Air purgers with compression tanks

Systems with plain steel compression tanks are referred to as air management systems. Meaning that the air bubble in the compression tank cannot be removed, it is the expansion space.

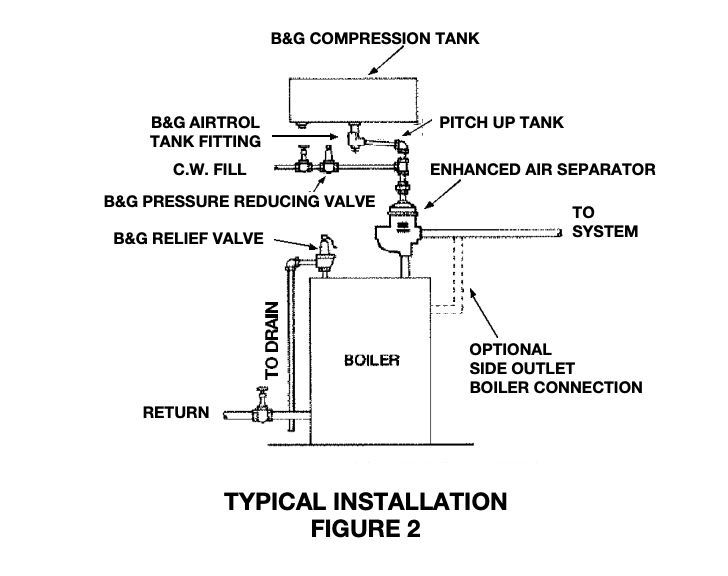

B&G and others devised a couple components to allow air captured in the top of the boiler sections to be placed into the tank via their Airtrol ™ components.

B&G also shows both the IAS inline air separator and the EAS enhanced air separator, a micro bubble type air separator being used instead of the Airtrol fitting into the boiler.

I believe both of these B&G products have been discontinued.

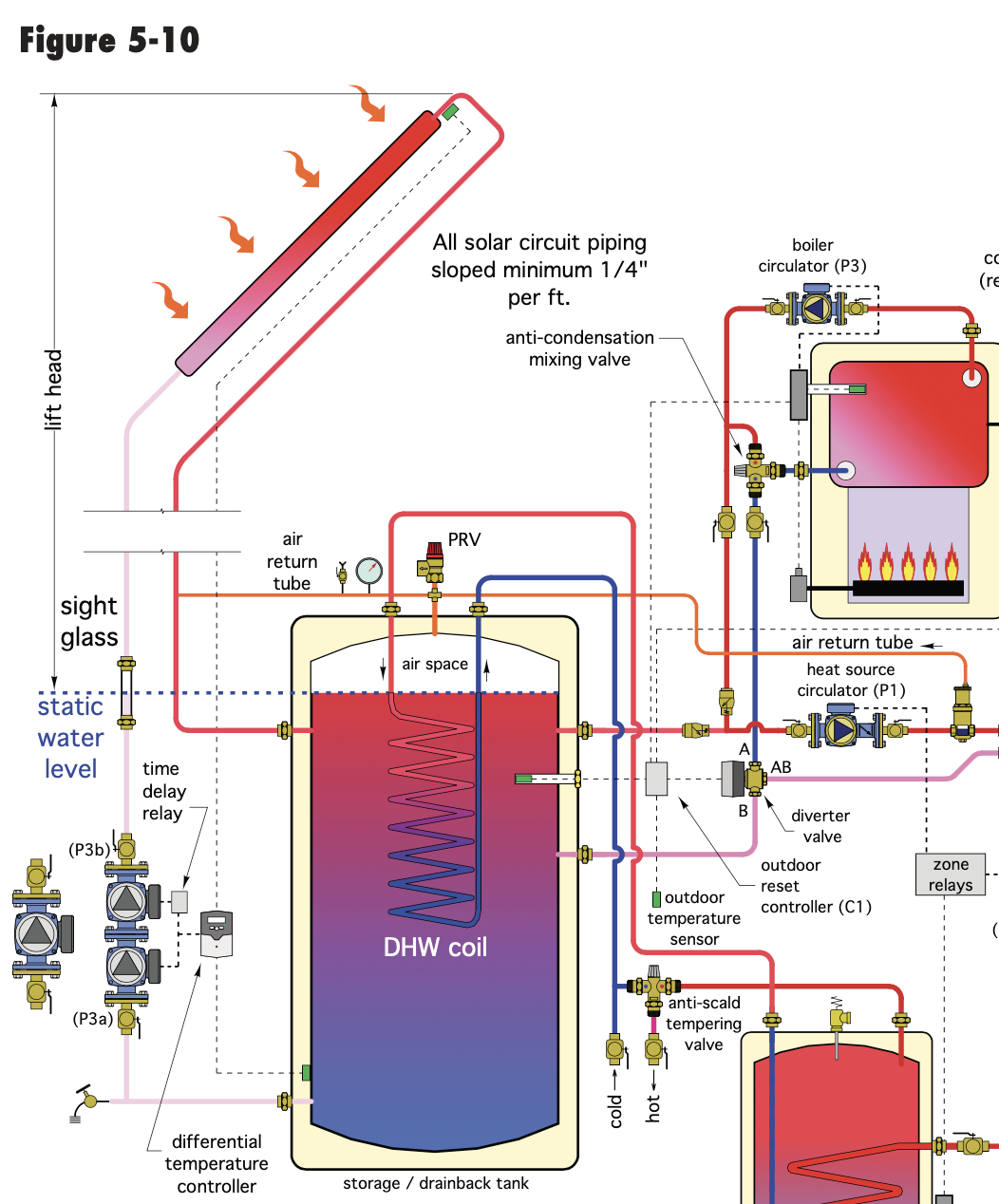

On my solar drainback tank at my last shop I piped the air vent discharge from a Discal up to the air space in the solar tank. In fig 5-10 it shows the Discal piped to the top of the tank at a cross fitting, and the siphon break air tube piped to that cross. So any air removed from the circulation, gets placed in the air bubble at the top of the tank.

I believe any microbubble type purger with a treaded vent connection could be used on a boiler system with the steel compression tank.

Any experiences with this arrangement?

trainer for Caleffi NA

Living the hydronic dream

Comments

-

Hello Bob,

According to Xylem/Bell and Gossett The ATFL, ATF air management valves and steel compression tanks are still offered by them.

My Bell & Gossett 15 gallon steel compression tank was manufactured by The Wessels Tank Company.

Happy thanksgiving.

0 -

-

Can an air purger produce gas at a high enough pressure to go into a compression tank? If it can then eventually compression tank will be charged with nitrogen as oxygen is consumed. My guess is that purgers should exhaust into some sort of vacuum tank. I've seen compression tanks charged with compressed nitrogen. A Cadillac system uses a vacuum tank for expansion. The tank has to be installed at high point. Very rare today but for taller buildings before circulator pumps; who is old enough? My guess is that overhead distribution was used.

2 -

this B&G piping shows a basic micro bubble air sep going into a non diaphragm, plain steel compression tank

I think the airtrol fitting into the boiler is just venting the air into the compression tank also.

I have heard of diaphragm tanks pre-charged with nitrogen, but I haven’t had that confirmed by Amtrol or any other manufacturer

I was told that refrigerated air, dried air, is used to pre-charge tanks.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

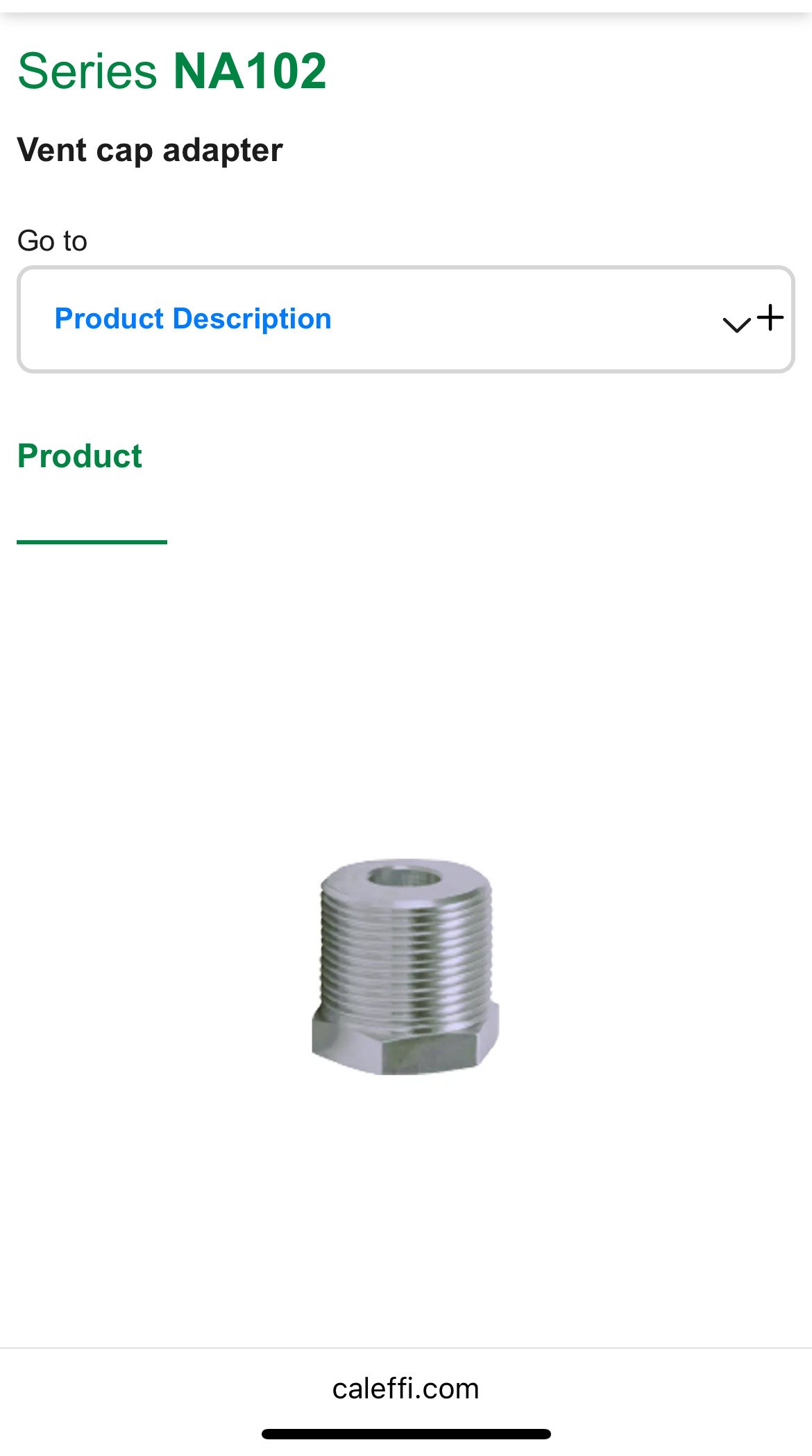

This thread adapter fits most of the brass air vents, Taco offers them also

This just converts that metric thread to NPT so you can can put a copper tube on the outlet

While the spiro has a 1/2 npt, the hole in that stem is around 1/8”, that would be the limiting factor in how much air vents out

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

@hot_rod I've seen air separators going into compression tanks but who has measured how well that works? Tanks still get water logged so where is the air? I've also seen doohickies to vent air (to atmosphere) but not water at top of system. If pressure is controlled correctly no apparent issue. I've seen that work well for decades until somebody/something increases pressure enough to pop the doohickey.

0 -

i think if you use a standard microbubble air separator you would either need to remove the float and needle or pipe a second pipe from the system to the tank so that water could flow freely both ways. ideally you would also have a tank fitting or pipe loop to prevent gravity circulation out of the tank too. The schrader cap to npt adapter would make almost any microbubble separator work.

0 -

-

If the water fill valve is left on or there is water leaking into the system a steel compression tank will waterlog. They always work as long as they are sized correctly and the water feed valve is closed and not seeping into the system as long as the proper air to water ratio is created with an airtrol valve to maintain the point of no pressure change.

0 -

An improvement may be to somehow locate separator at lowest pressure. That would be at top of circuit. Some buildings located boiler on roof of building.

0 -

suction side of circulator.

0 -

The Xylem/Bell and Gossett information sheet describe how the steel compression tank or multiple tanks are plumbed in parallel with one airtrol fitting in each tank are hung between the ceiling joists in a basement above the boiler feeding the air bubbles stripped out by an Internal Air Separator that is used in a pumping away method.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements