Pressure drop with hot water demand

Hello,

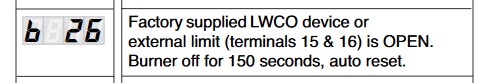

We have a thirteen year old system, installed in 2010: Triangle Tube Prestige Solo 175 paired with Turbomax109 indirect water heater, CH is also provided by the TT. Lately, about two months ago, when there is a demand for hot water (filling the tub for example) pressure in the system starts to drop quite significantly (from 20 psi to almost 0). At the beginning of the this problem TT would throw a b26 error related to LWCO, but I would bypass the LWCO by shorting the wires and system would build up the pressure back to normal during water heating cycle. Lately, though, the pressure started to drop more often with hot water demand and if the TT is idling and builds up back again when TT is heating DHW.

What could be the problem? Scale/sludge build up in the Turbomax? It was never flushed during the service through 13 years.

Thank you.

Comments

-

The only thing that can change the pressure in a closed system is a leak or the differential pressure created by the pump.

If you had a leak in the HX or piping to the Turbomax, you would see it on the floor or if in the tank, the pressure would go up, not down.

You say after awhile, the pressure comes back? Can you turn off the fill valve when it drops to zero and see if the presuure still comes back?

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab1 -

"turn off the fill valve" - do you mean to close off domestic cold water supply to the Turbomax and see if there is communication between the DHW circuit with the boiler water supply? Water actually sometimes comes out brown from the hot water faucet when filling the tub (very rarely).

0 -

-

This one? Set it to zero?

0 -

Don't mess with the dial on top. See the grey dial at the bottom? Turn it counterclockwise and it will shut the valve.

8.33 lbs./gal. x 60 min./hr. x 20°ΔT = 10,000 BTU's/hour

Two btu per sq ft for degree difference for a slab0 -

I'm having real trouble figuring out how a hot water demand, such as from a shower or the like, could affect the pressure in a presumably closed hot water heating loop. Something does not add up here — the pressure in the hot water heating loop should be well below the minimum pressure in the domestic hot water at all times.

if it is the pressure in the hot water heating loop which is falling (and tripping a low water/low pressure code) when domestic hot water is being used, something very peculiar is happening.

Piping diagram or photos?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Got it. Thanks. Will test it tonight.

0 -

Yeah, that's the enigma which is eating me out as a homeowner. Almost looks like a bottleneck somewhere in the system has appeared about two months ago and is getting worse. HOt water is supplied, but not replenished at the necessary rate. Photos of the system are attached.

0 -

-

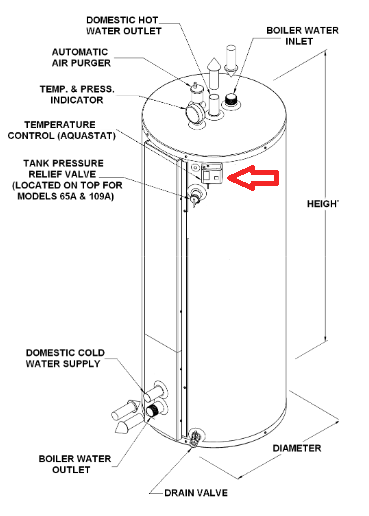

Is there a way to test the pressure valves? I have two - one is on the boiler (end of the pipe, where actually the LCWO sensor is located) and the second is on the water tank.

0 -

Both of the expansion tanks seem to be free of water.

0 -

-

Drained a little from the system to ~ 5 psi and the pressure stays low. I did rotate the bottom dial of the PRVas Alan (California Radiant) Forbes advised and then I've heard a rush of water and the presuure went back to normal. I guess the PRV was getting stuck and not letting the water into the system. Does that sound correct? I guess the PRV should be replaced? Thank you mattmia2!

0 -

You may have a leak or issues with the expansion tank. I would close it again and see if the pressure stays. If it loses pressure you need to figure out what is going on, either it is leaking somewhere or the expansion tank isn't working and it is seeping out the pressure relief vavle when it is hot. It will lose a little pressure as the air from the fresh water you added works out through the automatic vent. You could also leave the makup water supply on for a few days to let it work most of the air out then turn it off and see if it holds pressure over a few days.

0 -

There is a little drip from the backflow preventer vent (see attached pic). I did close the valve on the PRV completely (it was open before). I will also put latex gloves (will tighten them with scotch around the pipe) on both of the pressure relief valves and see if they accumulate any water. Not sure how to test the expansion tank (any ideas?). If the pressure still drops and pressure relief valves are dry?

Could there be small holes in the Turbomax which allow communication between boiler hot water supply and the DHW circuit? Again, the system developed this peculiar condition about two months ago after 13 years of usage without problems

.

0 -

This is why having that additional pressure gauge on the Caleffi fill valve is useful! It's always nice to have a little redundancy to double check if something is working correctly. (edit: noticed there isn't even a tapped port there! I guess they didn't come with one back in the day?)

What didn't make much sense was this

"but I would bypass the LWCO by shorting the wires and system would build up the pressure back to normal during water heating cycle. Lately, though, the pressure started to drop more often with hot water demand and if the TT is idling and builds up back again when TT is heating DHW."

What you have is an automatic fill valve set at what looks like 16-17psi. This valve does not care what your boiler is doing. It can be off. It will feed water into your closed loop if it drops below the set point.

So when you say it only builds up pressure again when heating the water, something is already wrong here. Unfortunately, the only gauge you have that I can see is on the boiler itself.

What I believe Alan was asking you to do was to shut off that fill valve after it oddly drops pressure from using your domestic hot water. Not manually draining the system. What we want to see is if the pressure returns without the use of the Caleffi fill valve after losing it to running the domestic hot water.

0 -

it's possible that the coils have a pinhole. Eventually the boiler pressure would match the water pressure in the building. It that is over 30 psi, an operating 30 lb boiler valve would discharge.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

Seems like burning, but it is not:) Guys did some soldering and churned the plastic air intake on install 13 years ago.

0 -

Ah yes, I suppose a hot pipe wouldn't leave burn marks like that!

0 -

Shortening the LWCO sensor wires will prevent the b26 error from occuring on the triangle tube and resume normal operation and during the hot water heating cycle the pressure will normalize. That was the only purpose for bypassing the LWCO sensor.

One pressure gauge is on the boiler and another one is on the Turbomax water heater tank - both show exactly the same values.

Well, I closed the boiler water supply circuit completely by closing the pressure reducing valve and will see what develops.

What would be your suggestion on the replacement of the existing PVR and backflow preventer I have? Link to the product with the integrated pressure gauge will be helpful.

Thanks.

0 -

You have hard water. Look at the hard water deposit (scale) on the atmospheric vent which was (is) dripping on the double check before the Caleffi auto fill. You can delime the caleffi and the double check or any other valve (thermostatic mixing valve) that has moving parts. The thermostatic mixing valve can scale up and not function correctly and mix more cold water in with the hot from the tank coil giving you lukewarm water. Then use conditioned water in the boiler.

A problem is, hard water in the coils of the domestic hot water supply can scale the interior and exterior of the coil reducing heat transfer from the boiler water to the domestic hot water.

I don't think domestic hot water demand side is the problem execpt with a scaled up mixing valve. You have a indirect tank circuit with a pump, maybe on priority setting. I woud look at that pump and any check valves on that circuit.

Are you on well water?

The knob on the bottom of the Caleffi fill valve is a shutoff knob and should be in the open position so water can flow to the boiler sys should the sys need water. That valve has a cartridge in it that can be cleaned.

0 -

It would be the same one, it now comes with a pressure gauge port and can be bought with the gauge as well.

But, I don't think we're at the point of blaming the Caleffi fill valve? I don't see anything that would point to it as the culprit.

—

0 -

17.5 on both. Pressure was the same on both of them when the pressure drops - low presure on TT, same low pressure reading on the turbomax. Water pressure in the faucet though was fine, but lukewarm water instead of hot (understandably) when b26 error on TT prevented call for hot water.

0 -

I was mistaken on how the TurboMax works. The boiler water is actually what is in the tank, and domestic cold water goes through the copper coil. Which makes sense now why they also can use it as a hydronic buffer tank.

Need to think again

0 -

All right I was able to reproduce everything with one more piece of information suggested by Alan Forbes.

- initial state: Caleffi valve completely closed, pressure is at 17.5 psi. LWCO sensor connected as normal in TT.

- opened a hot water faucet in the tub upstairs, pressure started to drop quite fast, down to ~0 in a span of a minute. Boiler threw b26 error (LWCO sensor). Hot water still flows in the tub with normal pressure, but became brownish.

- Closed the tub faucet, bypassed LWCO sensor on the boiler (b26 error dissapeared), boiler called for hot water, pressure building up. All these with the Caleffi valve comletely closed. After the hot water heating cycle finished the system pressure was up to 19 psi.

Communication between boiler hotwater circuit and the DHW in Turbomax?

0 -

The only communication between the two is a sensor that tells the boiler to turn on when there is a demand for hot boiler water in the tank.

The aquastat may have a probe that pokes into the tank which may be scaled up and not reading the tank temp accurately.

The low water cutoff is exterior to the TT? Are you looking at the temp/pressure gauge on top of the TurbMax or on the boiler?

0 -

Thank you for the maintenance info on Caleffi. We are not on the well, te water is city supplied (Colorado). Here is the water report from 2021. I doubt it changed much.

Substance Sample Date Average Range Found MCL SMCL Common Sources

Alkalinity, ppm Weekly 44.7 23 - 57 n/a None Erosion of natural deposits

Chloride, ppm Quarterly 45.5 16.3 - 86.8 n/a 250 ppm Erosion of natural deposits

Hardness, ppm Weekly 130 39 - 185 n/a None Erosion of natural deposits

Iron, ppm Monthly < 0.01 < 0.005 - < 0.01 n/a 0.3 ppm Erosion of natural deposits

Manganese, ppm Monthly 0.013 < 0.005 - 0.018 n/a 0.05 ppm Treatment

pH, su Weekly 8.7 7.4 - 9.3 n/a 6.5 - 8.5 su Treatment

Potassium, ppm Quarterly 2.8 1.6 - 3.8 n/a None Erosion of natural deposits

Sodium, ppm Yearly 15.4 15.4 - 15.4 n/a None Erosion of natural deposits

Sulfate, ppm Quarterly 86.4 36.2 - 122 n/a 250 ppm Erosion of natural deposits

(TDS), ppm Quarterly 269 113 - 397 n/a 500 ppm Erosion and storm water runoff

Zinc, ppm Quarterly 0.04 0.02 - 0.11 n/a 5 ppm Erosion of natural deposits0 -

Never used an aquastat on the turbomax - for some reason it never worked, so that wire out if the turbomax is directly wired into the TT board. LWCO sensor is internal to TT.

BTW, we do not have a mixing valve. We keep turbomax temperature at 60C (140F).

0 -

I don't see the mystery — other than your domestic water static presure is low. If you open a hot water tap upstairs, and the pressuren on the heating side of the boiler drops… you have a leak between the boiler and the hot water. Either a baclflow nfrom the boiler fill to the hot water line (you mentioned the backflow preventer vent drips? if so, it needs repair or replacement) or in the Turbomax coils. Those are the only two hydraulic connections. All the electric stuff is irrelevant to the pressure problem.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Hmmm, 140 is a little high for a boiler without a mixing valve, but that is boiler tank water temp and not domestic delivery temp, I suspect. What wire out of the TurboMax? connected to the TT, where and how?

That LWCO sensor could be plugged. Is it a real LWCO or just a pressure switch?

Jamie, if there was a leak thru the HX in the TurboMax the boiler pressure would be the street pressure, much above 30 psi, don't you think?

Palisandr, I don't think your piping is correct (just an after thought) TT recommend a hydro separator between the boiler circuit and the heating circuit. I can't see the piping very well in your photos, tho.

The LWCO is a pressure switch. Sometimes the opening get plugged up and a cleaning of the hole will restore the switch. It get plugged up with hard water deposits or other debris.

Replacing it may be necessary. https://www.supplyhouse.com/Triangle-Tube-PGRKIT20-LWCO-Device

0 -

You have a ball valve (red handle valve on the wall) before the Caleffi fill valve/backflow combo. You can re-run your test using the ball valve to shut off boiler filling instead of the valve on the Caleffi to rule it out.

I also had questions about the piping, but didn't really think it was pertinent. Could you let me know which way the arrow is facing on the circled pump?

0 -

dko, could that be the indirect pump?

0 -

A faulty lwco switch is possible, but does that answer why pressure drops in both the indirect tank and the boiler? It seems the lwco is functioning as his pressure is indeed dropping.

It also doesn't answer why he suddenly gets brown water after running hot water for a while as if he was using up all the water from a tank. His hot water is direct from the cold main, through the coil, and then to his fixtures.

It does seem it would be a hole in the coil and the tank's boiler water is getting sucked in while using it.

If this is the case, the only question remains is why his relief valve doesn't go off as a leak is a two way street. And why then during repressuring does it stop at exactly 17.5 psi and not continue to rise? And why it also returned to 17.5psi when the fill valve was shut off.

I think we had another post here recently where pressure would go missing and come back by itself and he did not even have a fill connection. Wonder if that was solved..But in both cases, feels like something very simple is being missed.

0 -

yes, it connects to the bottom of the indirect. just curious as to which way it was pumping, as the factory position would have it pumping towards the indirect, then the top supply would act as the return.. but it's connected to the boiler supply. either way seems like it all could have been piped differently.. especially incorporating the turbomax as a buffer tank/hydraulic separator.

it's probably not what I think, as he says it was working fine for the 13 years.

0 -

Does he have galvanized iron domestic water piping (brown rusty water) ? What is the street pressure? Too, high a flow for copper pipe size leading to pipe erosion?

What ever the Caleffi fill valve is set for the Expansion Tank air cushion charge should be the same pressure. The gray tank. The white tank air charge should be the same as street pressure.

0 -

The arrow is pointing to the boiler.

0 -

I am pretty sure that the LWCO is not a culprit here as it functions as intended - pressure drops, it throws the error.

0 -

Just to confirm, when using any other circuit (all your other heating zones calling) the problem does not present itself?

0 -

Correct. Only hot water call.

0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 427 Carbon Monoxide Awareness

- 119 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 165 Indoor-Air Quality

- 3.7K Oil Heating

- 76 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.6K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements