tiny droplet leak from the oil tank firomatic shut off valve.

Ever seen anything like this? What are my options? I put a drip pan for now. Should I run the tank empty and replace it? Or will that create other issues? Is that firomatic valve easily available? Standard size?

Comments

-

-

Tank is old. Rounded shape. Tank is currently at 1/2. Using oil for hot water in summer.

How does draining work? Is draining the last 1/4 or so a big operation. Siphon into 50 gallon container in the driveway?? Or let it run dry?

PS: How can you tell 1/2 vs 3/8 just from a photo???

0 -

the 1/2x3/8 reducer is a big clue

0 -

Normally you can't but oil filters are always 3/8" pipe in residential and the reducer goes up to 1/2"

If you measure the 1/2" nipple outside diameter it will be about 7/8"

0 -

Plug the vent, hook up your soot vac to to the fill, and do it on the fly.

Is everything looks wet, or is that just the pic? How old is the tank? What's all the speckles on it?

0 -

I think that is what remains of the paint…

0 -

-

I don't see any oil stain on the concrete floor just below the valve or the oil filter. This looks pretty normal to me. that coating of shiny fuel glaze on the pipes, fittings, and oil filter seem to be normal from my experience. If there were dripping fuel, that would be a different story. I would expect to see a darker stain on the concrete floor all around that tank leg like this:

But if you have a constant drip… drip… drip and the only place on the concrete that is showing the oil stain is that small spot, then the black rim must be a sump pump pit that is cemented into the basement floor. If all the dripping oil is ending up in the pit and pumped away to the pump's discharge termination, wherever that is, then you have a real problem.

If that is the case, you need to solve this sooner than later.

Good practice for replacing oil tanks

- Do not put any oil from the old tank into the new tank.

- If you are going to use a contractor that is including putting your old iol back in the new tank, then get another contractor.

- With 1/2 tank of oil, you will need three 55 gallon drums to remove all the old oil in order to remove the old tank

- If you can install the replacement tank in a different location, then you can avoid pumping old oil from the old tank. leave the old tank in place with that drip pan for collecting the dripping oil while you burn off the oil.

- With all the old oil removed from the tank and the new tank in place (or the new tank in a different place) you can have new fuel delivered from a delivery truck while the tank installer is on location. It is always good practice to have two people for the first delivery in case there is a problem with the install, the person on the inside can alert the delivery driver to stop the delivery so the problem can be fixed before it becomes a bigger problem.

- Have the 55 gallon drums remain on site with a temporary fuel supply from the drums to the oil burner until you run out of old oil.

- If that is not an option and you can not install the new tank so the old tank can be the temporary storage, then donate your oil to a local church or pay to have it disposed of. While your fuel oil is on your property it is either a usable fuel or a hazardous waste, you get to decide.

- DO NO PUT ANY FUEL FROM THE OLD FUEL TANK INTO YOUR NEW TANK, no matter how good of a filter your contractor says he has.

Finally I have told this story before: read the EDIT: Case History here

Did you happen to read that I don't recommend old oil be placed into a new tank?

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

I think it's fully open. I turned it CCW and it didn't move.

But, I did not twist that hard b/c this thing scares me.

0 -

@EdTheHeaterMan Thanks for your wisdom. There is a small drip that lands on that dark spot. I now have a cookie tin over that spot, held down with a rock for counterbalance.

1 -

Can this valve be repacked like a steam radiator supply valve? The drip is at the very end of the protruding screw

0 -

Yes. the valve can be replaced with the same size. FIROMATIC 12830

Or you can purchase a tank valve that will accommodate the 1/2" tank opening and the 3/8" oil filter. FOROMATIC 12640

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

A few drips of oil are not dangerous. Its something that should be fixed and not be ignored but I wouldn't panic about it. I would run the tank low and have it fixed. If the tank is old it may be time to change it.

1 -

-

My old tank had a very small similar leak in 2015 (couple of oz a month?) but I knew it was about 45 years old. I ran it within about 10 gallons of empty and got rid of it that fall When they cut it up to remove it it was apparent that was the right call.

The last thing you want is for that leak to suddenly fail when it's half full of oil, then you will really be up against it with your options limited to how badly do I want to get screwed today?

Smith G8-3 with EZ Gas @ 90,000 BTU, Single pipe steam

Vaporstat with a 12oz cut-out and 4oz cut-in

3PSI gauge0 -

The tank is very old. Rounded shape. Could be 80 years old. I have no idea of exact age. It's partly encased behind a bathroom wall with a small door access. How can someone eyeball a tank and know it needs to be replaced. If I call a guy, I will 100% be told I need a new tank and boiler just because it's old.

The tank is not leaking, just the valve. I was going to keep an eye on it, and wait for a sign of a leak from the tank, and then I'd replace the entire tank.

0 -

Tanks will usually seep with small drips rather than just let go but there is no guarantee.

0 -

There is a reason a professional would want to see you replace the tank and it's not just $$$. I have seen some pretty expensive cleanup costs from oil leaks in my day especially if they are in finished areas of a building

0 -

I verified the fireomatic valve was turned fully open and this somehow increased the drip frequency. Now, it's one drop per minute into the catch pan.

Tank is currently at 1/4 full. My "one man" oil delivery company told me to let the tank run dry before swapping the valve. Is that the typical approach?

0 -

The shop vac is the usual approach but with that tank being so old there is a good chance you will create a much bigger problem doing it that way.

0 -

Shop vac? They suck out 50 gallons with a shop vac?

0 -

no.

they put negative pressure on the tank so the oil can't come out when you unscrew the valve.

0 -

They can carefully use a shop vac to carefully pull a slight vacuum on the tank and change out the valve on the fly.

Unless you’re in a jurisdiction that actually checks, I would put a ball valve first, then a firomatic.

But based on just a little bit of that picture, how old is that tank?

0 -

-

Service tech came and said to wait until the tank runs dry and then call him back out. I thought you were here to pump out the 1/4 tank. He said he'd rather play it safe, in case the suction does not hold or creates a new leak. I agreed, I told him that's fine but then why did they send you today, as I told them all this over the phone.

0 -

" I agreed, I told him that's fine but then why did they send you today, as I told them all this over the phone."

If you were to call my company and said the word "LEAK" in and form, I would send a technician at once. I need to determine the severity of the "LEAK" so I can make a determination. You know that there are some customers that are clueless when if comes to all things mechanical. The person answering the phone at the service company may not be able to distinguish you from those clueless folks. That is not part of their job description. I know the two women that answered my business phone were not that good at determining any mechanical solutions for the customers, I didn't pay them for that ability. I paid the technicians for that ability.

And as my best friend used to tell me: "they're not operating a charity."

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

I hear you, but I told them there is a drip that I am catching, and that I was told to let the tank run dry. She said they'll send a diagnostic visit, I said I'll send you some pics before you send anyone out. The next day, they said they were sending someone out to do the fix. I made sure they are coming to drain the tank, to make the fix. They agreed. Oh well.

Are there any risks in letting the tank run dry? I kinda rather pay more to get the drain/fix now, instead of waiting another 2 months. Else, I risk sludge feeding into the lines & burner, and have no hot water for maybe a few days until refill.

0 -

The risk of letting a gallon of milk run dry as you get that last drop out of the bottle only to find that there is not enough to fill the cereal bowl and that you can not enjoy it. What a bummer! There may be a higher concentration of clean freshly delivered oil compared to the amount of Tank Bottom Deposits (TBD) from a 30+year old tank. but that oil is moving thru a 3/8" oil line at a relatively slow rate. Not much agitation there to worry about. But that is why you have an oil filter. So then you will have a new valve after the tank runs dry of fuel.

Now comes the real problem. Filling the tank with fuel entering from that 1-1/2" hose at 60 to 80 gallons per minute, splashing on the bottom of the tank. Now that will churn up the TBD into a nice cloud of dirty oil with all kinds of particles of all sizes floating aimlessly in that tank with the new valve ready to allow them into the fuel line. That is where you are going to encounter the problem. It is actually the reverse of what you might think. In order to reduce the problem that you are afraid of, I would recommend that you keep the oil valve closed during the fuel delivery process and for several hours after the delivery. That will allow time for gravity to act on the larger suspended particles causing them to find their way back to the bottom of the tank. After about 4 to 6 hours have passed, open the valve to let the fuel flow from the tank past the valve into the oil line and oil filter. Then you can operate the oil burner.

You may need to purge some air from the fuel line (commonly called "Prime the Burner") at this time, but the majority of the TBDs will have settled to the bottom and only the smaller particles that will not cause a fuel line blockage or clog the oil filter will be suspended in the fuel. After several days all the suspended particles will have settled to the bottom and you can then replace the oil filter refill. You may also want to look at the nozzle at that time too. FYI Any time I purge air and fuel from an oil line, I don't stop as soon as the oil reached the pump. I allow the fuel pump to purge more oil until it runs clear.

Closing the priming port with dirty oil in the line is sure to add more dirt the the nozzle and you could end up with a partially plugged nozzle. So you have a flame and the burner will run but the combustion will never be properly adjusted until you replace that partially plugged nozzle.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

1 -

Thanks Ed. This is a great insight.

Same logic might also apply to filling when down below 1/4, normally.

Bottom line: Run it dry, change valve, close valve, refill tank, let it settle overnight, open valve, bleed/purge line (like after filter/nozzle/strainer change).

This will require 2 service calls? First the change the valve, and another 6 hours later to purge/bleed/prime the line?

0 -

Also, what exactly is going to happen when it runs dry? Will the boiler keep trying to fire once the water gets cold? I may not be home or may be sleeping when the oil runs dry. Is this dangerous? At some point, I will notice there is no hot water. At that point, I can flip the power light switch and turn off the boiler. Then I will call the oil company. How dangerous is the delay between oil going dry, and me not noticing this for possibly 12-24 hours?

Recall my boiler had the oil delay valve safety thing bypassed? Is that a concern?

0 -

Ideally you would figure it out when it is down to a couple gallons but if it actually gets to the point that it is pumping air the primary control will hard lock out when it fails to detect flame and the burner will not attempt to fire. Depending on what other controls are on the boiler, those might try to do their thing.

0 -

-

Also, what exactly is going to happen when it runs dry? You will have no flame

Will the boiler keep trying to fire once the water gets cold? Yes it will try to fire, and when there is no flame, the primary control will lock out by safety.

I may not be home or may be sleeping when the oil runs dry. Is this dangerous? No

At some point, I will notice there is no hot water. At that point, I can flip the power light switch and turn off the boiler. YES

Then I will call the oil company. How dangerous is the delay between oil going dry, and me not noticing this for possibly 12-24 hours? Only danger I can think of is pipes freezing if the temperature is below 20° when you run out of oil and have no heat for 24 hours. I don't see that as a problem this month or next month.

Recall my boiler had the oil delay valve safety thing bypassed? Is that a concern? Bypassing any safety control is always a concern. NEVER PERMANENTLY BYPASS A SAFETY DEVICE. We bypass a safety device during a diagnostic process to determine what is the cause or the reason for a failure to operate. Once you get the system to operate after bypassing a safety device, you shut the system down until you can reset, repair, or replace the safety device in question. I hope you are not operating your system with safety devices disabled, jumpered or otherwise bypassed.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

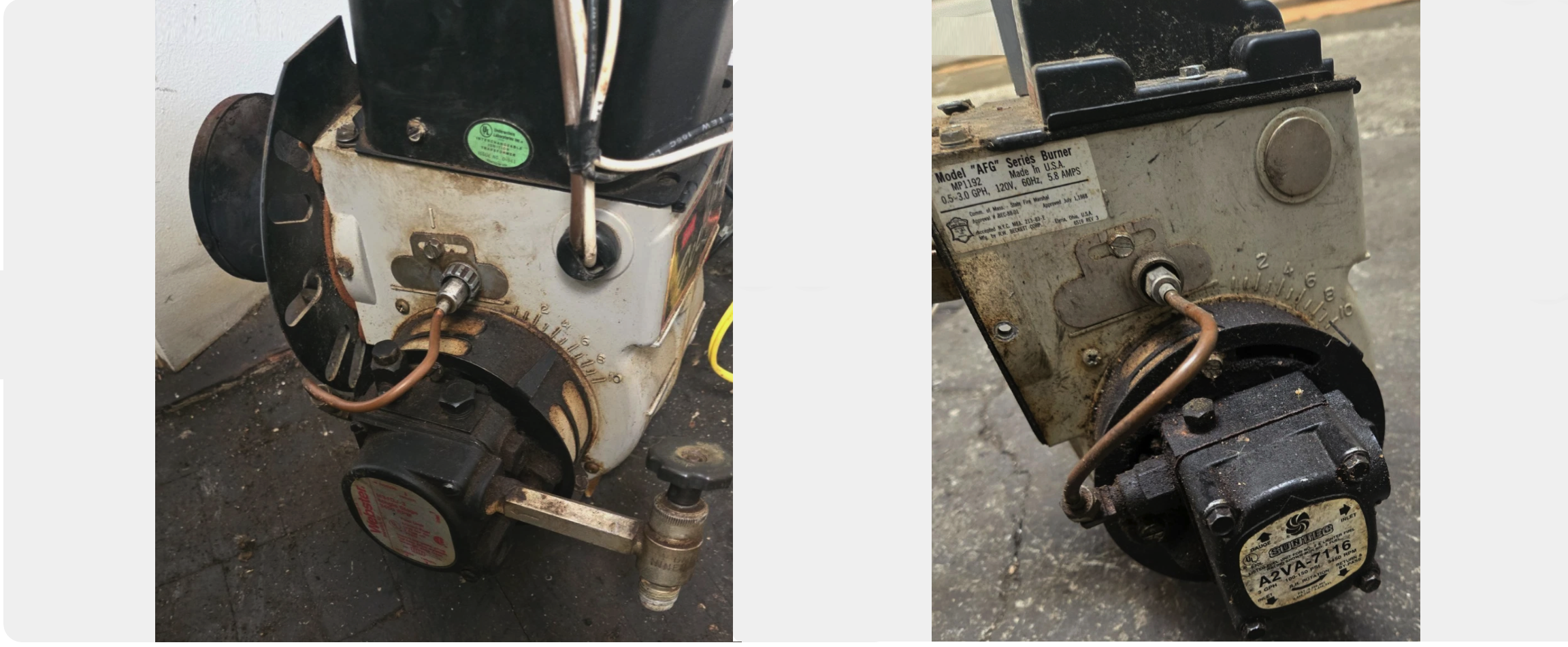

I took some time to read your post about the delay oil valve. That oil valve is not a safety device. It is an efficiency device. Operating a burner without a solenoid oil valve (be it a separate part of part of the fuel pump) does not make the burner unsafe as a matter of fact R W Beckett Co. offered the AF and the AFG burners with no oil valve for some manufacturers of heating equipment. Here are two examples of those oil burners.

So operating an oil burner without an oil valve is safe. It just is a small percentage less efficient.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Some great advice here!

And @CoachBoilermaker, replacing a tank isn't ever someone looks forward to but I'd say all signs indicate that the tank is probably getting close to the end of its life. Murphy's law states that the tank will start dripping during the coldest cold spell in January. Will it be a drip that a cookie sheet can catch? Or will it be much worse?

Like some of the very old boilers we see on this site, no one knows if they will keep going for another 6 days, 6 months or 6+ years. But Ol' Murphy always shows up at the worst possible time.

Perhaps you can share a few more pictures of the tank for the real pro's here to add their thoughts?

0 -

@AdmiralYoda, This was from his older post:

"And I can't figure out why the oil company won't deliver to me anymore"

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

2 -

How can I tell if it's down to a few gallons? Tapping the tank isn't reliable since it's double walled?

The boiler is 80 years old. The burner may be 20-30 years old.

I'm concerned b/c I have no idea if there is a lock out feature or if it even works.

Should I test the lock out by turning off the valve? But, then I'd need a tech to restart/prime.

Ugh, this is stressful. I should not have bought a house with this ancient HVAC / ticking timebomb. I'm too mental to replace a working system. So, I just obsess about it constantly. Too many questions and unknowns.

0 -

The tank is encased behind a wall and sink. I can't really take a good photo.

I assume a drip will flow down the center of the bottom of the rounded tank and drip under the center axis of the tank? I slid a long cardboard sheet under it, and check it weekly.

0 -

you could disconnect one of the motor terminals from the primary control and make a call for heat. with the burner not running it should lock out in about 1/4 of a minute if it is a modern control.

I think that is a single wall tank although it would be hard to tell what's left when it is basically empty without being able to stick a dipstick in it.

0 -

The cardboard idea is a great one. This will let you know when the tank is leaking somewhere other than the valve location.

Have you considered replacing the tank in a different location that is more accessible? Outside above ground is an option, but I like to see basement tanks whenever possible. When selecting a new tank location, make sure the hose from the fuel delivery truck can reach the fill pipe. Don't install a tank that can not accept a delivery.

After the tank os installed, have a fuel delivery and check that there are no leaks on the fill pipe. When the old tank runs out of fuel, you will have a new tank full of fuel ready to connect to your burner. Then it really does not matter when you run the old tank dry.

Abandon the old tank until you are ready to do a renovation for the room that is covering the tank. in 10 you can rip out the wall and the sink and you will be able to add two feet to that room after the tank is gone.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 116 Geothermal

- 169 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements