Boiler for pool heating

I picked up an old unused commercial domestic hot water boiler for nearly scrap value. I am going to use it when a second stage of heat is needed for my swimming pool, a couple of weeks at the beginning and end of summer, so not much use. It is rated for direct pool heating without a separate heat exchanger. It is non condensing and asks for 110 degree return via primary/secondary piping. I was thinking of piping it primary only, with the intake temp being a minimum of 84 degrees. It won't get much use. An HVAC engineer friend of mine thinks its not a big issue since it won't get much use. I know it will be harder on the boiler but it does have a copper heat exchanger and stainless burner. I am trying to not spend much since it won't get much use. Is this a bad idea?

Thanks,

John

Comments

-

I think… opinions may differ. It may not get much use, true — but on the other hand, it will never see return water much over 84, so it will never dry out on the flue side and will condense and corrode, unless you piped it primary/secondary. On the other hand, you have a situation is very steady state once it is actually running, so I think (personal opinion here!) that you could do very well indeed with a simple fixed bypass with a throttling valve on it. Throttling the bypass will take a bit of fussing, but once you go it set the system should be able to hold a nice constant return temperature pretty much anywhere you wanted it.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

So you are saying adjust the bypass so the flue gas is hot enough and leaving water isn't too high? What temps do you suggest?

Thx. John

0 -

I think that Jamie's idea is great. But the flue gas condensation idea is the reason for the minimum return temperature

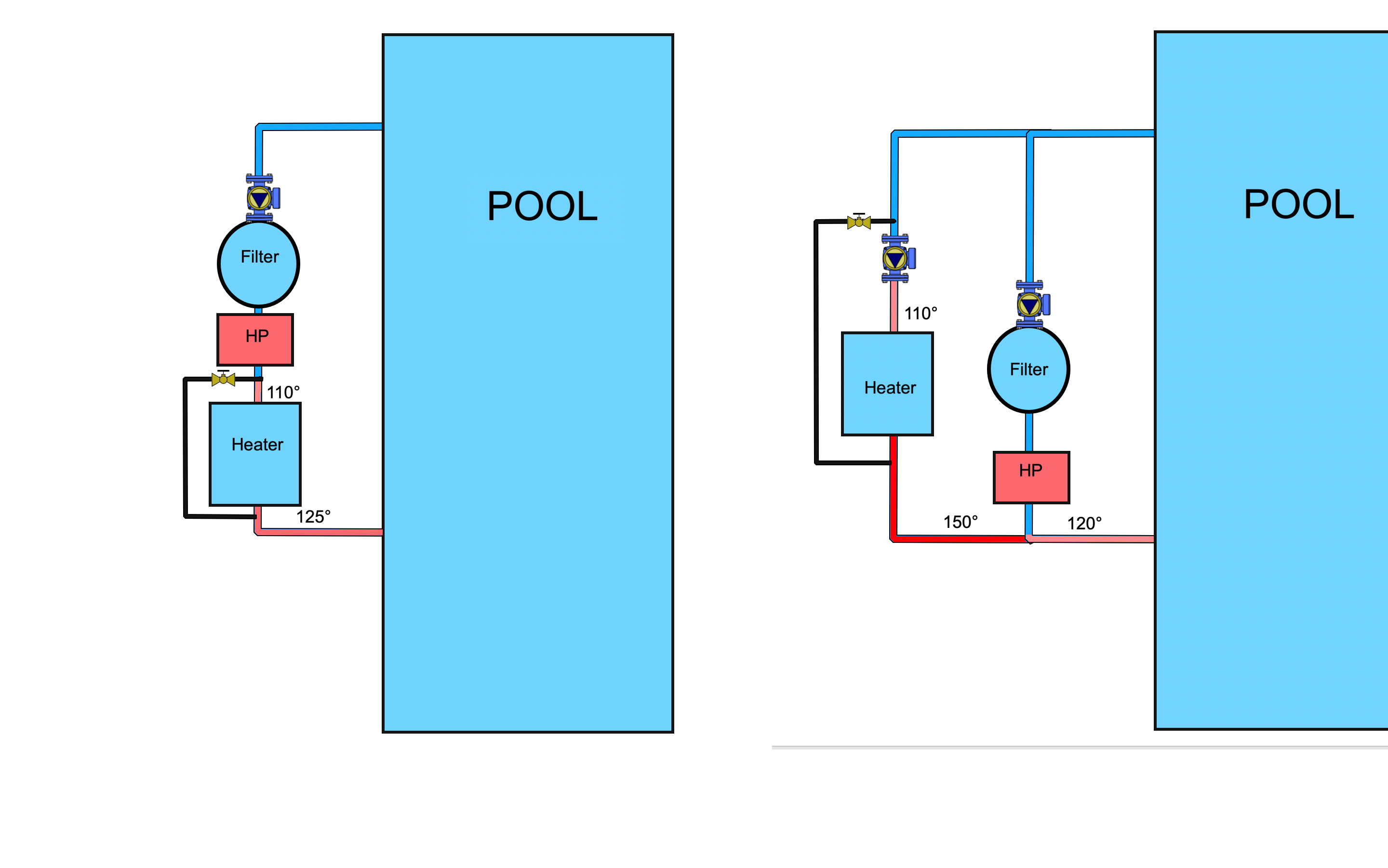

Actually the boiler manufacture is looking for 110° return water temperature, so you are looking to adjust the bypass to get the minimum 110° return to the boiler. the supply water to the pool can be as hot as ypu want. just be sure that the water that is entering the pool is not so hot that someone that decides to get close to the warm water will not get scalding hot water flowing on them. So the location of the water inlet to the pool will determine the water temperature from the pool heater. I think that 125° would be a maximum unless the pool heater water is mixed before it enters the pool.

Are you looking to reduce the number of pumps?

I know that I used the filter pump when I heated my pool with a home made contraption years ago. and I assume that there are several valves and bypasses installed with your heat pump pool heater and filter setup, that this simple diagram does not show. the concept of using the bypass and the pool filter to get 110 inlet to the pool heater without primary/secondary and two heater pumps to accomplish that is what I'm illustrating here. If the fossil fuel pool heater is added to the system like the illustration on the right you may not get the outlet of the heater to be much more than the 125° illustrated in order to keep the water entering the pool at a safe level.

If you add the heater as illustrated on the right, you can get a higher temperature from the fossil fuel heater and mix it with the lower temperature water to accomplish the safe water temperature entering the pool. either design uses the bypass with a valve to adjust the inlet water temperature to 110°. Once you get that valve dialed in to get the 110° then you should be able to lock that setting in and leave it alone.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Leaving water is more or less irrelevant — adjust the bypass so that the return water hitting the boiler is at least 110 F. To clarify a bit, the circulating pump will be at the boiler, pumping away from the boiler, followed by a T which goes to the pool or the bypass, or on the return, pumping directly into the boiler, with the bypass upstream of the pump (on the pool side of the pump).

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Thanks all. Ed I think I will try your left picture first since I don't have an extra pump laying around. The system already has 2 pumps in it a 1/3 HP pump that runs all the time giving 10 gpm all the time on the system, then a 1/2 HP pump in series that activates with the heater to raise the flow to about 25 gpm (moves both pumps lower on the head/gpm curve) when a heater is running. I have already closed the pool for this year but will try in the spring. I can always add a pump and go primary/secondary or bypass if things are not going well. After the water mixes, I am only expecting a delta T of about 20 degrees based on the 25 gpm and 200,000 btu's from boiler.

My primary 50,000 btu heat pump does a good job of satisfying the pool heat and house cooling for 80% of the summer. Yes its a contraption with many relays, switches and thermostats. I did create a wiring diagram so someone else could troubleshoot if needed, but he likely wouldn't like it, I'm sure.

Thanks, John

0 -

How is that cast iron going to deal with the excessive chlorine?

0 -

It has a copper heat exchanger. No cast iron. Factory approved for pool water.

John

0 -

copper is no good for chlorine either.

0 -

Documentation says factory approved for pool water.

0 -

ok

0 -

if it was a dhw copper boiler it will have bronze headers or enameled cast iron

Pool boilers typically have larger headers to handle pool flows of 30 gpm or so, depending on the boiler size

The pool boilers also have a thermostatic valve built into the header between the S&R pipe connection

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

The headers do look bronze. It is an RBI Spectrum sitting unused since 2016.

0 -

If it has that thernostatic valve you don't need a bypass — and you certainly don't need any more pumps, bypass or no. If you follow the piping sequence I gave you. This is not primary/secondary. It's a tempering bypass. Completely different concept.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

"Ed I think I will try your left picture first since I don't have an extra pump laying around."

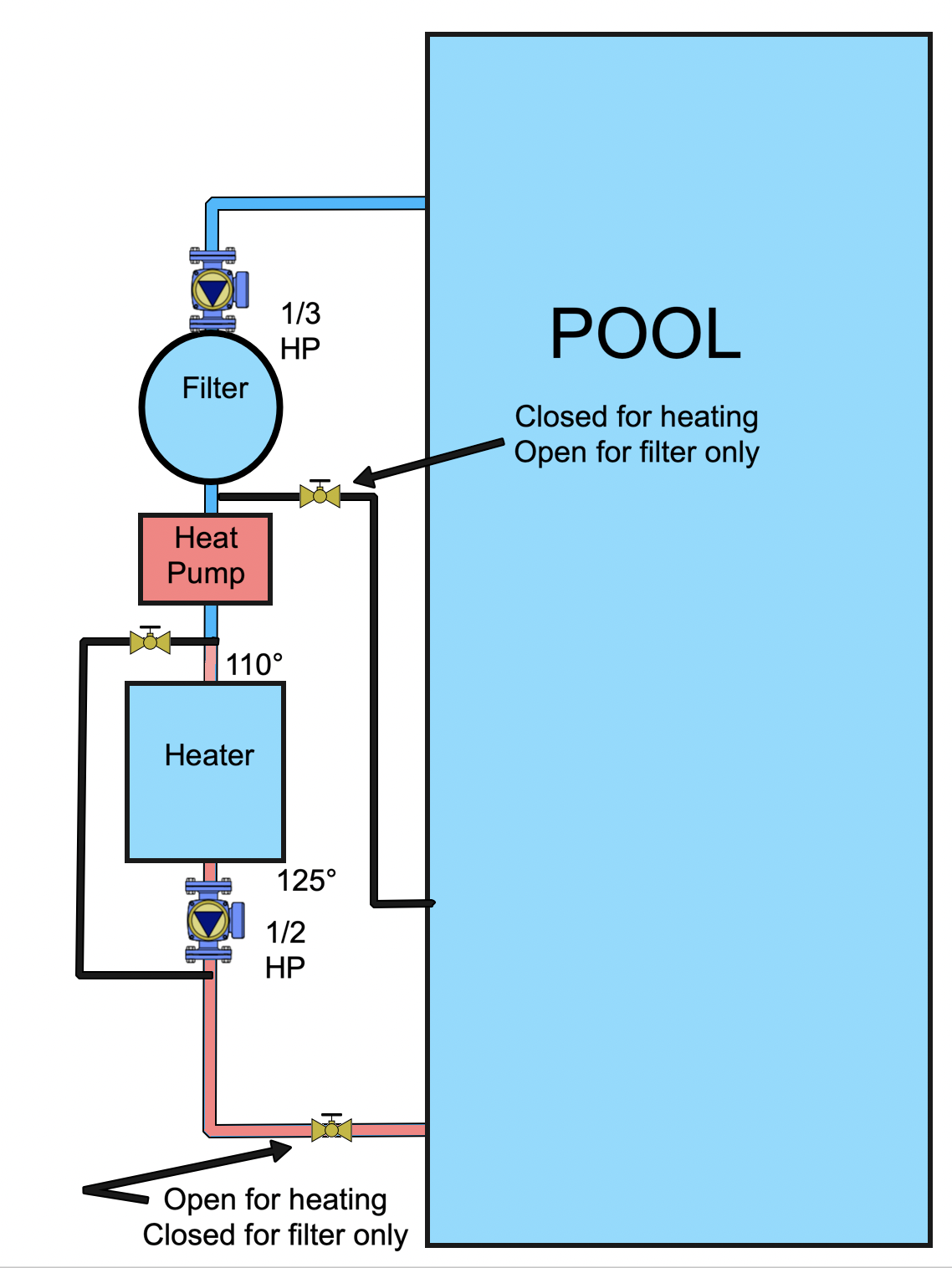

I'm not sure how you are already piped and which pump is first in line, or if there is a different path for filtering only, but here is how I might do what you are thinking of. I believe this might be in line with Jamie's recommendation also.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

yup

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

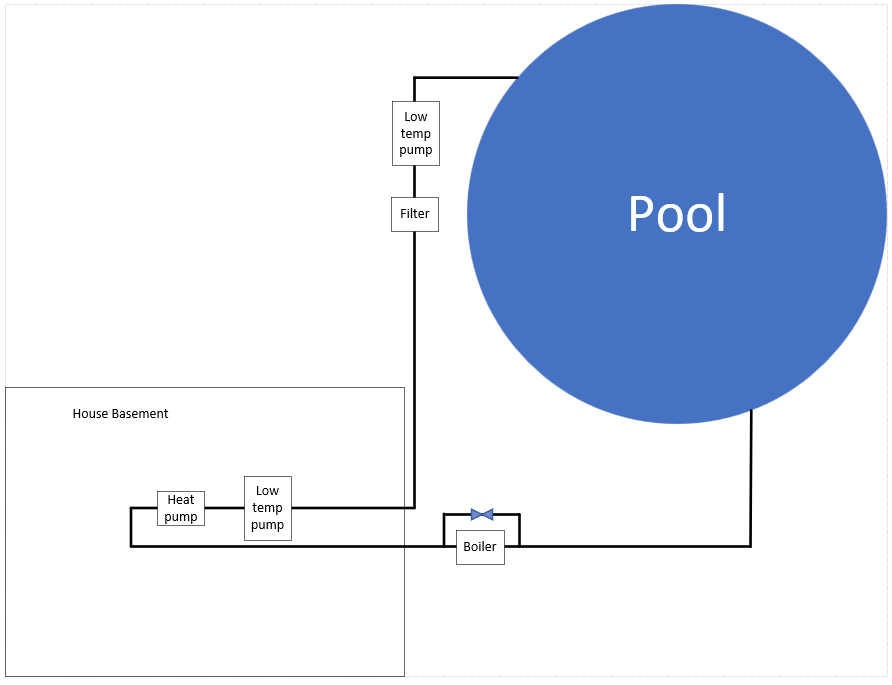

Based on Ed's 2 pump concept I understood the following to be what I would pipe. If I am misunderstanding let me know. I don't intend to run both heaters at the same time. When the house gets hits minimum cutout temp, the HP will shut off and the boiler will fire. There is about 100' of pipe to get the water from the pool to the basement and back to the pool.

Thx. John

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements