What happened to Rems Tools(USA)

young heating guy, what happened to rems? I was looking into learning how to bend copper and fell into the rabbit hole. Stumbled upon rems and their expensive tools. Don’t really see anyone using them today or any guys bending Hard copper like they do in Europe.

Comments

-

Not sure...but Ridgid makes high quality copper tubing ratchet benders. I have them in 1/2" & 3/4" Work great 👍. Mad Dog

3 -

do you have ones you recommend?

0 -

-

Teal Industries in Minnesota is the importer and repair point for REMS. I've sent my tools there for repairs. Are they still open? REMSusa.com

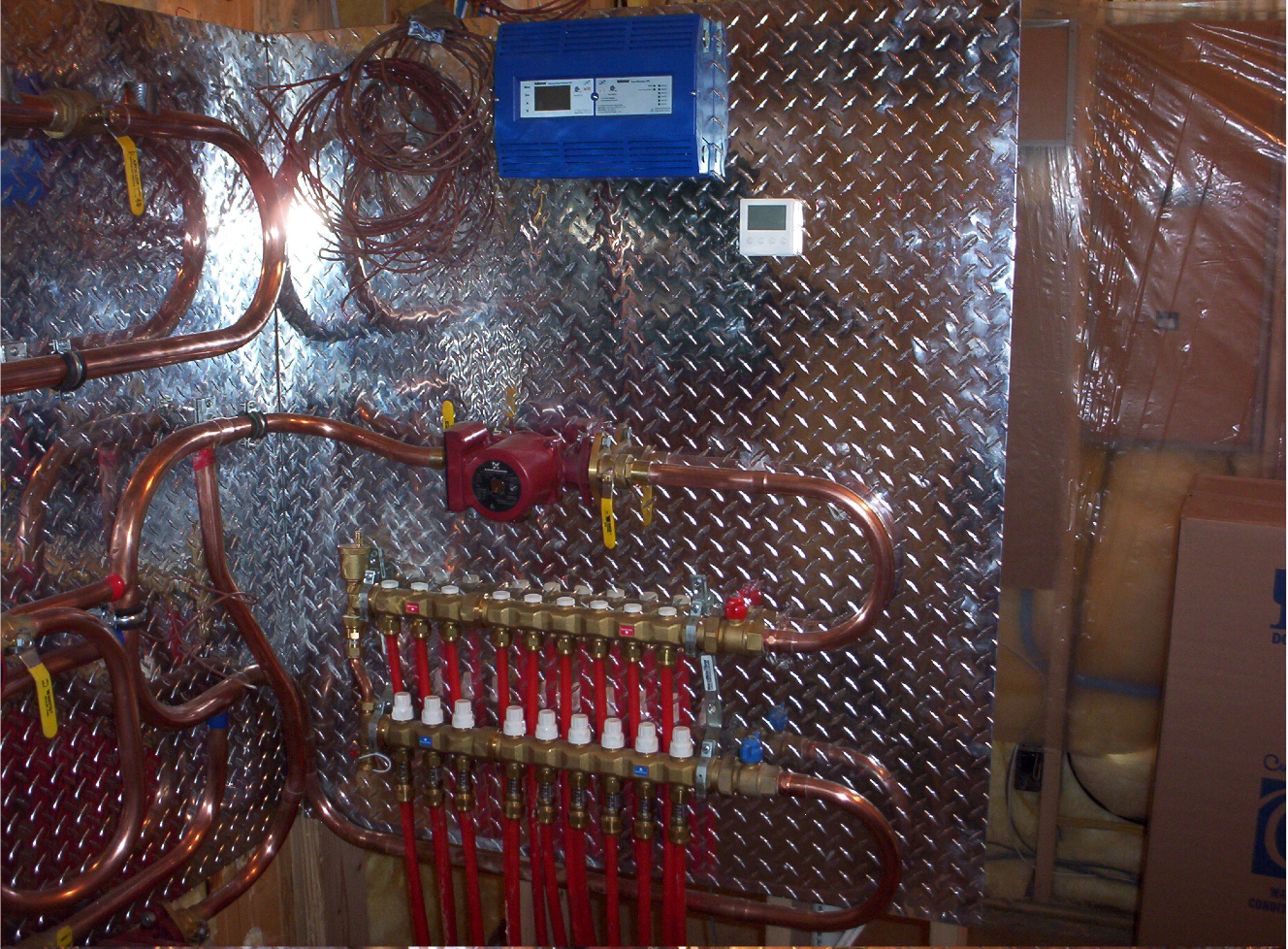

There is a handful of guys that post on IG that do a lot of bending, Mike Flynn flynnstone1 and jeffdemhvac have done demos at some trade shows, AHR and others.

I used to do a lot of bending on my jobs, mostly hobby stuff now. You can also bend steel pipe and PVC pipe with it, cold!

I think Rothenberger has a bender also.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream8 -

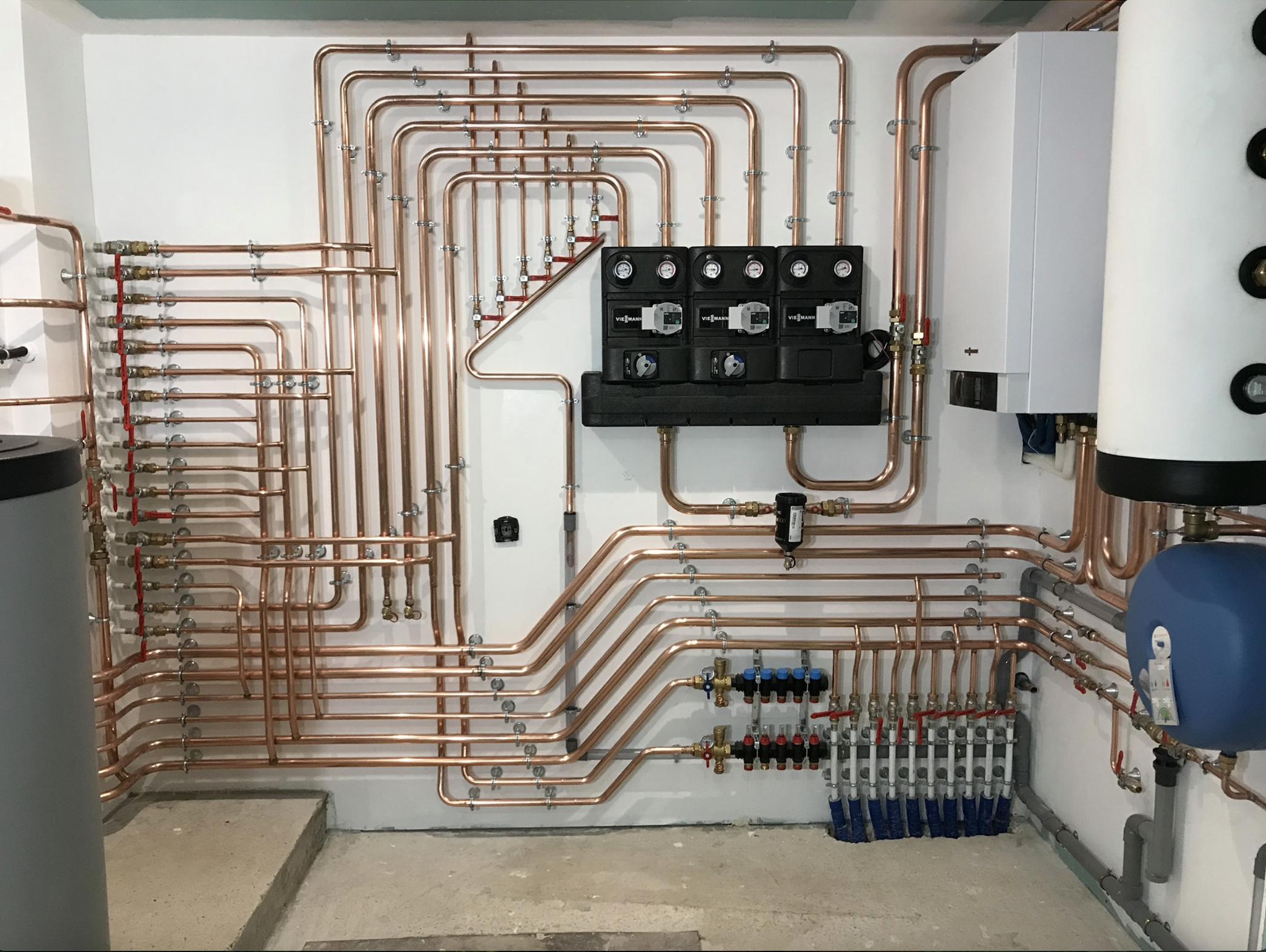

Those photos look really awesome

I'm just wondering How is bending vs soldering time wise?

And isn't the copper getting thinner when you stretch it, like if it was type L wouldn't it be like type M after a stretch?

0 -

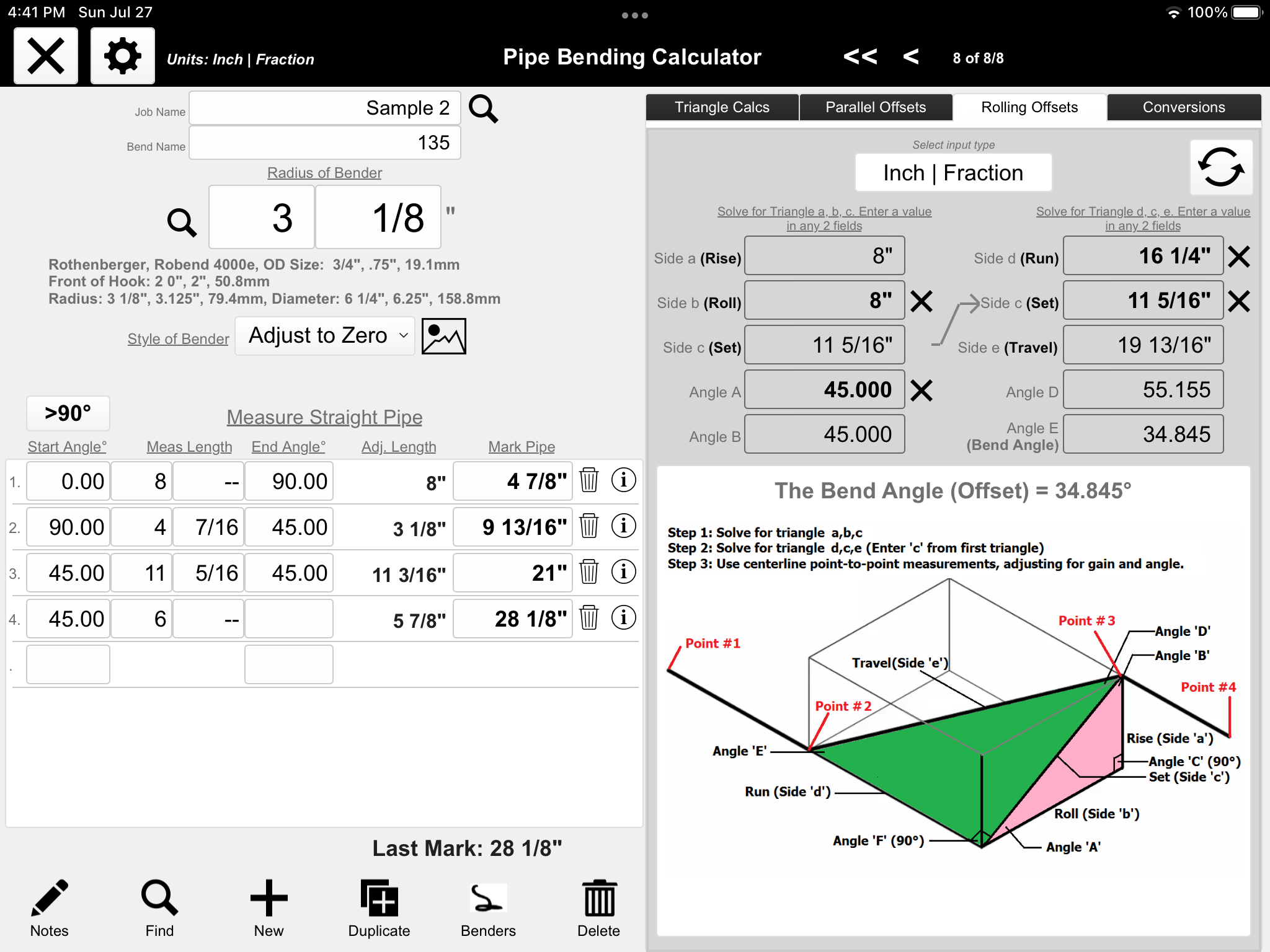

Ever watch a good electrician bent EMT condiut. Once you get the math down it goes pretty quickly. There are some bending software programs also.

I doubt it is as fast as press fittings, but faster than sweat copper.

Yes the outer radius thins and the inner "bunches up", I suppose:)

I know those return bends on the end on HW and refrigeration coils are very thin copper. They run some pretty high pressures.

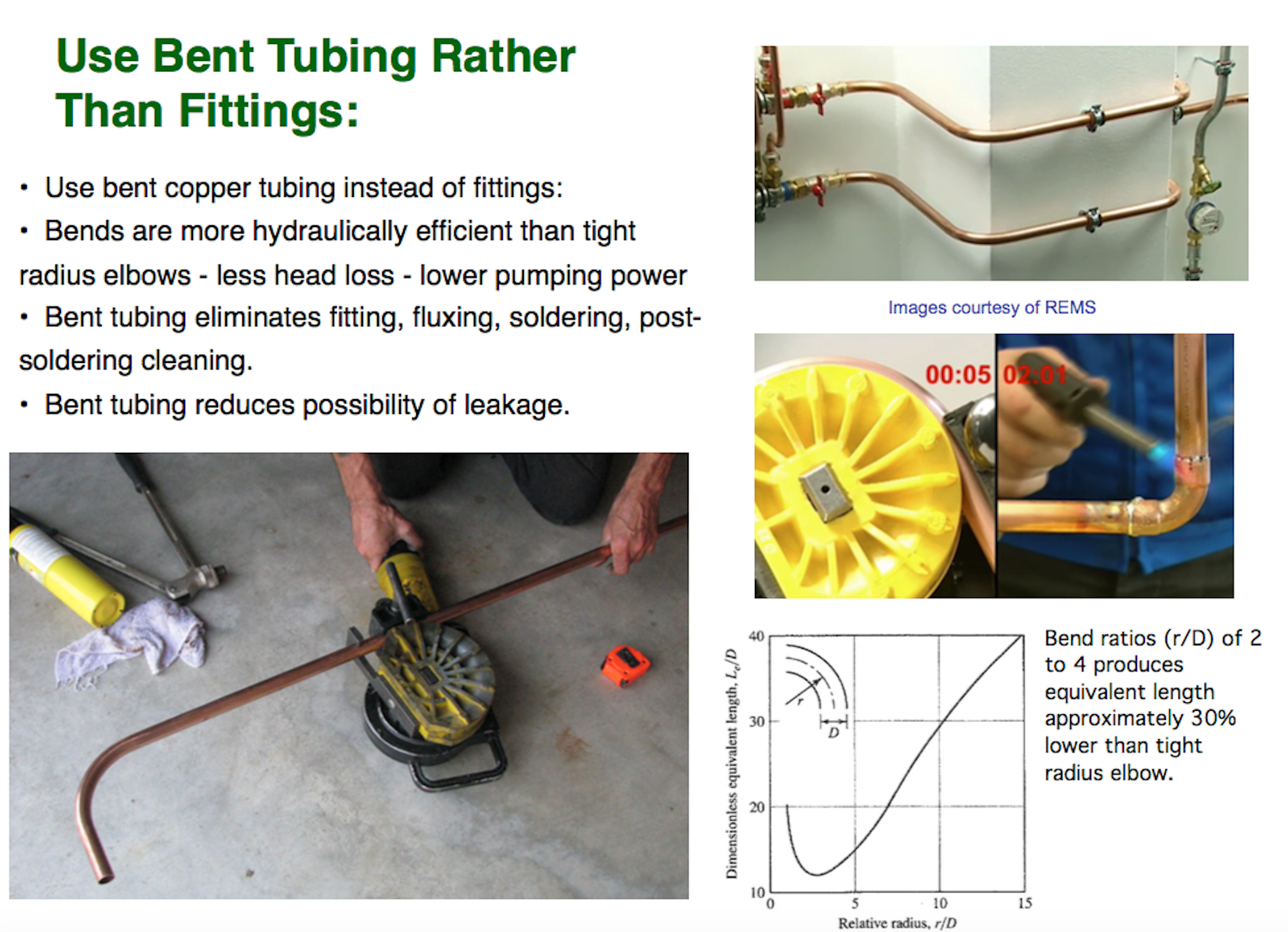

Bending is addressed in the CDA manuals and I believe is accepted in all the plumbing and mechanical codes.

I have bent some type M, but it tends to pucker up on the inner radius, L works best with plenty of lube.

I have found that old copper tends to split on the bend, for some reason. Like it hardens on the shelf??

There is a rep/ wholesaler in Illinois that made hundred of copper tube radiant ceiling grids. They had a home made copper bending tool. They kept the layout drawings of all the jobs, dating back to the 1950's, till recently so they could furnish repair loops!

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream4 -

Hi, I use REMS for bending and tube expansion. A neat thing about the long bends you get is that the water doesn't know it's changing direction with bends over five pipe diameters, so no real turbulance or friction loss. This helps prevent erosion and can even allow you to use smaller pipe in some cases. Good way to go.

Yours, Larry

5 -

@hot_rod in the last picture they're all mechanical tee's looks like, I only once saw a guy doing that it took quite a while. So how is that compered to sweat

This photos really make me think if at all I know what I'm doing, I mean that photo is hydronics at it best

Thank you

1 -

Old tubing gets work hardened. I don't know how if it is just sitting but it is a real thing.

Old tubing flares will split. When you flare old stuff you can heat it to anneal it or flare it a little and back it off flare some more etc with a little oil on the flare cone.

Same with bending

0 -

-

I know that copper work hardens. If you ever have tried to use a brass compression ferule that has been sitting around for a few years you will know that they harden over time. I assume the copper work hardens over time as well as with actual work. maybe temp changes are the same as working it.

0 -

A large shop could do the layout design in advance and pre bend a lot of the tubing as part of the install kit.

0 -

The RE#MS tee puller is a lot less $$ compared to a T-Drill. This is a T-Drill notch tool, however. Notching a piece of solar absorber tube .

By code it needs to have two dimples on the stub. One gets silver soldered over, the other is for inspection to assure of the depth. This older tool only does one dimple.

i have seen an even simplier tee puller that goes into a cordless drill I think Flynnstone posted it somewhere.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream2 -

That t drill notch tool is wickedly expensive

0 -

Why copper hardens. Bending the copper causes

work hardening (or strain hardening) because working or straining the copper introduces defects, known as dislocations, into the structure. These defects interfere with further deformation, making the copper harder and stronger, thus making it more difficult to bend further.

Additionally, The processes responsible for the embrittlement of copper are:

diffusion of hydrogen into the copper /copper oxide matrix

. reduction of cuprous oxide by hydrogen to produce H20. entrapment of H20 in the crystal structure increasing dislocation density, severely.

No, I'm not THAT smart. I just know how to do research. :-) And remember, Hydrogen and Oxygen never sleeps… Me? I'm not aging. I'm oxidizing :-) Those aren't wrinkles, they're oxidation marks.

Field wise, I have seen 40 Y.O. copper that was SO brittle that if you grabbed it with Channelock pliers, it woud easily crush. Crystaline structure. System had been operated at over 200 degrees F for a very long time. Went through the "Turn it up" syndrome. Apartment complex.

Enjoy!

ME

2 -

Oh how i remember the days of copper racks with " hard " tubing and " BT" tubing. The wrath of my father if I grabbed bt to do straight runs.

Robert W.

Energy Kinetics

0 -

The REMS came with a pair of pliers with a couple prongs to dimple the tube. I lost mine.

The T-Drill tool cuts the curve profile and puts the dimples in. When you look down the trunk you do not see ant branches protruding in. You do with the REMS tool, however.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 123 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements