How to delete boiler coil and replace it with a HPWH

Hi everyone, I've decided to stop using the coil from my boiler to heat domestic water. I'll be getting a HPWH to replace it….80gl, 240v.

I am not sure how to go about connecting it to the existing pipes. I see a couple of valves plus a Dole flow (circled in yellow). The other two valves are there just to flush the coil.

Do I just connect them at the bottom by the elbows? (see arrows in red and blue). I'll be adding an expansion tank as well. I am on city water and it is required in my county.

Thank you!

Comments

-

Good decision. As you can see, using a boiler for hot water results in a LOT of extra pipes and hassle.

If you are unsure of what can be hacked out of there, find a knowledgeable plumber to help you.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

Upper blue valve looks like cold supply, that goes to tank C.

The copper tube going vertically behind the brass reducing valve looks like hot to building. That connects to H on tank.

Expansion tank goes on cold feed. Piping examples are usually included in the box with the tank

Run a hot water faucet and put your hands on the pipes to see which gets cold, which gets hot, to confirm.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you Hot_Rod. Correct, I've marked the cold and hot with the arrows. My question is, can I just connect at the elbows where the elbows are pointing then? I just want to make sure I should keep all the different valves, etc above them.

0 -

As @hotrod said follow the instructions in the HP manual. You can go on line and download it if you don't have the HP on site yet.

The cold should have 1 shut off valve then the expansion tank then into the cold connection on the new tank. Your State may require a vacuum breaker installed on a tee in the cold water supply. Massachusetts does..

The hot on the tank connects to the hot to the building. Nothing else needed but you can put a shut off valve if you want.

Your choice has made @ethicalpaul very happy!!!

Disconnect the old coil and leave the pipes open. Not capped. You may want to do some control work on the boiler so it doesn't maintain water temp.

2 -

Thank you ebebratt, appreciate the response. I need to look into the vacuum breaker.

I'll keep the coil pipes uncapped then.

I already have shut off valves for both, cold and hot.

I've read the documentation. I'll go ahead and connect the lines at the elbows I've marked then. I'll also install the water expansion tank between the elbow and the tank on the cold water line.

Thank you all!

0 -

Plumbing codes indicate when a vacuum breaker is needed.

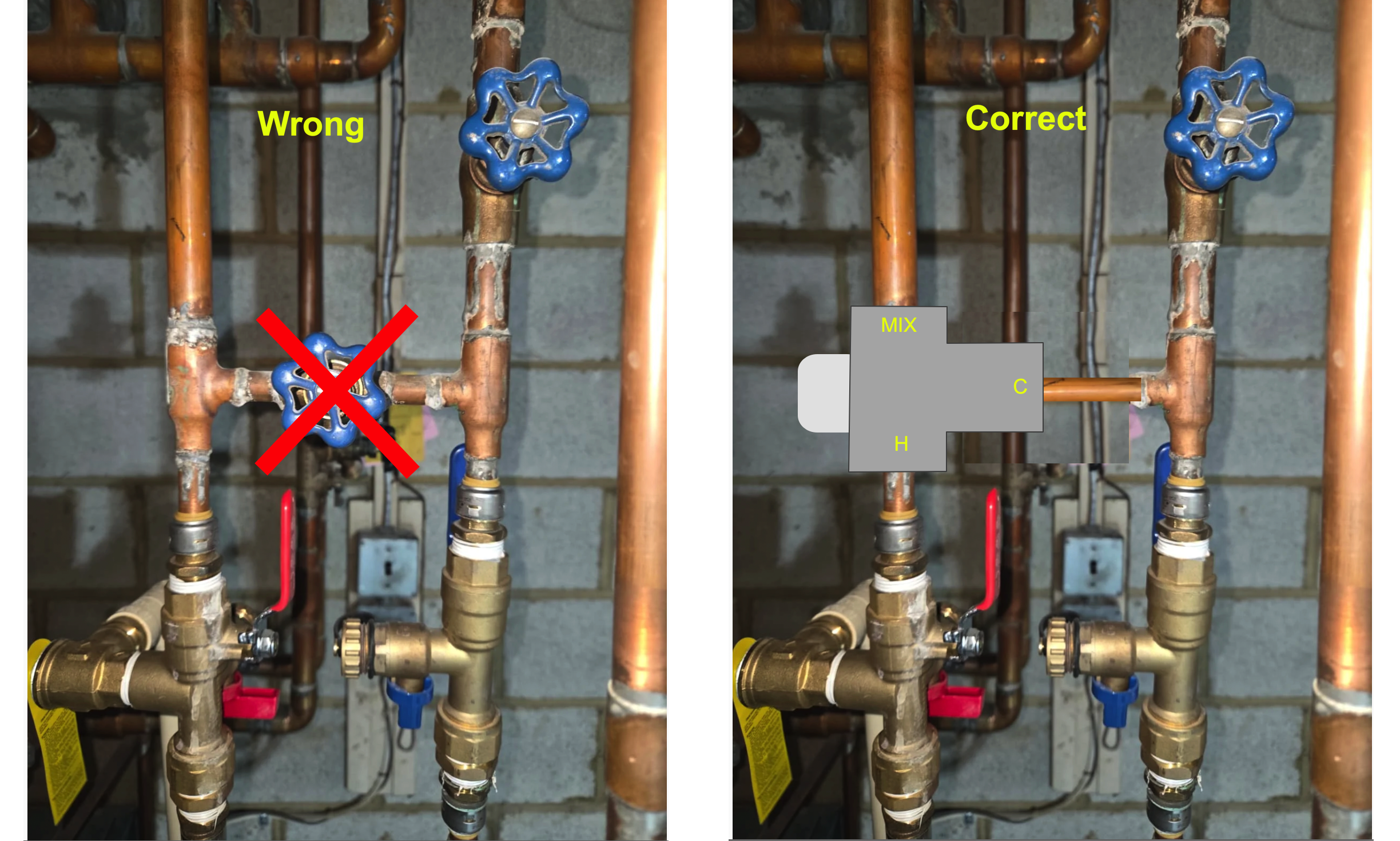

You don't need these purge valve, the bypass, the check valve, or the relief valve.

Just pipe cold to the tank, hot from the tank, delete all this. Use a new ball valve and flex connectors for seismic requirement, if that applies in your area?

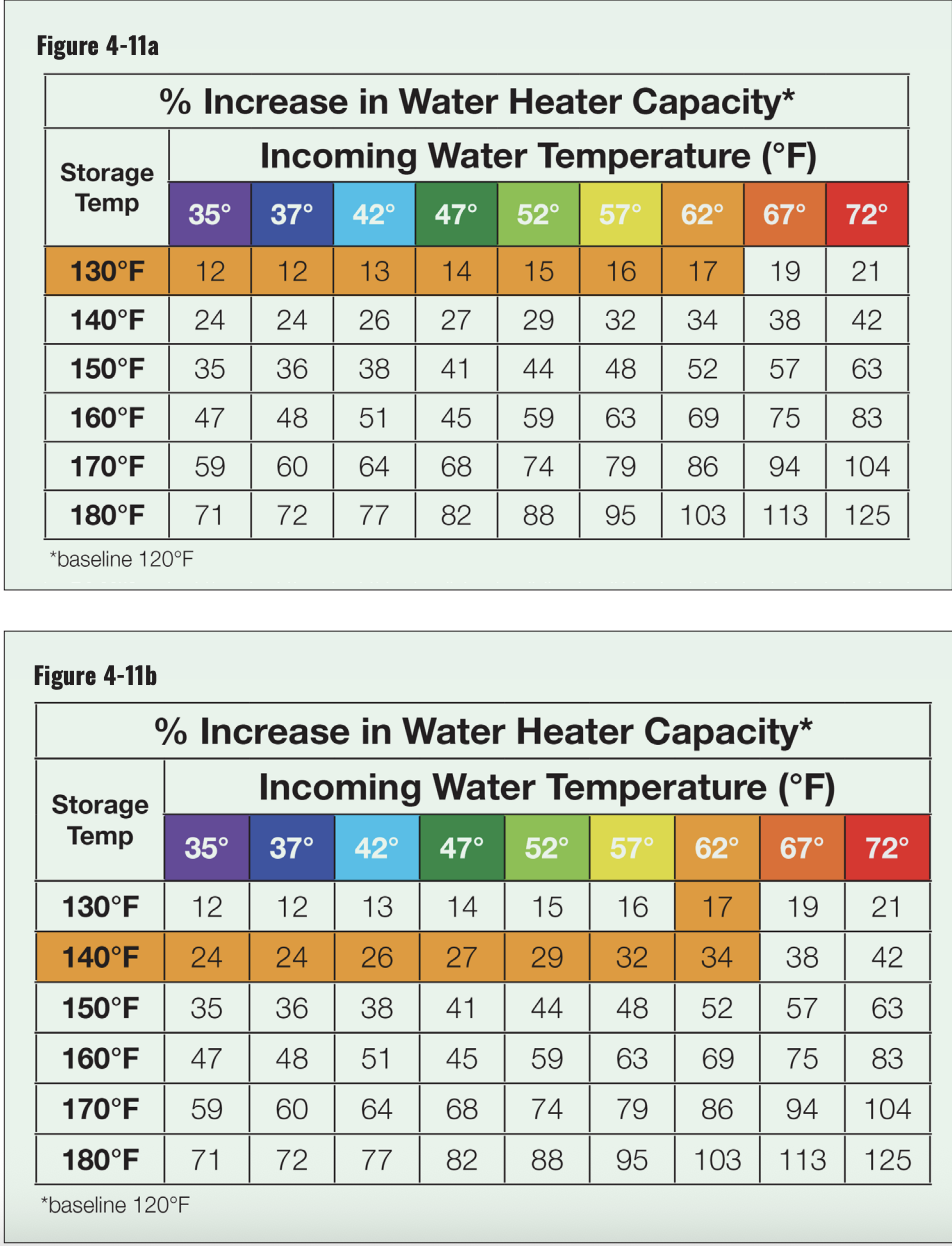

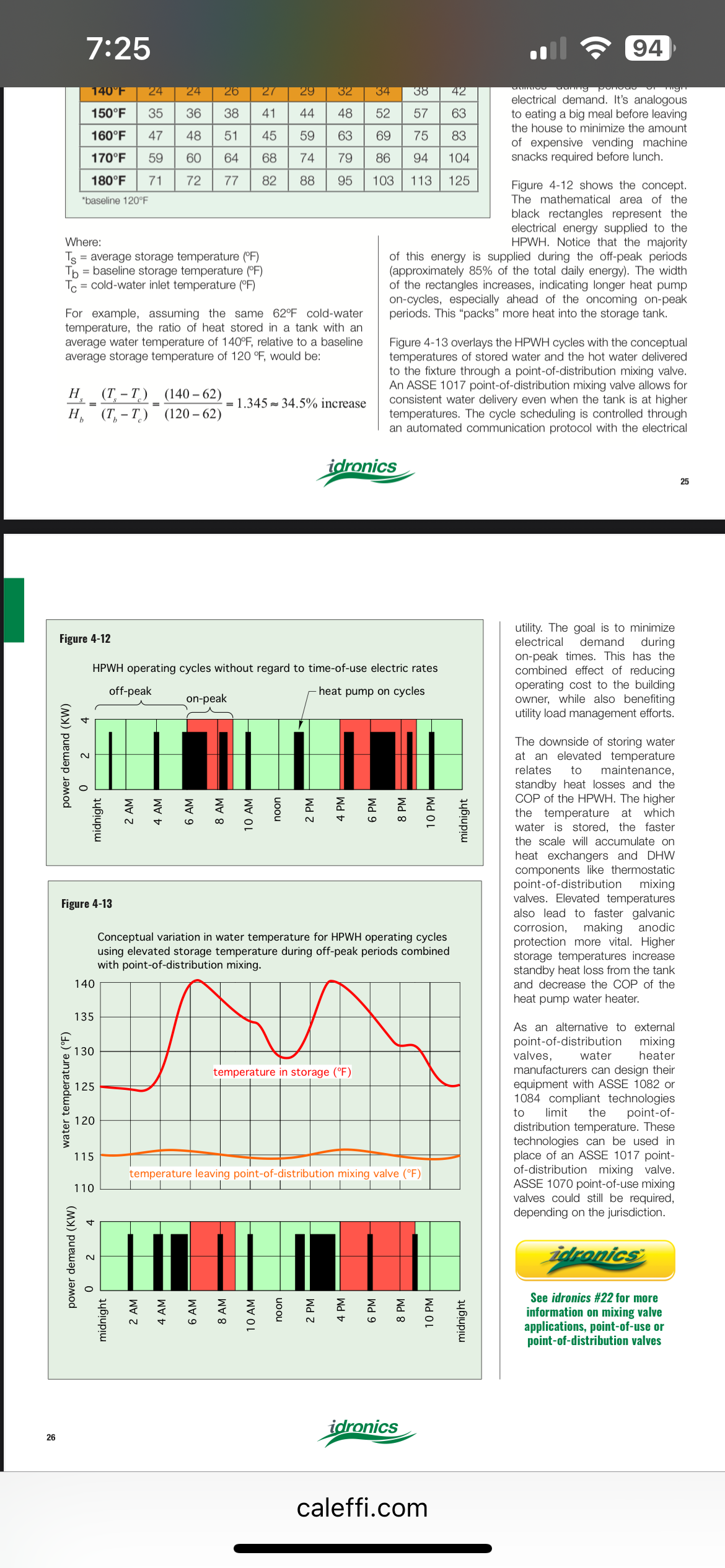

In some areas a thermostatic mix valve is added and the tanks operate to 140F durning the evening hours to leverage lower electric rates. With enough tank capacity you coast all day without starting the HP.If that applies in you area.

My power suppliers has a few low rate options, but they all have a catch, i.e. they can brown you out when the grid is falling behind, as a trade off for you off grid "deal"

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream3 -

Thank you Bob, this is great! Appreciate all the info you've provided. I just learned a ton. I'll make sure to review the code in my area. Thanks again!

0 -

IMO, you don't connect to the existing pipes pictured. Where is the water heater going to be located in relation to where those pipes are? It can't go anywhere in the picture frame. Cut hot and cold at the coil and leave the coil open like @EBEBRATT-Ed said. Then cut and cap the existing hot and cold up high. Set the new water heater in a good serviceable location. Don't block access to any part of the boiler. Tee in your new 3/4" hot and cold near the ceiling at the location of the water heater. New valves. New vacuum breaker if needed.

0 -

Good points HVACNUT. The HP will go to the right of the boiler….about 4 feet away. Should be enough room to service the boiler. I like the idea of the tees near the ceiling. It will look very clean.

Thank you!

0 -

-

Noted. Thank you Kaos!

0 -

This is a good introduction to HPWH and some of the lessons learned so far regarding installation and performance.

HPWH will not perform the same as a gas fired tank. Nor will they perform like a tankless coil or a tankless water heater. They are all unique in the way the operate and provide DHW. It's good to know before you go.

It sounds like you may have a good application. Enough room volume and a cast boiler to grab residual heat from.

Be aware of summer use, the heat needs to come from SOMEWHERE, for the heat pump to "pump"

They discharge cool air, around 45°F. So do't place one next to your bed :)

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Not sure if a HPWH can run to 140 and use a mixing valve?

0 -

agree 140 is pushing it pretty hard

In Idronics 33 we show 3 options for elevated temperature operation These examples come from A HPWH advisory group that is studying various options. The elevated temperature concept is mainly used to leverage off peak rates

With DHW, it as always comes down to what the customer needs, wants, or is used to. I would guess most homeowners have no idea what their dhw use isBob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Hi, I've been studying this with Gary Klein and indeed, the cold output. done wrong will damage other equipment or cause moldy areas on walls. Even the manufacturers are taking notice of this. Also do make sure that the in and out airflows from the HP do not mix, or you cut performance by pulling in cooler air.

Yours, Larry

2 -

-

-

it doesn't need to be exactly 140, that is more of a legionella guideline temperature

Anything over the useable temperature of 110- 120, you get the extra capacity with higher tank temperature

Some plumbers run a line before the mix valve to the dishwasher

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

140°F

ASHRAE Hot Water Temperature Recommendations

ASHRAE recommends storing hot water at 140°F to prevent the growth of Legionella bacteria. For most households, the U.S. Department of Energy suggests setting water heaters to 120°F to minimize scalding risks and reduce energy costs. However, for households with immunocompromised individuals, a higher setting of 140°F may be necessary. In healthcare facilities, careful control of water temperatures is essential to prevent scalding and ensure safety. CED Engineering

1 -

-

I doubt the plumbing codes will ever have more than legionella guidelines

There are different opinions from the various groups , ASHRAE, CDC, ASPE, and state and local codes or guidelines, etc

One guideline suggest the recirc run 24/7 but energy codes suggest recirc pumps need to be timer, demand or temperature controlled

Then there is the chemical option instead of elevated temperature

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

I am planning on doing the same here next year with abandoning the domestic coil and installing a 50 gallon HPWH. House used to have a tank water heater many years ago so installation for me should be fairly straightforward. I've already won my condensate line over to the sump pit and it will end up living between the oil tank and boiler.

0 -

So today the electrician replaced the panel with a larger one and added a 240v 30amp breaker plus junction box next to where the HPWH will go.

The domestic hot water is getting worse now that outside is in the 40s . We can't even shower anymore. The HPWH won't get here until Friday. I have a service contract with the company that delivers the oil and they are coming tomorrow to take a look.

I decided in the meantime to take a look myself. One thing I noticed is that the pipe coming up from the coil is super hot, but once it gets to the area where the valve circled in red is, the temp is about 65 degrees (from about 140 below that point).

I tried to take it apart but it is way too tight and don't want to break it. I then disconnected the pipe right above the flushing valve since I have a sharkbite and tested. Sure enough, the valve in red (not sure what it is called) does NOT close all they way and there is water always going into the hot side.

If the service company doesn't fix this for me unless I pay them, should I just cut it off and cap both sides? I just don't see the purpose of it.

I'll probably keep moving forward with the HPWH but I would like to keep the coil as a backup. It would also be nice to be able to shower the next few days :).

Thank you again for all your help!

0 -

Looks like that valve is a manual tempering valve. The washer is probably bad. You could take it apart and replace the washer.

0 -

Thank you Ebebratt, I'll try with a bit more strength. It is really tight. Removing it all together won't hurt correct?

0 -

A better pic of that valve would help. Generally a tempering or mixing valve has 3 connections, hot, cold, and mix. and a knob to make adjustments.

I think that bypass valve, in the red circle, is what is doing the tempering?

If the coil is limed up, performance drops way off.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you Bob. Correct, that valve in red is the one leaking cold water to the hot side. Here are a couple more pictures.

The coil I flushed 9 months ago and started performing a lot better but now because of this valve it is terrible. If I can't take the valve apart, I'll just cut it off and cap both ends unless someone thinks it is a bad idea?

0 -

the cross over valve needs to be there and work properly to temper the coil output temperature.

If you delete it the dhw will run close to the boiler operating temperature, not advisable.

It is a pretty basic rubber washer valve, with the handle off it should disassemble easily

A box wrench or deep 6 point socket would be the best grip, channelocks or vise grips can squeeze the brass out of round and make it hard to unscrew.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you again Bob. I was able to remove the valve and replace the washer. The leak to the hot side stopped, but now I get no hot water. Does this mean the coil is completely limed up? The pipe up to the crossover gets very got. If I open the tempering valve then I get water again, but very cold.

Service should be here any minute. I'll ask them to flush the coil.

Please let me know if you can think of anything else. Appreciate all the help!

Update: Service came and came to the same conclusion. They'll be sending someone to flush the coil sometime today.

0 -

it was wise for the plumber to install those flush valves!

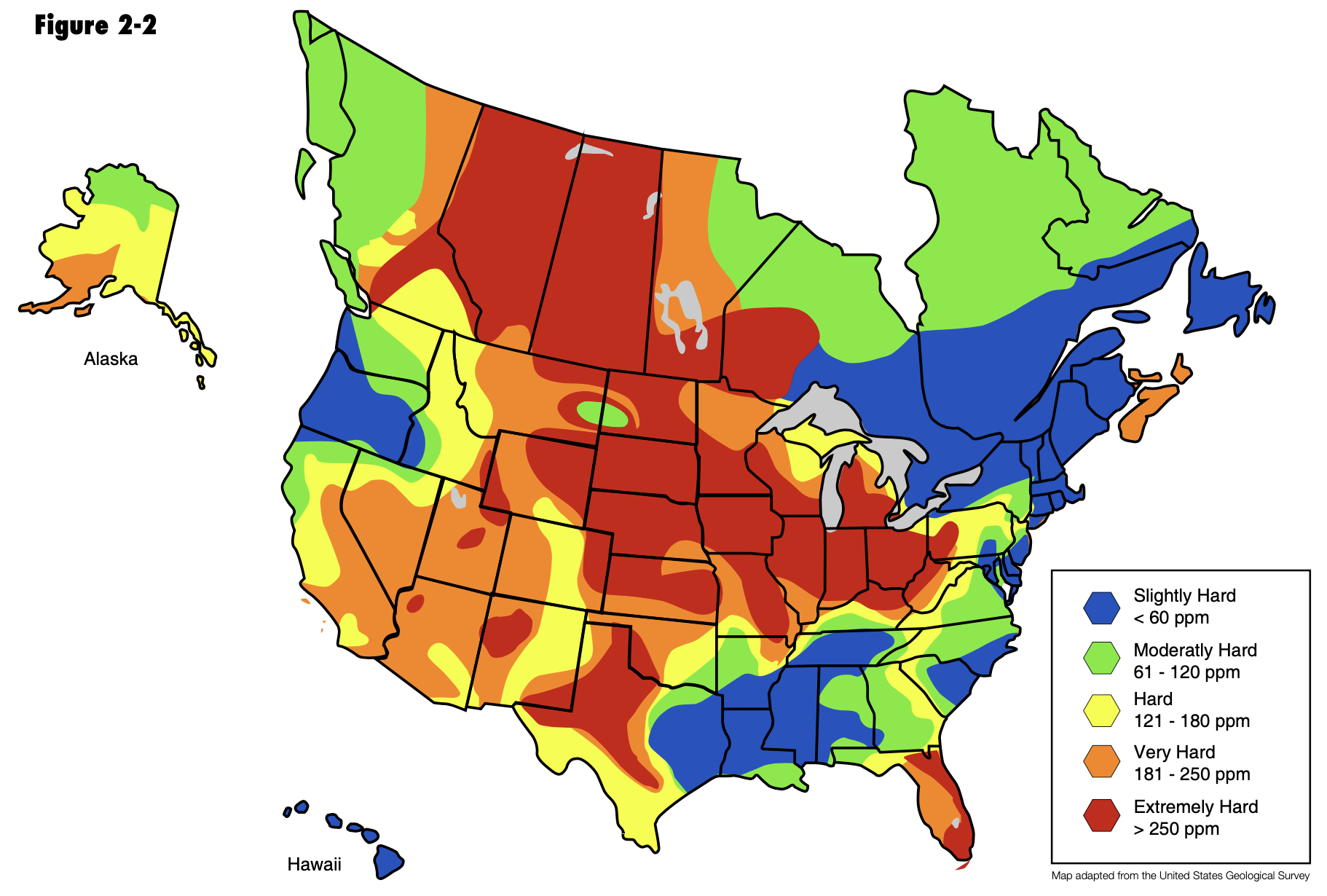

Anyudea how hard you water is? The hard water is the cause of the lime scale.The high temperature that those coils operate at really encourages the minerals to precipate out of the water.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The water is moderately hard. I installed the flush valves myself about a year ago so I could flush the coil. Took about 3 days of 4 hour flushes. Much better afterwards but it is due for another one but I would rather take advantage of the service contract and have them do it.

Any whole house filter you might recommend? I used to have a softener at my previous house in California and I rather not have to deal with one. We are in Maryland now.

0 -

I am not a fan of salt based ion exchange softeners either. We had extremely hard well water in Missouri, so it became a necessity along with an iron filter.

My compromise was to install the softener just on the hot water. So the cold water feed to the HW tank had a softener piped in.

This reduced salt use, left cold water for drinking and outdoor watering. Dishwasher and cloth washers like the soft water, soap consumption drops, spotting on glass was minimized.

With the mix valve on the WH set at 120, not much cold needed to be added at the shower or tub.

There are other types of water treatments like TAC, and some magnetic devices that you can look into. I don’t believe they actually remove the scaling ions, but keep them in suspension?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Ok, good to know Bob. Thank you for the explanation. I need to ask my neighbors and see what they are using. I was hoping a high quality filter would be enough. I need to start with a water test and take if from there with their recommendations for my situation. Appreciate your help.

0 -

If I understand what is happening here,

- You don't have enough hot water to take a comfortable shower.

- You added valves to flush the tankless coil and after cleaning the coil your hot water improved

- There is an incorrect manual mixing valve where an automatic mixing valve should be

- You get very hot water out of the coil up to the mixing valve location

- After the manual mixing valve location the water is no longer hot enough for a shower

- Your conclusion is to replace the tankless water heater with a tank type water heater that will cost more than 20 times the price of a proper mixing valve.

That is because the water temperature in the boiler is in constant flux. Always changing depending on a call for heat or not, the boiler can get as high as 190° (or hotter depending on the high limit setting) or as low as 150° if the low limit is set at 160°

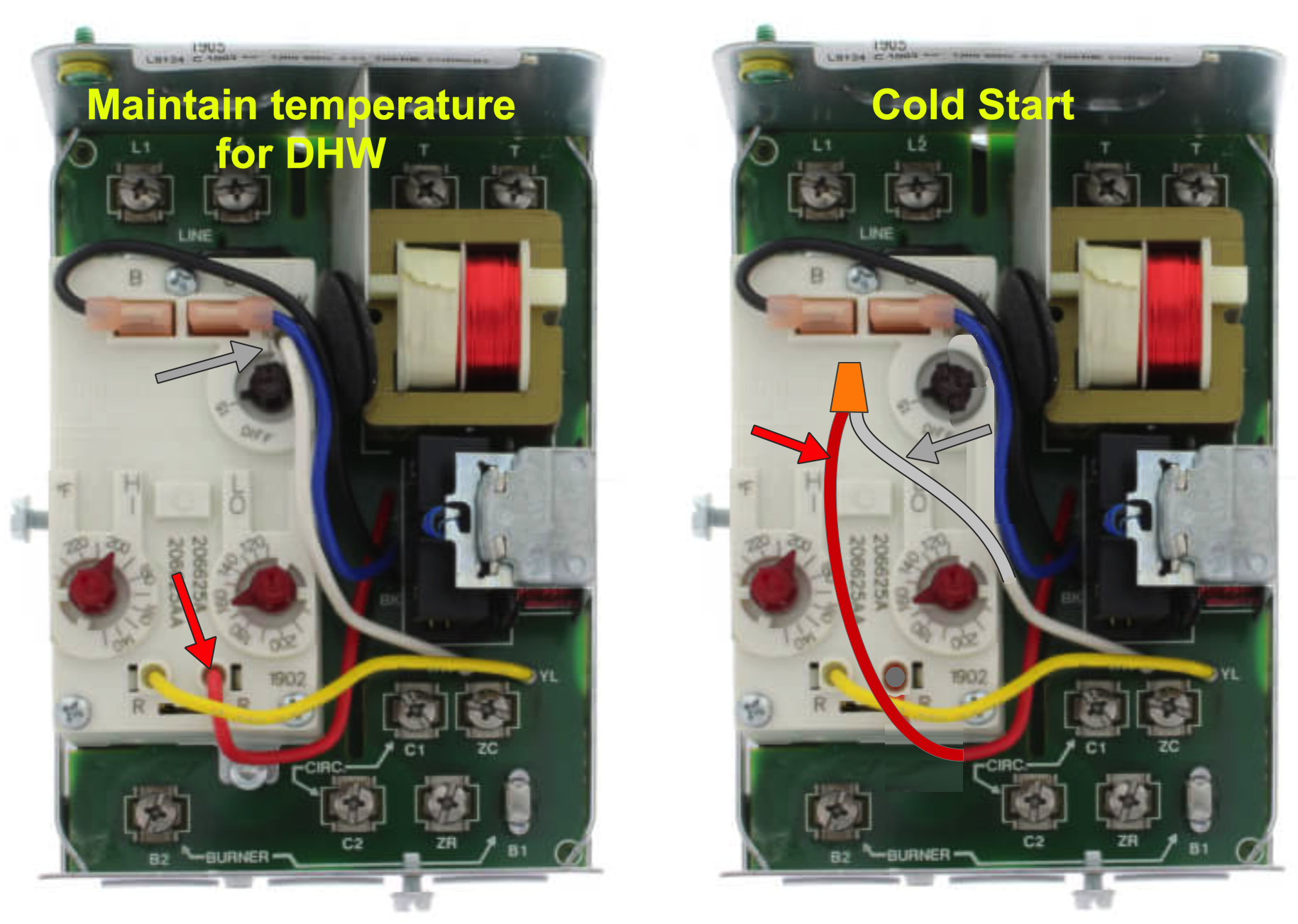

That logic aside you will want to reduce your oil consumption by rewiring/recontrolling the oil burner to be a cold start boiler. the very same day you switch to a tank type water heater you will want to set the control so it no longer makes hot water that you can not possibly use. If no pipes are connected to the water heater you can not use the hot water from that water heater. So then you don't need to have the control make hot water for that water heater.

Depending on the boiler's triple aquastat relay, you have several options

L8184A,C,G or L is easy to do by removing the R and W wires from the LO limit side of the control and connecting them together. That changes the control from a maintaining minimum temperature for DHW to a cold start boiler.

If your plumber indicates that you don't want that because you don't want a cold start boiler for some fake reason, then that plumber is lazy or clueless

If you have the Electronic control form the OEM, the best you can do here is to set the LOW as low as you can… that would be 120°F, then turn off the burner switch in the summer.

If you have an aftermarket electronic like the L7224U, you can set the Low limit to OFF. and that will make it a cold start boiler.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

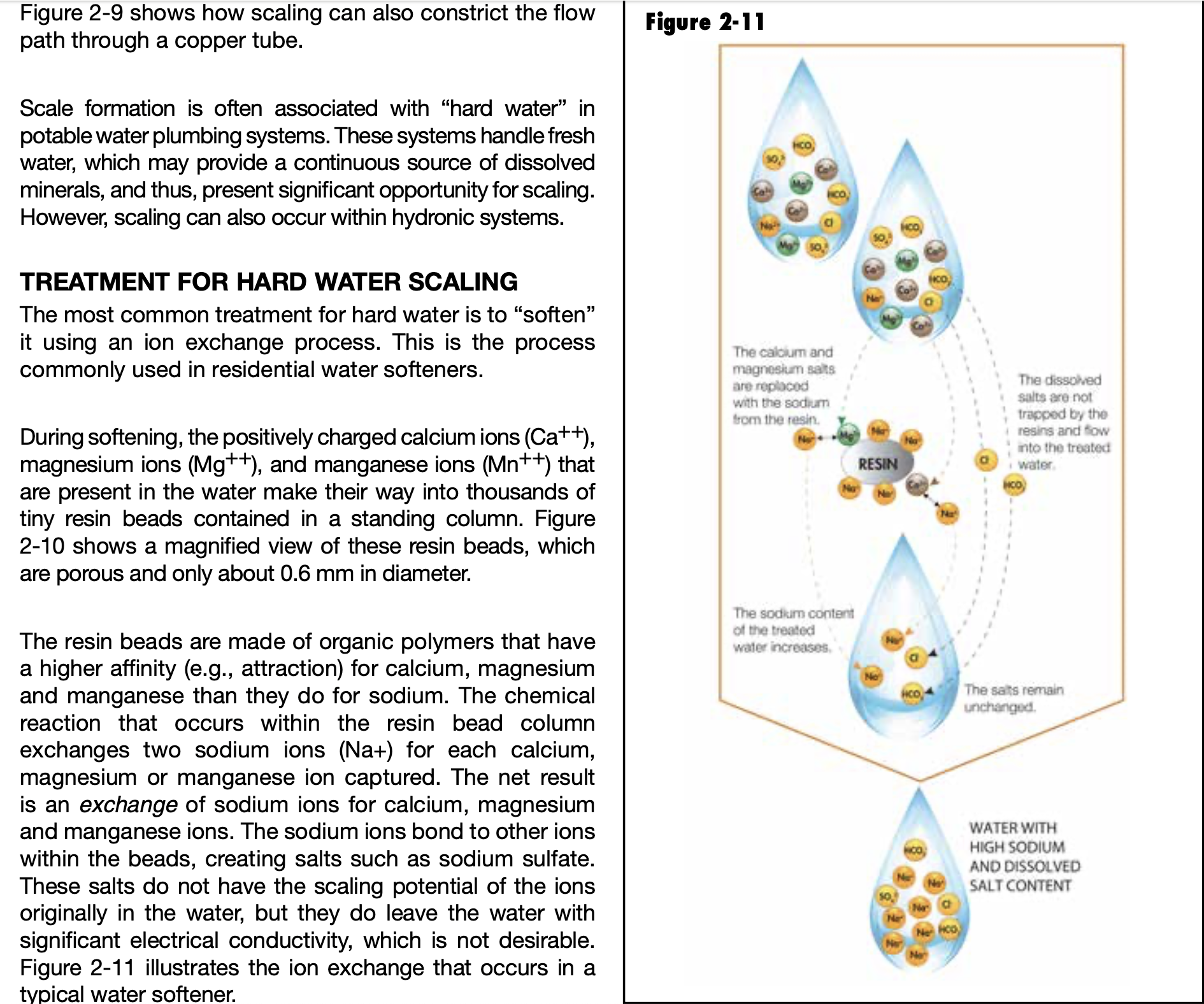

Here is a graphic and explanation of how an ion exchange softener works. You are removing any scaling ions the ++ charged, replacing them with the sodium (salt) in the resin bed.

A deionizer or demineralizer would remove the + and - ions and give you pure water. A bit over-kill for residential potable water.

It is always wise to have the water tested to see what is in it before you start adding filters or softeners.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hi, It seems pretty certain, but you could confirm the scaled coil by checking to see what flow / pressure drop you get through it. From the description, it sounds like flow is nearly blocked. If that's the case, once it's cleaned, see how well the existing piping arrangement works… or doesn't. That will help to guide next steps.

Yours, Larry

0 -

The more you want to know about what is in your water, the more it will cost. Once a year my city water provider sends out a water analysis. Mainly looking at components that could be a health issue. They don't address hardness.

If you just want to know hardness, test strips or a basis test kit will work fine.

But you already know you have hard water? Will putting a number to it change your mind about adding a softener?

If a tank type heater is in the near future, the scaling minerals will be less of an issue perhaps. A HPWH will not operate at those high temperatures, so less scale formation in the tank. And tanks tend to collect the minerals at the bottom.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Thank you Ed and Bob.

Ed, appreciate all the details you shared. I do have the L8184A Aquastat so I'll set it up to cold start the way you showed me once the HPWH is up and running.

The reason I am getting a new HPWH is because the tankless coil is just not sufficient for us. It just keeps getting less and less efficient. The mixing valve won't fix this since the flow at the coil is highly restricted. I have a new coil sitting in the basement ready to swap but I missed the window to do it without having to worry about having heat in the house. The few plumbers I called plainly ignored me. I can do it myself but might need a couple of days since most bolts will probably break. Also, having to fire the boiler in the summer just to shower is not only impractical but also expensive with oil at $4 a gallon. The 80 gallon HPWH is $2500, but I'll get a BG&E rebate of $1600, plus a tax credit of 30% of $900. For $670 I'll end up with a much better setup, and more importantly, a very happy wife and kids :) I'll be adding a recirculating pump with a valve kit at the furthest bathroom as well. This will save a ton of water.

Thank you again Bob. I am by the Chesapeake bay so looks like my water is slightly hard. Interesting explanation on how water treatment works. I'll definitely get the water tested.

Any moment now someone from SMO will come flush the coil. We'll see how that goes. I just need 4 more days of hot water. The HPWT gets here on Friday and I have everything ready to go.

Thank you again to both of you!

0 -

I agree with your HPWH decision.

This Idronics issue, liked below issue talks about HPWH in general and some of the concerns with recirc and HPWH.

Check out the Metlund® Demand recirc system. I think that is a good match for HPWH recirc systems.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thank you Bob. I'll make sure to read it. Some great info in there.

I'll be using a similar pump to the Metland's. It is made by Watts. I'll install it at the HPWT, with the valve kit at the farthest bathroom. Right now the plan is to use wi-fi outlets controlled from the cell phone. Anytime anyone wants to shower, they'll have to tap the timer on the app, preset to 3 minutes.. This will minimize the issue with the recovery rate. Not sure my wife will go for it but I sure will. If she doesn't get used to it, I might get one with a remote button, but I am having a hard time finding one with multiple remotes to control one outlet. Hub is an option but I'd rather not go that route.

1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements