Steam contractor in Utica NY area?

Note nothing comes up under “find a contractor “ for Utica area.

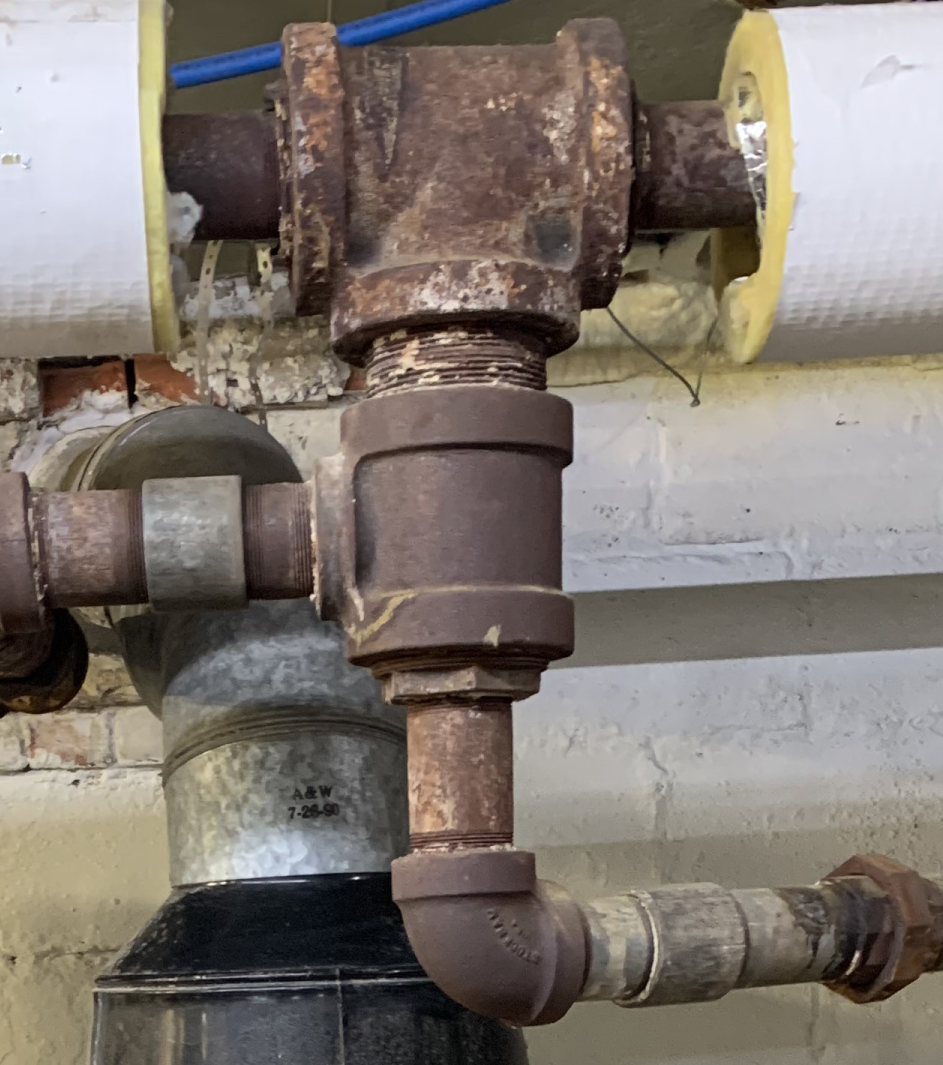

I think I’ve done as much as I can do. I can’t figure it out. I’ve got it down to the mains are getting lots of carryover. several things I’ve done hasn’t helped. Including repiping the header. All pipes are pitched , water line is correct, riser is 32” above water line, drop header, clean water ( was skimmed after header repipe). It’s been an ongoing existing issue. So is there a steam contractor recommendation in Utica NY area? Two pipe system gravity dry return in a residential property.

Thanks

Josh

Comments

-

Does one of @JohnNY 's businesses work upstate? @Mad Dog_2 can sometime be convinced to consult outside the city too.

1 -

Have you monitored your pressure with a good low pressure gauge to ensure it’s not pushing the water out the back?

I can’t remember if your system is the kind that can have that effect

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

the gauge I have reads about 1/2 psi max during a cycle.

I separated one of the two mains and have a small stream of water coming out (along with the steam) I have a video of it . I also scoped the main with my camera I don’t see any water sitting or pooling in it. If I shut down the boiler after the point after making steam , let it set for 5-10 min the kick it back on it the issue is much less prevalent . One main is much more so than the other but both are affected.0 -

Sounds like you have done all the correct things.

Have you posted any pictures of the boiler and your system in the past?

Two pipe dry return so you have traps on all the radiation?

How steady is the water level when steaming? How much does it fluctuate?

When you shimmed the boiler did you use any TSP or washing soda?

0 -

there is a post from a month or so ago. we got confused, it sounded like they had water that was there when the system was off but it was only there while it was steaming so we went down the wrong path. they very possibly just need to do a lot of skimming now, if they can figure out where the skim port is on that old boiler.

1 -

I looked at the other recent thread. Your system looks like it has counter-flow mains (mentioned before) and that is a reasonable sized boiler with only one steam riser (steam velocity).

Since it appears to have counter-flow mains yet I don't see any drips on either side of the boiler the keep the condensate coming back out of the header. Are there drips elsewhere to handle the bulk of the condensate ? Are the mains all insulated to minimize condensate generated in the mains ? Is the pitch of the mains correct ?

The old system had some huge piping to help separate the steam and condensate. Although the steam supply directly under the Left main may have been problematic.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

yes traps and all rads, I have replaced all the elements .

I posted a video of the water line during a cycle on a FB group and most said it looked fine. I could said surging. I wouldn’t call it during but the line drops about an inch during a cycle. No water hammer during cycling.

probelm was present before boiler pipe work . I thought old poorly piped header was the problem. Repipe didn’t change it.

I have used treatment in the past but nothing while skimming and haven’t tried any anti foam / surging chemicals.0 -

all mains are insulated ( except at header where repipe was done) probelm existed with old header and bullhead tees and problematic equalizer so I repiped it, and still have same issue.

mains are all pitched to the boiler.0 -

It has a skim port on the side I used after the header repipe . Skimmed for about two hours. Problem existed before repipe.

Is it possible it was never skimmed 50 years or whenever ago and still is causing a problem even after I skimmed it ? It’s been skimmed and drained several times by me.

0 -

-

All returns are cooler than main.

Vents near boiler on dry return

I also added end of main vents because I thought that might help. It didn’t.

I did clock in the meter last fall and it was right on the money.0 -

I remember this now.

If your mains are truly counterflow (the one on the left sure looks like it is) you need to add drips.

The way to do this is as follows"

Both risers come off the header. You want to install a tee immediately after the elbow at the top of the riser. The branch of the tee should look straight down. I would make the branch size 1" black and you can reduce it to 3/4" copper (or Blk pipe) below the boiler water line. You need a tee in both supplies if they are counterflow. You can ty both drips together below the water line.

As far as skimming goes TSP or washing soda. the ratio is 1 lb/each 50 gallons of boiler water. You need to find out how much water your boiler holds by draining it into 5 gallon buckets. So if the boiler hold 10 gallons you would need 3.2 oz..

mix it in a bucket with water and pour it in to the boiler through the skim port ot by removing the safety valve. Start the boiler and when the supply pipe gets hot shut the burner off before you get steam. Then add makeup water as slow as pissible and start skimming. A stream the size of a pencil is good. I have never had to skim more than an hour or so. Drain the boiler and refill, do this twice and then fill and run

0 -

can you help me understand why it would need drips? Isn’t it the function of the header (3” compared to the 2” mains) the equalizer to move any water carryover back to to the Return and out of the mains ? Are drips for counter flow only?

0 -

since i'm guessing that boiler is from the 50's is 60's from the gas train, could a lot of mud in the boiler itself cause surging?

it would have been nice to have wanded the boiler while you had the return apart

0 -

The larger header pipe is to reduce the steam velocity of the steam coming from the boiler so the water droplets can drop out and flow down the equalizer.

The drips are so any returning condensate does not get into the header. I can see the returning condensate of the left main dripping through the steam flow.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it is 2 pipe

0 -

so the only condensate in the main is what the piping condenses. if the main has to deal with significant water it is carryover or possibly something else going awry.

0 -

@mattmia2 So ??? It appears to me and others the Mains are Counter-flow. Carryover or not how does the condensate in the Mains return and get back into the boiler ? Presently via the header, possibly contaminating the steam.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

This may be a clue.

" If I shut down the boiler after the point after making steam , let it set for 5-10 min the kick it back on it the issue is much less prevalent. One main is much more so than the other but both are affected. "

Preheat the mains, let them drain then resume heating, minimizing the condensate in the mains during the remainder of the heating cycle.

Here you go, The Lost Ar of Steam Heat Revisited bottom of page 137, oversized boilers, excessive steam velocity, It will keep the condensate from flowing back to the boiler causing a number of issues like the OP is complaining about. That boiler only has one supply pipe. I wonder if it is capable of two.

Also same page are the mains pitched 1 inch in 10 feet ?

And yes I know this is a two-pipe system. Seems to me it could have the same issues, just not as bad which seems to be the case here.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

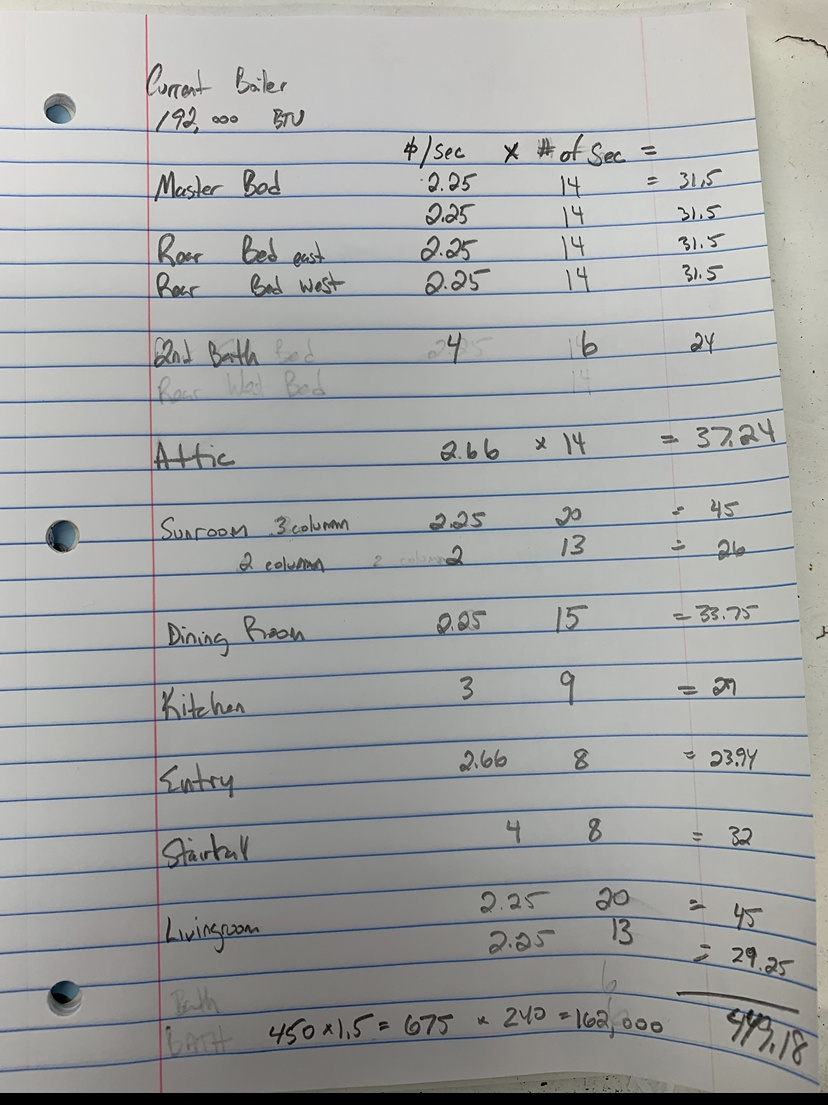

I ran the numbers on boiler size , here they are. Current boiler 192 k btu . My calculation for size is 162 k .

mains are visible pitched and when I camera scoped one side was dry as far as I could see.0 -

It is a bit strange to have counterflow on a two-pipe system. But if that is what it is so be it.

@JoshP yes drips are used with counterflow mains

With a straight counterflow system the mains are increased in size and the pitch is increased because the pipe instead of carrying just steam and minimal condensate it carries all the condensate.

In you case being two pipe it is hopefully not carrying all the condensate, but it is carrying some.

Lets make it simple. Regardless of the type of system or how it is piped no water should be draining back into the header.

0 -

At this moment, I am only 1 1/2 hours from Utica. If you're up send me a PM. Mad Dog

1 -

I also added a valve and drain near the end of the main and main vent. If I drain out the water that is in the main during the cycle there isn’t any more accumulation of water. It works fine.

so it seem it’s something with the first production of steam or cold mains or somethhing along those lines.0 -

get @Mad Dog_2 to look at it

0 -

maybe what is happening is the combination of the header not being pitched toward the equalizer and the missing drips is causing it to retain that relatively small amount of condensate from the piping in the header and throw it out in to the mains.

individually they are wrong but usually don't cause a problem, together they might add up to a problem.

did it get better but not go away entirely when you insulated more of the mains?

it looks like there is space to rotate the equalizer a little and tip the header that way.

0 -

-

"I also added a valve and drain near the end of the main and main vent. If I drain out the water that is in the main during the cycle there isn’t any more accumulation of water. It works fine. "

The simple fix here may be to just add a return with a water loop seal from the far end back to the boiler to drain the far end. Or add a water loop seal at the far end between the main and the existing return if the heights are appropriate to drain the main.

I suspect the pitch is present but not sufficient (pitched 1 inch in 10 feet) for proper condensate drainage from the far end of the main with steam flow. And/or with the steam movement there is a Seiche type phenomenon going on at the far end of the main that keeps the condensate stuck there during steam production.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

@DanHolohan I have the utmost respect for your opinion, you've read and forgot more than even most of the people that do this every day know. What part of this do you disagree with? I think the problem in general is tough because there are a lot of little thigs that aren't quite right but aren't so wring they usually cause a problem so I don't think I was on the right trail there.

0 -

Thanks . Yes agree and had the same thought that I can tie each of the mains into each of the returns with a wet loop. I have a spot I know on one side that will work without much trouble. Similar to the pic below. Is that what you also had in mind as far as wet loop? I was would like to fix the cause of the issue but i may just go this route .

0 -

-

@JoshP Yeah that's basically what I had in mind. You would definitely need the water loop seal if you tie into the existing return. If you ran a dedicated 'drip' from the end of the main and terminated it at the boiler or the nearest wet return under the water line the water loop seal may not be needed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

thanks yes I agree at this point someone should be here in person.

also thank you for all the info you have shared about steam . I’ve got you lost art of steam book (and a few others) and have gone through it a multitude of times . I also have a YouTube folder of numerous video talks of yours. Although I haven’t tied this problem down I certainly gained a great deal of knowledge of steam heat and how it works from you.0 -

@JoshP if @Mad Dog_2 can get there your problem will disappear.

All steam lines (anything above the boiler waterline) is supposed to drain completely back to the boiler when the boiler shuts off.

For some reason yours isn't draining.

1 -

-

I think I may have found my solution with the help of posts here, Dans book and his and other videos I’ve watched. Also why changing my header and all the other things I’ve done and checked didn’t change anything.

Here it is….

my system is two pipe COUNTERFLOW.

it was originally a coal fired system, and the mains are always warm with that system so when it called for heat there would be little to no steam condensate when the steam down through the mains

… now it’s gas fired and mains are cold between cycles. The water in my mains are just from the condensate from the beginning of the cycle . I know this because once I purge / drain out that water in the main heats as it should.

also there is no water hammer so I know it’s not pooling cold water . The water is the condensate from the cold main. Also why if I shut it down near the start of the mains heating up, let it set for a time and fire it back up problem is for the most part gone.

So this would mean I need to add the previously mentioned by some, DRIPS to the HL near the boiler header to both of my mains so that condensate in the mains at start up can drain back.Thoughts ?

0 -

The drips near the boiler may help, however that probably won't drain the far end, which seems to be your primary issue and concern.

I only see a few options from here;

Increase the pipe pitch, (are the pipes even sized correctly ?) a lot of work and expense.

Add a dedicated return to drain the ends of the main(s).

Custom boiler burner timing control. Call for heat, burner on, warm up the mains, shut the burner down, let the mains drain, burner on to heat the home until the thermostat is satisfied.

The custom timing thing is probably not very efficient, from your experiments it probably would work. And it may be hard for most folks to implement and others may not understand it.

Adding a dedicated return to drain the ends of the main(s) is probably the most practical resolution.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements