Steam Near Boiler Piping

Good evening,

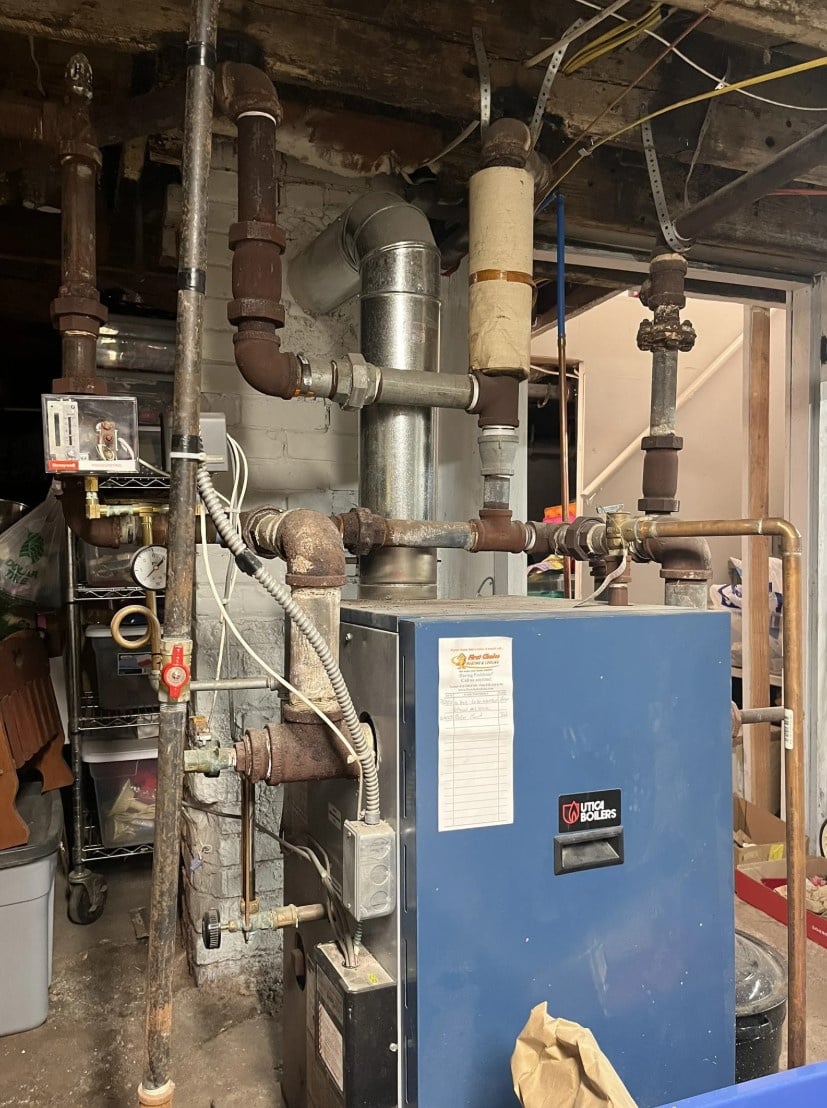

I am working on the near boiler piping for my new Utica boiler and have a few questions. The overall photos below show my work in progress and context for the following questions (and photos). Apologies in advance for a lengthy (physically due to photos I think) post.

Does the Hartford loop bottom pipe have a minimum length (MAGENTA line in photo A)?

Should the TEE for the water feeder be below or above the water line? Photo B

I am planning on using a 1 ½” to ¾” TEE for the water feeder. I am going to place it on the return pipe prior to the Hartford loop.

Side question: should I supply from the domestic hot water side for the feeder? It seems like the water in the pipe would get cold waiting for a call from the feeder.

The photos C and D are of my mock up for the return lines. There are two, one coming back from the north and one from the south.

My plan would be to combine both return lines (both 1 ½”) at the ceiling and drop them down to the Hartford Loop. Would there be any issues combining both of the returns to one at that point in the system?

The 1 ½” to ¾” nipple mocked up on the one return will be for the main vent. Each would have one.

One other thing to note with my setup is that I flipped the Hartford loop from the back to the front (photo E). This was due to my mains leaving from the back and the returns coming in from the front.

I can’t see any obvious concern with this approach other than the left side of the boiler getting a bit crowded. Am I missing anything in that thought other than ease of access?

Apologies again for the long post and thank you in advance for any insight, this forum and the people on it are amazing!

David

Comments

-

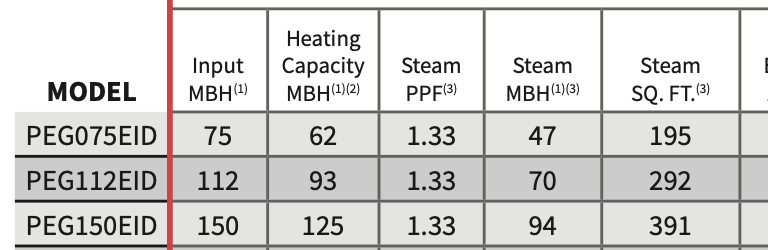

What model is that Utica? Should be PEG- something………..

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

the dry returns must drop below the water line before they connect together. if they connect together above the water line, steam from the main that fills first can flow to the main that isn't yet filled through the return and close the vent on that main, preventing it from fully venting and making it slow to heat.

2 -

" My plan would be to combine both return lines (both 1 ½”) at the ceiling and drop them down to the Hartford Loop. Would there be any issues combining both of the returns to one at that point in the system? "

NO !! If this is a 'One Pipe' system the returns should be connected way below the water line at the wet return level. You need steam isolation at the end of the returns.

Youtube, the "Silent Steam Team" videos, many example installs. Looks like you are trying to build it like the manual shows, Good !!!

Is this a 'Close' nipple ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

It looks pretty good. The over head returns may be combined together but they have to connect to each other below the bottom gauge glass tapping or lower is better. Same for the water MU below the water line into any return pipe.

0 -

Good morning

The boiler model is PEG150EID. It is rated for 391 sq ft and I currently have @ 315 . I believe there was a radiator in the bathroom that was removed by a previous owner.

@mattmia2 + 109A_5 + EBEBRATT-Ed

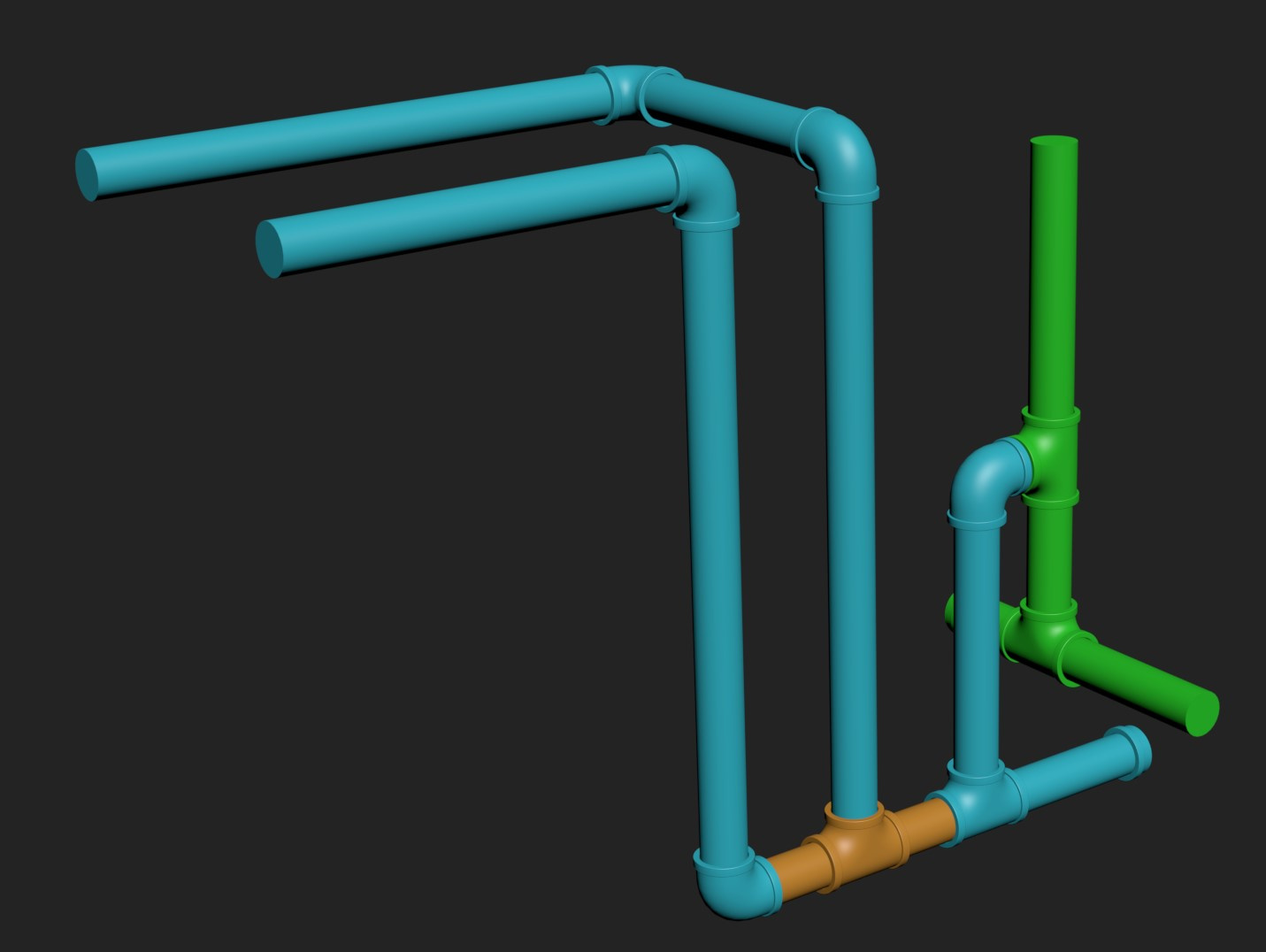

I am glad I asked the question about where to combine the returns. I did not even consider that potential fight between the two sides. I have revised my direction, image below.

@109A _5

That is in fact NOT a close nipple. I had that question in my queue to ask everyone and then prior to posting I did some research to make sure I was not asking questions that were already answered here or in other locations. Both the manual and Dan’s Q&A on the Hartford loop took that question off of my list. I wanted a nipple I could get a wrench on but I will be following the instructions and picking up a close nipple today.

The one question that no one had an input on was the length of the bottom pipe on the Hartford Loop (ORANGE in the image). Is there a min/max? If I were to revise the returns as shown in the image above are there dimensions for that pipe that I need to be mindful of?

I guess a subsequent question would be the size of the pipe. Would there be any concern from a volume perspective combining the 2 - 1 1/2" dry returns together into a single 1 1/2 wet return?

Thank you all for your help. Appreciated always.

David

0 -

Should the TEE for the water feeder be below or above the water line? Photo B

It doesn't matter.

Side question: should I supply from the domestic hot water side for the feeder? It seems like the water in the pipe would get cold waiting for a call from the feeder.

It doesn't matter. Just not from softened water.

My plan would be to combine both return lines (both 1 ½”) at the ceiling and drop them down to the Hartford Loop. Would there be any issues combining both of the returns to one at that point in the system?

Someone probably already said this, but combine them under the waterline.

Ed I think you are understating it 🙂 This install is very good.

The boiler model is PEG150EID. It is rated for 391 sq ft and I currently have @ 315 . I believe there was a radiator in the bathroom that was removed by a previous owner.

But it's a pity you oversized your boiler. Why didn't you pick the 112?

Both the manual and Dan’s Q&A on the Hartford loop took that question off of my list. I wanted a nipple I could get a wrench on but I will be following the instructions and picking up a close nipple today.

It doesn't matter. But use a stainless steel one if you don't want to worry about it rusting out.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Mocked up the return loop. Photo below. This feels pretty straight forward based on the feedback. Still with parts I have laying around, I will use the close nipple when I build it.

David

0 -

Looks good. I assume you are going to put a valve on that pipe that's pointing toward the black plastic bin for very occasional flushing of the very short wet return?

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Length of the orange nipple does not matter. Anything goes below the water line. As far as combining the 2 1 1/2 returns into 1 that is fine as well.

The overhead returns carry steam and water, so they are larger when you drop below the water line they are wet returns and the smaller pipe is fine.

Should work well Congrats.

1 -

Those pipe sizes are fine for that model boiler.

And as others have said, do not combine the returns until they drop below the boiler's waterline. This will keep steam from going into one return and coming up through the other one, which can cause banging and unbalance.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

You could also use a street ell instead of an ell and close nipple at the hartford loop. In reality in a 1 pipe system the longer nipple would be fine. The close nipple is used to minimize the surface of the water in that riser so if steam gets down that riser it is less likely to hammer. The only way steam would get down there is if it had to push through to the return to equalize the pressure in the supply and return. Since the supply and return are directly connected out in the system in a 1 pipe system, the pressures will be more or less the same and that never is going to happen. Maybe it could happen with a false waterline or something like that.

1 -

Thank you everyone. I am going to keep plugging away. I will follow up once the project is complete

David

0 -

As I am mocking up the connection from the near boiler piping to the supply runs I realize I am running out of vertical height to maintain slope away from the boiler (gravity returns). Would there be an issue running the first 5-10 feet of the main lines (from the near boiler piping) at a reverse slope? My thinking is that the pressure should push the steam through the system regardless. If there is any condensate the reverse slope would return it to the mains and it would end up in the equalizer. How far off is my thinking on this?

0 -

You can use a drop header to get additional height on your risers from the boiler. Here are a few pics of @EzzyT 's installs that use drop headers:

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

if you did that you would need a drip before it gets to the boiler to remove the condensate.

A drop header would be a great fix if it solves your problem but it sounds like you can't get the main itself up high enough?

Looks like you are already using a drop header.

0 -

How was it originally ? Probably could have dropped the drop header more to accommodate the connections to the main. Not sure we are understanding the issue.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

You don't need a drip if there is a counter flow near the boiler. There is very little condensate generated by that much pipe (especially if it is insulated).

The steam certainly won't care, it will go any direction happily.

The small amount of water will either flow back down or it will eventually get re-vaporized by the steam.

I have seen this with my sight glasses on my own boiler which has a few feet of counter pitch nearest the boiler.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

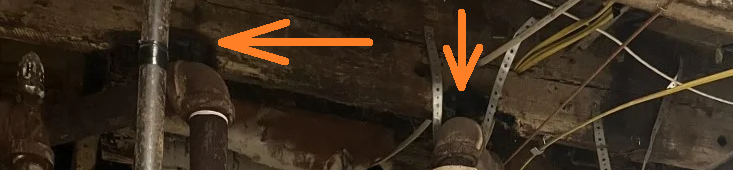

What was there before is what I am trying to avoid (image below)

My concern is where the supply lines start at the ceiling. As mattmia2 said at the end of his comment, I can't get the mains high enough with the clearance I have. I can probably get the slope back to the boiler, however, I may be touching wood at that point. Everything on the supply piping likely needs to be redone, for now though I need heat. The NBP should help considerably compared to years past, I imagine my returns will just be "slow". As I have been checking for slope they are all just a little bit sloped with one I check being level. The house has settled over the years (built in1890) so I will go back and readjust. That will make my clearance issues at the boiler worse not better most likely.

What is a drip and do I have counter flow at my boiler? Sorry, still learning.

Latest photo of the new return mock up at the bottom

0 -

I would think that if there was any condensate it would drop back down the risers to the header and then into the equalizer. Either because the steam in the header pushes it in that direction or because I have sloped the drop header.

0 -

0

-

I agree with that, except there will be very little liquid water in there and it probably won't even flow, it will either get pushed on down the main, or it will re-vaporize. There will be a little more on startup when the pipes are heating up. No biggie.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el2 -

A drip is a return teed off the bottom of the main to drop the condensate out of the main and down in to a wet return. It drops down below the water line and individually connects to a wet return. It allows condensate to drain out of a low spot in a main when it can't be sloped to the return.

Can you drop the return ends of the mains down a bit to get the needed slope?

0 -

A drip is also for a system with long counter-flow mains to keep the condensate from entering the header assembly, helping to maintain the driest steam production.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Is the drip required? With the drop header and the short distance to the equalizer?

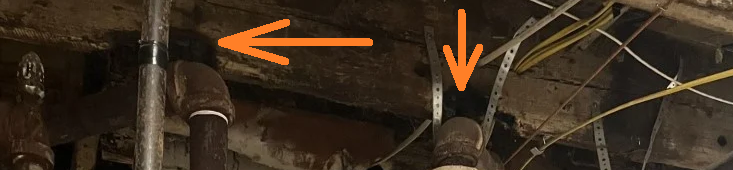

The clearance issue was a bigger deal than I originally thought due to the existing supply position, house settling, bent pipes or whatever may have caused it. I’ll need to repipe in the future. Either way, I had to drop the one main about 2” or it would have gone through the floor by the time it hit the risers (slight exaggeration) Photo below. The run from the riser to that offset is roughly 5.5’.

The second picture is charred floor joists. There are others nearby where there were joints which I wrote off as someone being careless with a torch while encouraging pipe removal. That one was in the middle of the pipe. These shouldn’t get hot enough to burn wood. Right? .

this particular pipe has been a pain Almost there though, hopefully1 -

If the counter flow part of the main(s) is short probably not a big deal. Insulating it as best as possible helps also.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

That joist dilapidation does seem strange. Kind of makes me wonder if there was a dry fire event that was caught in time.

If it is in fact rot there probably was a steam leak there. Two steam leaks ?

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thinking through how it was before, even if the NBP was wrong, that pipe made it over in one piece with no crazy offset like the one I just built. I bet they put it in, braced it from below and then had a couple of guys hang on it. That’s the only way it would have made it without the offset. I’ll need to look at the pipe in the morning to check that theory. If that is the case it still would have been counter flow. Then again not much was right with that piping. At least not for the newer boiler. Someone showed me (Ed I believe) what boiler might have originally been there. The piping made more sense with the older boiler.

The spot I photographed is in fact char. Picture doesn’t show it correctly. The temperature would not be hot enough as noted. I’m a good bit away now so I’m not worried. Once I know I have no leaks I’ll insulate as well.

It’s late and I’m rambling. Thanks again for all of your insight.

And just for fun…1 -

I have steam pipes so close to wood I can't tell if they are touching or not, no dilapidation like that. I'm sticking with a dry fire event that was caught in time.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Torching without protecting the nearby combustibles is severely reckless. Isn't AI great, Faster charring happens at a lower temperature ??!!??

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

you can make threads on a pipe that are intentionally not square to the pipe, that might be how they put pitch in to the pipe to make it line up.

0 -

I kind of like the idea of someone hanging on the pipe. Not proper, but it would work

0 -

I am up and running and have heat! Unfortunately I also have a hazy house that I believe is the burn off from the new piping…hopefully that’s it and it goes away

My heaters running and I have the windows open and fans running like it’s June.

Question on the pressure gauge. It’s been running for a bit now and I am not seeing the gauge move at all. Should it?

0 -

-

If it is a 30 PSI gauge that may be a good thing. If your boiler is properly matched to the radiation the pressure should be very low. My slightly undesized boiler heats the house just fine at no more than 2 inches of water column (or 0.07 PSIG). I added some low pressure Dwyer Magnehelic Gages to see the actual boiler pressure.

BTW looks nice.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

any issues with the haze? All black pipe. Stinks. Most of what I am reading says it’s ok and deal with it. It will eventually burn off. For the tears it was running, before the new boiler and piping, there was always a stink from the radiators. This time though it’s a haze. A good one too.

0 -

Manufacturing oils will burn off of the boiler itself but that shouldn't last long. The piping doesn't get hot enough to burn oil.

0 -

it was burning something. Dust? The basement was a haze. Upstairs a bit as well. I’ll keep the fans going

0 -

Not seeing a makeup water valve, usually it is kind of close to the boiler.

Looks like some skimming is needed.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements