Homeowner and plumber disagreement

Hello everyone

About two weeks ago, I had a plumber come to my house to do some work. I had been experiencing my cold water mixing with my Hot Water.

So, the plumber sends me a list of items to order. The list included:

1 Ptrol-tank

Multiple ball valves (white handles)

Two “swing” checks

One “spring” check

And a mixing valve. He said the mixing valve was code.

And an aray of various fittings

I proceeded to order all of these parts. The plumber came to my house and installed everything.

Well, as you can imagine, the Hot Water is no longer mixing with the cold water.

So far so good, everything seemed fine.

However, shortly after he left I now had extreme water hammer throughout the house. Every cold tap in the house had a degree of hammer. Even the toilets. The washing machine was the worst.

I could hear that noise from outside.

I called the plumber immediately and explained my problem.

He once again gave me a list of materials to buy at the plumbing supply.

His plan was to put a large hammer arrester, three more ball valves, and some other expensive fittings, behind my washing machine.

This is where the disagreement occurred. In my humble opinion, it seems that the p-troll tank is in the wrong place. Also, I feel it is installed in an unsightly position.

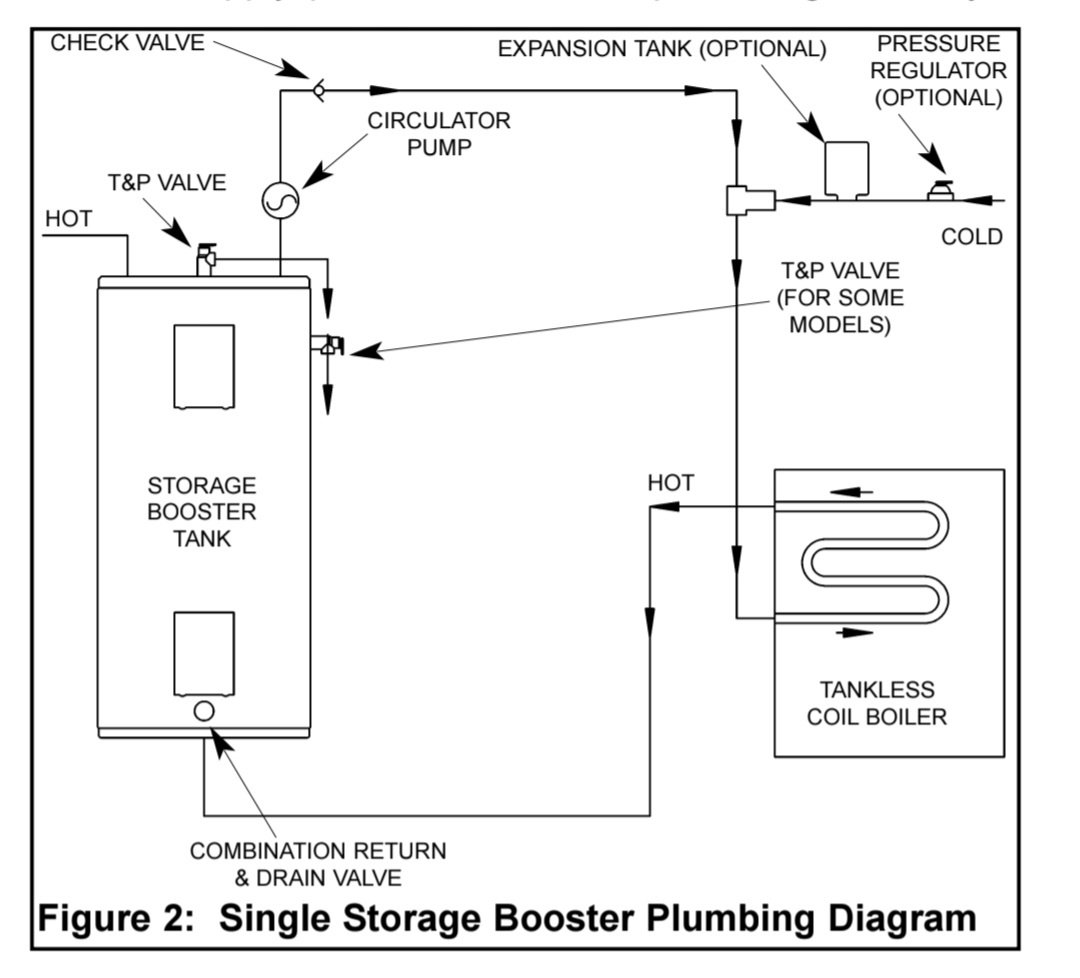

According to my own research, and considerable reading. It would seem that the p-troll tank should be on the cold side of the system installed vertically (just above the Red handled ball valve). that’s the cold supply pipe from the street. You see, that is not a hot water heater. It is simply a holding tank for the hot water with the pump that circulates it through the coil in the boiler. Both pipes going into the top of that tank or Hot. The pipe that he teed into is the hottest pipe in the loop. That pipe comes directly from the coil in the boiler.

I hope that I explained everything clearly and correctly so far.

The plumber noticed problems as soon as he was finished. His solution was to throttle the ball valve just before the mixing valve. So that’s what he did, and then he removed the handle. He left the handle on top of the water tank. I put it back on after he left and opened it up like it should be.

When I told the plumber my feelings about all of this and what I think should be done.

His reply was “Good luck.”

So, what do you guys think about all of this. And please take a look at the photos and give me your opinions.

Comments

-

It would be a lot simpler if that electric water heater was completely separated from the boiler. I'll be interested to see what the other folks think. My feeling is in the year 2025 there is no reason to be tying a water heater to a boiler like this. It costs too much in installation, materials, and maintenance to possibly make it sensible.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

depends on relative fuel costs. though the water heater will only last a decade or 2, the rest of it will last much longer so you have to keep buying tanks but you only have to buy the rest of it once and buy the other parts occasionally as they wear out. it costs less than an indirect and has a much faster recovery rate than an electric or heat pump or even gas direct fired water heater. you can usually run it as electric only in the summer and not have to heat the boiler because the incoming water temp is significantly higher in the summer.

0 -

it looks like an electric water heater. But it’s not. It’s just a holding tank. The coil that’s in the boiler creates all the hot water. The little circulator pump at the bottom, circulates the hot water between the coil and what is now called holding tank. The tank looks like it’s new . But it is just a replacement for a tank that was there for 30 years. The plumber did not do the tank replacement. That was done a few years ago.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

does all the cold water to the house come through that plumbing above the hot water tank for some reason?

0 -

Both pipes on the top of the water holding tank are hot

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

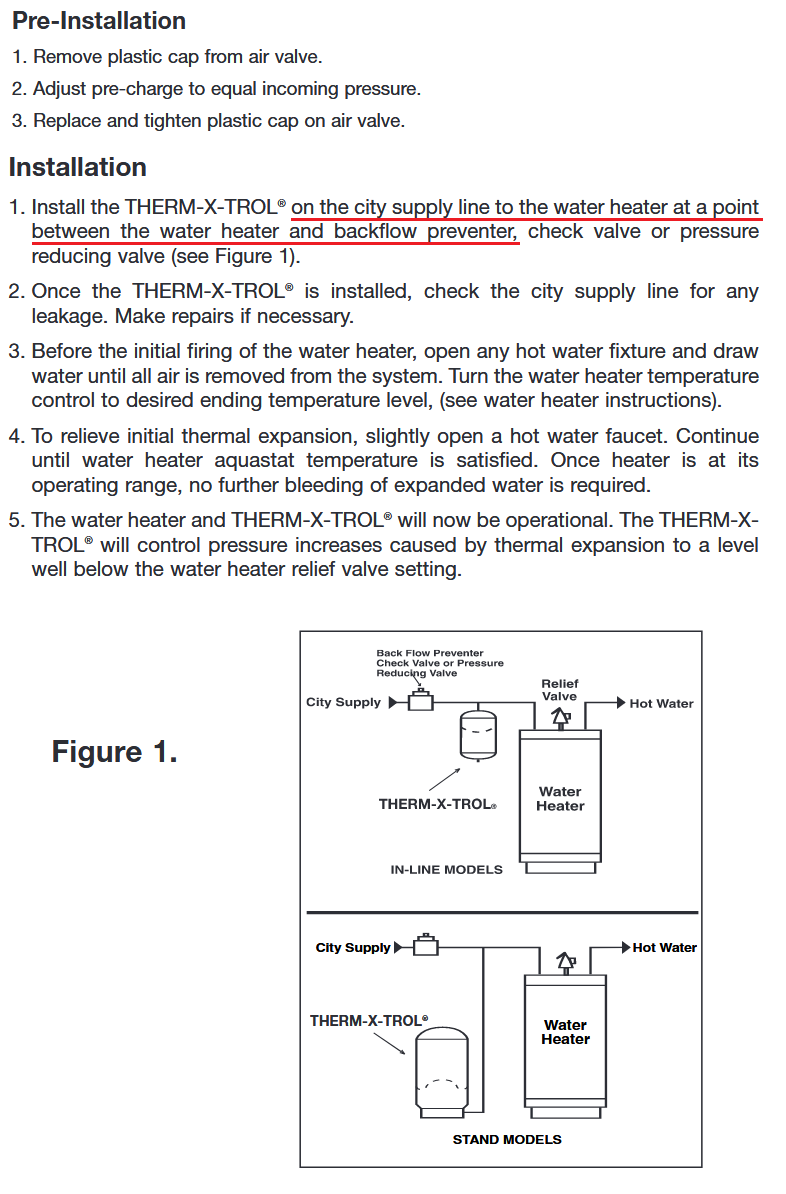

The what you call the

" 1 Ptrol-tank "

Make and model ? Find the installation instructions, paper with the unit or on-line and review them closely for the proper installation connections and orientation.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

it’s a

THERM-X-TROL ST-12 Expansion TankOrdered from supply house

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

The piping looks right to me. I question if you need 3 check valve as they may be contributing to the water hammer. Do you know how much water pressure you have?

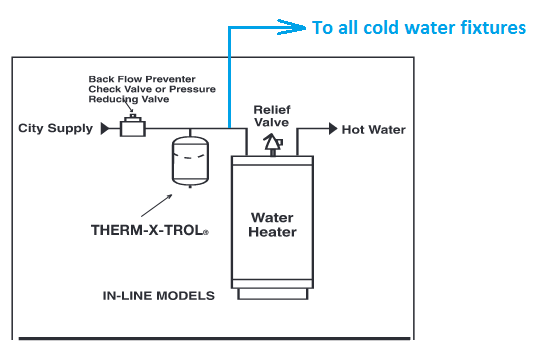

It looks line the pump pumps out of the tank bottom connection and into the tankless heater and the cod city water ties in there as well. Out of the tankless to the tank inlet with a tee to the expansion tank. Hot water out of the tank to the mix valve and the cold water also to the mix valve and mixed water out to fixtures.

Also you need to know the water pressure and the expansion tank air pressure needs to have air added or removed to match your water pressure or the expansion tank will not work right.

0 -

just got an idea. it may not be water hammer per se but the check valves opening and closing as water bounces in to that expansion tank then slams the check valve closed as it tries to get out.

0 -

Did you have an expansion tank before the recent work ?

I'd say it is installed wrong, looks like it is on the Hot side, and some instructions specifically state they want it vertical like it is pictured. Maybe it is more critical with boilers to not trap air in the water side.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Not a Plumber, however if you want the functionality of the air cushion for the whole house I would set it up this way.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

The only check valve needed is the one before the 006. The extrol needs to be on the cold side, and charged to match the domestic cold water pressure. They only come pre charged to 40 psi.

0 -

I'm sorry to disagree with you, but that Rheem Performance water heater, complete with electric cable and two heating elements is a water heater.

But in its current configuration it is costing you a lot more than a water heater in terms of annoying water hammer, much extra labor and parts in all that extra plumbing, and the fact that you have to run the whole boiler to heat up a few gallons of water.

Here's an easy hack to make your life easier. Disconnect all those pipes between those two appliances and shut off your boiler for 8 months out of the year instead of heating up your house all summer, especially that massive dinosaur of a boiler (don't get me wrong, it's great for heating your house, just not great for heating your shower).

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el1 -

He isn't using it as a water heater even if it is one. Lokk at the circulator the wiring goes into the tank and the power goes in the top. Its a 2 wire Romex so it can't power the heating elements at 240 and the circ at 120. Unless they illegally used the ground as a neutral.

Maybe the EX tank should be on the cold but with all the valves open it makes no difference. That is not the source of the problem.

1 -

I’m not saying he IS using it as a water heater, I’m saying he SHOULD

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

Just saying his complaint is water hammer.

0 -

we used to drill a very small hole in the check valve flapper so it wouldnt slam shut. on that piping arrangement if we didnt we got banging in pipes

0 -

ethicalpaulThank you so much for your reply. I truly do appreciate it.

You are correct. It is a

Rheem Performance water heater.

Well, anyway. That’s what it was when I purchased it.

However, it has been electrically modified.

Both of the heating elements have been disconnected.

The only thing that is left with power is the two thermostats.

One on the top, one on the bottom.

So basically, the wire that you see going into the top of the water heater is connected to the two thermostats. After that, it pokes out through a hole that I made at the bottom and connects to the pump.

When the water in the tank drops below the set thermostat level. It trips the pump on. That pump in turn pushes the water through the coil. And then back out again. Round and round she goes. So what I have done is, I have turned a stock, hot water heater into a storage tank.

The coil in the boiler makes all of the hot water. The tank stores that Hot Water. All of the pipes at the top of the water heater are hot. Except the one that feeds the mixer valve.

This set up has been in the house for 30+ years. It has always worked very well.

What plumber did is did is add the expansion tank , and the mixing valve. he also added the two additional swing checks, and the one spring check.

I will attach a photo from long ago. From before I replaced the hot water tank.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.1 -

Ebebratt-Ed

You are correct sir. It might look like a water heater, but it is not. It is just a holding tank. Everything has always worked fine. Until one day my hot water started mixing with the cold water. I called the plumber to fix this problem. What you see in the photos is his solution. I believe the hot water has stopped mixing with the cold water. That would make sense given the amount of check valves that were installed. However, the waterhammer throughout the house is unbearable. He has the expansion tank on the hottest pipe in the system. The pipe he teed off from comes directly out of the coil. I believe it is effectively doing nothing. I think the expansion tank should be on the cold pipe coming from the street. I think it should be teed into that pipe before anything that he installed.

I think, it should be above the red handled shut off valve.

I think that would solve all of the waterhammer problems. By the way, I did not have any waterhammer before this Plumber came to the house.

The waterhammer that I am having is on the cold taps only. Every cold tap in the house. Even the toilets, and the washing machine is the worst.

The plumber in question wants to go behind the washing machine and install a hole **** load of parts. Including a rather large hammer arrester.

This is where we have the disagreement.

I think he should address the root cause first. That would be by moving the pressure tank where I previously said. After that, if there is a small thump by the washing machine that can be addressed separately.

So what do you think about all of that?

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.1 -

There may also be check valves built in to the mixing valve.

The expansion tank has to be after the check valve, it is to allow the water in the tank and the coil to expand as it is heated since with the check valve it can no longer flow back to the street.

0 -

109-A5

That’s a pretty good diagram. I understand that you are not a plumber. And by the way, neither am I.

But everything that I have read, and researched says:

The pressure tank should be on the cold supply coming in from the house. Just like you have it. Except, it also says.

The pressure tank should also be before all check valves and all mixing valves

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

Are you looking at a well pressure tank or a domestic hot water expansion tank?

What you have is a domestic hot water expansion tank.

0 -

hello again, everyone, and I would like to thank everyone for taking the time to look at my pictures and read my story.

Every pipe going in and out of that tank is hot. It is simply a hot water loop. With the little pump on the bottom, pushing hot water through the coil in the boiler and back into the tank.

I do not have any water hammer on the hot side. I did not have any before that pressure tank was put on. The system in my house never had a pressure tank. What I have is water hammer on the cold side everywhere in the house. So, does anybody think moving the pressure tank to the cold side where it comes in from the street would solve this problem.73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

Matmia2

Thank you very much for the reply. I have read it a few times, but I do not understand it

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

A swing check is not a great choice.They have a long travel length and can really hammer when flow stops quickly. They need a pressure differential to close and seal properly. In your case the pressure may be the same on both sides, so the flappers just float, in limbo :)

Swing checks have fairly high Cv, flow rates, so inadequate flow cause them to operate somewhere between open and close. Any valve should size to flow rate expected not pipe size.

As mentioned above that mixing valve could have check valves built into the H&C side. If it is an ASME 1070 listed or a dual listed 1017/ 1070 the checks are required, and often installed by the manufacturer.

If so two checks in a row like that can set up a pressure wave and hammer the swing check.

Swing checks are fine for sump pumps, well pumps, lift pumps, etc.

Best choice is a spring, soft seal type check. Which need to be low lead in your application.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Hvacnut

I believe you are exactly right. One check valve. Right before the pump. Makes a whole Lotta sense to me. And additionally, your suggestion to move the pressure tank to the cold side. I also think is correct. Where exactly would you move that pressure tank . My thoughts are to move it just above the red handled shut off valve. That’s the pipe that brings the cold water in from the street.

Does that sound about right to you?

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

one more thing,

I seem to have isolated where the waterhammer is coming from.

It is coming from the spring check that was installed below the red handle shut off valve from the street. When I put my hand on that spring check valve it is buzzing and rattling like crazy.73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

-

this is a photo of what my system looked like before the did the work

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

I hear you. I'm saying that this whole arrangement and all its complicated piping (now more complicated with the additional expensive parts recently added) seems to me to be the cause of his original problem of temperature mixing, followed by water hammer after fixing the temperature mixing and it would all be avoided if there was a standalone water heater, which is by no means an expensive or difficult solution.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

A buzzing/ vibrating spring check is caused by air in the system, debris in the check seal, or it is oversized and the pump is not pushing it all the way open.

The expansion tank, assuming it was pre-charged accurately, behaves just like a water hammer arrester. The air cushion inside will accept some of the pressure wave caused by a slamming check.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

If it is before the check vavle.

Since it has to be after the check valve to allow the water in the tank and tankless coil to expand as it is heated because the check valve is now preventing the water from flowing backward in to the cold water system as it expands it won't quite act that way.

I think what is happening is when they water suddenly stops flowing that energy flows in through the check valve and in to the expansion tank then once the shock of it stopping dissipates in the cold water, the energy that was just stored in the expansion tank tries to get out but the check valve closes because it is reverse flow and what you are hearing is the check valve slamming closed. I suspect that you were getting some sort of gravity flow within a single pipe brining the hot water out of the tank and in to your cold water piping and a heat trap loop of pipe probably would have stopped it.

0 -

yes. Two check valves are one spring check has stopped the hot water from mixing into the cold water. I don’t think I needed a very expensive plumber to tell me that.

The addition of the mixing valve, although possibly code in my area, and the addition of the pressure tank sideways on the hot side seems to be doing nothing.

so the addition of all these expensive parts have now caused water hammer on every cold tap in the house. Even the toilets. When I put the washing machine on the bang might wake up the neighbors.

my plumber was told all of this.

his solution is another box of expensive parts including 3 more ball valves???, and an industrial sized hammer arrester.

all to be installed behind the washing machine. At my cost.

I asked if this would solve all of the hammer in the house. His reply was, “maybe”.I feel every thing he did caused this hammer issue.

why would the maybe fix be at any additional cost to meI don’t think that all those additional expensive parts behind the washing machine will be fixing the root cause.

He said “ I came to fix the mixing issue”

He said “this is a separate issue”

And he will be charging me again to fix what he calls a new issue.

He also got mad when I suggested the pressure tank is installed wrong and should be on the cold side.This is a very experienced, very licensed, master plumber.

he took offense to me suggesting a different way of doing it.he is also not taking responsibility for causing this problem.

What should I do?

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

-

Do you have a before pic of what is happening at the ceiling and above the tank? The pics in your previous post didn't seem to show all the way up to the ceiling.

The plumber owns this problem, it wasn't doing it before and it is the check valve that they installed that is making the banging.

Most likely the expansion tank is necessary if you solve the ghost flow with a check valve.

0 -

The expansion tank and where it is connected to the system has little to nothing to do with the water hammer.

I also asked if the expansion tank was pressurized to the incoming water pressure and everyone is ignoring this important fact.

If the tank is over or under pressurized then in either case it is like having no expansion tank at all. Your water crossover between hot and cold could be at the washing machine or shower valve although you think the check valve fixed it.

Which pipe has the water hammer hot? cold? or both?.

If you look at the drawing @HVACNUT posted of an Aquabooster install you effectivley have 2 check valve one by the pump and one in the PRV MU water.

As this is a temperature controlled tank I don't see any need for a mixing valve. That just causes more issues.

Moving the expansion tank will do nothing.

Where the expansion tank is located it has access to the tankless coil and the storage tank which is just what it needs.

0 -

Yes the before photo does not show the ceiling. All that is up there is the 3/4 inch pipe goes directly to a high flow shower. The 1/2 pipe feeds the rest of the house. Both of those pipes heading up into the ceiling are hot.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

As far as the pressure in the tank. I did ask the plumber about that. He told me that it comes pre-pressurized. There was no regard to the pressure in the house and there was no check of the pressure in the tank

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

The water hammer is only in the cold pipes. In everything that you were looking at in that picture, there is only one cold pipe. It is the one coming down with the red handle shut off valve

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0 -

Going back to that “before” picture.

What was happening was whenever the pump turned on, for instance after a shower, the pump would not only push the hot water into the coil, but it would also push the hot water up into the cold pipe with the red handle.

That Hot Water could be felt all the way to the street.

So after we were done with that hypothetical shower. We could run any cold tap in the house and it would be very hot for quite a while. And then, after running it for a while, it would go back to cold.

That’s why I felt the spring check on the cold pipe coming down with the red handle would stop the mixing.

73 year old one pipe system with original American standard boiler, oil fired becket, 2 inch steel pipe main, 100 feet long, with 8 radiators above.0

Categories

- All Categories

- 87.2K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 59 Biomass

- 427 Carbon Monoxide Awareness

- 117 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.7K Gas Heating

- 111 Geothermal

- 163 Indoor-Air Quality

- 3.7K Oil Heating

- 73 Pipe Deterioration

- 1K Plumbing

- 6.4K Radiant Heating

- 393 Solar

- 15.5K Strictly Steam

- 3.4K Thermostats and Controls

- 55 Water Quality

- 51 Industry Classes

- 49 Job Opportunities

- 18 Recall Announcements