Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

Tekmar 252 supply settings

Options

northlakes

Member Posts: 95

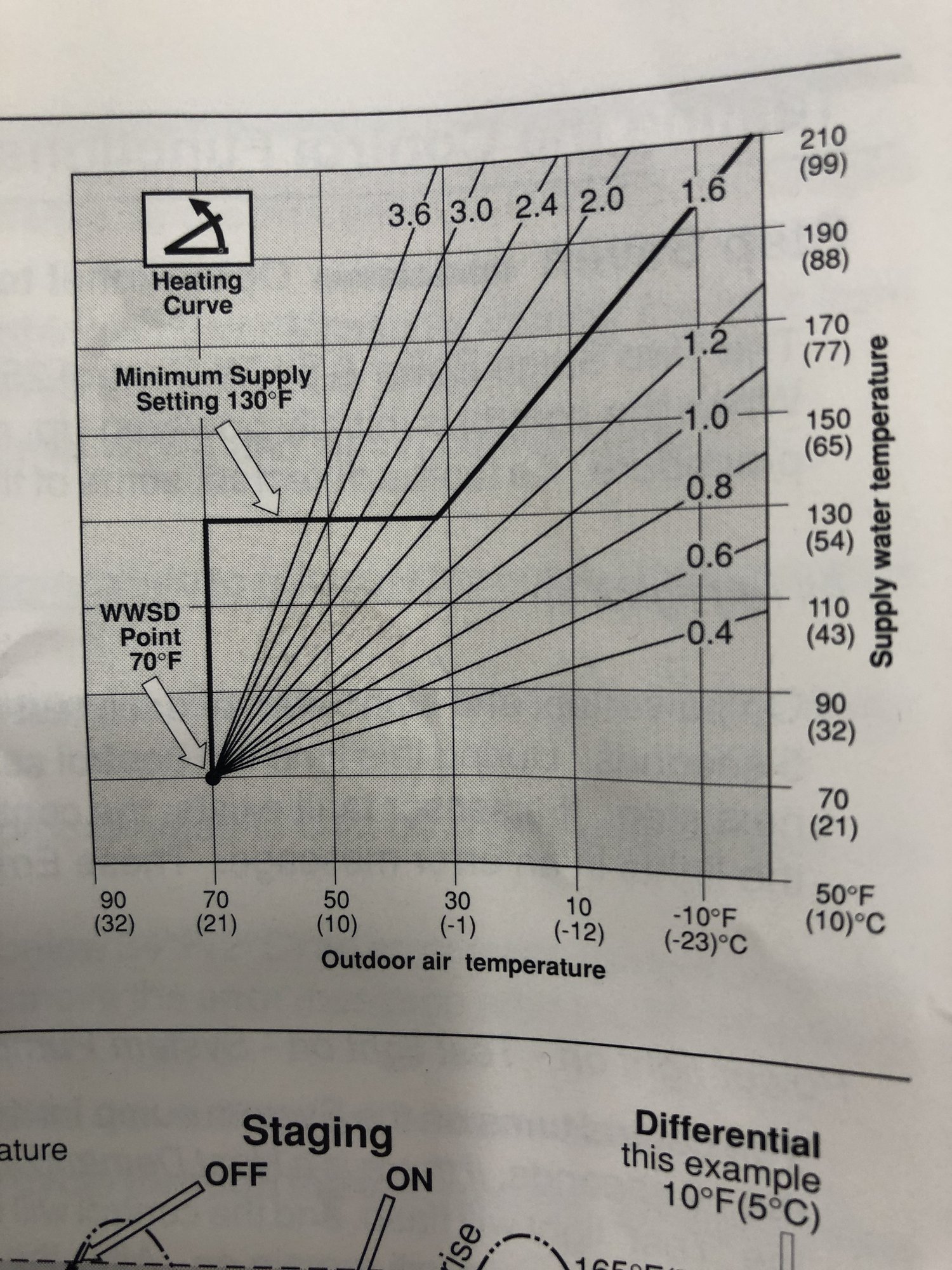

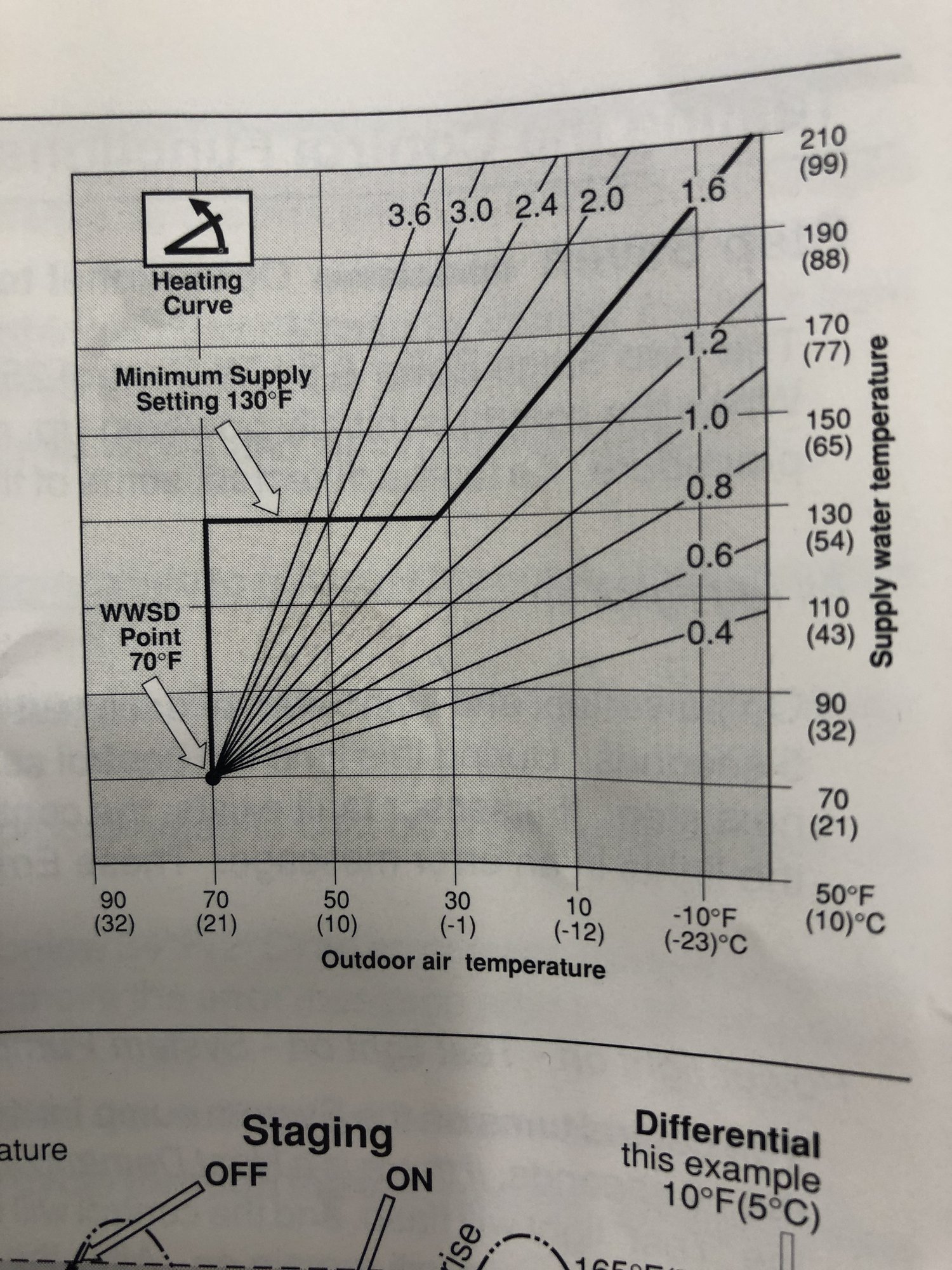

I’m just now installing an old Tekmar 252 and trying to understand the principle of minimum supply temp and heating curve.

As I understand it: If the outdoor sensor is below WWSD and there is heat demand from end switch, the control will look at heating curve and minimum boiler temp and see if it should cycle boilers on/off based on this, within +- range of differential setting.

For example if my minimum supply temp is set at 140 with differential of 22, (curve at 1.6,) the boilers will fire until supply sensor reads ~151, and turn off until supply sensor reads ~129. As I understand it, it happens this way because we are not yet “in” the heating curve as outdoor temps are still too high (55 F.)

With 1.6 curve set, when we get closer to outdoor temp of 30 F, the control should begin using the curve and heat beyond the minimum supply temp + 1/2 diff, all the way up the curve to boiler aquastat setting.

With 1.6 curve set, when we get closer to outdoor temp of 30 F, the control should begin using the curve and heat beyond the minimum supply temp + 1/2 diff, all the way up the curve to boiler aquastat setting.

I’ve been taught this cast iron boilers+hydronic baseboard system should be running at a temp of 180, and so because the supply sensor is a bit downstream and it seems several degrees below the boiler temp, I’ve set the min. supply temp dial to where it’s shutting stages down just a bit below where the boiler aquastat is set, (kind of defeating the purpose of a supply control for the moment, I guess?)

Depending on how the timing lines up, the thermostat can shut down heat demand and because circ pump also shuts down with no call for heat, the boiler can continue to rise in temp and I would guess it could get hot enough to fire the high temp cutoff. (Hasn’t yet.)

if it won’t harm the boiler and equals some energy savings, seems I could lower that minimum supply temp, but my main purpose with this control was to rotate the boilers and maybe get more out of the 2-boiler system on the very cold days. Maybe it will become clearer how this control is useful with regard to supply temp when the weather actually gets cold and “curve begins.” Boiler has primary/secondary loops that mix return and supply so I’m assuming that helps avoid the condensation.

Depending on how the timing lines up, the thermostat can shut down heat demand and because circ pump also shuts down with no call for heat, the boiler can continue to rise in temp and I would guess it could get hot enough to fire the high temp cutoff. (Hasn’t yet.)

if it won’t harm the boiler and equals some energy savings, seems I could lower that minimum supply temp, but my main purpose with this control was to rotate the boilers and maybe get more out of the 2-boiler system on the very cold days. Maybe it will become clearer how this control is useful with regard to supply temp when the weather actually gets cold and “curve begins.” Boiler has primary/secondary loops that mix return and supply so I’m assuming that helps avoid the condensation.

Am I close to grasping this correctly?

0

Comments

-

I think you are understanding the "old-school" outdoor reset of the 252.

As for the optimal boiler temps, while still avoiding flu gas condensation, we would need a bit more info. How are the primary/secondary loops piped? Is your vent galvanized? Is the vent entirely within the building envelope? Pictures would help."If you can't explain it simply, you don't understand it well enough"

Albert Einstein0 -

@Zman Circulators at boilers are in backwards in this drawing but this is how it’s piped. Yes vent is galv inside I think.

@Zman Circulators at boilers are in backwards in this drawing but this is how it’s piped. Yes vent is galv inside I think. 0

0 -

System was designed originally with an old WM control and was wired to same basic setup with outdoor temp and supply temp sensor like I have right now with the 252. Can’t find anything on original WM “System 1” control but it appears to have been something similar to the 252 in terms of being an older outdoor reset control.Outdoor temps are still in the 50s now, so it may just be that there isn’t enough heat dissipation to test properly, but when I let it run a couple of hours and time the system cycles, it’s 10-12 minute off-on but then once it gets the zones up to TS temp (72 for testing) heat demand cuts off, it begins to short cycle, with a longer OFF cycle, but ON is about 5-6 min.Min supply temp: 135

diff: 22

My boiler temp gauge ranges from about 140 at stage 1 on, to 180 at stage one off. I assume this temp difference is just how it works when supply sensor is ahead of system circ pump. (Is this the right place for it?) Return pipe temp measured at “primary loop” at boiler fire time does seem to be a bit lower than it should be, (125-130) but the piping here does mix return and supply.

If I set the system to permanent heat demand the cycles are more like I’d expect ( >10 min) on the OFF cycle but short on the ON cycle, but I think this is because the zones were up to TS temp and their valves were closed. Is it a common thing to run boilers continually heating and circulating, and then the zones open as their respective thermostats call for heat? It’s worth noting here that there’s a smaller 1st floor loop where the zone valve has been removed for “some” reason, and so a “constant on” or any heat demand condition always circulates that loop. Said loop also contains a run near a garage door, vulnerable to freezing if it were to stop circulating...?I ask this because it appears this is how things were wired when we occupied the bldg: the pump wired as on all the time, and I now believe there was also intentional wiring for a constant call for heat, with firing managed by boiler aquastat alone. (I had assumed along with heating contractor that based on the old equipment, there was a better way, but maybe there isn’t?)

In this “permanent demand” setting, is it possible to simulate something closer to the delta of colder days by raising the thermostats? Does the primary-secondary piping make it safer to increase the diff and let the boiler temps drift lower, to achieve longer cycles?

Does all this testing just work a lot better when it’s finally cold enough outside?0

Categories

- All Categories

- 85.7K THE MAIN WALL

- 3K A-C, Heat Pumps & Refrigeration

- 49 Biomass

- 418 Carbon Monoxide Awareness

- 71 Chimneys & Flues

- 1.9K Domestic Hot Water

- 5.2K Gas Heating

- 92 Geothermal

- 149 Indoor-Air Quality

- 3.2K Oil Heating

- 59 Pipe Deterioration

- 847 Plumbing

- 5.8K Radiant Heating

- 371 Solar

- 14.5K Strictly Steam

- 3.2K Thermostats and Controls

- 50 Water Quality

- 38 Industry Classes

- 47 Job Opportunities

- 15 Recall Announcements