Weeping PRV.

Hello all. My expansion tank failed this morning in my gas fired hydronic system. In an effort to save a some hard earned cash, I changed the tank myself since it was easy to isolate with shutoff valving. I did not however replace the PRV valve and after flushing Im still getting a very slow drip. Any chance it may totally re-seat or is my only option to replace? This does not as easy to isolate as the tank was. Appreciate the help in advanced.

Comments

-

it is not uncommon for a fill valve to not shutoff tightly if it hasn’t been used for some time. Rust and debris , especially with the iron body types, gets in the valve mechanism. If you have a manual shut off valve, turn it off and observe pressure .

Did you check the air pressure on the tank before you piped it in?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

By code you can not have any valve between the boiler and a relief valve. that would defeat the purpose of the relief valve.

What is the pressure on the gauge when the relief valve is weeping? The relief valve is doing its job if the pressure is near or above 30 PSI. If the boiler pressure is at 12 or 15 cold and increases to 18 or 20 then your system is operating normally with the new expansion tank. if your relief valve is still weeping at these lower pressures, then try to operate the valve two or three times with a fast snap action. thn see if it seats a little better.

After that if the valve does not seat properly, then replace it.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I did check the tank before installing. Was pre-charged at about 14psi.

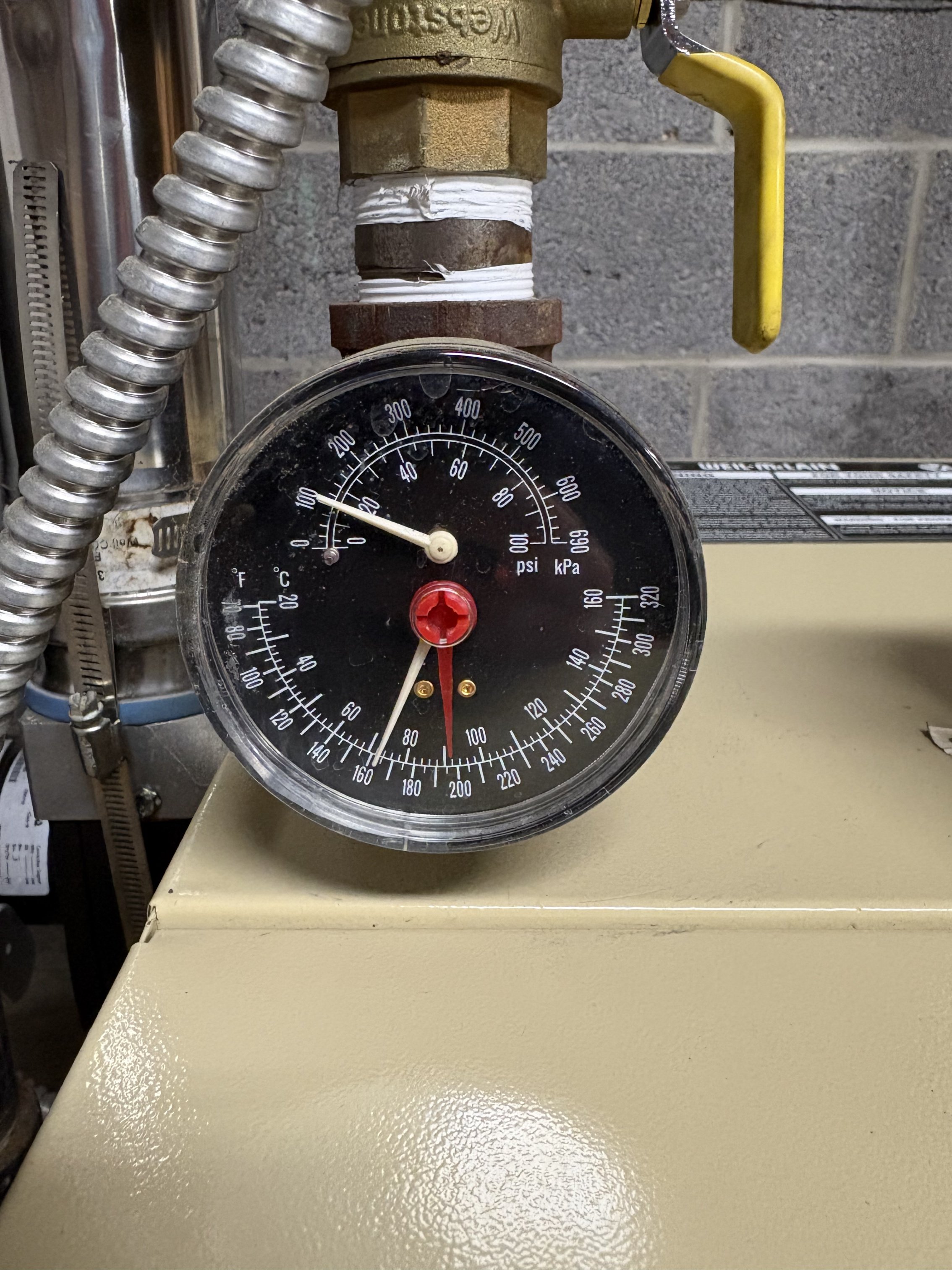

My boiler pressure seems to be staying within normal operating ranges. About 12-15psi cold, which matches the pressure of the infeed automatic fill valve (15psi) Works it way up to about 20psi under a heating cycle. The PRV has a very slow drip throughout the range.

0 -

Do you mean that the feeder is passing? Dripping from where? Is it a dual unit with a feeder and relief valve combo, or a combination unit with the feeder and backflow? Take a pic so we can point you in the right direction.

0 -

-

Sorry all. I should have been more clear. Pressure relief valve. Checked on it this morning (now) getting ready for work. Boiler pressure right at 15psi with the circ pump on and indirect tank zone valve calling for heat. Very minimal water in the pail I put under the relief valve to monitor. Pics attached. This amount of water is about 9hrs as I wiped the pail out at 7PM. 4AM now.

0 -

PRV is generally used when referring to the Pressure Reducing Valve (automatic fill valve). I believe you're talking about the 30 psi boiler relief valve. There's some confusion.

You don't need to drain the whole system. Isolate everything you can. Close air vent caps if any. Drop boiler pressure to 0 psi. Have the new one prepped and ready. Pop the lever on the old one before removing to verify no pressure. You might need to purge. Check the zones.

Whoops. Just saw your post this morning. The drip leg even has a compression adapter. It'll take you less than an hour. I was going to question if the pressure on the tridicator is correct, but that's hardly a drip.

3 -

TPRV is your device that is leaking. A Temperature Pressure Relief Valve. PRV for the Pressure Reducing Valve or "fill valve."

0 -

-

When changing your expansion tank, something got caught in the relief valve that has slightly damaged it not allowing it to seat water tight. The only thing left is to change it.

If it were my house, I would give it a chance to right itself. Why? Because the amount of water it is losing is very little and might just stop or heal on its own. Ive seen that happen quite often. Monitor it and see.

0 -

The issue with it healing on its own is that it might just get crusted shut with scale causing the valve to possibly not function as intended. I would change any boiler relief valve that has discharged due to a high pressure event, definitely if it is weeping after. I might be nuts but the relief valve is a pretty important safety device in my opinion.

3 -

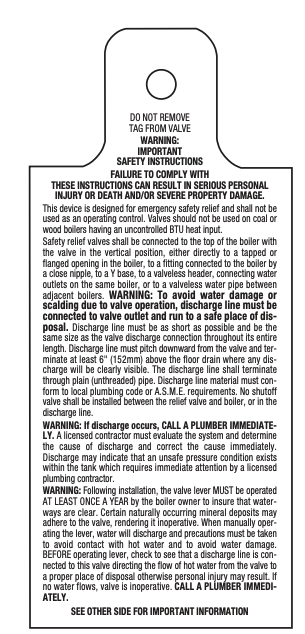

The tag attached to Watts boiler relief valves indicates testing yearly and the corrosion can render the valve inoperative. I imagine other brands have the same instructions?

I have seen water heater relief valves locked closed from scaling.

It is one of the least expensive component on the boiler, cheap enough to replace for the amount of protection it provides and eliminate fresh eater from entering the system.

If you do open a valve to test it, have a spare on hand, more often than not they drip after a test opening.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hi, Agree with what @hot_rod just said. I've tested thousands of T&P valves, and in my area one in forty is plugged solid with mineral. It could easily be considered negligence to not test them. 🤔

Yours, Larry

1 -

manually open that valve fully then reset it.

sometimes you get lucky.

keep a spare on hand0 -

Absolutely. I have seen all of the warning labels and all the rest. His does not look like a need to go into some level of panic mode. It should be fine, and if he wants to test it. Certainly. Why not. Just hope there is a new replacement on hand.Its not a huge issue yet. Hence the words in my earlier post stating…"monitor it".

0 -

The state boiler inspector wants to test these all the time, (it is the only thing they can mess with every year).

So after they leave they are dripping and the owner calls.

I open them to get a good flow of a gallon or more and then let the lever Snap shut that will usually fix it. If still a drip I tap on the lever/rod with rubber handle of a screwdriver, if a no go then replace it.

4 -

Yes. Absolutely good advice. And as the OP home owner and DIY'er, he will need some coaching along the way if he decides to replace it. No green scale is apparent or other corrosion that would hinder it at this time. The thing even looks new in the picture above. Monitor it.

I cannot count the amount of times they have stopped weeping on their own simply because the washer and seat have re-molded due to the boiler heating and cooling with a few heating cycles then were tested and working properly afterword. And with what @JUGHNE good advice says above.

Ive also done replacements to soon and could have waited a bit as this OP can, he's the home owner. He's not making a service call. I have even changed them under similar circumstances (proper pressure and temp.) and have had the new one leak. Go figure.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements