Two pipe steam heat banging

Home built in 1900. I’ve had near boiler piping repiped, but it still bangs tremendously. It is: two pipe, gravity return, no traps, I have found check valves at the returns of the radiators underneath floor boards, one main vent in basement (Hoffman 75H), boiler running .5 psi, each radiator has one Hoffman 1A vent. The boiler is toward the front of the house. Banging is only toward the rear of the house with the longer main. The shorter main has no banging. Shorter main is 15ft, longer is 40ft. There is clicking at the radiators and the banging from the longer main comes up through the pipes. Banging is at the beginning of the cycle. All radiators properly pitched. I have not found any traps or other vents. 15ft main return pipe mostly stays cool except for the pipe closer to the boiler. Long return pipe with Hoffman 75H vent is piping hot and I think that is the issue. What can I do to stop the banging? Water line to wet return is 5”, water line to main vent is 58”, water line to headers is 45”.

Comments

-

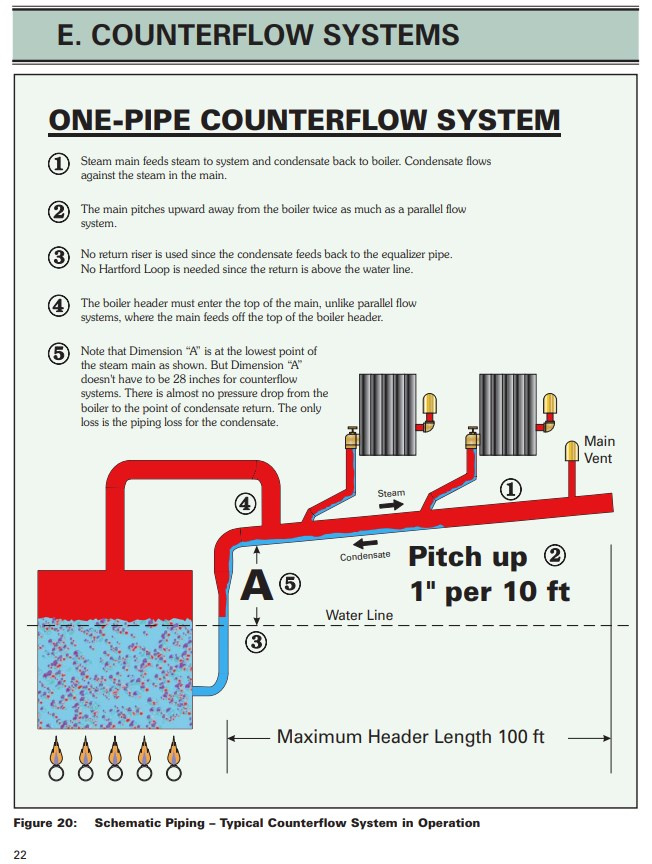

I think we need a couple more photos from different angles. That's a mess (sorry). So it is counterflow mains? My understanding is that in a counterflow system, the condensate in the main should flow back into the boiler through the equalizer only and the header should be located higher than the equalizer (your parallel header) and elbow into it from above and before where the two mains tee off of it.

Edit to add - sorry. I realized it is a pdf with lots of photos and I just scrolled down and saw them all.

0 -

Somebody really liked bushings (which cause puddles). Hartford tee looks low from that angle. The boiler has a pressuretrol which means when it's under pressure its running at 1.5 psi (lowest possible cutout). Need more pics, and pics of rads.

0 -

Why is this bushed down to such a small diameter from the Tee and then the reducing elbow brings it back up to a larger diameter?

0 -

This, the vertical section of equalizer, should be more like min. of one pipe size smaller instead of being bushed down so small. Seems like in a counterflow main situation this might be all the more critical:

0 -

Just trying to narrow things down for the OP instead of widening things out here—the equalizer size is not causing the banging.

The header sure is weird.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

How are the mains connected to the dry returns, if at all?

My bet is going to be that that long 40 foot main has sagged. It doesn't take much of a sag to cause a mighty anvil chorus on startup. So… take the insulation off or use a probe, and check the pitch of that main between every single hanger. If there is more than four to six feet or so between hangers, add a hanger and set it to pitch. You don't really need that much pitch — but it has to be consistent and it has to go to a drip.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

Above near boiler piping issues were not intended as an all encompassing solution to the problem by any means. We need some more information. Here's a few questions I have. All pipes need to be properly pitched in the system of course, so that there is no pooling of condensate. Wet steam and near boiler piping issues will make things worse but is by no means the main cause of what you are experiencing.

What is happening at the sight glass when the banging occurs? In other words, is it bouncing up and down dramatically? Has it gone down lower than the initial level and how much has it gone down? What is the exact height of the Hartford Loop close nipple relative to the normal water line? What is your water quality like, ie. is it filled with rust particulates when you drain some from the bottom of the boiler?

What boiler manufacturer, model, and size do you have?

0 -

header is wrong. i don't think the reducers are a problem but the equalizer should connect after the mains so any carryover returns to the boiler thorugh the equalizer, not gets propelled up in to the main. your equlaizer connects in the opposite direction of the mains.

0 -

@2pipesteam You drew your pen and paper sketch as a counterflow main situation. Is that correct, ie. the pitch of the mains goes downhill towards the boiler?

What is the pitch of both the first header and what you referred to as the parallel header? If the other parallel header is not pitched downwards towards the equalizer, and you have counterflow, then you are going to have a problem.

1 -

if it is counterflow there should be drips on the mains before they get to the header although you might get away without them on 2 pipe if the header were otherwise correct.

0 -

Yes the mains are counterflow and the mains are not connected to the dry returns. There are no drips on the mains. Is it a problem that the return pipes get so hot? So with this setup will the equalizer prevent steam from entering the dry returns? My theory was that steam was entering the dry returns and making them bang around, but the pitch of the mains could easily be a problem as Captain Who and Jamie Hall pointed out. The long main is encased in drywall, but sounds like that could be the culprit. The short dry return towards the front of the house does not get as hot as the long return and does not bang. There is no banging at the near boiler piping, all the banging comes from the long main at about 20 feet from the boiler where it is encased in drywall. There is a slight pitch of the header toward the equalizer. I don't know the reason for the bushings other than to match the diameter of the mains going out. As Mattmia2 pointed out, in the drop header, steam to the main goes in one direction and steam toward the equalizer goes in the opposite direction, can that be done? Won't the steam hit the waterline in the equalizer and stop? Also, I think the carryover will drip into the drop header and drain back towards the equalizer right? All radiators are setup the same way, as attached. Hoffman 1A, gate valve for supply at top, return on the same side at the bottom with radiators pitched toward the return. No traps.

0 -

If the dry returns are getting warmer than warm, steam is getting in them — and that should NEVER happen.

Possible causes. Failed traps, number one. Excess steam pressure, number two. In your system, where there are no visible traps, my money is on excess steam pressure. Anything over 8 OUNCES per square inch is too much, and half that is better.

You may need a vapourstat to control your steam pressure.

You need to find out why and how steam is getting into the dry returns, and fix that. Then go back and work on the banging.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

Vaporstat is a great idea. I will check the pitch of the headers, right now they produce no noise. If I have counterflow mains where the mains don’t connect to the return, the system would be trap free right? The Hoffman 1a effectively act as a trap because they stop letting steam into the radiator once the steam hits the last radiator column.

0 -

Now I'm confused. On the one hand, you say there are no traps. On the other, you say there is (are?) steam vents.

The one radiator in the photograph .pdf above is piped as a two pipe radiator, although a bit oddly — but with a steam vent, which will accomplish exactly nothing, assuming that the return is vented.

What the vent won't do is stop steam coming in — it will, if the pressure is great enough, go right back out the return pipe.

Are all the radiators like that?

Now if they are, and your steam diagram .pdf is correct (further up), you do have a two pipe system. Why someone put vents on is beyond me.

And I will go back to what I said: get the pressure down. If the return pipe gets steam hot, more drastic work may have to be considered… probably orifices, since the valve at least in the picture is unsuitable for being a metering valve.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

this looks like some sort of 2 pipe air vent system which can have steam in the returns. if the steam in the returns is normal then the returns need to be arranged so that the steam won't collide with water and hammer.(i might be wrong about the 2 pipe air vent but it is hard to say from what we have seen so far. those radiators don't really look like they've had much reworking, it looks like the vent belongs there)

if it is supposed to be a vapor system then the original valves need to be on the radiators and they need to be adjusted correctly or they need to have orifice plates or they will let steam in to the returns. the mains probably need to have vents one way or another as well.

that near boiler piping is not a drop header, it is an abomination of fittings put together to put the pipes together with no understanding of what those pipes needed to do.

the steam is flowing toward the mains so depending on what the velocity of the steam is, it could be pulling the water wit it and up in to the mains, too much velocity and the water can't get to the equalizer, that is why the equalizer is supposed to be beyond the main connection, not in the opposite direction. since that piping is all pretty small my bet would be on the velocity being enough to prevent the water from running downhill and pulling the water up in to the mains.

0 -

I think we need to pump the brakes here. Is everyone, including the OP, absolutely sure this is originally a steam system? We have seen contractors mistake a gravity hot water system for steam before.

The radiator piping is creative, and looks far too small to reasonably be for steam. It also doesn't align with a gravity hot water system, so I'm not even sure what to make of it.

To the OP if this really is a 2 pipe steam system, none of the radiators should have vents on them. 2 pipe air vent systems, which are really a one pipe with drain, have one pipe sized piping and both connections on the bottom. So the radiator pictured doesn't align with that either.

Are all the radiators in the house piped similar to that one?

We see a lot of unusual stuff on this site, but for me, sometimes it goes past unusual and presents as something is wrong.

I honestly don't feel anything can be addressed or even answered until we determine exactly what the system was originally.

1 -

i considered that it was gravity hot water someone put a steam boiler on but it didn't really strike me as that. in a gravity hot water system the mains and returns will be about the same size, in a 2 pipe steam system the mains will be much larger than the returns.

0 -

I agree with @KC_Jones here. If this is steam, it's verry odd. Can't be hot water — the vents wouldn't hold against hot water.

Boots on the ground time.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

After doing some more digging and rereading the Art of Steam, I think that this is a vapor system given the house was built in the early 1900s. There are check valves (see picture) on the return side underneath the floorboards (not visible from the pictures of the radiator). I think that this is a Donnelly weighted swing check valve. The check valve won't open to discharge condensate into the return until a half-pound of pressure is present in the radiator. Once open, the steam pressure moves into the return piping and combines with the "A" Dimension to put the condensate pack in the boiler. There is a tiny hole to allow air to pass, but only a tiny amount of steam can pass through the tiny hole. Maybe the check valves stopped working so the way they tried to fix it was by adding the Hoffman 1A vents? I have only been able to find one main vent in the basement at the ceiling of the dry return right before it drops down to the boiler. Without a vaporstat, I will continue to get the banging as the system was design to use just ounces. Is there anything else I should add with the vaporstat? Also, if it is a donnelly system, should it have a lever handle valve sized to allow only 80% the amount of steam that the radiator can handle? At the same time the system was repiped, all new gate valves were installed at each radiator. Is this a situation where I should consider removing the check valves and installing traps?

If I crank down the pressure even more, won't that increase the velocity and run the risk of putting more water in the mains?

0 -

Hmm pretty sure the only time you vent the rad on a two pipe is when each rad drops its return into the water, which is not the case here

Besides the banging, does it heat the house well or poorly?

0 -

that is the typical 2 pipe air vent system but i think there is a diagram in tlosh that shows multipole radiators on a common return. this means steam is likely to get in the return but i don't think it is a problem because if it enters a radiator from the return it will rise to the top and push the air down so I thikn the radiator will still fill with steam from the top and push the air out the vent regardless of if the steam comes in the supply or the return.

in conventional 2 pipe steam with a radiator trap the steam in the return will enter the radiator through the trap and immediately close the trap, preventing the radiator from venting properly.

it might cause a problem with water hammer in the returns if they have places that they can collect water.

0 -

if this is indeed a vapor system you either need the metering valves on the radiators or to put orifice plates in the union for the valves.

in addition to the vaporstat I would add a low pressure gauge that can read in the range of the vaporstat. if the boiler is sized properly it may not be building pressure in the first place.

if the metering valves are missing on the radiators, steam will blow right through the radiators and in to the returns.

0 -

The system heats the house very well. The return pipes get hot with the radiator, but I think the check valves should stop the steam there. So sounds like I need to buy appropriately sized handle valves?

0 -

you would either have to use a metering valve like this

or an orifice plate. the original valves are no longer manufactured. whoever removed the original valves instead of rebuilding them butchered the system

0 -

Understood! Thank you!

0 -

I just installed the vaporstat. Given this is an old vapor system, Donnelly I think, set the vaporstat, set the cutout at 7oz and cut in at 3oz?

0 -

-

On my system, a 4psi vaporstat won’t give me the low pressures I need will it?

0 -

-

@mattmia2 do you have a preference or recommendation which is better an oriface plate or a metering valve? I plan on installing the 0-16oz vaporstat running at 6oz with a 3 oz differential.

0 -

the valve is easier to adjust, the orifice plate is much less expensive but you have to change the size of the hole if you need more or less steam to that emitter.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements