Observations on my old, rotted out wet return.

The first place to fail was, naturally, at one of the joints, because the threads are cut halfway into the pipe, creating a weak point. When I inspected the rest of the return, I found that it was badly rusted in places where it had been painted with ordinary house paint. The paint was loose and flaking, and when I scraped it away, I could see deep pits in the pipe. I have some theories about why this happened, but it's just speculation. My solution was to run dry returns until just before the boiler, and piping the underwater leg in copper like most of the pros seem to do.

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-24

Comments

-

you have pictures of the lines that are rotted out?

0 -

There is a potential problem with your solution: if there is more than one drip from a steam main into that wet return, or if you have real dry returns and they dripped into that wet return, you have created some potentially problematic alternate paths for steam flow.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England2 -

-

-

Copper? is that really what the professionals of today. I thought the Dead Men never used copper in steam piping mains and returns and preferred black iron/steel

Im all ears on this comment

Regards,

RTW

0 -

Copper is fine below the water line simply because there's no negative for it there, and there is a good reason to use it, its corrosion-resistance.

The dead men were just men

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

-

You're missing the whole advantage of copper: it doesn't rust. Since I replaced the black pipe with copper, my boiler stays much cleaner. I never realized how much rust was forming in the wet return before I installed sight glasses on the drips and could see that it's perfectly clear, clean water before it gets into the wet return. With copper, it stays that way and my boiler water stays clean all winter.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-244 -

Both, but the rust from the outside was mainly happening where it had been painted. I'm not sure why that is, but I definitely don't recommend painting pipes unless you use rustoleum.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

I noticed that most of the best professionals were using copper, so I decided to follow their example, and now that I've seen the difference it makes, I'm a convert. To be clear: the underwater portion of the return is the only place where copper should be used.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-243 -

Unless you connect dry returns above the water line, there's no potential for steam to go anywhere through the dry return. Steam will be present, because of the vapor pressure of the condensate, but steam won't be flowing in any particular direction.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Don't confuse dry returns (two pipe) which can and usually do connect above the water line with steam main extensions (one pipe and the odd two pipe) which must NOT connect above the water line…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

-

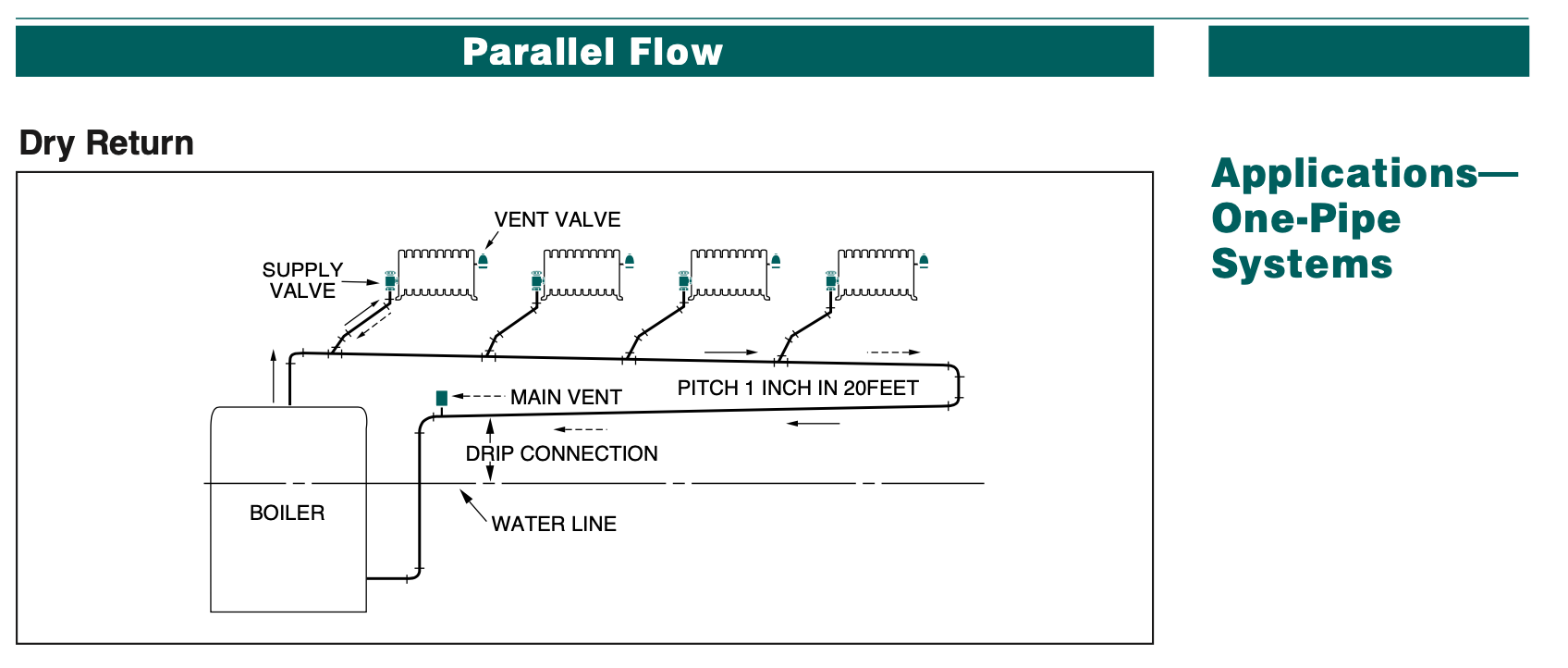

I'm not confused. You can call them whatever you want. I'm calling them dry returns, like Hoffman does. The only difference between this diagram and my returns is that the main vents are located at the end of the main, not the end of the return, because why make the return fill with steam before you start pushing steam to your radiators?

See page 3. See also the definition of dry return on page 11.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

Whatever. As long as one understands the absolutely critical differences in the way they function and how they must be piped, no problem.

Not enough people do… and a remarkable number of knuckleheaded systems, with interesting and sometimes very difficult to diagnose problems result.

I might add that i have pretty well given up the battle. If I see a system with incorrectly piped whatever you want to call thems, I'll mention it — once. And then let the poor folks trying to figure what's wrong have at it.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

venting the main extensions just gives the steam more opportunity to find a pocket of water and hammer. there isn't a great reason to do it unless a vent at the end of the main will be neglected or in an inaccessible location.

there's really no reason to use black iron for any part of the system that won't see steam. dry returns that can't vent and let steam in would be fine in copper too. the black iron is just to conduct less heat and keep the steam hotter and not expand and contract with steam temps as much. of course you still need to allow for movement with expansion in either material.

1 -

The main problem I see it causing if dry returns are improperly joined is that it can make it hard or even impossible to balance the radiators. There's only so much you can do with radiator venting if steam has an alternate path to radiators near the end of a main branch. So if you're tasked with balancing the system, addressing the return piping has to be part of the job.

Just another DIYer | King of Prussia, PA

1983(?) Peerless G-561-W-S | 3" drop header, CG400-1090, VXT-240 -

You're still stuck on one pipe steam, @Hap_Hazzard … there are other systems!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements