get out there,and the wet clay was just as wet as it was in February. This is great. Wet clay has high heat capacity.

0 -

Is cost the reason you did not use gravel bank concrete sand for the entire excavation instead of the local clay?

0 -

Dirt work looks good. What size tube for those 500' loops?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

is that 1" ?

Curious how big the pump will be to keep the laminar flow

0 -

40 plus is a tough nut to crack in the North, hope it works out.

"alternate loops"- how are you doing that? Manually or automatically?

0 -

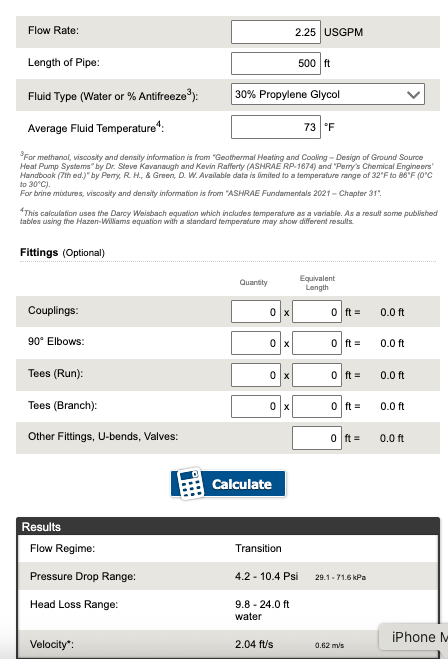

The PPI website has a useful calculator for plastic piping.

https://plasticpipecalculator.com/PressureDropHeadLoss.aspx

This shows a 500' loop of 3/4" pex. 2.25 gpm of 30% glycol gets you over 2 fps velocity.

It will take a circulator sized for that 24' head, at the gpm total of all the loops.

If all the tube is protected from freezing plain water really helps decrease the circ requirement, 9.8' with water

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

"We dug out along the first loop piping to get out there, and the wet clay was just as wet as it was in February. This is great. Wet clay has high heat capacity."

You don't want heat capacity, you want heat conductivity.

0 -

-

-

OK, let's spitball some numbers. The manual J above has a heating load of 31K BTU/hr at 49F temperature difference, that's 632 BTU per degree hour or 15K BTU per degree day. I don't know where you are but you say it's pretty mild, so let's say 4,000 degree days per year, or 60 million BTU per season. That would be about 435 gallons of heating oil per year.

You said that you moved 300 tons of dirt and that the trench is 6' deep. So that's 600,000 pounds of dirt; one sixth of it will be within a foot of the tubing so 100,000 pounds of dirt within a foot of the tubing. Your mean annual temperature is 49.8F, soil at depth will be at that temperature, let's call it 50F to keep the math easy. You've stated you don't want to let the soil temperature drop below 40F.

Let's say the soil has a really good heat capacity, say 0.5 BTU/pound/F. So that 100,000 pounds of dirt requires 50,000 BTU to get it to change temperature by one degree. Cooling all of it from 50F to 40F will require extracting 500,000 BTU. At design load that's about 16 hours of operation. Another way of looking at it is that in order to store a year's worth of heat in that layer you'd have to store 600 BTU per pound, which would require a temperature change of 1200F!

Clearly, you need to be pulling heat from a much, much greater area than just the trench. The storage capacity of the dirt in the trench is minimal compared to your heating needs. The most important attribute of the soil in contact with the tubing is that is be able to conduct heat from the surrounding area.

0 -

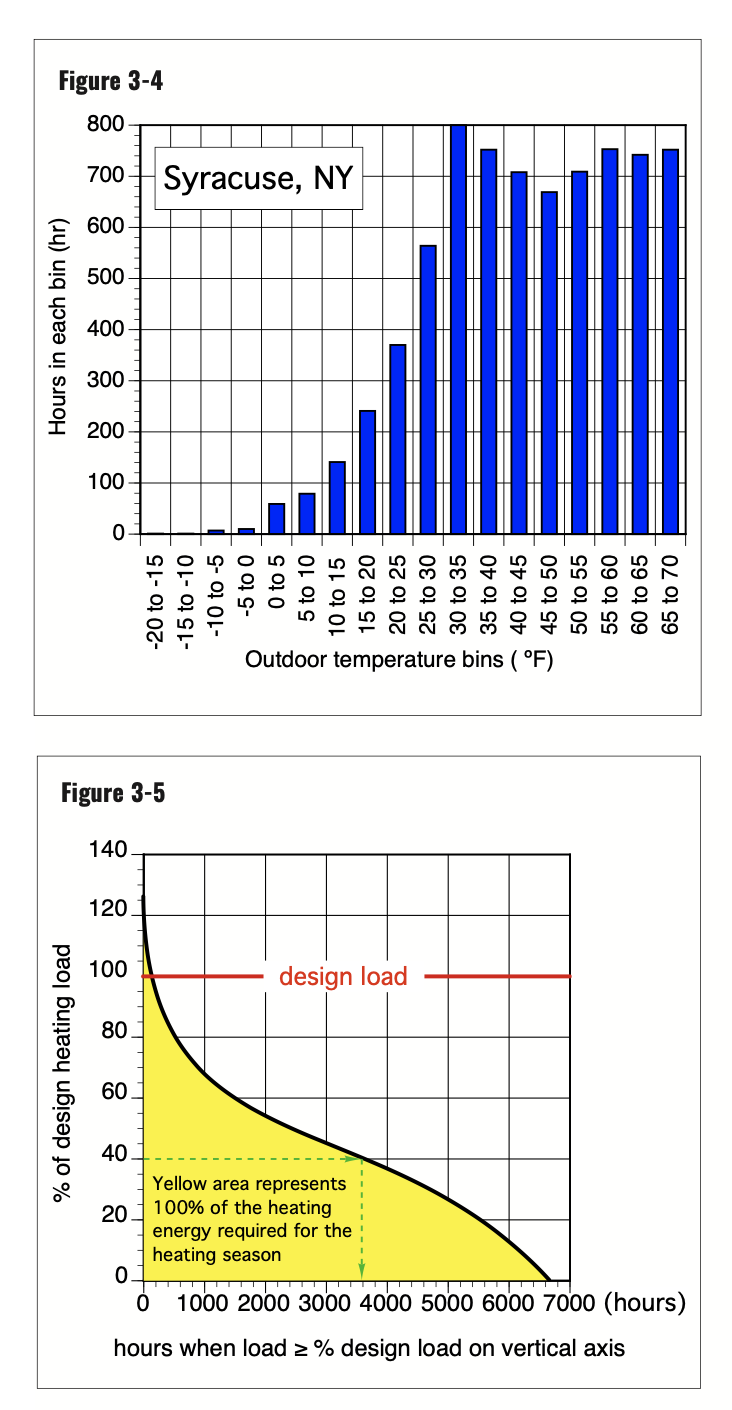

I doubt you will be at design load 31K? for more than a week or two per year. So the load on the field lessens. You can find temperature data for your location online, as an example for upstate NY. Design day there is 0-5°

I think moisture content of the soil has a lot to do with transfer, even in clay.

Really a GEO field is basically a giant solar collector/ storage. Suns energy will drive into the ground to recover the field also.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

"I doubt you will be at design load 31K? for more than a week or two per year." Design temperature should be 1-percentile, so one percent of the hours in a year are at or below that temperature. So 88 hours per year.

"Really a GEO field is basically a giant solar collector/ storage. Suns energy will drive into the ground to recover the field also."

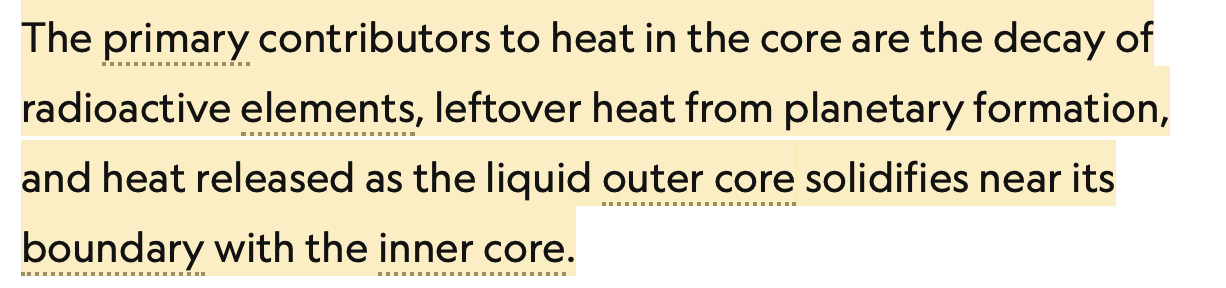

In most places at about ten feet the soil stays at the year-round average temperature all the time. Shallower than that it follows the seasons, warming in summer and cooling in winter. Deeper than that it gets warmer. The earth's core is at about 11,000 F but it's 4,000 miles away, so it's a pretty gradual increase.

For earth source you want your coils in that soil that stays at constant temperature, you don't want them cold in winter and hot in summer. True geothermal goes much deeper and actually uses the heat of the earth.

0 -

@DCContrarian it helps to use the numbers of the project.

Total pipe length 3400'

Installed @12" OC for a field total of 3400 SQ FT.

If we are to consider the storage capacity within a foot of the tubing, that equals 6800 cubic feet.

Wet clay ( and boy was it wet when I put the bulk in February!) weighs 110 pounds per cubic foot.

So my fields have 748,000 pounds of wet clay within a foot of the tubing.

It does indeed have a capacity of about a half a BTU per pound, and cooling it from 50 to 40 would yield 3.7 million BTU.

But that is not how it works. It does have great conductivity and will keep equalizing out to a larger extent than that foot either way.

@GW I will play with alternating fields manually. I have an odd number of loops ,7.

Each of the loops is a 10 pass by 45' or so, and separated by it's neighbor by 4 feet or so. There is also a 10' wide slot I had to leave out for the side sewer.

This is important, because our observations with my brother's field, a big 30x60 with 1800 feet of tubing in the 1800SF would cold soak pretty badly deep into the season. His soils were drier and less dense and not good conductors as @DCContrarian was talking about. We did not get much edge effect and that large contiguous field got below freezing by the end of the season.

I will manually run 3 fields that are separated by idle fields and the 4' and that 10'. That will be for the very low demand fall shoulder. I will watch for the differential of entering to leaving loop water and when it drops below 10 degrees it is a good time to change up.

Then I will dog off those 3 and run the other 4. I won't know how well it will work until we get into it, but I am significantly overlooped. The common conversion is 600' of 3/4" @ 12" OC per ton. I have 3400' and a 3 ton manual J.

The idea is to let the first 3 recover based on good conductivity and run with that. I may have to tap all 7 at the worst of it. My heating degree day is 23 F and cooling degree day is 79, so yes it is very mild compared to most. The straits of Juan De Fuca are only a few miles away and moderate the temperatures considerably.

1 -

Deeper than that it gets warmer. The earth's core is at about 11,000 F but it's 4,000 miles away, so it's a pretty gradual increase.

This is why "geothermal" is the wrong term. The heat this close to the surface does not come from the core, it comes from the sun.

And the trench, whatever size it is, does not define the heat he will have at his disposal all winter. Heat will warm the "trench zone" from surrounding soil (below and from the sides) all winter.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

Was simple shallow trenching for a single continuous run of pipe considered for thIs at all?

My neighbors geothermal system was run in a single shallow trench loop with black polyethylene pipe in the grass airport runway, they heat and cool a huge home with forced air heat exchanger using glycol.

Any colloidal clay which is what you have is a net insulator when it comes to geothermal heating and cooling.

0 -

-

"This is important, because our observations with my brother's field, a big 30x60 with 1800 feet of tubing in the 1800SF would cold soak pretty badly deep into the season. His soils were drier and less dense and not good conductors as @DCContrarian was talking about. We did not get much edge effect and that large contiguous field got below freezing by the end of the season."

Frozen soil is a much better insulator than unfrozen soil. If the soil freezes then the capacity of the field drops precipitously and it's pretty much game over.

1 -

"This is why "geothermal" is the wrong term. The heat this close to the surface does not come from the core, it comes from the sun."

Agree that this is not a geothermal system, it's a ground source heat pump.

It's actually an interesting question of where the heat comes from in a ground source system. I don't know, but it seems likely to me that the heat is coming from below, simply because when the heat is on the surface of the ground above is going to be colder than the loop and heat's not going to flow from colder to warmer. If the heat is coming from below, where is it coming from?

I don't know, and the answer may not be knowable. My understanding is there isn't any commonly accepted explanation for why the core of the earth is hot to begin with.

0 -

Knowing the load, using a GSHP design software, all the data is built in. Once you add location it knows typical weather data and ground temperature at various levels. So adding the soil type the program can size the loop tube and field size.

NORA has soil temperature by depth data for the US.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I don't know, but it seems likely to me that the heat is coming from below,

It comes from the sun (the warmth at the top layers of the earth). The heat into these ground source loops comes from below and the side (from earth that was previously heated by the sun)

My understanding is there isn't any commonly accepted explanation for why the core of the earth is hot to begin with.

It's quite understood:

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

-

The loops at 4-6' from the surface are probably more influenced by the sun than the core of the earth? I'd would suggest the same for well loops, deep, 100' or more or shallow.

AI knows :)

Hot pools at Yellowstone run 190° +

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements