Welcome! Here are the website rules, as well as some tips for using this forum.

Need to contact us? Visit https://heatinghelp.com/contact-us/.

Click here to Find a Contractor in your area.

If our community has helped you, please consider making a contribution to support this website. Thanks!

Time to make some threads

Options

ChrisJ

Member Posts: 17,067

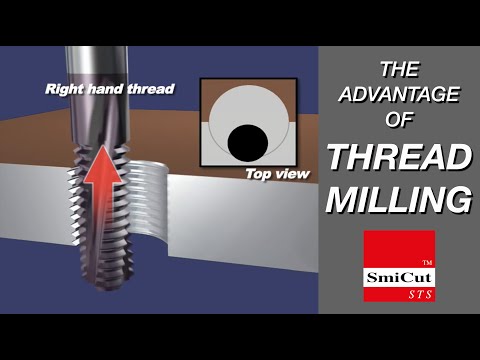

Due to issues with burrs on the last units we made I'm going to be milling some female 1/8" NPT threads in 316SS soon.

The things I like about thread milling is if a break the threadmill off it simply falls out of the hole. I can also adjust it so my threads fit a specific part perfectly with little to no slop. When done right and compared I feel it makes tapped threads feel pretty terrible.

This will be my first time doing NPT threads with one.

The things I like about thread milling is if a break the threadmill off it simply falls out of the hole. I can also adjust it so my threads fit a specific part perfectly with little to no slop. When done right and compared I feel it makes tapped threads feel pretty terrible.

This will be my first time doing NPT threads with one.

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0

Comments

-

So does the part need to rotate and move up and down the pitch of the thread as it rotates?0

-

On my machine the part moves in X and Y and the tool spins and moves in Z (vertical).mattmia2 said:So does the part need to rotate and move up and down the pitch of the thread as it rotates?

I'm going to try and take a video of it in the next few days.

I've done a lot of normal threads but this will be my first time milling npt threads

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Does that mean that the tool rotates around the work, or am I misunderstanding?ChrisJ said:On my machine the part moves in X and Y and the tool spins and moves in Z (vertical).

I'm going to try and take a video of it in the next few days.

I've done a lot of normal threads but this will be my first time milling npt threads0 -

The tool spins like a drill bit and moves up and down and the part moves around horizontally.ratio said:On my machine the part moves in X and Y and the tool spins and moves in Z (vertical).

Does that mean that the tool rotates around the work, or am I misunderstanding?

I'm going to try and take a video of it in the next few days.

I've done a lot of normal threads but this will be my first time milling npt threadsSingle pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

0 -

Single pipe 392sqft system with an EG-40 rated for 325sqft and it's silent and balanced at all times.

2 -

That's awesome. Do you use it to make male threads too?0

-

great animation!Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

-

I have been using a high-performance two-flute PCD (diamond) threadmill at work. M24x1.25 inside threads in aluminum in about one second. 18,000 RPM and .3mm/rev (automotive left the inch system long long ago) Up to this point all I have used is been plain ‘ol Emuge carbide.Love the remark about how a broken threadmill just falls out. The threads are still usually junk, but broken taps=sadness. Broken spindles = even more sadness. G0 does not a G1 make.0

-

I really enjoyed reading this THREAD! or is this a POST? maybe a discussion?

I'll call it a Thread, mainly for the contentEdward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 114 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements

https://youtu.be/rDnavOlGcdc

https://youtu.be/rDnavOlGcdc