Steam Main Vent; Do I need new vents?

Hi! Just bought a house with my wife with steam heat. Not 100% unfamiliar with how it operates, but the venting situation is where I get hung up.

Been reading a lot about going with faster main vents and then slower vents at the actual radiators. Went down in the basement to see how the mains were vented and found this:

Obviously there is steam making everything moist in the right section, but wasn’t sure if there was really anything I could install to remedy that or if I need to somehow redesign the pipes.

Also, the left vent whines the whole time it’s on, the opposite side of it does have a line of rusty water so it’s a bit corroded, the right vent with the dark water stain area doesn’t make any indication it’s doing anything at all no hissing, whining, gurgling.

Just curious if there are any solutions for the inevitable rot in that area I need to redesign out, and/or what main vents would be best to replace these with.

Comments

-

Those are pretty anemic vents even when they are working. It looks, however, as though they were assembled with tape, so replacing them with new ones shouldn't be that hard. I'd suggest Gorton #2s.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

#2’s for the mains, ok. I have a total of 4 radiators on the first floor and 1 on the second floor. Currently I have sputtering heat timer variavalves with the metal tab to adjust and was thinking about replacing those as well. I’ve seen various recommendations on #6’s for the radiators themselves but no real description on why that size.

I appreciate the help!0 -

get your mains settled first before trying to balance venting at the rads,

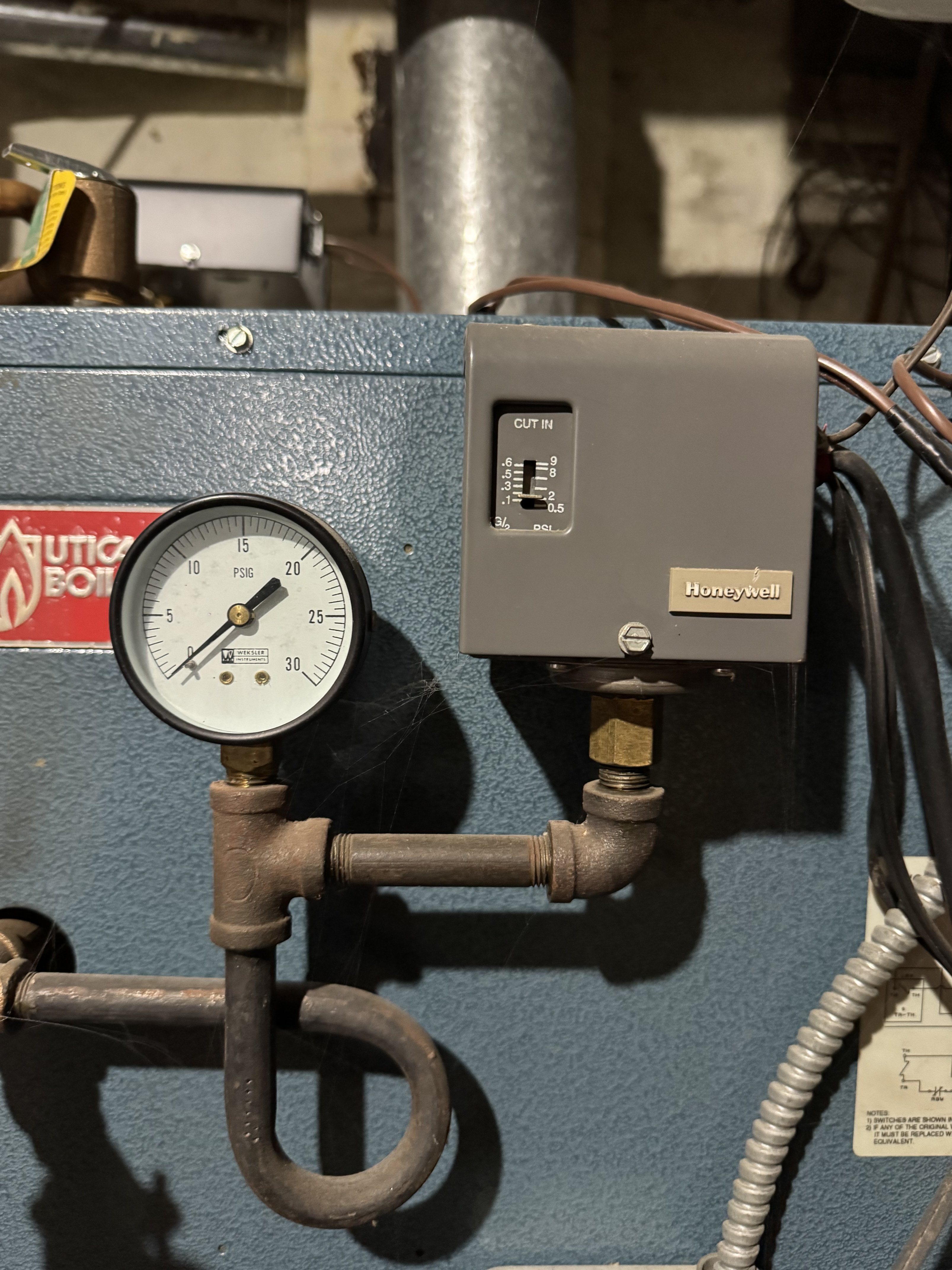

what pressure are you running the boiler at? have you serviced the pigtail so the Ptrol can see what the boiler is doing? pictures of the Ptrol, siteglass, LWCO, and maybe we'll see something there also,

known to beat dead horses3 -

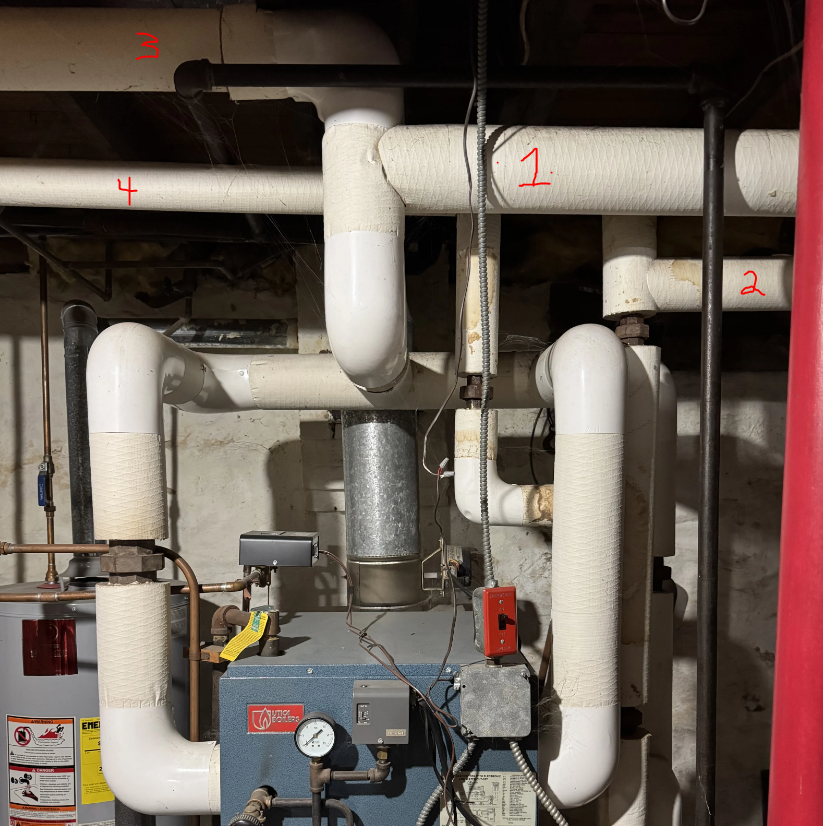

Also, how long are the mains, and what pipe size? This tells us how much air we need to vent from the mains.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

great question, not sure! I did read about the pressure possibly being too low for my gauge to register (first mark is 5psi) but feel as though that isn’t working either.

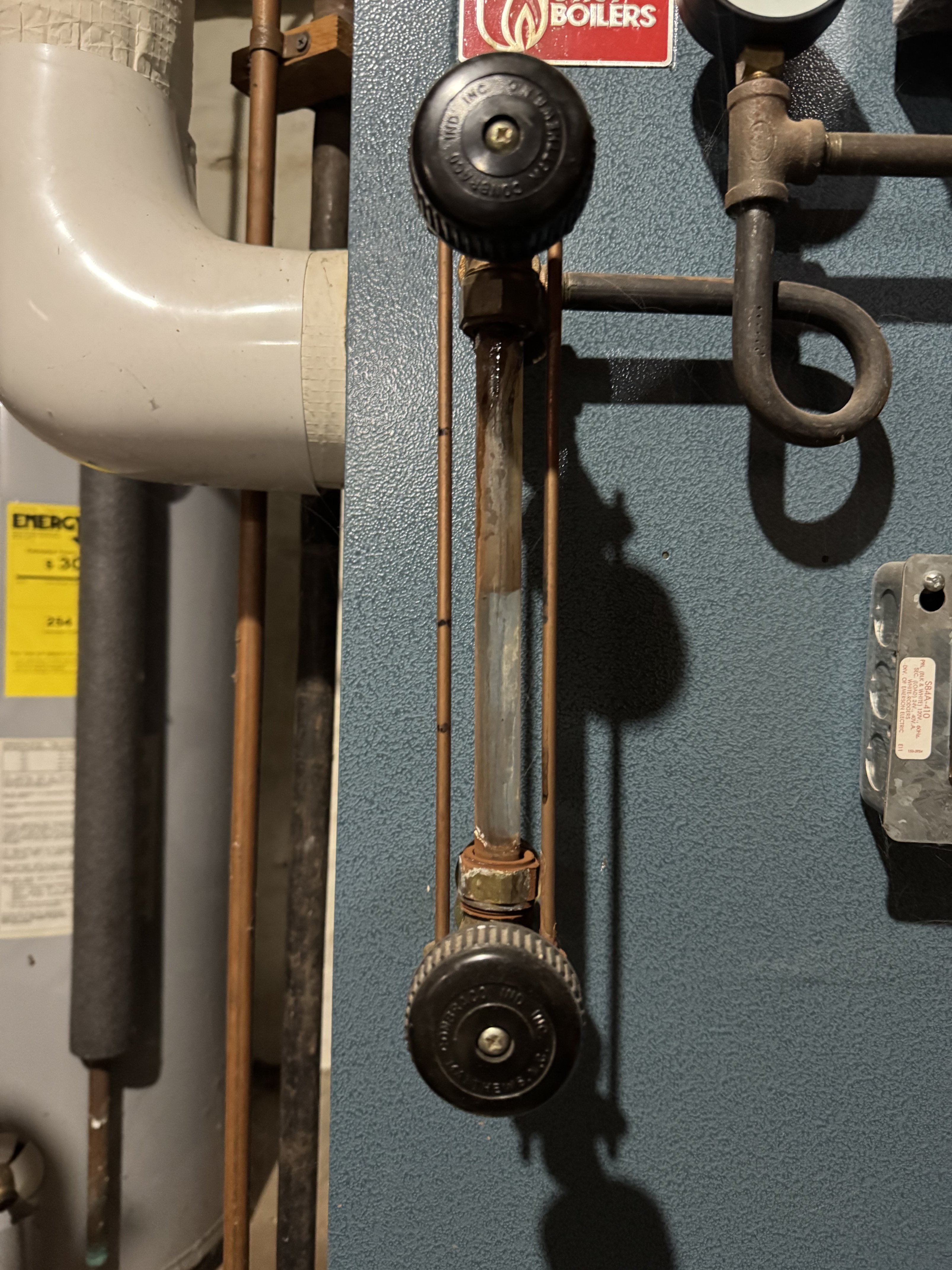

sight glass is normal as far as I can tell, there are sharpie marks where “too high”, “too low” and “normal” is, and it’s sitting at normal.

what I CAN tell you, at least at the moment, is that it ignites about once every 45 minutes, it has been extremely cold recently and when it’s a little more mild would be about once an hour or 90 minutes which seemed on par with electric heat and figured it was at least normal enough. I can also tell you that we were recommended getting it serviced but was told it looked recently serviced just not freshly serviced so we could probably run it this winter but definitely get it looked at in the spring so I guess average all around.as far as terminology goes, it’s a little Greek. I will provide images tomorrow of all of the system. It’s honestly nice to know people have all this knowledge directly, very appreciated.

0 -

"mains settled first" = get your main venting correct first before bothering to balance radiator venting,

Ptrol = Pressuretrol (or vaporstat) = device controlling the boiler pressure, gray box with a scale setting on it,

Pigtail = looped pipe under the Ptrol, should act as a trap and be protecting the Ptrol from direct steam, but prone to clogging solid so boiler pressure doesn't reach the trol, and boiler runs at excessive pressure, which blows vents and such, pigtails need servicing to keep them clear, yearly, or every couple years depending on water quality and mounting location,

LWCO = Low Water Cut Out, if water level gets too low, LWCO shuts the boiler off to prevent dry firing, or worse, also needs testing/service/blowdown depending on type,

siteglass so we see the water, when the boiler is firing, does the water level bounce much? more than an inch? does water wash down inside the glass from the upper fitting? both point at poor water quality, and could lead to some of the issues you wrote of, good that you see the level between the markings,

there's a book for sale on this site, or amazon(I think) "We got Steam Heat" it's a great easy read for steam owners, covers all above, and more,

https://www.heatinghelp.com/store/detail/we-got-steam-heat-a-homeowners-guide-to-peaceful-coexistence

known to beat dead horses1 -

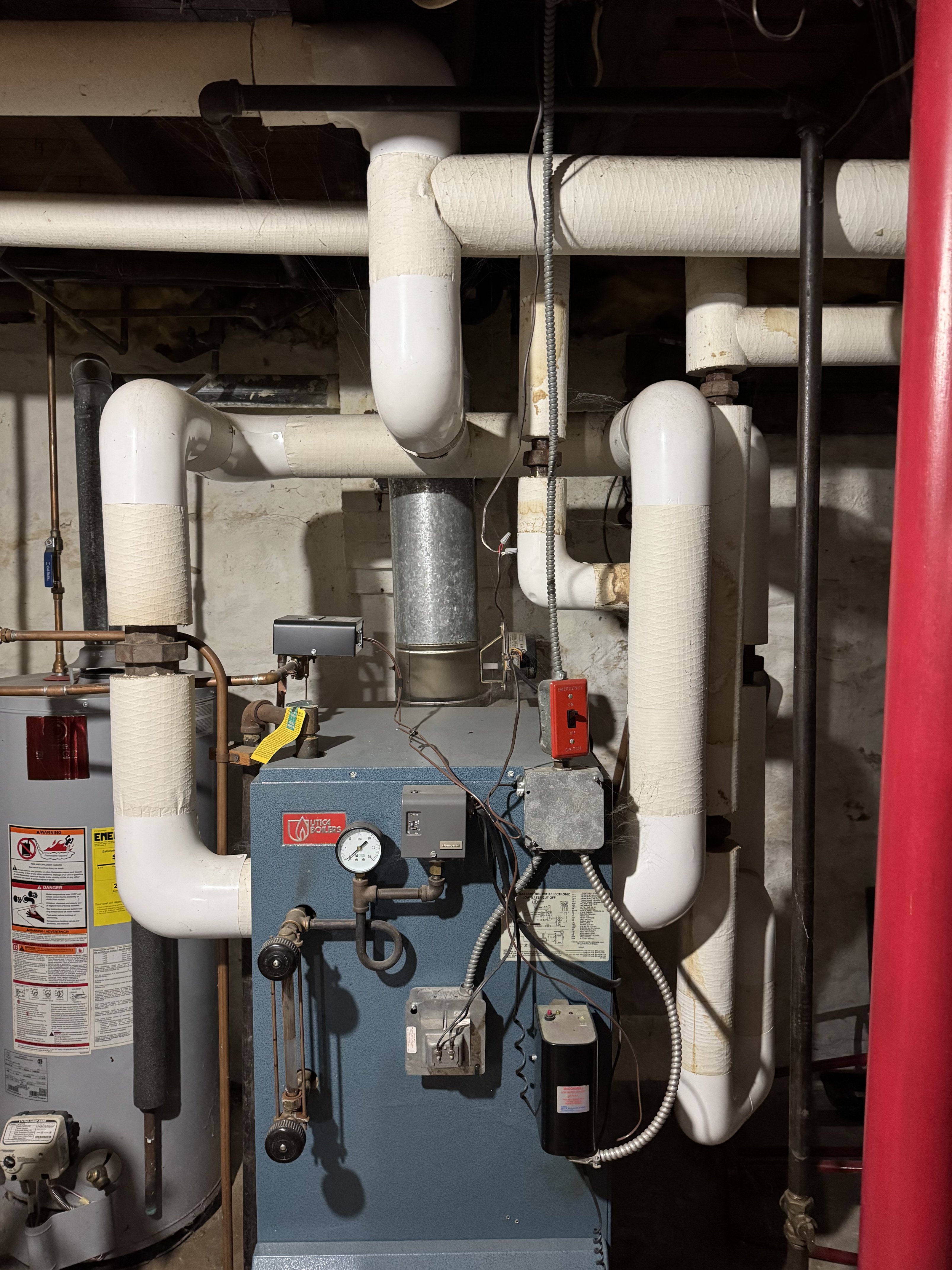

attaching images of all devices attached to the boiler.

someone mentioned the length of the mains as well. It’s about 8’ of total pipe before it reaches the vents. After that if say about 20’ until it reaches the closest radiator.

hope any of that helps!0 -

Do your radiators get warm?

It's cold. Boiler will run until thermostat is satisfied to target temperature setting.

0 -

The vents may be stuck open if leaking or hissing always. You can try to remove the vent and shake it loose. Big wrench or cheater pipe

If heat is working, I wouldn't mess with things until it's warmer. Like if you break the pipe or vent off. Dangerous time for emergency call.

Service tag when was boiler last serviced?

0 -

your pressuretrol (the gray box). is set too high. right now it's set to around 2-3psi (plus 1psi of internal differential). this means your ptrol wont shut down your boiler until around 4psi (assuming it s working correctly in the first place). those are very easy control devices. you can set/fix it yourself.

do yourself a HUGE favour and install 0-5psi gauge right under your ptrol.

here is a video that will help you:

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog1 -

yeah, dial the Ptrol down as low as it goes, don't go past when you start to feel a resistance, make sure the dial inside is set to 1, 1 points forward,

that 1st siteglass picture does look like it's washing over, and oiley/dirty, does it bounce much? do you have a skim port? a capped pipe sticking out the back, or sides? or a plugged port we don't see?

adding that low pressure gage is also a good idea when you check the pigtail, it will be easier to see what pressure you're getting to.

known to beat dead horses0 -

to answer both your replies. Yes! Heat works great, but hisses constantly and bangs. Things that are relatively normal but didn’t know there was a great community with lots of info! Don’t want to change anything at the moment as it’s freezing, but want to have a plan as soon as it warms up!

also service tag not there. The tag in the photo is a warning label about pressure relief! Will dig to see if I can find a record. Home inspection back in March said it “looked” like it had been serviced based on newer ball valves installed at the back and some evidence of cleaning at the burners.0 -

Thanks for the video! Very informative. I can set this as described but what should I aim for? .5? ~1? Definitely do want to get the alternate gauge!

0 -

Will dig into this more later in the week but appreciate the insight. To answer the question on the glass specifically, believe that the oily spill over is a remnant of an old issue as the water level stays pretty constant. As far as the ports and or caps, not sure but will take more of a look.

0 -

pretty sure one or both of the boiler oulets to your header were to be a Tee, and the plugged tee would be your skim,

do you have your manual? or download it,

known to beat dead horses0 -

"Obviously there is steam making everything moist in the right section, but wasn’t sure if there was really anything I could install to remedy that or if I need to somehow redesign the pipes."

If that is referring to steam/vapor constantly spewing out of the vent on the right, making the surrounding area moist, then that doesn't sound right - the vent may have failed open and if so should be replaced. That happened to me a month in to the heating season in the house I moved in to last year - it was also accompanied by an uptick in the water feeder adding water.

Check the sight glass and number on the water feeder routinely to get an understanding of how often water is being fed in to the boiler.

0 -

Please measure the total length of main pipe #1 from the T above the boiler to where it transitions into the return pipe #2 out at the end. Also tell us it's pipe pipe size (2", 2.5", 3"…?). Do same for main pipe #3. Also tell us the lengths and pipe sizes of the returns (#2 and #4). All these pipes need to be evacuated of air by the advancing steam and this will dictate the best main vent sizing you need. Your pipes look pretty well insulated so you may need to take some off to get measurements or you can estimate assuming you have insulation with a wall thickness of 1" to get the pipes OD and then from pipe sizing charts figure out the actual nominal pipe size from a schedule 40 pipe chart like https://www.engineeringtoolbox.com/ansi-steel-pipes-d_305.html.

0 -

you set cut in at 0.5 and differential inside at 1.

»»» See my steam heat YouTube videos:

https://www.youtube.com/@HeatingBlog0 -

I know the near boiler piping is not what is being asked about, but is that the equalizer on the R side of photo or is there no equalizer and that is the 2nd supply from the boiler? Also, the supply to the main is not supposed to be horizontal; supposed to be either a 45deg upward or 90 deg upward.

So hard to tell what one is looking at with only one view!

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements