Pressure gauge mystery

The boiler looks almost new. Its a williamson boiler 100K BTU Steam gas fired.

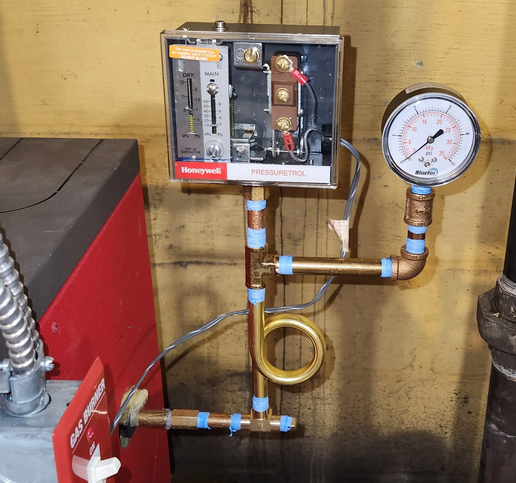

Noticed that pressure guage is almost horizontal and the pressure cut off is set at 8 PSI. Wonder why this is horizontal, is it ok to have it like this ( see picture). I can certainly adjust the cutoff to 2 PSI by adjusting the cutoff valve. Also the radiator vents are hissing loudly and am told the steam is kind of pushing hard to get in the radiator. Usually with steam systems there shall be little to no hiss on the vents, isnt it.

Does williamson ship boiler like this and did the installer forgot to change it to vertical, does the position have any affect given the pg tail ( looop) is there.

Please advise.

TIA.

Comments

-

That is not the factory installed position. I bet the installer had no clue. Can you take a few steps back and tank another picture so we can see the pipes that connect to the steam main. I bet you that they are all wrong.

When it is operating, are there any problems with noise, or unbalanced heating of the building?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I agree with you Ed, the installer had no clue as to what he was doing. The water in the sight glass is horrible.

Another clue was the sloppy install of the BX cable from the damper to the pressuretrol.

0 -

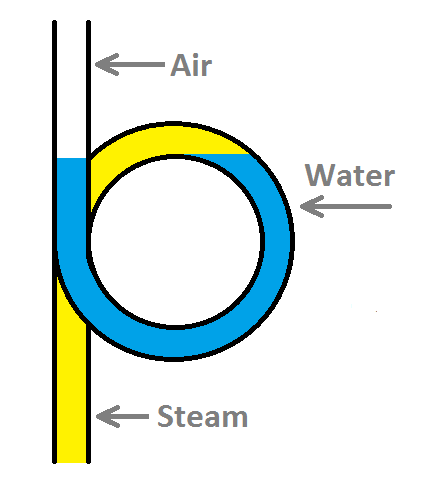

The pigtail to the pressuretrol pipe should be vertical like this. Water is trapped in the bottom half of the pigtail to protect the pressuretrol and gauge from the steam. The way yours is it won't trap water.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

I would guess the installer had no clue. In my 53 years in the business I have never seen a pressure control mounted like that.

But I don't think you can blame the installer for the wiring between the pressure control and the damper that is likely a factory whip.

I too would like to see more of the piping. Looks like some copper on the return which may be ok

0 -

And in the meantime see if you can turn the pigtail and pressure control so that it is correctly oriented — and dial the cutout pressure down to 1 psig.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

wow you said this was a New install?

0 -

-

-

-

maybe the BX whip for the vent damper was too short. Those are often factory connected to the vent damper?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

On those boilers, they come factory connected to the damper. There's a knockout in the jacket, and it gets field connected to the wiring harness inside the jacket. The BX is almost always too long. Typically, use a pipe strap or two to keep in place. Don't want to touching any of the hot pipes or dangling....

0 -

Its a package boiler :)

There was an error rendering this rich post.

0 -

If i just turn the control counter clockwise to orient it correctly would it be fine.

0 -

How much should the gauge be set at.. I know there is a screw at the top to adjust the cut out pressure, what should that pressure be.

0 -

The gauge? Just measures. The pressuretrol — the blue-grey box — does have a screw at the top, and it should be turned to set the index a bit below 2.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

The screw at the top should be adjusted so the indicator on the front should be just at the bottom of the scale, about 0.5 PSI. Take the cover off and the white knob inside should be set to 1, the number 1 faces the front.

If the pressuretrol does not work reliably at those settings raise the 0.5 maybe a 1/2 turn at a time and re-test.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

Turning the pigtail back 90 degrees may work fine. However that is usually not best practice with tapered pipe threads. Watch for leaks over time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

My bad above. @109A_5 above is correct — the index should be set down to just above the 0.5 mark.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

assuming there is water left in the pigtail. it is prob pretty empty in thst current position

0 -

Water will fill the pigtail after it is oriented correctly, from the condensation of steam within it

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements