T87F anticipator appears faulty

I have a 2-pipe vapor steam system. I've kept the anticipator on the T87F all the way to the left (longest cycle) for many years, basically off. When I try to move it even only a fraction of a mm to the right, I get a super short cycle, ~4 min.

I've tried to clean it. Removed from wall and sprayed electronic cleaner on it, swabbed it. Nothing changed. It is perfectly level on the wall. Any ideas on how to fix it or diagnose it further? Thanks.

Comments

-

how does it cycle on max?

0 -

What is the reason why you adjusted the anticipator ?..

There was an error rendering this rich post.

0 -

The temperature overshoots quite a bit. So there are very long cycles of an hour or more, and large temperature swings (say, roughly 4F).

When I got a new boiler in 1997, the techs repositioned the anticipator (maybe 0.8); it short-cycled (~5 min on); called them back; they said everything was set right (obviously not). Shortly after, I found the little anticipator lever, pushed it left until it cycled as before. Only in the last month did I discover that it is just a variable capacitor that goes on and off with the tstat switch; left=high resistance/less heat; right=low resistance/more heat. I figure dirt or something may have created a short. No luck by cleaning. It's hard to examine it visually, made as it is. Any ideas to fix or diagnose further?

0 -

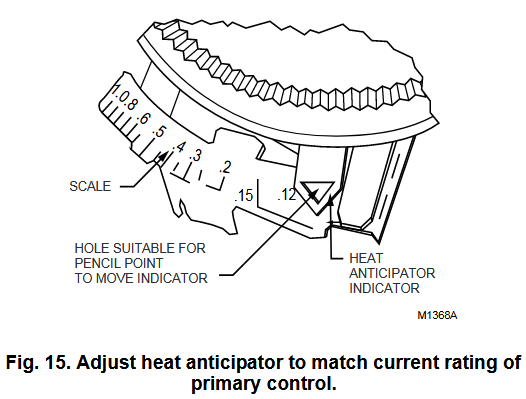

it is a power resistor in series with the heating circuit. if the tab or the surface is dirty it won't make good contact and I think the entire resistor will be in series and it will be at the longest cycle setting. try rubbing it with something like a business card with alcohol on it or try a couple drops of red deoxit. you can measure it with an ohmmeter.

0 -

Change the thermostat. On the older thermostats like the T87 you are supposed to measure the amps flowing through the thermostat and set the anticipator to that amp setting. I found that this did not work sometimes and you would get short cycling (close temp control) or long cycles (wide swings in temp) so usually you just play with the adjustment to get what you want.

T87s are long gone unless you can find one on E-Bay. Honeywell makes an electronic round model and of course there are other electronic stats.

I doubt you will have any luck fixing yours.

0 -

Are you sure it’s not short cycling on pressure?

0 -

@mattmia2 , I can try cleaning it some more. I put an ohm meter to it; the value jumps around a lot (not sure why). I'll try that again, too.

@EBEBRATT-Ed , I tried several position; all fast.

@HydronicMike , Short cycling on pressure? Hmm, I don't think my vapor system has ever experienced such a phenomenon…I think the pressuretrol is still a virgin…the 100 year virgin. I haven't seen more than 2-3"H2o on the 0-30 gauge, so, < 0.1psi.

0 -

make sure the pivot end of the wiper for the pot is clean too

0 -

I expect the resistance is quite low, an inexpensive meter may not do a very god job measuring the resistance. I also expect the wiper part of the circuit may have a poor connection, so you get the whole resistor (maximum anticipation, maximum resistance, maximum resistor heating) or where you had it originally, no resistance (no anticipation).

Some information here, although I think they got this part wrong.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

that seems like a lot to take the mercury off your hands…

0 -

Don't stick your hands in the mercury. That stuff can kill you.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Update: I took the T87F to the workbench; removed the plastic dial for clear access to the anticipator; I used electronics cleaner, alcohol, qtips, and compressed air. A resistance test gave a range of ~1-7 ohms, right-to-left, smoothly increasing. However, when I re-attached and tested the anticipator, it did as before; it cycled off much too quickly, ~5 min.

By the way, if it helps to know, the amp reading of the tstat wire at the boiler is 4.8A.

0 -

If the boiler control is drawing 4.8 amps through the thermostat…. something is odd. Ind of surprising the transformer can even supply that. The anticipator range is 0.1 to 1.3 amps, so naturally if you are pushing 4.8 amps through it it won't cope at all.

But I'm puzzled by that amp draw — most modern controls are down at the 0.1 amp range?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

what control or gas valve or primary control is it controlling at the boiler?

0 -

Can't be 4.8 amps. You would need a 115va transformer to support that.

0 -

1000 pardons! The amp reading is 0.48A.

0 -

Try thoroughly cleaning the anticipator slider and resistance coil. Do NOT use any abrasive! I use DeOxit for that kind of thing, but there are other contact cleaners that work too. Spray it on the coil, then run the sider back and forth and back and forth until you get bored…

0.48 amps is a little more reasonable. After you get things cleaned up a bit, start with the anticipator set just abut in the middle.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

" A resistance test gave a range of ~1-7 ohms, right-to-left, smoothly increasing. "

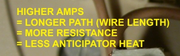

It seems maybe the resistor is connected backwards, although not sure how. To the left should be the lower resistance to the right the higher resistance. The goal is to produces a relativity small but consistent amount of heat for the anticipation function regardless of the needed primary control load current (different systems have different equipment).

So if you have a 0.8 amp primary control load you need less resistance (to the left) than if you have a 0.15 Amp primary control load, with the 0.15 you would need more resistance to generate the same amount of heat.

Since the primary control load is the predominant factor determining the load current, varying the anticipatior's resistance will slightly change the amount of heat generated. That's why moving the setting to the left is less resistance, less heat, longer system run time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

if it gets a higher voltage to the t-stat it can burn out the pot, make sure you have continuity between both ends.

0 -

I thought a higher resistance generates less heat. The highest resistance, e.g., a cut wire would generate no heat. All else being equal, the longer the wire the more the resistance, so less current, and so less heat.

My understanding is that the anticipator is just a variable resistor; when the copper lever with a pin contact that touches winding is moved along the winding, it shorts the wire where it is positioned. If moved left, the wire length (and resistance) increases; to the right, it decreases.

My primary control states 0.8A.

0 -

Ah. But a flaw — a minor one — in your logic. The current through the anticipator is not set by the anticipator — it is determined by the device being controlled. The actual resistance of the anticipator affects the current flow only slightly. So… the longer the path through the anticipator element, the greater the heat being generatred — and the quicker the anticipation.

Here is a good article on them…

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

@Jamie Hall I looked at that article before and when it comes to the resistance annotations I believe they got it wrong, hence the confusion out there.

@pacoit Assuming the resistance wire has a constant resistance (per mm) the small end (Left end) of the variable resistor's resistance changes a lot less for the same amount of wiper movement than at the large end (right end).

So if you have a 0.8 Amp primary control load you need less anticipator resistance (to the left) than if you have a 0.15 Amp primary control load, with a 0.15 Amp load you would need more resistance to generate the same amount of heat as compared to the 0.8 Amp primary control load.

Since the primary control load (not the anticipator resistor) is the predominant factor determining the load current, varying the anticipatior's resistance will slightly change the amount of heat generated. That's why moving the setting to the left is less resistance, less heat, longer system run time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

A pencil erasure works well

0 -

Ohm's Law: V=IR (Voltage = Current x Resistance)

This states that current is directly proportional to voltage and inversely proportional to resistance. So, for a given voltage, if the resistance increases, the current decreases, and vice versa.

As I measured the resistance between the wiper and the winding start, moving right to left, the resistance increased. Therefore, according to Mr. Ohm, the current would have decreased.

In fact the Honeywell instructions include a little noticed warning to not move the wiper too far to the right. I suspect that's because contacting too close to the winding start creates such a short wire (low resistance) that it might burn and break.

0 -

Aside from the minor detail that you completely neglecting the resistance, voltage, and current characteristics of the source (the burner controller), you are correct.

It might be well to verify the characteristics of the rest of the circuit?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

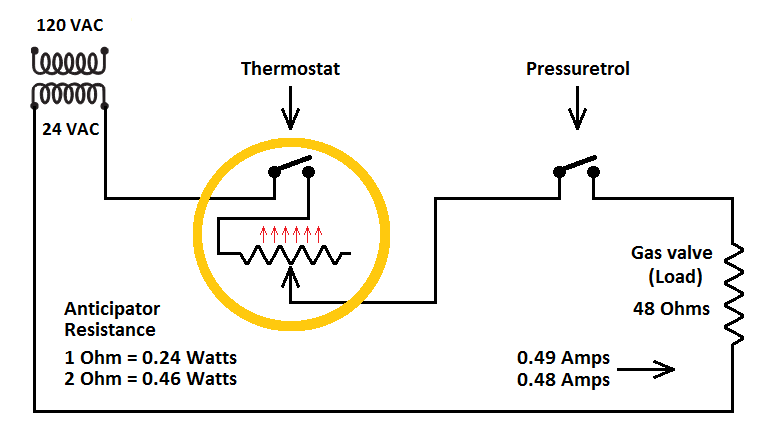

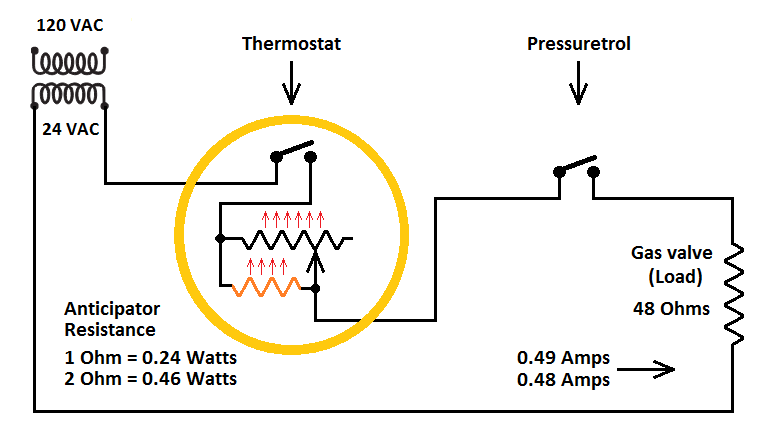

I believe the reference point to measure the anticipator resistance should be the Left side of the variable resistor (at least that is how mine is wired), so the resistance increases as the wiper is moved to the Right. As drawn in the example below.

Keep in mind the primary goal is to create a relativity fixed heat dissipation from the anticipator resistor with a wide variety of different system equipment and currents.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

That's it, pretty much… so simple.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

@Jamie Hall, "Aside from the minor detail that you completely neglecting the resistance, voltage, and current characteristics of the source (the burner controller), you are correct."

You lost me here. I don't know what you mean.

@109A_5 , Nice image. I am envious. However, you have the resistor inline with the switch; on my T87F (I think circa 1955), If I lift the wiper from the winding when the tstat is on, the boiler does not shut off. Apparently, the resistor is in parallel with the switch wire.

It seems to me that the anticipator is just a variable resistor that turns on and off with the tstat switch. It just heats up a little bit while the tstat is on. That's all. Various article online give it credit for controlling this and that; I think they are incorrect.

0 -

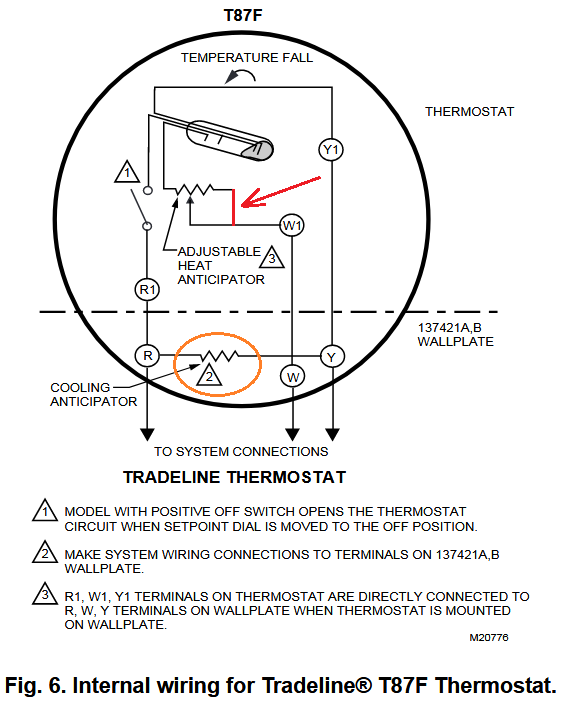

Something seems wrong, or maybe different due to age. As Honeywell drew it, if the wiper is lifted off the variable resistor the boiler should shut off. If there was an added connection (Red Annotation), that I believe does not exist the boiler may stay running and the resistor may warm up excessively and cause short cycling.

I'd carefully examine the whole circuit inside the thermostat, maybe the anticiptor resistor is connected wrong. On mine there is clearly a wire connected to the Left (small end) side of the anticipator resistor.

Possibly (but unlikely) the (Orange Annotation) if it even exists on your system is wired wrong, but I think that may keep the boiler running after the switch opens and it is in the wall plate and not inside the thermostat housing.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

" Apparently, the resistor is in parallel with the switch wire. "

If a resistor of the low resistance value of the anticipator's resistor was in parallel with the actual thermostat's switch the boiler would never turn off with the thermostat's switch opening.

The anticipator resistor is in series with the mercury switch as the wiring diagram shows. So it only heats up during a call for heat and cools down when there is no call for heat.

Normally the small amount of added heat simply causes the thermostat to open just a bit sooner, anticipating the heat to come briefly after the call is terminated. This provides better comfort and tighter temperature control.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

" Apparently, the resistor is in parallel with the switch wire. " i.e, not in parallel with the switch itself—-which, if it were, I see it would be as you say.

But, I should have ruled out what I was thinking because a resistor in parallel to a wire would I think do nothing, as the current would follow the path of least resistance: the wire. Pretty dumb, though my experience in circuitry is limited.

Well fool me! The resistor is in series. Honeywell does not lie. Though, I don't know why sliding a piece of card stock under the wiper doesn't turn off the boiler. Ah, my T87F must be special…

0 -

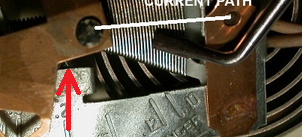

I would inspect it closely. Is your resistor orientation as it is pictured in this picture ? By the way I believe the white annotation in this picture is wrong the current path is from the Left side to the wiper. The Right end of the resistor is not electrically connected to anything else.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

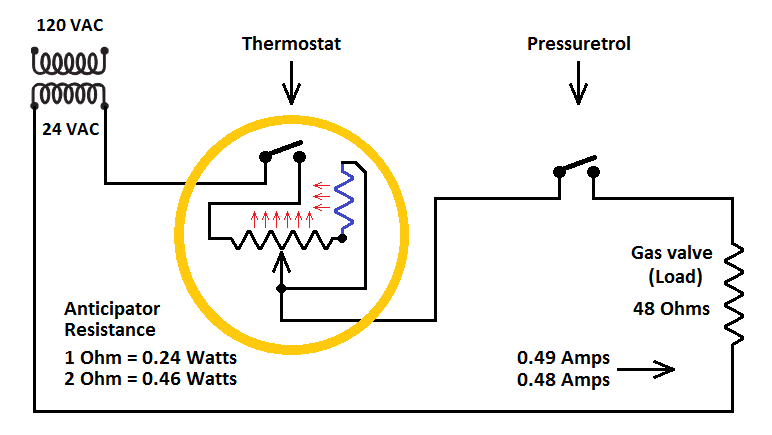

Neat diagram there @109A_5 ! Thank you.

Which illustrates, or at least helps to understand, two things. First, the resistance of the anticipator, even at the high resistance end, is very small in relation to the controller load. Therefore the controller sees the combined anticipator and mercury switch as a nice closed circuit. What you want. Second, I believe there is in deed a missing wire in the diagram. I haven't taken any of mine apart, and I'm not about to, but fo rat least one of them the documentation mentions a 1.2 ohm bypass resistor, so that when the anticipator contact is at the highest resistance end — or lifted from the windings entirely — that bypass resistor is still in the circuit in parallel.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

OK @Jamie Hall I'm not going to take mine apart either, its in use now and it is awkward to get to. With your comment I have made some modifications to the drawing. Here are two examples. Either way with the wiper open the system may still work. The second, I would expect, would have a great amount of anticipation.

Or with this copper leaf spring on the axle of the bimetallic spring, maybe the other 1.2 Ohm mystery resistor (that I have not located) is actually the bimetallic spring ? The Blue resistor below. I have one more theory that the variable resistor has a tap i'll try to draw it and post later.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

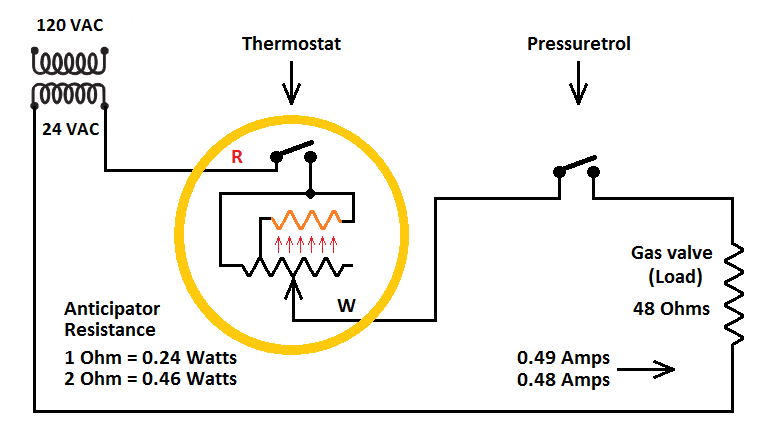

OK. I removed my T87F 2055 from the wall, cleaned and then inspected it closely. The heat anticipator resistor's wiper is the 'W' wire. The common terminal of the SPDT Mercury switch is the 'R' wire.

The heat anticipator resistor is actually two windings with a flying connection as a tap. That tap barely seen here (Red arrow) is connected to the metal of the adjustment scale.

The Right end of the anticipator resistor is open, no connection to anything. The Left end of the anticipator resistor has a wire connected that goes to the 'Heat' terminal of the Mercury switch.

The anticipator resistor's flying connection to the metal scale then via the copper leaf spring is connected to the axle of the coiled bimetallic spring. The SPDT Mercury switch is mounted to the other end of the bimetallic spring. The Mercury switch end of the bimetallic spring has an electrical connection that connects the 'Heat' terminal of the Mercury switch to the bimetallic spring. The Orange resistor in the image below is the bimetallic spring.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Brave man…

No matter how you look at — an amazingly simple device which just sits there and does its job.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

Yeah, sometimes my curiosity overrides my better judgment.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements