B+G Circ Pump making noise, coupler fine, bearing feels smooth

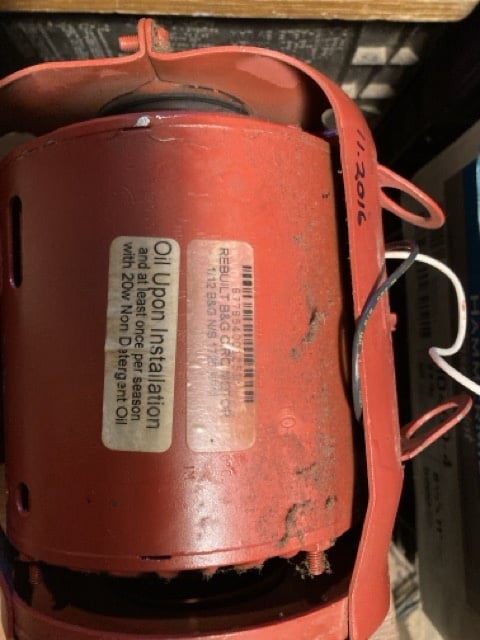

Hi folks, I replaced the B+G Circ pump in 2016, I can't recall if the bearing housing was replaced.

I started up the boiler heard a clattering from the pump and could see the coupling spinning. I took off the motor and the coupling is intact and attached to both shafts, the bearing housing seems to move smoothly. My guess is the impeller shattered.

The ID on the motor is: Bell & Gossett: 877854001251, 1/12 B+G N/S 1725rpm

I have not proceeded any further as I want to know the correct impeller kit to buy, also any tips on the procedure is appreciated. It's tight quarters.

Comments

-

Time to drain the boiler to do it all😮

0 -

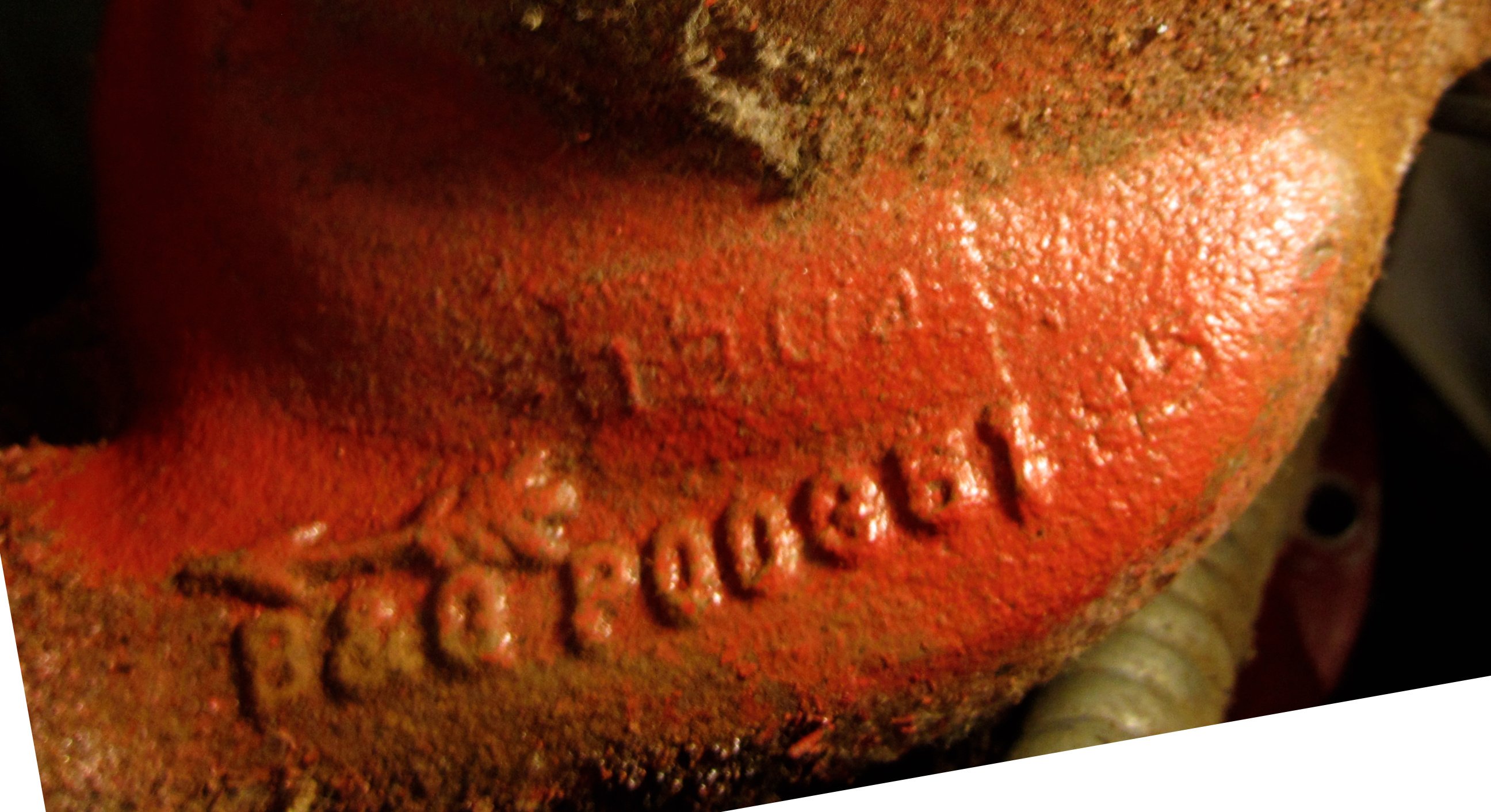

Still trying to ID my pump and what impeller I need, the volute says P00361, I can't find any info on it. Or maybe it is a P00351, hard to read.

0 -

The coupling is usually the most common failure but yours looks ok, then bearing assembly then motor in that order.

B& G parts are $$$. You may want to consider a modern wet rotor circulator as a replacement.

They are usually less $$. The only downside is if you have a lot of rust sediment in the system they may not hold up as well without a strainer/mag filter.

You may want to run the motor while disconnected, check coupling etc and try to find where the noise is coming from. Eliminate those two and then it would have to be the bearing assy or impeller

3 -

You’re probably not gonna find the impeller available as a separate part. At the least, you’ll have to buy the bearing assembly.But that circulator is 1950’s technology and an energy hog.

A Grundfos ups15-58 reverse flange (or equivalent) will bolt right back in there and cost a third of that dinosaur.

Like Ed mentioned, you may need to flush the system and add a dirt mag.

The piping is less than ideal with that ell that close to the inlet of the circulator.

A simple solution would be to remove the circulator, bolt a circulator flange directly to the one on the boiler and run the return piping up to where you can work on it. Then relocate the circulator, preferably to the supply side, down stream of where the expansion tank connects to the system - aka the Point Of No Pressure Change. This will help if there are any issues with air in the system.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

Thanks Ed and Ironman.

I took a drill with a metal rod and hitched it the coupler and bearing housing and didn't hear any noise at all, or feel any resistance like perhaps I should if the impeller was pushing water. I ran the motor alone, nice and quiet. The coupler looks ok, comparing it to new images.

This system is ancient, I think for me the only thing I would be capable of is replacing parts as they are now. I did find an impeller(s) on ebay cheap enough (part 189132LF for 100 series which is what I think I have), couplers, and I have seen bearing housings for sale as well.

Just odd, I can't find the noise now.

0 -

I reassembled and got the same noise. My only thought is would it make this noise if there was no water at the impeller? As far as I know my system has no leaks.

0 -

A clattering or clicking noise is usually a bad coupling because the rubber motor mounts are worn and the shaft of the motor is misaligned with the pump shaft.

Try replacing those parts and see if it stops. They’re inexpensive.

Don’t over oil: that’s usually what causes the mounts to fail.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.1 -

-

-

I guess that would make sense, How can you tell if they are gone? It looks like my pump is pre 1967 and has larger mounts 2.5 inches than the post 1967 pumps, 2 inch. I can't find the mounts anywhere. I ordered the Spiralink Flexible Spring Circulator Coupling in hopes that it may help.

0 -

Try lifting it up at the mounts and see if the noise goes away. I think those mounts are just standard motor mounts, not specific to bg. Maybe try a motor shop. Or the wet rotor circulator that will drop in. What kind of emitters does the system use? I see copoer at the circulator.

0 -

Not sure how I can lift up on the mounts, maybe a screwdriver wedged in the casing and pry up? The mounts look like these. Finned baseboard emitters.

0 -

Ok. I installed the new mounts, still waiting on the new Spiralink Flexible Spring Circulator Coupling.

Started it up, same noise. It is going to get down to 12 degrees tonight and I wanted to run it so my pipes don't freeze. baseboards got warm, but the pressure release valve let out some water when I was upstairs, not a lot about a couple of quarts. I shut it down.

The system says 20lbs of pressure, the valve is rated for 30lbs of pressure.

I would like to run it again before bed to warm up the house so the pipes don't freeze.

0 -

-

I just a "Pro" over who was clueless than me.

0 -

https://forum.heatinghelp.com/discussion/comment/1875533#Comment_1875533

You don't seem clueless or incapable. Just unwilling, maybe? Nostalgia?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements