Extracting Vent Plug from new Sunrad Radiator

Hi everyone,

Posted this question on a different DIY website but also hoping to get some input here. I had a cracked Sunrad radiator that I replaced myself and reconnected to my hot water heating system (caused a lot of damage to surrounding wall as you can see in pic).

The final step before I test it is to install the auto vent in the upper right corner, but I am having a very hard time removing the plug in there. I bought a whole allen wrench set but no size worked to grab and move the plug. It was suggested I drill into this and extract the plug, but open to any other suggestions or confirmations that this will work.

Comments

-

reverse drill extraction set.

0 -

-

It may be metric. Or you can try jamming a Torx (which you don't care about) or star bit in there.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Hi @dandandandandandan , If you bought a standard size Allen wrench set, get one that's metric and see if you get a better fit. Also, there is the old trick of tighten a little first, then back it out after it has moved. Some penetrating oil couldn't hurt. One cheap trick is putting a crescent wrench on the Allen, to give more torque and a better feel for what's happening. A snug-fitting Allen wrench is key.

Yours, Larry

0 -

figure out what size it is, sunrad should be able to tell you, and get an allen socket that size and turn it with a ratchet. be sure to push in very hard so the bit doesn't cam out.

alternately use a hand impact driver with the bit, the kind you hit with a hammer. hitting the socket with a hammer a couple times could loosen it up too.

1 -

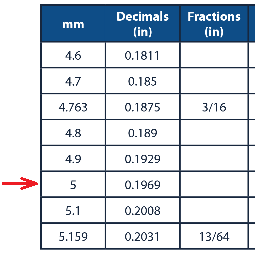

The Brass 1/8" NPT plugs I have are a 5 mm female Hex.

So 3/16 is too loose and 13/64 (not a very common size) is too big.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

Thanks everyone for the helpful comments. I went to the store and got a bunch of supplies — I started with the 5mm hex but even with a long wrench it did not budge.

I ended up drilling successive holes until I was able to extract the plug, and after turning water back on and bleeding air at the zone purge valve I was able to confirm there were no leaks…at the vent.

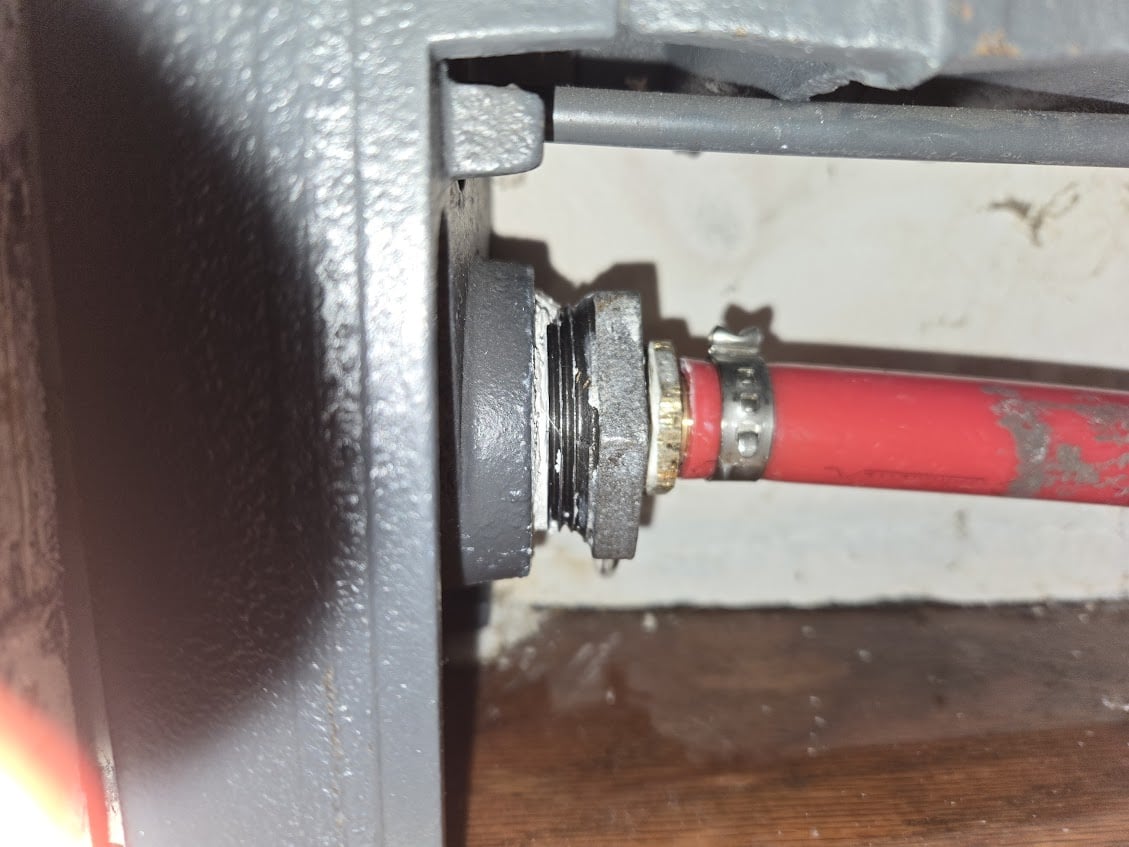

Unfortunately it does look like I have some dripping at (I think) my Pex to 3/4 inch adapter where it threads into the bushing. Any tips here? Is it just a matter of tightening the fitting more, or should I take it apart and start again (hopefully not). I don't have a ton of clearance but I am able to get a wrench around the fitting.

Sorry for the basic questions, and I appreciate any advice.

0 -

Look closely to see where it is leaking. It could be the crimp on the tube, the bushing to the pex adapter or the bushing to the rad. dry it off with a paper towel or rag and see where the water starts reforming. my bet is on the adapter to bushing. Probably ~4 wraps of teflon tape with the dope will stop it. You can use ball wicking if it is really stubborn.

I'd probably put a union in there somewhere so you don't have to cut the pex to remove the radiator.

0 -

Thanks @mattmia2 , I agree with you — based on what I see that is most likely where the problem is.

Would a basin wrench be appropriate to take the fitting off, apply the tape, and reattach? I am hoping to avoid bringing the radiator down again as it is very heavy so I would like something that can work with limited clearance.

0 -

Bushings unfortunately are known as leakers. Gas piping and other piping for industry usually do not allow them.

The reason is the Radiator being cast iron the casting is quite ridged and so it the bushing. With the quality of the material being what it is today (foreign made) etc. its not uncommon for a bushing to leak.

But where you used it on a low pressure system it should be fine. Take it apart clean it up teflon tape and dope and dope the female threads just a little and tighten it up.

1 -

" basin wrench " I don't think it would give you anywhere near the leverage to get it apart and if it does it was not tight enough in the first place so that it would not leak.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

First…find out very specifically…WHERE it is leaking. Without taking things apart…tighten the threaded fittings (individually) "a bit". The pex fitting should spin in the crimped red pipe. The already applied "white stuff" may work in your favor with a little further tightening.

0 -

Thanks everyone so much for your advice. I did have to remove the Pex to Bushing adapter as @mattmia2 suggested. Teflon tape, dope, and a newly purchased offset pipe wrench let me finish the job.

I had a lot of "fun" with this project and saved some money. Thanks all.

0 -

Is that potable water Pex?

0 -

No this is in my hydronic hot water system.

0 -

The question was if that is oxygen barrier pex. Oxygen barrier pex is available in red although it is more commonly white.

0 -

Oh ok. I am just using the same kind the previous installation had, not trying to do anything new.

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements