Pressuretrol question

Last night I just happened to be in my basement, when I hear my main line vent hissing louder than in the past. Up until this point, whenever I checked my 0-5 psi gauge at the boiler when my system was running I literally had no reading whatsoever. Checked the gauge and it was up to about 1 psi. Steam vents at my radiators were noticeably louder. Being that it was 11 pm, I turned down my thermostat 5 degrees from 70 and listened to my system all night making excessive noise out of my closest radiators.

After a sleepless night of worry, I figured that the pigtail (which I replaced just this past October) had to be clear since I was getting the pressure reading. This morning I took the cover off the pressuretrol and manually triggered the switch as the system was running. System immediately shut down. I turned my thermostat back up to about 68 degrees and watched the 0-5 gauge. It runs up to 1.5psi (which it never did before when set to 70, it barely moved if it did at all) and drops down to 0 in about one minute once the system shuts down. My main line vent, which used to hiss quietly, is noticeably louder now.

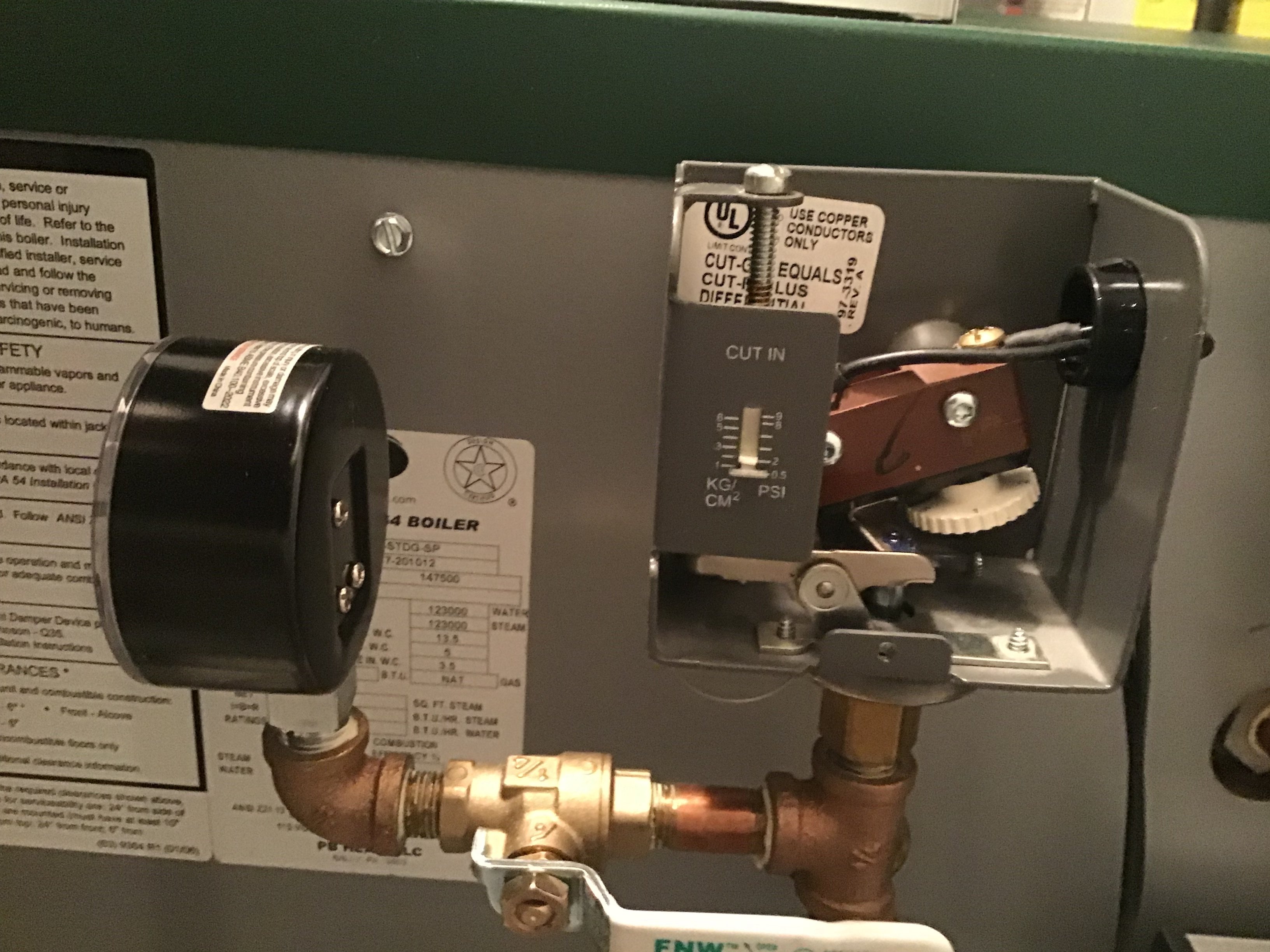

I’ve got 14 years of use out of this pressuretrol that came with my new Peerless boiler. Is it time to replace it, or is there something I can do to make it function properly once again. The dial has always been set to #1, and the cut in has always been set to what you see.

Is it time to replace the pressuretrol unit?

Comments

-

Does it go past 1.5psi? I would figure that out because it should cut out at 1.5psi based on how you have it set. That would not be a pressuretrol issue if it cuts out at the correct pressure.

0 -

Odd that you would be over 1psi before the main vent has even closed. .Makes me wonder if the main vent is functioning properly and not stuck partially open.

Any radiators get shut off?

0 -

So to further the conversation………..this morning I shut off my system, and took the cover off the PT. I manually activated the trigger switch about a dozen times. I didn't notice it really sticking or anything out of the ordinary, but I figured let me see what happens. At the same time I lightly tapped the PT, thinking like a neandrathal.

So it seems to be working normally again. 0-5 psi pressure gauge sits back down on zero. Heat is quiet. Water level in the sight glass moves ever so slightly, at 1/4 inch maximum or less. Main vent whispers out the bleed orifice.

@DanielDay - the highest the gauge went to was probably a little less than 1.5 psi……..at the time it was at it's worst I glanced at the gauge and it was definitely above 1.0, but maybe max at 1.2. I was a bit flustered when the system was acting up and my mind was scattered on what to do. IF it should occur again I will make sure to get an exact reading.

So my next question……….ride it out for now and see what happens, or change the PT……..or any other suggestions anyone might have. Appreciate everyone's assistance in this matter.

Thank you

0 -

@dabrakeman - the main vent was still bleeding air, but it was an excessive amount compared to when the system operates what I believe is "normal". I'm wondering if it was bleeding around the circumference of the body and not the bleed orifice of the vent. It's the original Gorton D from when I moved in 20 years ago, so it's got some miles on it. When the system is running at a "normal" pressure it bleeds air and closes up. I plan to eventually update the main vent but I'm a little reluctant right now during heating season. The main vent is a female base Gorton D set on a 1/4 inch nipple that sits in a 1/2 inch adapter. Both the vent, nipple and base adapter have teflon tape on them so that might help removing them when I get ambitous. I plan to remove everything from the adapter up, but not right now. If the main vent acts up I will order another and see about replacing it now.

0 -

Here’s a picture of the current main vent. I should believe that there’s room for improvement here.

0 -

I would think that Gorton would with the Teflon tape would come off fairly easy. Hard to tell what room you have for a bigger than with the wood theme in the background of the picture but usually there's a way to come figure something to get adequate main venting installed.

I'm still unclear on when you are seeing pressures up over one PSI. The system really should not start climbing to that range until both the main event is closed and most or all of the radiator vents have closed.

0 -

So AFA the main vent………I have sufficient room vertically and horizontally that you can't see in the picture. Reason for the tight up close shot is the main vent is in a corner closet of my finished basement. I had to cut out a section of the ceiling and put in a drop down 12x14 inch panel door so I can access it. I squeezed my Iphone in there to take the picture.

So right now, after messing with the PT switch (activating it on and off for a dozen times with the system shut down) my guess it unstuck the PT? If you read my initial post, just by chance I was in my basement and heard the main vent hissing loudly. That's when I checked the 0-5 gauge and saw it was just slightly over 1 psi. Up until this point I never had this gauge really register anything significant (it's a brand new gauge installed 3 months ago). So for the past 3 plus hours, everything seems to be operating normally. Gauge is sitting at 0, system is cycling properly and supplying quiet heat throughout the house.

My guess is it will happen again……..today, tomorrow, next week, next month, etc…….wish it could tell me when it decides to act up.

0 -

Main vent looks pretty crusty. Take it off and see if you can blow through it.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

So with my system functioning properly, (now) you can hear the main vent quietly releasing steam/vapor, and eventually you hear it click shut and the venting noise stops.

I'm going to see if the local old school plumbing supply house (they carry most everything) has a replacement Gorton D in stock, if not I will order one online.

0 -

-

the location of your main vent isn’t ideal and is subject to water hammer. Have you seen it spit water out?

0 -

I've never seen or heard it spit out water from the main vent, but it definitely had some water in the main in that area last night when the issue was occuring. You could hear a "wet" steam in the area of the main as the pressure was running higher.

So to further the conversation, I did see if the main vent would unscrew easily and it did. I went to my local old school plumbing supply and they had a Honeywell Pressuretrol in stock. The price was reasonable, and I figured best I grab it and have it in case I need it. I'd rather have it in case it occurs again, and if it sits in my spares container so be it. At the same time they only had a Jacobus/Maid o Mist #1 main vent in stock with all the fittings. I'm probably going to put that in place for the time being until spring rolls around. That's when I will try removing the insert that is in the main line elbow and set up a correct number of vents on an antler.

0 -

If i were going to change the pressuretrol i'd buy a vaporstat.

0 -

I think for now I will keep the system more or less as is, and attend only to any issues that happen to occur for the rest of this season. I have the spare PT in the event I have any additional issues, and I just finished swapping out the Gorton D with a MoM #1. If it gets me through the season I'm ok with it.

The good news is the system has been working just fine all day. No excessive pressure on the 0-5 gauge (actually don't see any reading at all) and all my radiators are heating nice and quiet. Curious to see if there are any changes with the MoM vs the Gorton main vent, but honestly I don't expect to see any since the outlet ports of both vents are pretty much the same size.

I'll read up on the vaporstat , if that's my best course of action……..but that will probably be next year.

Thanks everyone for your assistance today……….

0 -

The pressuretrol / vaporstat is a pressure switch that limits the system pressure by turning the burner off, It is NOT a throttle.

If your system normally runs with no pressure on the gauge and now there is abnormal pressure without an abnormally long run time, something is restricting the system's ability to dissipate the boiler's output, so the pressure rises. Or the boiler's output has somehow intermittently increased abnormally.

I believe changing the pressuretrol and the main vent will not help.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

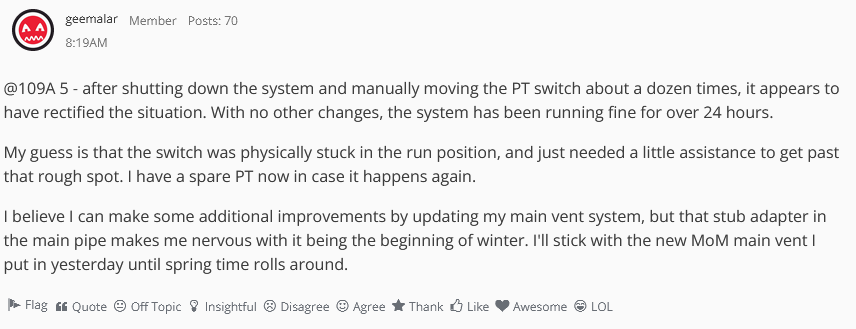

@109A 5 - after shutting down the system and manually moving the PT switch about a dozen times, it appears to have rectified the situation. With no other changes, the system has been running fine for over 24 hours.

My guess is that the switch was physically stuck in the run position, and just needed a little assistance to get past that rough spot. I have a spare PT now in case it happens again.

I believe I can make some additional improvements by updating my main vent system, but that stub adapter in the main pipe makes me nervous with it being the beginning of winter. I'll stick with the new MoM main vent I put in yesterday until spring time rolls around.

0 -

@geemalar, you stated;

"Up until this point, whenever I checked my 0-5 psi gauge at the boiler when my system was running I literally had no reading whatsoever." Second sentence in the post !

"It runs up to 1.5psi (which it never did before when set to 70, it barely moved if it did at all) and drops down to 0 in about one minute once the system shuts down. " And more symptoms you conveniently ignored…

So for 14 years the pressure gauge and the OP's ears have been lying to him and now by massaging the Presuretrol everything is fine ???

I wish I could live in that world…

Again, the pressuretrol is a limiting device, it is NOT a throttle.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

i never said the pressuretrol was bad, but if i were to keep a spare on hand I would buy a vaporstat.

0 -

@mattmia2 Your explanation was sure leading in that direction.

"it appears to have rectified the situation."

and

"My guess is that the switch was physically stuck in the run position, and just needed a little assistance to get past that rough spot. I have a spare PT now in case it happens again."

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I hate microswitches… a couple of thoughts. First, be sure that the cutin is not less than 0.5 psig. Anything less that that on a pressuretrol is risking not having it reset, even with everything else just fine.

Second, there no harm to a small spritz of WD-40 on anything that moves… Don't get carried away, but…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Ok I gave the screw on top 1/4 turn, it went from just above .5 to 1. And I gave the switch pivot mechanism an ever so slight dab of WD40 at only the pivot point.

Thank you

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements