Pressuretrol Type Question

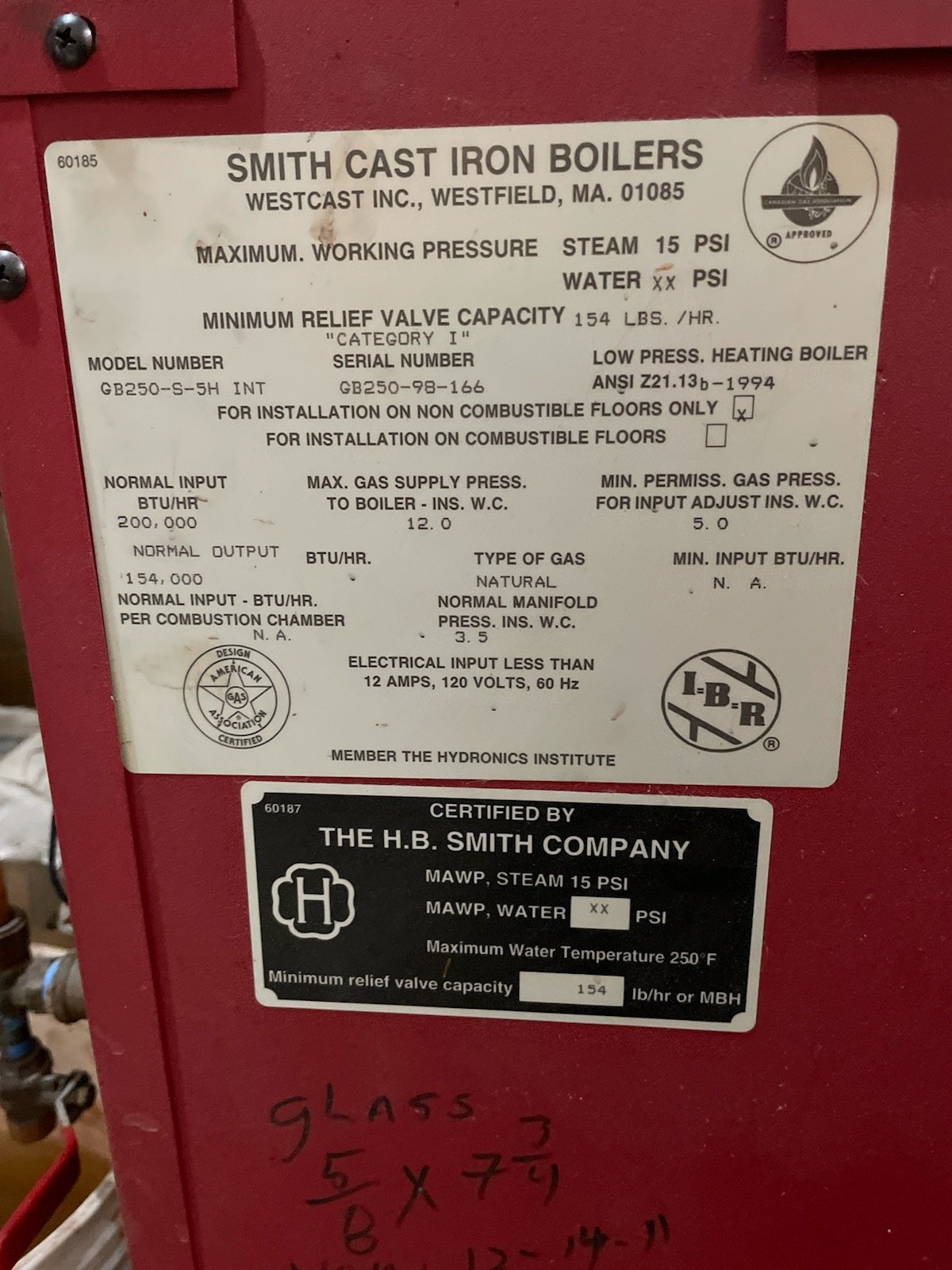

Greetings from Wyoming. I have this boiler:

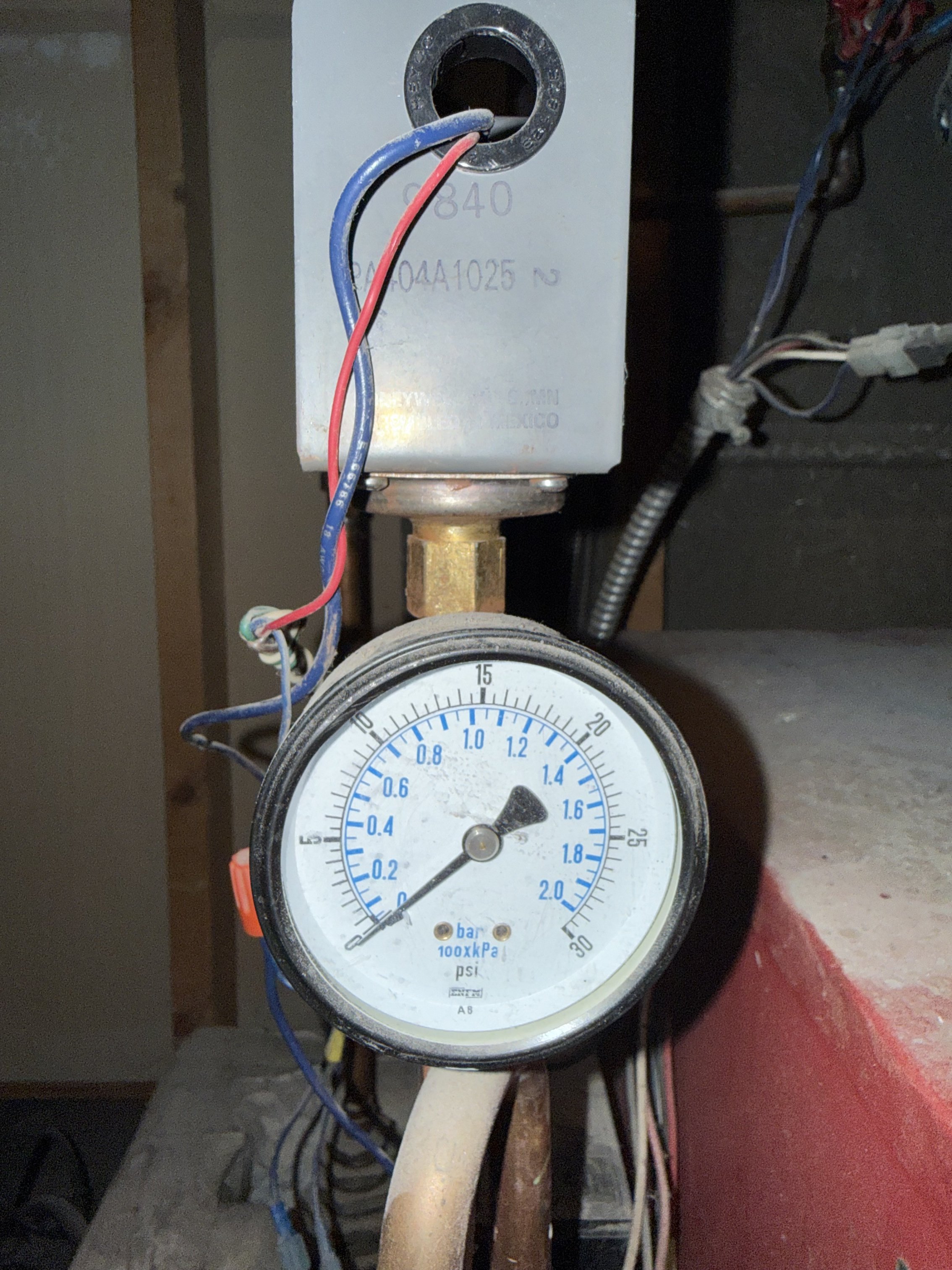

and this Pressuretrol:

I have the cut out set as low as it will go but I am wondering, is this the correct unit for my boiler? I’ve been reading a lot about differential style pressuretrols with two scales; main and differential and I’m wondering if I should pay to swap this one out.

This steam system has been left alone for many years and I’m trying to get all the traps and valves changed out to ensure the most efficient operation and this pressuretrol came across my radar.

Any suggestions?

Comments

-

If you take the cover off the control you will see a white wheel under the switch with #s on it. That is the differential adjustment.

The adjustment on the cover is the cutout pressure where the burner shuts off. It should be set to 1 1/2-2psi. The differential should be set about 1 psi.

Those settings on the scale are usually somewhat innacurate so you should install a 0-5 psi pressure gauge (leave the 0-30 on the boiler) to check the accuracy of your adjustments.

I would recommend taking the pressure control and pig tail off the boiler at some point and cleaning them as they collect sludge. Clean the opening into the boiler as well. A brass pigtail and fittings are better than black pipe. You can add a 1/4" tee and the 0-5 psi gauge on the pigtail

1 -

Here is picture of under the cover:

and pigtail with gauge:

0 -

3 psi is the lowest level on the scale so I don’t believe I can set it below 3 can I?

0 -

What's the model number? I believe the PA404A goes down to .5 psi. That one obviously does not.

0 -

Mine looks same except that the main is cut in with lowest setting being 0.5, which is what it's running at, and i set the differentiation at 2.5

0 -

Change the diff to 1.0 and you'll be all set

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I tried that before but the boiler short cycle a lot.

0 -

Yes, and that is more desirable than burning gas for no reason, at least to my thinking

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

it isn't the pressurtrol's that the boiler is too big.

but some people add a delay to delay the refiring a bit longer after the pressuretrol cuts back in to lengthen the cycles some. if the boiler matches the connected load the system will never build appreciable pressure.

0 -

Can you post the model of the pressure control? Most of those are cut in pressure on the face of the control but the way that one is worded it looks like cut out pressure.

The sticker inside should have the model #

@ethicalpaul isn't it on 1lb diff already?

0 -

Winter is not always THAT cold though, so there's no way the boiler always match the needed heat output.

Adding delay seems a viable idea but also one more thing to break.

0 -

that isn't how you size a steam boiler. it has to match the connected radiation, the equivalence of direct radiation, EDR, of the system should match the steam output of the boiler. if the boiler is oversized the system won't be able to condense as much steam as the boiler produces and it will build pressure and shut down on the pressuretrol. in many cases the edr of the system is significantly more than the heat loss of the building.

2 -

I guess it's probably bigger than needed. Any suggestion other than a new boiler? Does running it up to 3psi a problem? It actually had been running at higher cut-in 2psi and cut-out about 4psi for maybe 20 years when I moved in. I adjusted it a bit to get a bit longer cycle.

0 -

You could run the pressure up a little as long as you don't get any water hammer. You run the risk of any vents leaking but if it ran ok at the higher pressure it should be ok.

Its a catch 22 situation. You run the pressure up to prevent short cycling but the higher the pressure you run the more fuel you burn.

A timer is a good fix. You set it up to that when the burner trips on pressure you delay it from restarting for 10 min or so. This gives the rads some time to give off heat to the room and for condensate to return to the boiler.

Your not talking much money a timer, maybe a relay and some misc wire and stuff. No more than $50. They are parts that are not likely to fail, and you could put a switch on it to bypass the timer if you wanted.

1 -

Yes, the OP is but there's another person asking questions in the thread, not ideal.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

My pressuretrol is a PA404A1025. I am going to order a PA404A1033 which is the cut in primary unit. It’s been 8 years since the pigtail was cleaned so I’ll ask that be done as well along with a lower scale PSI (0-5 psi) replace the 0-30 gauge.

0 -

-

Understood, I will add the new gauge beside or in line with the 0-30 gauge.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements