Steam Heating Help

I have church I was working on. I replaced the 1960's Lennox oil burner with a new SF Beckett on a hot air furnace. While I was there the local big commercial contractor was there working on the steam system in the old part of the church. They were having problems with condensate return. They left and said it was working and 15 minutes later it was out again. I have read The Art of Steam Heating in the past and I know enough to not really mess with it.

My question is about the condensate pump and why its needed in this situation.

Comments

-

A condensate pump or boiler feed pump is used if for some reason some issue (usually elevation) prevents the condensate from coming back to the boiler by gravity.

Condensate pumps and boiler feed pumps are similar but different. A condensate pump is controlled by a float switch (like a toilet tank) that operates a switch to start the pump. When the condensate comes backit rises in the tank trips the float switch and the pump pumps the water into the boiler weather it needs the condensate or not.

A boiler feed tank also collects condensate, but the pump responds to a pump control mounted on the boiler.

0 -

the condensate generally returns to the boiler by gravity but depending on design of returns and how high it is possible for them to be kept the condensate may not be high enough to put itself back in the boiler by gravity as each pound of pressure reflects roughly 28" of extra height for the gravity to overcome.

if the return is carefully engineered and the boiler is run at what are considered vapor pressures, i.e., well under 1 PSI, it may be possible even on large systems to forego condensate pump but condensate pumps do the job with brute force in circumstances of low often 'wet' returns.

that said, condensate pumps are generally pretty straightforward and resilient. it is some thing to go wrong and I avoid where possible but they shouldn't be too hard to keep serviceable. worst problems i've had is having to macguyver the receiving tank where the attachment points for the pump have rotted or corroded.

this was a project that had a condensate pump which i believe was required because the previous boiler had a much higher water line but I expermentally bipassed the condensate receiver with one of the returns and running at vapor pressure the system had no problem operation without a return pump. I used clear polycarbonate tubing for the experiment so I could observe the process. What you notice is that the water in the return is higher than the water in the boiler by about the number of inches reflecting by the operating pressure. it is hard to gauge from those pictures because they don't have very much resolution the way they were posted whether there might be any opportunity for eliminating the condensate pump. on a guess this is an updated boiler perhaps shorter and having a lower waterline than the original but that is just a guess.

https://www.youtube.com/watch?v=GCv7iKi0xgg0 -

Al that's very fine — but the first thing to do is to see if the pump and receiver are operating as a boiler feed tank and pump, or a condensate tank and pump! The two often look exactly alike — except they are controlled differently.

The thing is, a condensate tank setup can, and frequently will, flood the boiler with unhappy results. The boiler feed tank arrangement, on the other hand, won't unless the boiler level switch malfunctions — which is rare. It does have to have an overflow to drain, however…

So that's step one. Which is it?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I have a feeling that the "old part of the church" may have had a large water content, hand fired, coal boiler some time ago. It may have been converted with an oil burner, and now there is a more modern boiler that you have pictured. The reason for the condensate pump or boiler feed pump is because the old boiler had a much larger water content than the newer boiler that is there now. As a result of the difference in size (not BTU size but water capacity size) there may be more water in the system than the newer boiler can accommodate as a result of the change.

This may have caused the new boiler to flood when the larger amount of condensate finally returned to the boiler. The fix is a boiler feed pump with a tank that can hold the extra water until the boiler feed control needed more water. The tank would supply the water rather than adding fresh water from the cold water feeder. That keeps the smaller water content boiler from flooding because the extra water is stored in the tank until needed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

@EdTheHeaterMan hadn't consider the flood problem, thinking more on A/B and the difficulty of getting water back in the boiler whereas getting too much hadn't occured to me. and this is along the lines of @Jamie Hall 's comment, where the condensate tanjk is more like a refrigerant reserve on a heat pump so it isn always that gravity couldn't put the water back but have enough in reserve. and i guess, maybe that is state of play vs. just a side car tank that isn't pumped but keeps the same water level as the boiler and piped parallel because a bigger tank might cost more money but its passive, i always prefer that. i've got an old weil mcclain rebadged triangle tube phase 3 DHW storage tank that I bought for 30 bucks on facebook as a side car on my steam for hydronic loads but the boiler side circuit only adds 6 gallons and for passive piping the high low side tappings for the boiler circuit are perfect although you could get 35 gallons of additional capacity if you used the domestic side in the boiler circuit with a circulator, or maybe if you reason out the piping you could get it to thermosiphon.

0 -

Okay that makes a lot of sense. Of it has an electronic water feed control. I think what is happening is the condensate is not coming back fast enough and the water feed doesn't feed enough water so it trips off on low water.

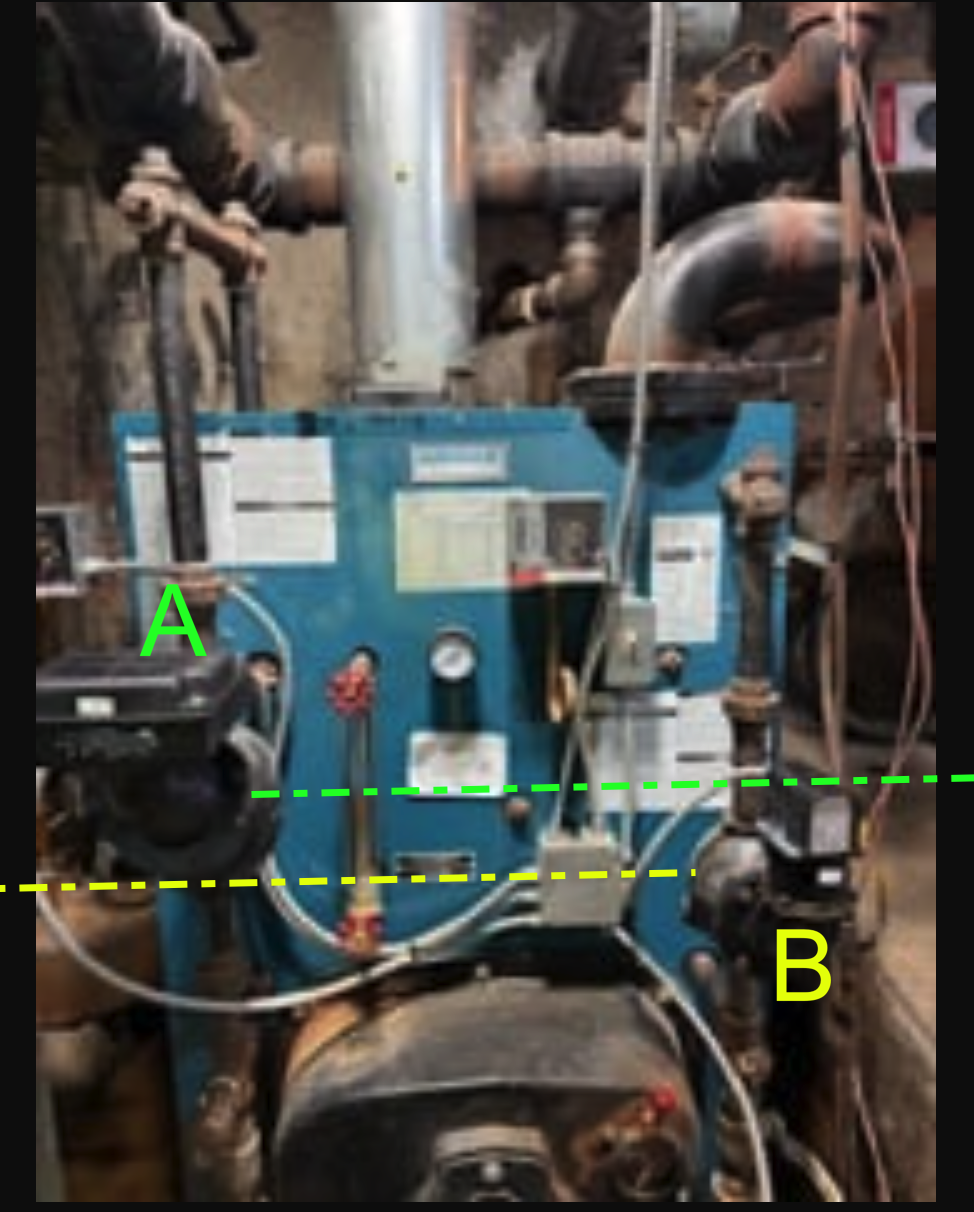

It is a small condensate pump you can see it on the left of the boiler. I wonder if a bigger condensate pump that holds more water would be a fix.

0 -

Looking at this photo there is a control to operate the feed pump on the left and another control on the right to add cold water if the feed pump can't keep up. The fresh water feed control should be about an inch lower than the boiler feed control. They are both low water cut off devices so it is tough to tell what the problem is without looking at how they are wired.

As a rule a boiler feed pump usually has a larger water tank. A condensate pump has the smaller tank and the church's boiler seems to have the condensate return size tank. As the system gets older and pipes get filled with mud and rust from years of operation, the condensate may not be returning as fast as it used to. The correct fix is to clean all the dirty wet return lines.

If you think you want to get involved, you really need to read up on the equipment and how it should be wired and how the condensate is actually returning to the boiler. Is it by way of the float in the tank turning on the pump or by way of the switch on the front of the boiler inside the control on the left?

Hope this helps.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

it would be helpful to have a few more higher resolution pictures of the boiler and the steam and return piping. i see two LWCO/autofeeds at two different levels as @EdTheHeaterMan points out, but am i hallucinating or is there another tank on the back left side so maybe one is condensate and one is feedwater tank? don't know if that is to mitigate temperature in feed water . . . ? I don't see returns to either tank. is it possible the mains are counterflow?

they aren't that high above the boiler so i can see a condensate return approach as a resonable caution but mostly because it is so damn hard to get good control on steam pressure. in the sample i showed in the video I moderated fire and kept it between 10 and 20 inches, but as @ethicalpaul points out and as i did on my last job I was running in the low single digits happily. i know steam is not a growth market but i can't believe we can't get someone to make a solide state vapor sensor to be paired with smart control to make for better vapor control and staging–to enable effective simmering, as it were.there is still an installed base of steam and the one effort i'm aware on the tekmar side that they charge plenty for steam controls to make up for the smaller number of units, but their pricey control is not focused on particularly useful indicia from my point of view, i.e. controlling vapor pressure and insuring stable operation. efficiency is, honestly, a secondary consideration for me but i think it comes with focus on vapor pressure. for the couple of grand the tekmar 289 misses the boat by attempting to mimic ODR with sensors for outside temp and condensate return temp but unless we are returning to vacuum systems ODR is largely irrelevant to steam–as has been much discussed in earlier threads. inside temp is what we are trying to regulate and it isn't that hard or that costly to get a thermostat with an anticpator. but the real problem with temp anticipation alone is it only chops cycles, it doesn't stage them or enable stable vapor pressure at low fire.

for most systems we deal with, you don't have zoning or smart valves that change the load and unless the space is starting from deep setback, the load in the rads jsut doesn't change much. it can change a little as some rooms warm faster than others but that would be somewhat regulated by condensation rate in that rad as long as the air valve is closed and the pressure is not rising. I'm mostly thinking of staging or even single stage operation as discrete rather than variable although I wonder why it isn't possible to make a simple variable control for atmospheric style. and they are expensive but available in power burners. maybe by indirect measures the 289 has an algorithm that really saves on insitutional size systems but i kinda tend to doubt it, although i'll go listen what those guys have to say in vegas.

but why no one has a staging controller with a solid state vapor sensor just blows my mind. how the hell hard is that? am i missing something? and what is needed is coordination with manufacturers so that staging can be effectively employed. and even if there is no staging, then you can reverse anticipate with time, e.g. downfire the single stage and then use ODR or time of day to start early in anticipation of load so that the lower fired single stage gets you steam by when you need it. (thus a lot of the anticipation discussion is on the wrong end of the cycle). if there are long downtimes and water goes to cold and there is any concern about condensation with low fire you could just keep warm the water and i don't think it would cost that much and would be balanced by downfire savings.

(sorry that's a little less about condensate return tanks although honestly it goes to their necessity in a lot of cases).brian

1 -

In this photo there are two McDonnell LWCO devices. the one on the left (A) looks like a M&M 150.

There are 2 switches in the control. One is a normally closed (NC) switch that can be used as a LWCO. The other switch is normally open (NO) switch and can be used to turn on a boiler feed pump, or activate a solenoid valve to add cold feed water. The switches are different from each other and can be adjusted to operate at different water levels so the water can be fed to the boiler while the burner is still running. Only if the water level drops further will the second switch open to cut off the burner.

The other control (B) appears to be a 51 series mechanical water feeder that is equipped with a No. 2 switch. (Often called a 51-2) the main purpose is to mechanically add cold water to the boiler when the float drops to a point where the boiler can accept more water. Much like the float valve on a toilet tank. That can operate similarly to the 150 because the valve can start to open before the No. 2 switch can shut off the burner.The fact that the two devices are more than 1 inch apart vertically tells me that they cannot function together as intended—one as a low-water cutoff (LWCO) and the other as a feeder that restores water so the burner can restart.

If the Model 150 shuts down the burner, the water level may stop dropping. If it never drops any further and the condensate return pump has no water to return to the boiler, the pump could end up running dry—which is not good for the pump. At the same time, because the water level is no longer falling, it may never reach the point where the Model 51-2 adds water. As a result, the water level would not rise enough for the Model 150 to allow the burner to restart.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I have made a drobox with high resolution images and a video.

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements