comms between LWCO and water feed?

troubleshooting an overfeed problem on a steam boiler and trying to determine if its the LWCO or the water feed.

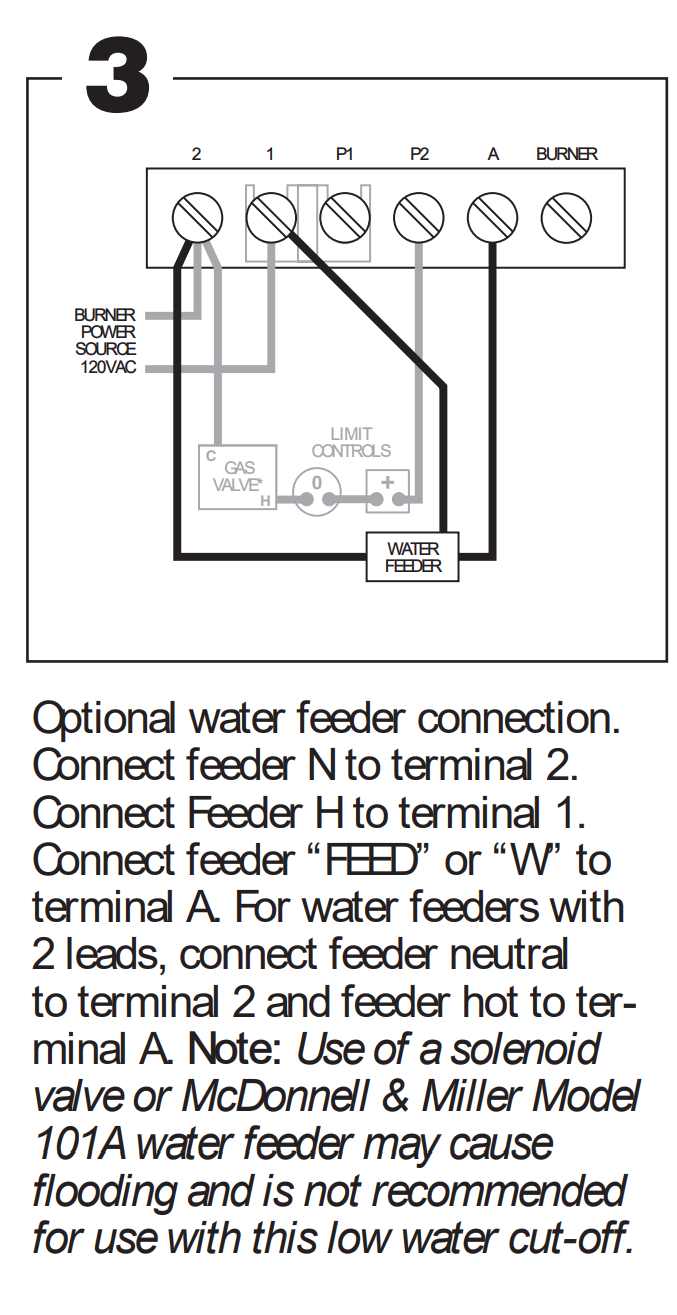

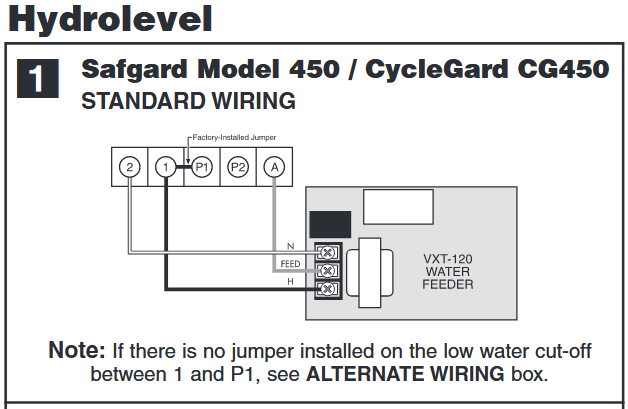

LWCO is a CG450 with outputs to the feeder on "A" , Neutral on "2", H on "1"

Feeder is a VXT-120

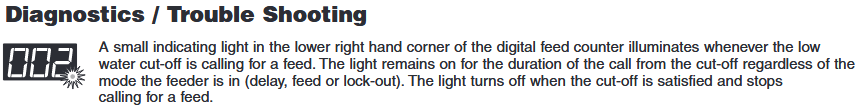

if I read between A and 2, I should be able to determine if the LWCO is calling for feed or not. I'm assuming that 120V would indicate calling for feed.

It blows my mind that HVAC manufacturers don't provide basic information like this in the manuals.

Comments

-

-

A closes to hot to call for feeding. The connection to 1 is for constant power for the counter. If there is power between A and 2 it is calling for feeding. You could also connect a 120v indicator light in parallel with the feeder to monitor it. If you turn the power off to the boiler and the level keeps rising, one of the valves isn't holding(or you have a tankless coil or indirect that is leaking).

1 -

HVAC manufacturers don't provide information like that, as every installation is slightly different. If one manufacturer made the whole thing, yeah — then they probably would. But in this case, the Cyclegard manual for your LWCO gives the connections at the LWCO (two possibilities) while the VXT-120 manual gives the connections to the Cyclegard. Nice of them.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

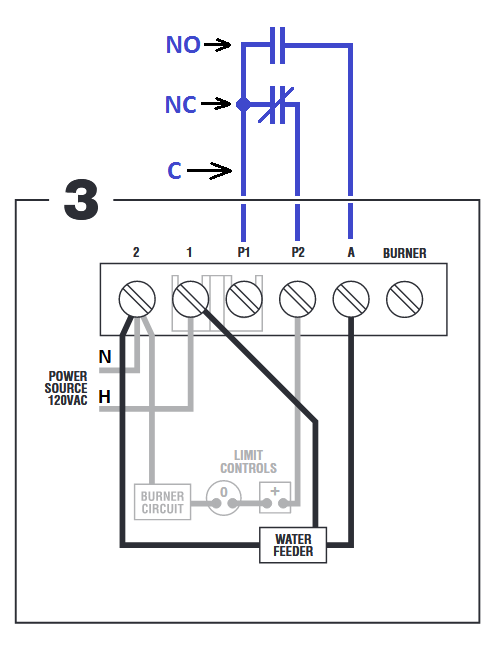

I believe when 120 VAC is applied to the 'Feed ' terminal that activates the feeder. Yes why Hydrolevel used that nomenclature is beyond me, I would have been happy if P1, P2 and A was NO, NC, and Common since I believe it is a relay inside. If you disconnect the wire between the A and the Feed what voltage was on the Feed terminal before and after in reference the the Neutral ? What state is the LWCO in ?

Parts cannon mentality, just change both units, it will probably fix the problem and it makes them more money.

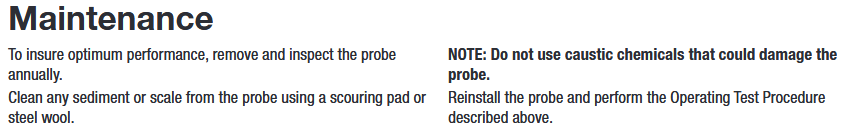

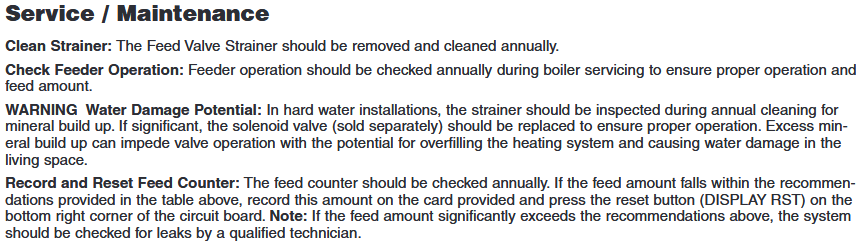

There are manuals for both of those units.

https://hydrolevel.com/wp-content/uploads/2022/03/CG450-CGT450-Instructions-012422.pdf

https://fwwebbimage.fwwebb.com/ProductInfo/VXT-120-Instructions-web.pdf

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1 -

-

To answer your question- yes, you should see 120V between A and 2 on the CycleGard when it is calling for water. It might take a minute or so for the voltage to appear, however.

But- does the boiler overfill when it is not being operated, such as now when the weather is warm? If so the valve in the VXT may need rebuilding. Shut off the water supply to the VXT to confirm this.

All Steamed Up, Inc.

Towson, MD, USA

Steam, Vapor & Hot-Water Heating Specialists

Oil & Gas Burner Service

Consulting1 -

-

Has the annual maintenance been done on both units ?

Also, may be easier than a multi-meter or disconecting wires.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

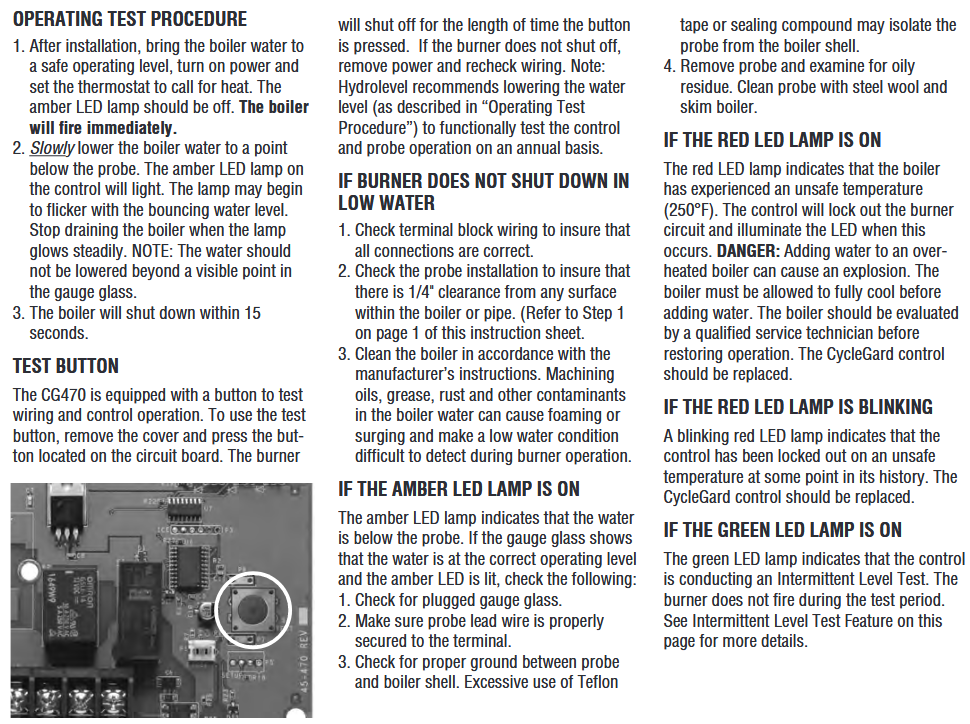

Yes, shortly after turning power back on to the boiler, it starts feeding water. To stop it from feeding water I have to secure the power or shut the water supply valve to the feeder

0 -

This isn't rocket science. Get a multimeter. Fill the boiler to the normal operating water level(do this manually). Turn on power to the boiler. Wait a bit. Now measure the voltabe between A and 2 on the Cyclegard. If there is power there, the Cyclegard thinks the boiler needs water. It's lying. If there isn't power there, the VXT thinks the boiler needs water and its lying.

If it's the Cyclegard, the first thing to do is the annual maintenance on the Cyclegard. Then reinstall — but what they mention only in passing is that when you reinstall it, do NOT use dope or tape on the probe! It much have a good solid ground from the probe to the boiler block. If some overambitious person has used dope in the past, you may have to chase the threads in the boiler with a wire brush or even a tap to get rid of the dope, and also clean the threads on the probe.

Then try again. If it's still misbehaving, you may need to replace the Cyclegard.

If, on the other hand, it's the VXT — again, perform the annual maintenance.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

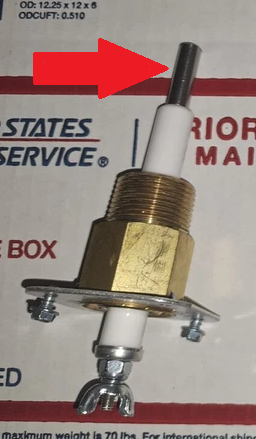

Unless you use a ton of tape and don't tighten it much at all(or the threads are very malformed), enough of the dope or tape is going to squeeze out from the high points of the threads for the 2 to make metal to metal contact. You can test it with an ohmmeter. What is more likely is that it could be installed in such a way that there is a pocket of air trapped in the fitting it is installed in which is why I asked for a picture of it.

0 -

I confirmed the LWCO is bad. It has 120v between A and 2, and interrupts the limit path "p2" all the time. With the water level correct and the Low water light is off, and when the boiler is drained enough to light the Low Water LED. It seems like a stuck relay.

Thanks for all you comments

0 -

Have you checked and/or cleaned the probe ???

If the probe has been contaminated or coated to the point that the electronics can no longer detect the presence of the boiler's water the CG450 LWCO will be continuously in alarm.

In this case simply replacing CG450 LWCO unit and reusing the original probe will probably result in the same issue.

This area (Red arrow) needs to clean. The white insulation area between the probe electrode and the brass threads should be contamination free also.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

I'm am aware of the maintenance requirements of the probe.

To be clear, when the water level is correct, the Low Water light is NOT on. When I drain the boiler below the probe the Low Water light IS on. correct me if I'm wrong but I I think that mean the probe is doing its job.

0 -

Does suggest that the electronics are OK — except for the last bit which trips the LWCO. Unhappily, that relay also shuts the boiler off… so you don't have any LWCO control at all.

You need a new control.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England1 -

OK, I get it now. Yes, it seems like something is wrong inside the CG450.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

As @mattmia2 stated it easily could be a failed solder joint, if the relay 'Fail-Safe' logic is structured that way. Failed solder joints at relays is common. It could be other things too.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements