Indoor wood boiler plumbing

I've done a lot of reading on this forum and it has been very helpful throughout our house construction. We went with in floor radiant heat with a propane boiler using outdoor reset to control water temps. Now I'm adding a pressurized indoor wood boiler to the system and think I have a decent layout for the plumbing side of it but just wanted to make sure there's nothing I'm missing.

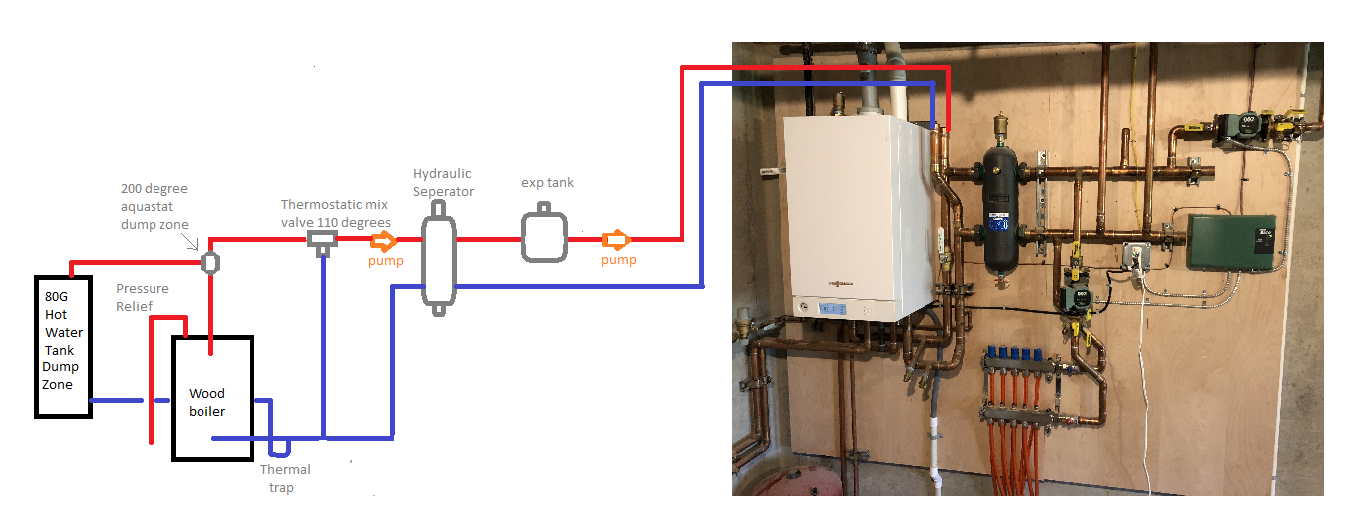

Here is a picture of my current setup in the mechanical room:

And here is a layout attaching indoor boiler to current system:

Comments

-

That will work. What size wood boiler? You may need a buffer tank to control it on small load days.

\This drawing is similar, you have a separator on place of the buffer shown here.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

It is a thermo control 2500, which has 170 gallons in the water jacket and a 200K output. Forgot to mention that it is located in a room off of our attached garage which is all heated but the pipe run with be roughly 100' to that mechanical room in our basement. My plan was to use 1.25" black iron pipe all the way.

0 -

Also, do I need another auto fill/backflow prevent like I have sketched in there if I already have one circled in this picture below:

0 -

Basically that plumbing you've shown will work — and you not only don't need another autofill, you don't want one.

Now I do see one problem: I see no dump zone for the woodburner. I may be old fashioned… well, it's not "may be", it's "I am" — but I have yet to see a woodburner which didn't run away at least once. You really do want to have a place to dump the excess heat while you scurry about calming the thing down…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

What do you plan on doing with the pipe, placing the 2 pipe runs on sand and 1 by 1's and foaming them in the trench?

You need more storage to act as a heat dump by putting a New Horizons rectangular 490 gallon insulated tank next to the forest eater and balancing/mixing the water temperature down to 150 degrees.

1 -

if you learn how to control the size if the fire to the changing heatloss it can work well. We need more info like the heatload of the various buildings.

If it is a gasification boiler, they like long hot runs, so you need a good load to keep them burning clean and efficient

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you. I didn't label the dump zone clearly in my sketch but it's the 20K btu radiator above the wood boiler. I've read 10% of boiler output for a dump zone is adequate and this boiler is capable of 200k. I found a used cast iron radiator that is roughly 6' long and 30" high that seems to be rated for 20-25k.

The plumbing to the dump zone and for the 100' run with be 1.5" black iron (not 1.25" like I mistakenly said in a earlier post), so I'm hoping for decent thermosiphon through the old radiator with 1.5" pipe and it being higher than the boiler although 15' away.

0 -

So the pipe which is 1.5" black iron, will be exposed along the wall in the attached garage so everything is indoors and insulated heated rooms.

I'm going to try without storage 1st. The bottom of this boiler is 1 layer of fire brick which I'm adding more brick to and shrinking the firebox to use smaller and hopefully hotter fires by way of the fire brick.

0 -

You should plan on filling the fire box volume half full of standard fire brick up to the flue breech. This creates a huge amount of thermal mass for you, and it radiates the heat back into the fire box and boiler walls slowly and at the same time it creates a hotter fire and much less smoke/unburned fuel lost up the chimney. I did this with my old hand fed wood and coal boiler and I will tell you it works.

2 -

In my view, that 10% suggestion for a dump zone size is… perhaps OK if you have three things: a good pressure relief valve, a set of fireproof gloves with which to remove the fire if needed, and — most important — someone there at all times to keep an eye on the fire…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

looks like that boiler has a means to shut down the air. If it works and the door is closed and sealed tightly, it should ramp down quickly

Leaky door gaskets cause over run most often

How to load the stove is the learning curve

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you, I may have gotten that idea from reading one of your posts. Can't remember but I did read that on here somewhere.

0 -

Yes this boiler shuts down in 3 different scenarios- aquastat setting, power outage (damper is held open by power), and stack limit switch on chimney.

The company says the water volume is great enough that as long as the damper shuts, the water can absorb the heat without going over the danger level without a need for heat dump. This boiler is also uninsulated so it radiates a decent amount of the heat as well. That was my reasoning for only a 10% dump zone. I plan on testing a worst case scenario once I get it hooked up.

0 -

I made a couple changes and am about to have this installed finally. The boiler tech that is doing this install wants to use a hydraulic seperator like he used on our propane boiler in this picture. I think that's a good idea too after some research. My main question now is: Is it necessary to have a boiler protection valve on this setup? I removed it from my original at the top of this page to now only have the one Thermostatic mixing valve set at approximately 110 degrees as that is what my floors require on coldest days. If my wood boiler is running 160-180f as its set points then will I have enough hot water coming off that mixing valve to keep my return water above 140f? The mixing valve will be right at the boiler like in the picture I've drawn. Thanks again for any advice

0 -

Most wood boilers, even the control-able gasification types want some amount of buffer tank. I would use the buffer as part of the piping not just a dump zone. It can also serve as the hydraulic separation device.

If it is a boiler that can ramp down quickly, a piece of fin tube can be enough of a dump. This method also works if you have a power outage, and/ or with a temperature controller

The mod con could tie into either side of the tank. If you want it to use the buffer, to cover micro zones, connect it to the same side of the tank as the wood boiler.

I guess it depends on what type of tank you have? Does it have 2 or 4 connections? What size?

There is another piping option for tanks with only two connections.

If you don't want to disturb the nice piping you have, this sketch gets you a 2 pipe, direct to load buffer, and return protection valve, and heat dump

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I have not bought a tank yet, the 80 gallon tank was suggested because it would lower the wood boiler's 170 gallon water jacket quicker then just fin tube or a radiator. I only have room for a 120 gallon max tank size next to this wood boiler, would 120 gallon's of additional storage on top of the wood boiler's 170 gallon water jacket be enough to make much of a difference? Either the 80 or 120g tanks have 4 connections so piping wouldn't be an issue. Also, would having 120 gallon's of additional storage allow me to not worry much about a dump zone because of the extra buffer of water volume to soak up a run away fire?

0 -

Keep in mind that you need to shed the heat and the heat causes the water to expand.

A series of open fin tube without covers will work just as well.

You would have do a bit of soldering to hook them together in series with elbows and then hang them up using pipe strap.

0 -

So your saying that open fin tube would cool down the boiler quicker than a 80 gallon water tank if the water tank was to only function as a dump zone and not a buffer tank?

0 -

The radiation emmitted by the aluminum fins would vacuum the heat out of the water. The only thing better would be a large round tank from New Horizons with 4 copper coils connected in series in it.

0 -

your primary goal is to not over fire the boiler and need to deal with a dump zone. I have been using wood boilers for many years of all types and have never needed to dump heat. It’s about building the fire size based on the conditions. If it is a modern gasification type, they can slow down quickly and have a small firebox. Unlike an OWF

There is a bit of a learning curve with wood boilers as they are a manually fed system.

With a 2 pipe buffer, the buffer is only used when the heat loads are dropping off. So output goes directly to the heat load, it doesn’t go into the buffer until the heat zone pumps turns off. Then it charges the buffer. On the next heat call temperature in the buffer supplies the heat. When the tank cools down the wood boiler is fired to load it up again

Here is an example of how a 2 pipe direct to load buffer works. The gpm are just guesstimates.

1 When both zones are calling the boiler output goes directly to them. Flowrates from WB is equal to load of two zones2 If one zone drops off that portion of flow from the WB goes into the tank and starts warming it.

3 When the second zone drops off, full boiler output warms the tank to setpoint temperature, typically 180f. The boiler pump shuts off, fire dies down.

When the next heat call comes on, flow comes from the buffer, until the temperature drops, then the wood boiler and pump start again.

So the larger the buffer, the more run time for the WB. Ideally you want a large buffer 350 gallons or more so you have a longer burn cycle for the wb. They like long hot burns compared to small, short firing. This becomes evident on mild days. Low load condition, tank is already warm. What to do with the WB heat? This is where the operator has to learn how much fire to build and control. Some folks chose to use one of the zones as the dump. May as well put the excess heat somewhere. Garages make good dump zones.

Oh and another thing. You have low temperature radiant, so you need a mixing valve at the buffer as it will be 180f or more most of the time the WB runs. You cannot run the WB below 130 or it will creosote badly. That is what the 280 protection valve does, keeps the boiler warm before letting flow to the system or buffer.

It does get a bit complicated to pipe this to cover all bases.

What size is the WB? What is the heatload of the home? The bigger the mismatch, the harder to control the WB. They want to run full speed ahead to burn cleanly and efficiently.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Zenon at New Horizons was my go to guy for wood boilers and info. Here is his suggestion for buffers. His math is pretty accurate. I installed a bunch of his 40kw units, Atmos, EKO and PK. I think he manufactures his own brand now.

I found 300- 500 was a good size for buffers. That provided a system that ran efficiently and you could load and walk away from for 4-6 hours depending on the burn time of your boiler.The larger the system volume, buffer and piping, the larger the required expansion tank, also. As you see in this pic.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, fin tube is cheaper and takes up no floor space so I will go that route. Thanks

0 -

Thank you for those sketches, the two pipe buffer set up makes perfect since now. Would I want the thermostatic mixing valve to be right before or right after the buffer tank? I will be mixing down to roughly 106-110*. I just checked my mod con boiler output temp right now because it’s -6*F and it’s showing 104-106*F.

It’s using outdoor temperature reset which shows 5* in the pic but it has always read higher, weather channel says -6*.

0 -

with a grain of salt that 200,00 btu/ hr boiler output. That is usually a lab test, very best operating condition number. Full chamber of ideal wood burning hot.

The 170 gallons of water in the unit will absorb some over-shoot. If you set the control at 160 to turn off, you may coast up to 180 or so. It really comes down to fire sizes vs the load size.

I think you mentioned a garage zone? Why not use it for a dump? If the boiler reaches, say 190, that zone opens.

The only other possible concern is a power outage. Some wood burners use a small computer backup power pack to run the system, one or two pumps, for a few hours to prevent boiling and flashing to steam.

Being a pressurized system you can go well over 212f before you flash. Any Pex tube could be a weak link when you start talking 200+ temperatures.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The wood boiler is located in the garage and the garage has a in floor heat zone running it at 60*. I don’t like the idea of sending really hot water into the concrete but if I used 30-40 feet of fin tube above the wood boiler (thermosiphon) it would just radiate that extra heat into the garage. I was going to use a mechanical aqua stat that would open at a high temp set point, whether it’s a power outage or some type of pump/draft door failure that caused the temp to rise I would be covered.

0 -

You need to avoid using pex for feeding the dump zone fin tube to avoid a leak and a mess of water in the garage. If you can run black iron pipe all the better and use a sweat to pipe nipple to avoid disimular metal corrosion.

0 -

Ok thanks. The boiler tech started today and he is using all 1.25" copper instead of black iron for all boiler piping. I will post pictures when he's done so if other people are curious about a similar setup they can see how this was done.

Again thank you guys for the help and suggestions, it's very appreciated.

0 -

So many different way to pipe multiple boiler systems. Some are 100% manual switch over, some can be 100% automatic, some can use input from both at the same time. It really comes down to how you want YOUR system to operate.

The more automatic, the more complexity and cost, of course.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Boiler hook up is almost done and I have one more question:

In the picture below I circled in green the dump zone valve. I would like that to be a mechanical valve (requiring no electricity) that opens on a high temp setting such as 200F. That way it wouldn't matter what causes an over temp situation whether it be no power, loading door left open, door seal leak or pump failure. I'm having trouble finding a suitable valve for this, is there any available that would do this? Thanks again

0 -

NO

0 -

The dump zone valve I have on my wood boiler is a zone valve (Automag) that is electrically powered closed (referred to as "normally open"). It only protects the system if the power goes out when the wood boiler circulator is operating. With no power, the valve opens and boiler water circulates by thermosiphoning.

0 -

Most temperature activated valves with 2 ports are relief valves. A water heater relief discharges at 210, but usually will not seal after they go off

You probably want it to reset at a lower temperature?

Three way mix valves might activate but they have pretty tight passageways and may not thermosiphon.There were some solar protection valves that could bypass to a fin tube dump behind the collectors, but they would need a pumped flow also.

Just another version of a thermostatic valve

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Some of the bigger TRV have a pretty decent CV. You can get an actuator with a remote bulk which you can strip to the pipe for controls.

0 -

Finally got it running. So far it has been working great. I did have to add a 3’ chimney extension to get a little better draft. Right now I’m running it without storage and the 170 gallons of on board storage at 175 max on the aqua stat with a 15 degree differential (160-175 water temps). Then I’m mixing down to roughly 110 degrees going to my radiant zones. I’m getting roughly 10 hour burn times but I’m only loading it half full and it seems to be burning really clean with a little smoke when I reload that clears up quickly. I really like that he put a hydraulic separator with a pump running 24/7 on the wood boiler side of it, it keeps the 170 gallons in the boiler at a very even temperature and I think helps with return temps if they fall slightly under 140 every now and then. The pump from this wood boiler to my zones won’t kick on until the boiler temperature reaches 140 degrees. Here is some pictures:

0 -

Too clean to be a woodburner :) What do you have for combustion air?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Nothing for combustion air at this point, this room is open to a large garage with 5 overhead doors so I was assuming there was enough air coming through those although the garage is pretty well insulated. What would be the harm in running it this was vs adding a fresh air intake?

0 -

So I've been running this for about 2 weeks now and I'm having trouble with my garage temps. What's happening is this boiler is in the garage(2400sf) and it puts off enough radiant heat that my thermostat for my radiant floors never kicks on. Every 2-3 days the conditions get right that the slab thermostat setting of 65F gets low enough to kick on the slab heat and then it sends very cold water back to my boiler because the slab has cooled down to 45F after not running for 2-3 days even though the air temp has been above 65F from the radiant heat off boiler. Then for my wood boiler to bring the 45F slab up to 65F takes forever and consumes a ton of wood. I'm open to opinions but I was going to start with insulating the wood boiler to limit the radiant output? Or would changing my T-stat to a slab sensing one instead of the current air sensor help? What would be the best fix for this as I know running a slab at the much of a temp variance is not efficient at all, defeats the purpose. Thanks for any suggestions

0 -

Slab sensor. With those big doors opening and closing from time to time, the air temperature is going to be all over the place — and a very poor guide for a slow responding system like a slab.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The radiant heat off the wood boiler will also trip the air thermostat if there is that much coming off it? Maybe insulate the boiler so you have less jacket loss?

I had a wood gasification boiler in my last shop, except for the flue connector and small loading door, the sheetmetal jacket around it was just warm to the touch.

Constant circulation is another way to keep a more consistent room temperature. It might move that wood boiler radiant heat around the shop better.

Actually once the slab is warmer you have a massive thermal storage. Opening and closing the door, that radiant energy in the slab should bring the temperature in the room back up very quickly. That radiant energy moves at the speed or light from warm to cold. Same with bringing in a cold vehicle, a warm floor will bring its temperature up quickly.

You really don't want 45° water going to the boiler ever, even for a short burst of time. You may have a creosote monster in the works. Add a boiler return protection valve.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok thanks that makes since

0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements