Reanimating Frankenstein - a gravity heat story

Hello all, in the spirit of Halloween, I felt it's time to share my journey of replumbing towards the goal of having a functional gravity system from a bare skeleton of pipes and a tired, but present and now verified functional 1960s American standard boiler. All this to heat a 1915 3 story brick row house purchased in a tax foreclosure, that from what i can tell, hasn't been heated since the 00's.

So, let's begin our journey with a brief forensicly reconstructed history and horror story of my building. The are 5 chimneys built in to the brick. The earliest heat system there is evidence of is of gas space heaters infront of each of the 6 tiger oak mantles of the 2nd and 3rd story apartments. Those acount for the first 3 chimneys. The grocery store on the first floor was likely heated with coal in the basement using chimney 4. Chimney 5 took the exhaust of 3 cast iron cooking stoves from each floors kitchen.

Fast forward to the 1930s. This building and the saloon next door pass hands to two brothers who seek to take advantage of the newly repealed eighteenth amendment and open a restraunt combing the two sister buildings in to one bar/ grille. It is at this time i believe the gravity heating system was installed in its orginal configuration. Horror #1: it would seem this was built using reclaimed materials and installed by no plumber, but rather the brothers themselves. 4" supply and return traveled down the spine of the building with 1.5", 1.25" and finally 1" pipes shooting off the the left and right each supplying one to two ornate radiators, never supplying multiple floors. Horror #2: In addition to the 4" in our building of question, an additional pair of 4" pipes jut through the foundation into the basement of the saloon building next door.

Thirty years, pass multiple generations of the restaurateur family have made the buildings their home. The old coal boiler is getting a bit long in the tooth. Coal gas had been replaced with natural gas and it's now legal to use a gas boiler for heat. As such, a beast of a American standard boiler is installed. 1" gas supply on a dedicated meter. Sized to heat 6000 sq feet of both buildings, the 650,000 btu rating isn't excessive. However, an untimely death and the restaurant business no longer feels the same. The resturant closes and the families move away. The buildings go up for sale, but since the 2 buildings were never officially combined as one address, the boiler in the 1915 grocery store cannot heat the 1879 saloon. And such is horror #3, we now have a boiler sized twice whats needed.

A hardworking couple buys the grocery store half of the restaurant and intends to rent the 3 floors. There are 3 gas meters, so there is no reason not to run an individual boiler on each of the 3 floors. The horizontal black pipe is cut and removed. Most of the ports on the 4" main are plugged. The vertical piping gets a reducer to 3/4" at the elbows and copper plumbing is piped into new hot water boilers with domestic hot water loops and steel compression tanks. Changes to the area now make the commercial first floor difficult to rent, so it too will become an apartment. (Horror#4) In go partition walls, wood paneling and a drop ceiling covers the historic tin ceiling. Out go the old fashioned ornate radiators. And in their place is roughly 80 feet of cast iron baseboard. Now what, pray you is the 80 linear feet of baseboard heated with? Obviously, the monstrous 650,000 btu American standard boiler. Why not? It is only a few years old, after all, and it's not like the landlord has to pay the gas bill. Horror #5.

It is this arrangement that was in use for 4 decades. No circulator, 4" supply and return pipes 3/4" plunge into various oversized antique gate, ball and globe valves connecting 6 radiators. The aquastat was set to 200f. (Horror #6) I'm sure this monster boiler would short cycle like crazy in this sub optimal configuration. Then it gets abandoned.

Gone are the antique gas space heaters, the tiger oak mantles, even the tangential hand rail and stair spindles. Paint is peeling from the walls and vandals have since broke in and sledgehammered the ornate radiators for scrap. Horror #7

Fast forward to my ownership. All copper pipe had been stolen from the reconfigured 3 heating systems as have the ornate radiators in the upstairs apartments and corresponding boilers. The large 4" supply and return lines are no longer attached to the basement joists and have sank several feet.

And this is where i came in. Now most people would have taken one look at what's left of this heating system and wrote it off a hopeless. No radiators, all pipe connections cut and in disarray. An ancient boiler half buried in basement rubble. Tear it all out and start fresh.

My first big break came in the form of 10 used radiators for $200, of these, 6 ornate ones were particularly useful to go where the orginal gas space heaters were located. There were three with 6 sections and three with 10. They happened to be the correct height and configuration of inlet and outlet. The only downside was they were all tapped for 3/4" fittings and the pipes were almost all 1". I needed 6 equally sized radiators. I stripped the paint, cut the tension rods seperated the sections, retapped to the larger thread and ended up with six 8 section radiators. If i were to detail how i accomplished ask that it would be another 10 horrors. These radiators went in with v110 thermostatic regulator valves. I picked up, stripped and installed several more radiators and sorted out that aspect of the heating system.

Finally, I had a matching game with the basement boiler plumbing: Remove the plug/ reducer with copper stub within the 4" pipe union, and cut new black pipe to connect to the corresponding vertical riser going to the radiator(s). I filled the system with water replaced the pressure relief valve, fixed minor leaks. The altitude gauge still registered pressure. I cleaned the burners, installed a new baso, thermocouple and pilot and double checked the wiring. Then I got the power company to turn on gas and electricity. Aside from the minor hicup of a closed needle valve on the vent of the diaphragm gas solenoid valve, she lit. The temperature also registered on the combination gauge.

Thank you for reading this exceedingly long post.

Comments

-

Have fun!

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

0

-

-

TRVs will greatly restrict the flow and you may end up short of heat and a boiler constantly tripping high limit.

Never heard of TRVs on a gravity system

0 -

I figured the trvs are the modern way of adding restrictions on the upper floors to balance heat between the three apartments. There are no trvs on the first floor. Remember, until recently, this boiler only heated the first floor. I'm not saying that was correct, but I'm hoping this will prove to be more appropriate for the boilers size to have more radiators hooked up. Each radiator feeds of the main trunk individually so one shutting off will not prevent another from heating.

0 -

@novajke , that boiler is missing its "roll-out shield", a cast-iron plate that goes over the front opening where the burners are. I would not recommend operating this boiler unless you have this shield and can put it back on.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting0 -

-

-

I remind you, this is a Halloween special, meant to induce nightmares in y'all! But yes, i have the shield, It was buried in rubble behind the boiler. I hadn't placed it in the photo because i just installed the cleaned burners and new pilot components. The building is currently vacant and I do not intend to let the boiler run unsupervised until a low water cutoff is installed. Clearly judging by the jacket, rollout has been a problem on this boiler in the past.

0 -

At the time the obsolete trvs were cheaper on ebay than radiator valves. I'm running the dinosaur boiler as a proof of concept for now to see how well the slow moving gravity heat plays with the trvs. Ultimately, I'll get some quotes to replace the boiler, but first I'll see what the system does. If valves with insufficient valve flow coefficient are giving you the heebie jeebies, good! It is all in the October spirit of the new genre of hydronics horror!

0 -

-

You could also ad a circulator to that boiler.

0 -

I already have a honeywell t475a1057 outdoor reset. I was going to run it in conjunction with the thermostat on the first floor, but given the setup it is probably redundant because of the thermal mass of all the cast iron and water.

0 -

TRV's will regulate the room temperature and the outdoor reset will regulate the temperature of the water needed to heat the building at that time. Adjust the outdoor control to heat the coldest flat and the TRV's will slow the flow to the other floors or rooms to prevent overheating .. The old thermostat serves no purpose other than another switch .

There was an error rendering this rich post.

1 -

My outdoor reset control has a factory differential set at 6 degrees, which it's the minimum the controller. I'd just like to confirm my intuition that with the thermal mass in this system, and the trvs, I shouldn't change it.

0 -

How is it working ? Fire her up and test it ..

There was an error rendering this rich post.

0 -

I'm waiting on an immersion well for the bulb and having to sort out a lwco before I'm running it continuously.

0 -

Please don't fire it up , I just reviewed your photos of the boiler . For your safety .

Please excuse this old grunt …

There was an error rendering this rich post.

0 -

I'd love to know what specifically concerns you? I've done all the layman approved repairs: new pilot burner, new thermocouple and baso. I cleaned the burners and inspected/ brushed the inside of the boiler. It had almost no soot. The gas safety inspection passed and the utility turned on the gas. A mason rebuilt the top part of the chimney and inspected the rest for obstructions. When up and running, a combustion analysis will be performed.

The only thing that gave me pause was the lack of a low water cutoff- something that was rectified in the photos below.

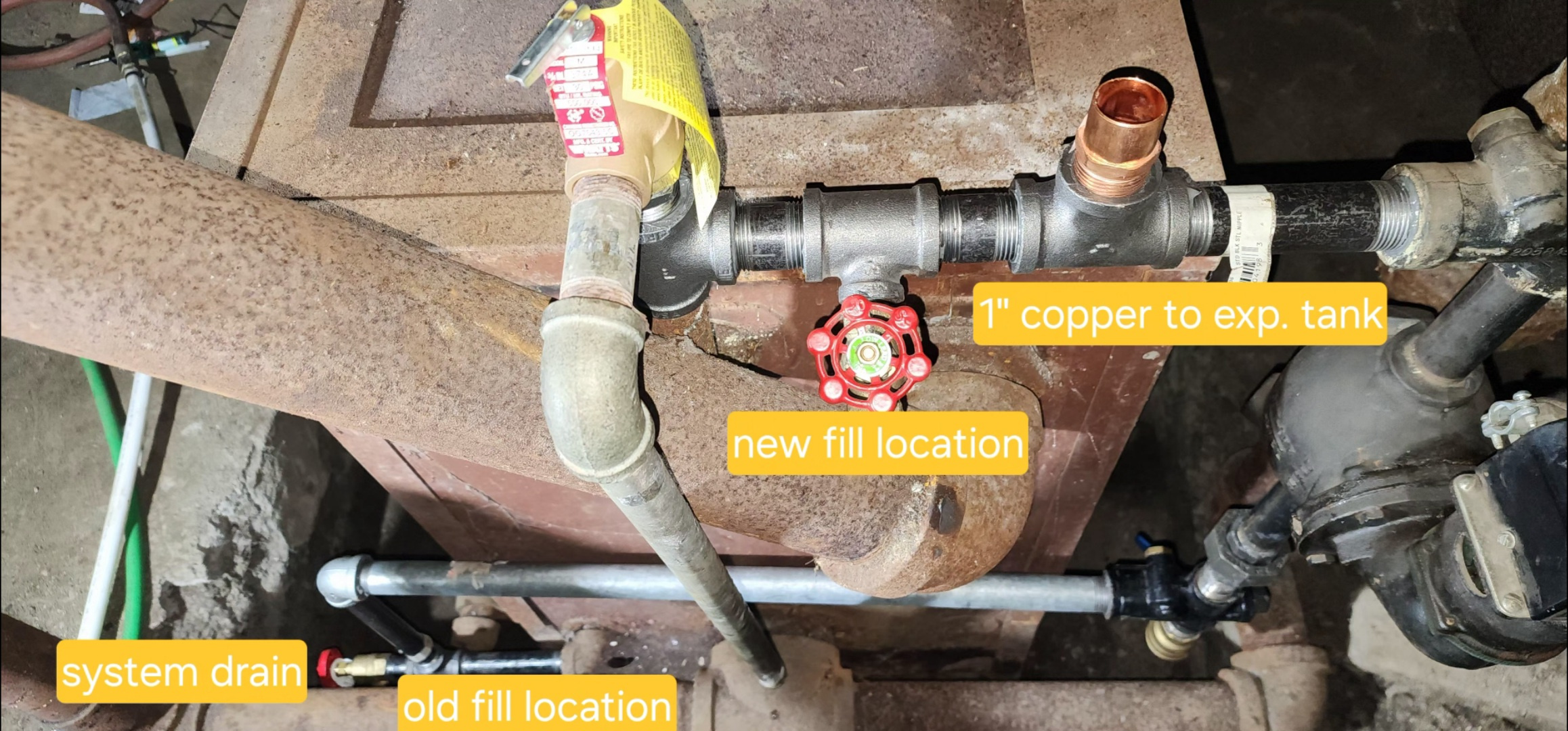

The orginal fill location was at the bottom next to the drain. It now connects to the lower port of the LWCO. The tee on the top tapping below the pressure relief orginally hooked up to the steel compression tank. Now it has a 1/2" port for the new fill, a 1" port for the new 33 gallon bladder expansion tank and the upper connection of the LWCO.

Short of removing a steel plug from a 75 year old boiler, i believe this a good way to get some modern safety to this old system.

0 -

Low water cut off switches for hot water systems using my boiler as an example:

- are wired to be the first control of the boiler where it will shut the electricity off on the boiler completely in the event of a water loss

- have the LWCO probes threaded into a steam chest tapping or in the hot water riser.

3. have a manual test button that breaks/opens the power circuit

0 -

This boiler only has a single low voltage signal wire control. Every safety cutoff and control is wired in series on this 24v circuit. If i keep this system, an upgrade in the future will be to convert to a millivolt gas valve and thermopile to operate independently of grid electricity.

Yes, a probe style would be installed as you say, however, maintenence on a yearly basis to clean and inspect the probe requires draining all the water from the system. A drain and refill introduces a lot of oxygen. Also, all probe style LWCOs I found require external power.

The blowdown valve with additional test-n-check valves allow for quarterly verification as recommended by the manufacturer McDonnell & Miller. This results in minimal water loss.

There is no autofeed on this system.

0 -

You do not have to clean a probe type low water cut off switch annually, the float type low water cut off switch will have to be disassembled and cleaned and parts replaced as needed depending on your water quality.

Who is a going to wire up that low water cut off switch for you?

0 -

-

My M&M #67 went more than 40 years without disassembly and cleaning.

Although apparently commonly ignored… Many probe types should have annual maintenance.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Not disagreeing with you, he could install an RB-122-E in the riser with 2 ball or gate valves to segregate the probe type LWCO to allow for removal and cleaning.

0 -

" If i keep this system, an upgrade in the future will be to convert to a millivolt gas valve and thermopile to operate independently of grid electricity. "

If all your safeties and limits are not certified compliant for a millivolt type system you may have issues.

Many McDonnell & Miller LWCOs have switches rated for millivolt service, not so sure about the 63M.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Yes the RB-122-E has the spinney thing to self clean the probe.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Just plan on running it through the winter so i can have a bit of warmth while finishing remodeling work in the upper floors. The building is built into a hillside so the boiler room is 15' below grade. The cellars has lime mortar brick foundation and exposed dirt floor in areas. Waterproofing/ humidity control etc is needed before anything with a circuit board is installed down there.

0 -

Is there an open to air expansion tank in the attic or third floor of this building or are the radiators used to create the point of no pressure change by leaving an air gap in the top of each radiator?

You need to maintain the 4 inch risers in place for the hot water to rise and for the take offs to feed the radiators quickly and return the cool water to the boiler sump to heat it.

0 -

wasn't this the one with another post about how to hook the compression tank back up?

0 -

Yup, come to think of it now matt, yes. I hope he leaves the two 4 inch risers in place.

0 -

There is no vertical riser- just 1" or 1.25" pipes coming off the large horizontal supply and return pipes in the basement. The individual pipes go to a wall and supply either one radiator (for 1") or 2 radiators (for 1.25") an attic atmosphere vent exists in the bathroom, which has the only 3/4" pipes coming up. If there ever was a tank, it would have been in the bathroom on the wall above this radiator. The vent pipe was located above a drop ceiling and still goes through the attic and out the flat roof.

0 -

You need a licensed plumber to find all the hot water heat piping, fix this the right way and add back an open to air expansion tank.

Please check the find a plumber section on the home page as we may know someone in your area that can fix it the right way for you.

0 -

The 33 gallon bladder tank in the basement will be more than enough to deal with expansion. I have been doing all this work under the direction of a retired plumber friend. He sold me his old rigid 300, half of the cast fittings i ended up needing and found the second hand components I documented adding (lwco, expansion tank, a couple of radiators). I've read that keeping the system open to atmosphere will result in more o2 in the water and water loss from evaporation. Aside from simplicity, what is the benefit in reopening the gravity system to atmosphere?

0 -

No circulators, no bleeding of radiators if a top fed system is piped, one thermostat to maintain a 170 degree hot water temperature, slow even heat; the bottom fed system only has to be bled if the system has been completely drained. Air bubbles migrate to the open to air expansion tank. Water in the system prevents rust below the water line.

The only time a gravity hot water system performs poorly is if the piping is not reamed correctly leaving metal burrs to slow the flow of water from the hot water riser to the radiators or if there are metal burrs on the pipe joints to the takeoff piping to the radiators or if the take off piping to the furthest radiator is not sized correctly.

0 -

-

There are gravity hot water systems still in use today that are over 100 years old and still intact.

0 -

Yes. How you doing Leon?

Bryant 245-8, 430k btu, 2-pipe steam in a 1930s 6-unit 1-story apt building in the NM mountains. 26 radiators 3800sqf

0 -

Thank you Guzzinerd for proving my point. I am sending you a PM.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements