Boiler pressure rising and expansion tank location

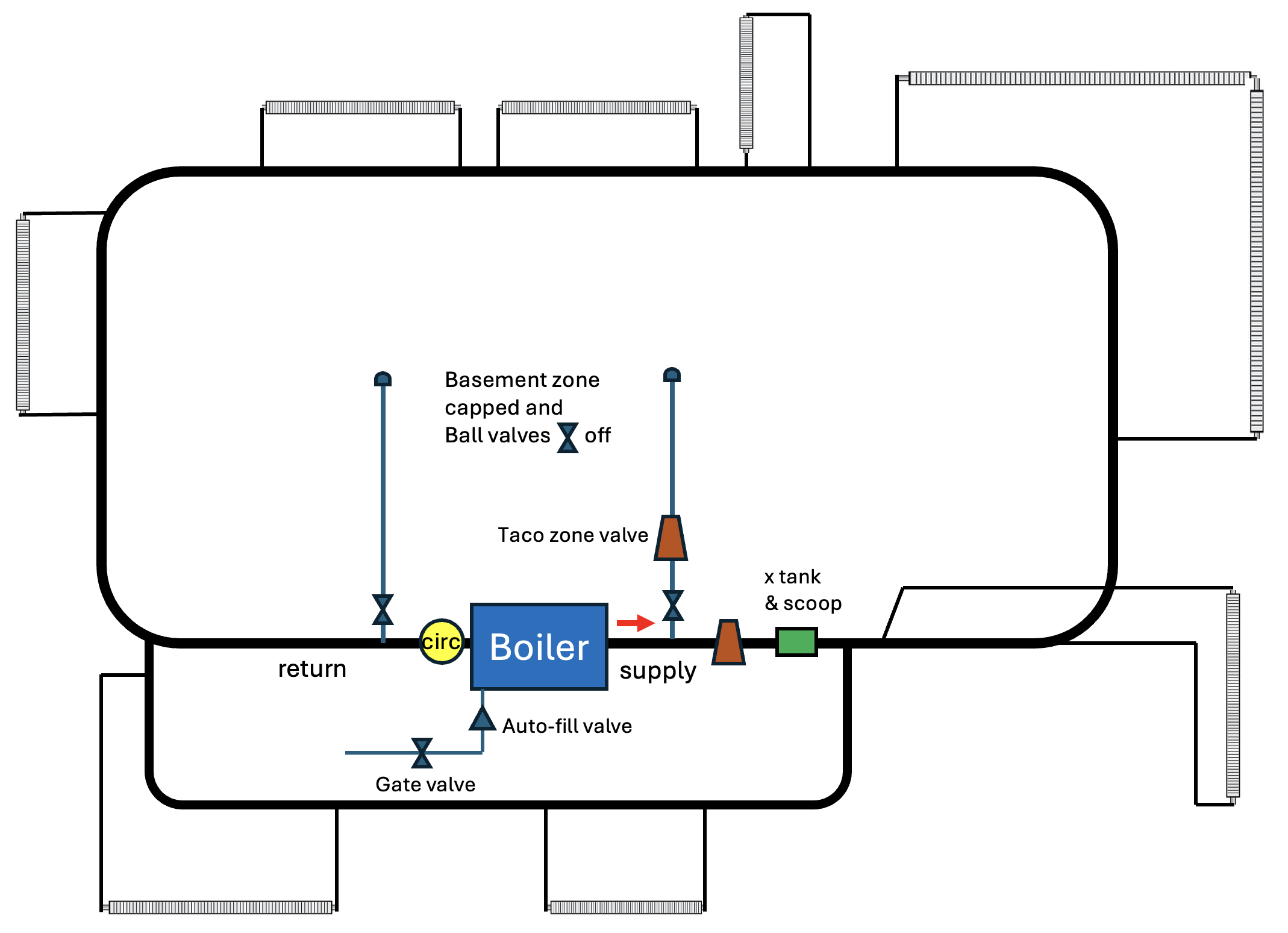

I recently removed a few baseboard units from closets and took the opportunity to replace the steel expansion tank (which was noisy) and an old, rusty air scoop with a clogged vent—likely 70 years old—in my hydronic system (HydroTherm HC-85-C boiler). The circulator is on the return side, and the expansion tank is on the supply side.

I also shut off the basement zone and initially replaced the steel tank with a 4.4-gallon diaphragm expansion tank (photo attached). After purging air and running the system, the boiler pressure occasionally rose above 20 psi. Two days later, after about an hour of operation, the pressure relief valve discharged (over 30 psi), and the boiler pilot shut off.

I then upgraded to a 6.3-gallon tank, but the issue persists. The tank appears fine upon inspection. Even when idling overnight, the pressure continues to rise. I’ve been monitoring the system and manually discharging pressure through the relief valve. Could a faulty auto-fill valve be the cause? I tried isolating it by closing the inlet valve, but the problem persists. Also, the boiler’s pressure remains in the low 20 psi even after the thermostat temperature is reached and the boiler idles and starts cooling down.

Many online sources suggest mounting the expansion tank on the return side (the “point of no pressure change”) while keeping the air scoop on the supply side with its tank port capped. Does this configuration make sense for my setup, or is it time to call a plumber?

Comments

-

Wrong expansion tank location. Are both zone valves in use? Do you have 2 thermostats? Why are the manual ball valves closed? What type of radiators are you using? Are there monoflow tees in the basement that lead to the radiator returns?

I need to study this more.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

This looks like a high head circ, is it pumping towards the boiler. In any case the expansion tak needs to be connected on the inlet side of that circ.

A slow creep in pressure could be a fill valve leaking past.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

A few things:

- What did you set the precharge air pressure to on the expansion tank?

- Are you sure that the shut off valve before the fill valve is holding?

- Could there possibly be a check valve in the pump? If so, when the zone valves close and the pump stops, the boiler is then isolated from the expansion tank and there’s no place for the water to expand into. There should never be a check valve when you have zone valves.

- Moving the expansion tank connection to the return, upstream of the circulator, would be a good for helping to remove air from the system, but I doubt that it would have any effect on your issue.

- An MBR, like a SpiroVent would have been a much better choice than the air scoop.

The most likely culprit is the fill valve, but I’d like to see some pics of the piping where you removed the radiators.

Bob Boan

You can choose to do what you want, but you cannot choose the consequences.0 -

Is there an indirect water heater connected to the boiler or tankless coil in the boiler(I don't see either but that is a common source of a leak in to the system). I would almost be surprised if that globe valve is holding if you haven't changed the washer relatively recently.

0 -

I see that the expansion is on the other side of the zone B zone valve. This will be a problem.

Look at the red arrow in the boiler that originates at the circulator. You also need to understand the concept of the Point Of No Pressure Change (PONPC starts at time stamp 21:30 in this webinar). Or you can "take my word for it" for now and watch the entire webinar when you have time With that information in the back of your head, the system that is full of water with no circulator operating will be about 15 PSI in the basement. When the circulator operates the pump creates a pressure difference between the inlet of the pump and the outlet of the pump. When zone B is open the pump will push against the 15 PSI in the expansion tank. So if we account for the pressure drop thru the boiler at about 1 PSI that means the pump discharge is at about 16 PSI. If the pump is producing 6 PSI of pressure difference, that means that the inlet to the pump has dropped to 10 PSI.

However when the B zone is closed and the A zone is open, the pump is no longer pushing against the PONPC of 15 PSI. It is now pulling away from the PONPC thru the entire zone B loop with all the pressure drop of that zone B piping system. Now that will be the 15 PSI of the expansion tank PONPC minus the pressure drop of the entire zone B piping all the way back to the closed zone valve. That long run of piping and radiators may have a pressure drop of more than 15 PSI at the pump inlet. When that happens the boiler will change pressure to 0.0 PSI at the pump and 6 PSI at the outlet of the pump to the ability for the system to remove air and if that may also be causing the second floor radiators to actual operate under a vacuum since the will be operating below the minimum static pressure to keep the higher floor radiator air free and eliminate pump cavitation. You can stop watching at about time stamp 28:39

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks for the response!

Only one zone is in use. Yes, I'd have 2 thermostats. The closed ball valves are for the basement zone, which is not in use (will be expanding this in the future). Baseboard radiators. Yes, there are monoflow tees installed for the radiators. Please see the a rough sketch of the system layout below (apology in advance if I am not using conventional plumbing symbols).

0 -

You have 2 thermostats. are they in use?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Only one of the thermostats is being used. The other, for the basement zone, is not in use.

0 -

OK so you have only one zone operating. Is the one thermostat you are using operating the zone valve?

OR

Do you have the zone valve open manually and the one thermostat is operating the boiler control directly? It does not really matter, I just would like to know.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Thanks for the response! I have considered moving just the x tank to the return side.

From time to time I am noticing a small leak on the gate valve (very old) that connects to the auto fill valve.0 -

The operating zone or zone valve is controlled by its corresponding thermostat (not manually opened), which also is operating the boiler control. The other thermostat is still connected to its taco head, but set to the lowest temp settings. Do you recommend I disconnect its wiring?

0 -

No need to remove the wiring to the unused zone valve. That does not appear to be the issue.

When you use Monoflo Tees there are too many paths for air so get stuck in the radiators. You can not depend on purging to remove all the air. There must be individual air vents on each MonoFlo radiator loop. Oftentimes those air vents are hydroscopic type vents that are somewhat automatic. But if you have not changed them lately the auto portion of the vent may not work so well.

That said, since you are pumping to the PONPC, that means that some of the radiators may actually be dropping below atmospheric pressure in the higher radiators. Those hydroscopic vents can actually let air into the system when the pump is running. This addition of air may be the increase in pressure that you are experiencing over time. The only other place you can add pressure to the system is at the boiler feed valve. If that manual valve is passing and the auto feed is passing, that is the reason for your problem.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Although the piping could be better the tank is not isolated from the boiler unless the pump has a check valve.

I would look for a check valve, remove the tank and check the precharge and go from their.

0 -

-

I am planning to implement the piping redesign you suggested above. It looks like that my circulator (grundfos type ups15-42f model 868) does not have a check valve. Will I be fine using something like the Everbilt 1 in. Brass Check Valve EBCV100NL or Viega ProPress 1” Check Valve?

0 -

You do not need a check valve. You have zone valves. In the future when you have both zones operating, the zone valves will do the opening and closing of each circuit. A check valve in a pump can only make for problems when a closed zone valve is able to isolate the pump (with IFC) from the expansion tank. NO CHECK NEEDED. The fact that there is no check valve means that your boiler pressure rising issue is not associated with the IFC in the pump because it is not there!!!

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

No one is concerned with the 3 flue pipes into what appears to be into the same flue?

0 -

I saw that just now, but I was more curious about the two expansion tanks and the plumbing mess.

Aren't the burners missing a cover too?

0 -

@EdTheHeaterMan thank you, sir!

Yesterday, I implemented your suggestion and everything seems to be working fine. Boiler pressure is right around 19-20 psi during operation and 18-19 psi while idling.

I installed the x-tank directly underneath the air scoop and am noticing that the top portion of the tank (water) does get hot, about the same temp as the scoop itself. Is this normal? Or should I install something like a 4” brass niple fitting between the x-tank and the scoop?

I will share pictures once I finish cleaning up the wiring for the stat and power.

0 -

I installed the x-tank directly underneath the air scoop and am noticing that the top portion of the tank (water) does get hot, about the same temp as the scoop itself. Is this normal? Or should I install something like a 4” brass niple fitting between the x-tank and the scoop?

That is normal and you need not do anything about it

Mr. Ed

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Below are some pictures of the redesign. I reworked the piping and installed new electrical wiring and thermostat connections. It’s been running great for the past four days. The boiler pressure is holding steady around 18–20 psi.

Based on what I’ve observed, the system overall is working much better and noticeably quieter than before, when it had the old steel expansion tank. Down the line, I plan to add a few more ball valves to isolate certain components and make maintenance easier.

Thanks @EdTheHeaterMan and everyone else who provided input!

I’m planning to complete the plumbing for the basement zone soon using PEX and baseboards. Any suggestions or things I should keep in mind?

0 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements