How do I fix my circulator pump?

This is kind of a long explanation before I get to my questions because it's an odd situation. I have a vintage circulator pump that I believe was originally a complete Bell & Gossett. I believe it's from the 1950s and is perhaps an early Series 100 or a predecessor to it. It appears that the motor was replaced at some point in time with a Dayton 3K516. The part with the oil reservoir has a metal tag with three labels, “size 1-1/2, P3-6, and 3-N”. The volute has one stamped marking “P3-81”.

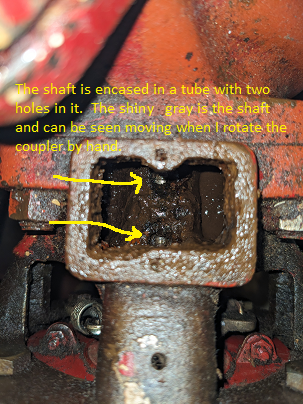

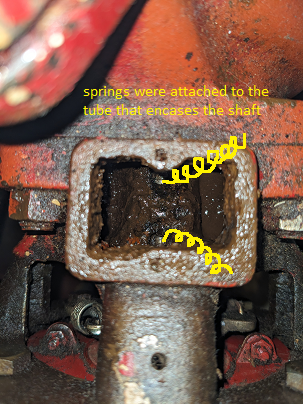

Until now, I have been oiling it through the little flip top hole on the oil reservoir, but this time, I decided to take off the little plate and oil it that way. Unlike other Bell & Gossett pumps I've seen, the plate was not retained with clips, rather, there were springs holding it down. One of the springs was still attached to the shaft encasement, and the other one had already broken off prior to me opening the reservoir. I couldn't figure out how to detach the spring, and it eventually broke free from the shaft encasement. Also, there was not any rope inside for wicking the oil like I've seen in other pumps.

My questions are: Do I need to add a rope or something else before I add some oil, or is it possible that this model never had rope?

Now that the “spring-hold-down-apparatus” is broken, should I just break off the other parts of it and screw back on the little metal plate?

Any additional insights or suggestions would be much appreciated.

Comments

-

-

That is an obsolete 1-1/2 pump. you can still rebuild the bearing assembly sne some supply houses will have that rebuilt bearing (the center section between the motor and the part attached to the piping) in stock and will want the old bearing assembly in exchange. The impeller may be something that you will want to bring with you also. The replacement bearing assembly may not come with an impeller and your eill need to use a puller to remove the old one from the trade in before you give it up. You may even look at the impeller and decide to replace that also.

The motor mounts on the motor are often fatigued from over oiling the motor cups. You should probably pick up a set of those also. If you find that the bearing assembly is rather expensive, you might consider a newer pump to replace that old dinosaur with a wet rotor pump that does not need to be lubricated. That replacement pump might be about the same price as the repair to the old pump.

The supply house personal that have B&G parts should be able to help you with selecting the correct bearing assembly, impeller and or replacement pump.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

-

Agree with @EBEBRATT-Ed. Definitely change the whole thing to a wet rotor circulator. It looks like there's a valve below the circulator so you won't lose everything. Just drop the pressure to zero. You will need to make up the height difference. They used to make spacers with longer bolts. Add a longer nipple and new flange above the circulator. Its still easier than messing around with a 3 piece.

1 -

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements