Hybrid Heat Pump/Gas Furnace Retrofit Questions

Setup: My studio/workshop is an ~2400 sq. ft 1904 church. (1200 sq ft up, 1200 sq ft down). The current NG furnace is a 92% single-stage unit from the late 90's. It runs OK, but is showing it's age. The envelope is tight: I've made extensive improvements to insulation, glazing, spiral supply and return ductwork with additional filters at wall returns besides the one at the furnace return box. The building doesn't have AC, and needs it to get through the dog days of Summer. Near St. Paul Mn, with -12F Winter/90F Summer design temps.

Let's say I can get by with 80kBTU at coldest design day, and 36k(3-ton) btuh for cooling. I haven't done a Schedule J, and I will. I'm sure the 'guesstimate' is in the ballpark.

I am looking at options for a new, high-efficiency NG furnace, evaporator atop, and outdoor condenser. Options I'm looking at:

- 100k 2-stage or modulating furnace with variable speed blower + 3-ton inverter AC only condenser.

- 100k 2-stage or modulating furnace with variable speed blower + 3-ton inverter heat pump (HP good to +5F)

- 80k 2-stage or modulating furnace with variable speed blower + 3-ton inverter heat pump (HP good to -20F)

Any opinions on which option to select, or whether I should looking at something else?

I'm not so sure the 10:4 I'd get in a modulating furnace vs 10:6 for a two-stage furnace is worth the added expense and risk of failure.

For Option 3, I'd think a -15/-20F HP to make up 20k btuh from going with a smaller furnace would be a given. I've had standard splits just shut down when outdoor temps go below +5. Pretty sure that was controller driven: 'hard stop at +5, don't even try…'

Thank you!

Comments

-

Simple is better. Using a gas furnace in conjunction with a heat pump adds another layer of controls to the system. And from what I understand, any variable or staged new AC system will have all kinds of electronics to bring on the compressor, they don't even use a contactor anymore. Then you need to consider the defrost cycle when the outdoor coil starts to ice over. The compressor will go into the air conditioner mode to pump hot gas into the outdoor coil to melt the ice on the coil while the indoor coil will be getting cold line summertime operation. (that cant be comfortable)

Since you are looking at variable speed, higher efficiency stuff anyway, you can certainly look at the Heat Pump idea You will need to look at the price point and if you are going to use the communicating control (ABCD) or a standard legacy thermostat R Y G W system to control the system with the addition of W2 and Y2 and O/B and possibly C. More wires are needed for all those additional features.

At what outdoor temperature is it more efficient to operate the electric HP and when is it cost effective to use natural gas. That gets into the COP (Coefficient Of Performance) for the HP you select. That is the number of how much less expensive it is to use the heat pump compared to electric resistance heat. Let's say thatGas will heat your home for $50.00 and electric resistance heat will cost you $100.00 to heat your home for the month. If your heat pump has a COP of 5 then that means it will put out 5 times as much heat for that same $100.00. Since you don't need 5 times more heat, then it would be safe to say that you would only use $20.00 in that month to heat your home with a COP 5 heat pump. That is the simplified explanation.

The COP is actually constantly changing as the outdoor temperature changes because 10° outside air has less heat for the heat pump to use than 40° outside air. So that lower cost to heat with electricity is actually changing as the outside air temperature changes. That COP 5 rated heat pump may actually have a COP of 2 when it is 20° outside. and a COP of 1 when the temperature is 10° outside. So there is a point when the heat pump actually costs more than using Gas. (there’s an app for that) So who selects that “Break Even Point” to switch from HP to Gas? Usually the installer. And they are only guessing at what that number might be.

You can believe what you want about the “NEW LOW AMBIENT or COLD CLIMATE” heat pumps, the fact remains that the outdoor coil is removing heat from the cold outside air, then compressing that heat into a hot refrigerant gas so it can be “Pumped” into the indoor coil to heat your home. The colder the outside gets, the less heat there is in that air to compress. The less heat there is to compress, the lower the efficiency of the compressor will be. The compressor still uses the same electricity when it is cold out at a COP of 1.5 as it does when it is mild outside at a COP of 5. The amount of heat it produces is what changes.

Edward Young Retired

After you make that expensive repair and you still have the same problem, What will you check next?

0 -

Ed - Thanks for the advice. Yes, I need to 'run the numbers' both for final system sizing and $$ saved during use vs. $$ spent upfront and on maintenance. I have no real qualms about installing, monitoring, or maintaining any system, but nothing pisses me off more than hardware that fails 'early and often.' Especially when I spend a lot of time to set up a system.

I installed a 4-zone Mitsu split system in when we renovated our 1915 house a few years ago. ~18 SEER and rated down to maybe +% for 100% heat output. It works really well for cooling. All the multi-splits I found were reversible heat pumps, so I looking for an AC only unit wasn't a factor.

We never use the split system for heat - not even during shoulder season. The NG mod-con with 10:1 turndown and constant pressure/variable flow circ pump covers heating for less $$ at any outdoor temp.

You have me thinking 'Option 1' is the way to go for the forced air stem at the shop: Cover heat with the NG furnace, and cool with AC-only unit. My brother-in-law has a modulating gas furnace in his house. He's not sure it saves much $$ over a two-stage gas valve, but with the modulating burner and variable speed blower, he says heat is very consistent. Analogously, I'll probably go with an inverter AC. Bang-on/bang-off can go away for most any control system these days. PID and decent programming can be very reliable, and is definitely easier on equipment and more energy efficient.

1 -

look at the rebates and incentives for the hp option www.dsireusa.org. I got a utility rebate, federal tax, and also a state energy upgrade rebate. close to 2 grand in all.

I have a few week on this new Amana HP system with gas furnace. The gas takes over at 40 degrees, it is adjustable, 40 is what the installer runs on her own system.

So far I have been very pleased with the variable speed blower. It seems to run most of the time with weather in the 90, it does ramp down in the evening. I also have it set to run the fan every hour for 10 minutes to filter the air

The outdoor it is much quieter compared to the old Tempstar

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

Thanks for the tip, Bob.

When we renovated our old house in 2018, I calculated with natural gas vs. electric costs in Mpls/St. Paul area, I was better off considering heating and cooling systems as being non-related. Part of that was beacuse we stuck with hydronic heat (I love it) and needed a better way to AC. I wasn't gonna do forced air. Rebates were irrlevant, because I designed and installed the systems as a homeowner. Rebates only went to professionally installed systems, and my equipment isn't under waranty since it was a DIY install (which is why I avoid certain brands like the plague…)

EDIT: I started investigating current Federal tax credits for energy efficient home improvements, and it looks like you can get credit for the equipoment without it having to be part of a professionally installed package. That is encouraging! (Wanna bet on how long until that gets axed? 😉)

I have another question: Do hybrid systems usually have the ability to control them so you can run the HP in shoulder season, switch to gas during 'normal' winter, and then add the HP back in (even at low COP) to get you through the coldest days? That's what I was hoping for, because It might let me use a smaller NG furnace with an effectively greater turn-down 90% of the time.

If I had to run a 'cold weather' rated HP at low COP for a few days here and there to keep indoor temps up, fine. If they can't be controlled at both ends, then I'm back to size the furnace for coldest design temp, size the AC for hottest design tmep, and don't worry about the condenser running in reverse.

1 -

You can nail down the heat loss with your historical therms used.

With dual fuel, many of the multiple stage benefits disappear. The minimum turndown of the furnace isn’t useful, because you’d be using it when it’s warm out, when the heat pump is most efficient. The low temp performance of the heat pump isn’t relevant - you have the furnace for the subzero temps!Let’s nail down the heat loss though.

0 -

The building is a studio/workshop, and not lived in. It gets used intensively , and then sometimes not much at all. The tstat is left at 57, and manually overridden when I'm working. I wonder if the Manual J won't give me a better picture of heating and cooling requirments than trying to piece it together from a gas bill?

0 -

Good point - unless you have daily/hourly data a manual J is probably better.

57F is wonderful for a heat pump.

0 -

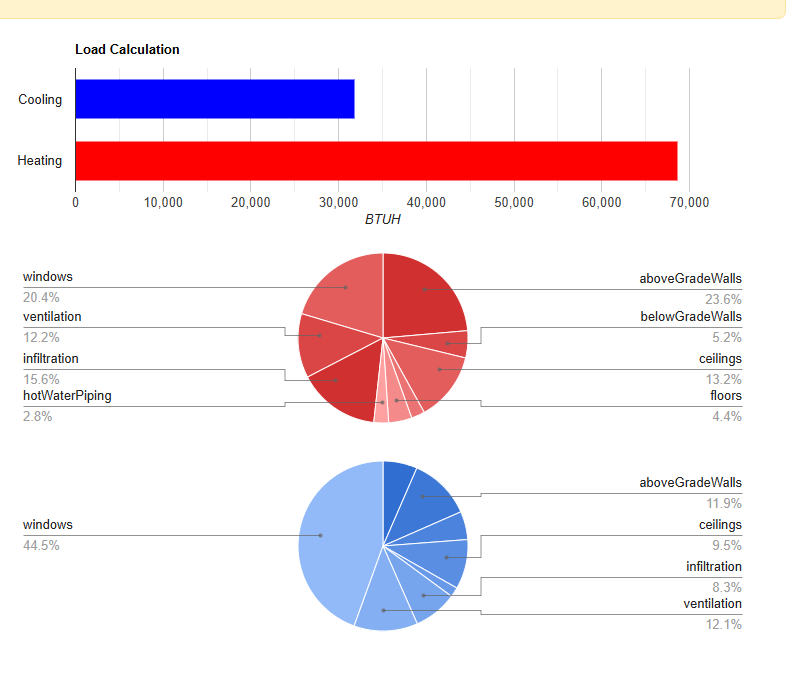

Screenshot from a run using CoolCalc MJ8, with 88/-8F design temps:

This is pretty close to my guess at needing 100k furnace and 3-ton refrigeration unit. I trust CoolCalc numbers, as I used it for our home renovation and verified the numbers against another program. The system in the house is right-sized and the numbers have proved out over 6 years. I might be OK with an 80k gas furnace.

0 -

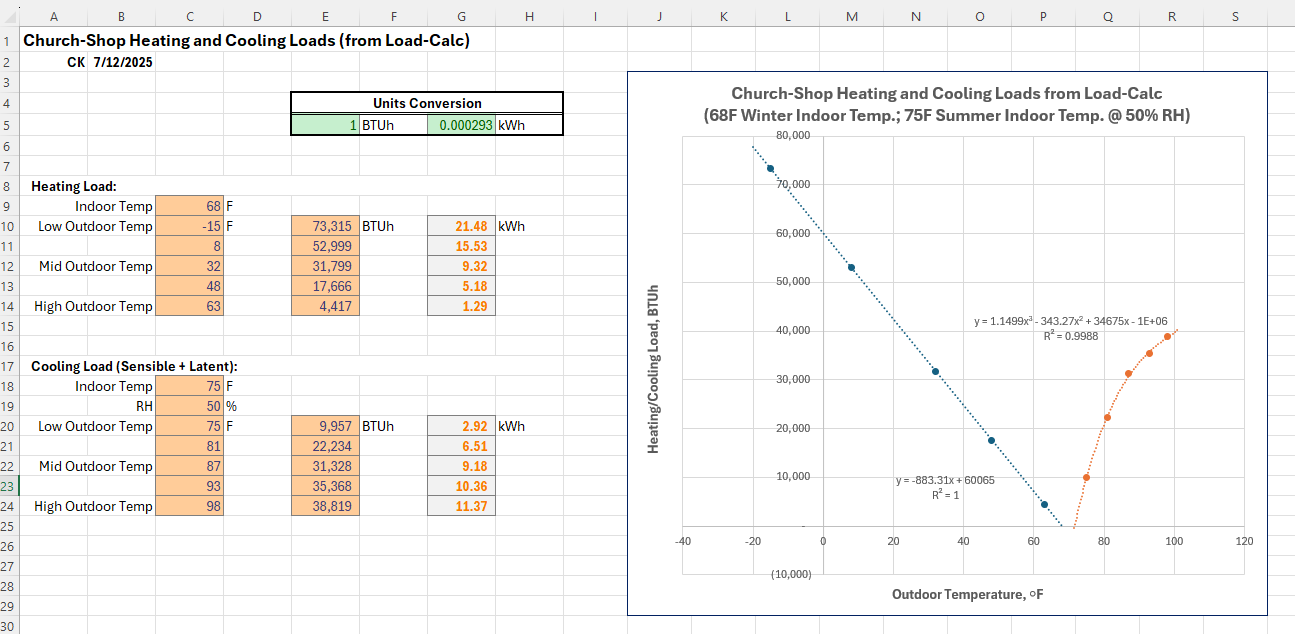

I ran a check on building loads through Load-Calc, which came in pretty close to Cool Calc. This screenshot from a Q&D spreadsheet shows heating and cooling at 5 outdoor temps:

Heating is linear, so it's over-specified. Cooling isn't linear as it also includes latent heat. The orange trendline curve is a cubic polynomial, which happens to fit without oscillating.

I think this tells me if I use a dual-fuel system with a 3-ton heatpump, it's probably gonna be done heating the place somewhere around 30-35F. This will vary depending on the unit. A 'cold-weather' pump may cover the heating load down to 20F.

I'm disinclined to pursue all-electric/futureproofing scenarios. The added electrical load to the building is a negative (I already have several welding and machine circuits on a 200A panel.) Sizing a heat pump to cover heating down to -10F is going to make it too big for efficient cooling. Time to to check the energy cost and equipment costs.

If a heat pump is cost-effective vs. gas in the shoulder seasons, I still see value in a modulating gas furnace if it fills in steps between 60% and 100%. The 10:1 turndown on a modcon boiler is great - there are a lot of steps to use between 32F and -12F! Maybe gas furnaces don't modulate that finely?

0 -

it still seems like a high heat load for 2400 sq ft with extensive energy upgrades?

Spitball a high load number of 25 btu/sq ft. 25x 2400=60,000 btu/ hr

New energy efficient homes are seeing heat load numbers in the teens. If you load was 20 btu/ sq= 48,000. Your numbers are twice that?

The switch over from hp to gas might be decided by comfort. At some point luke warm air covers the load but may not be comfortable to sit around in the space. That was my experience living in a home with a water to air hp, no backup.

Efficiency and output drops with lowering outdoor ambient. The hp data sheet may show that derate.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

With the design outdoor temps, you have and the square footage you have I think your #s are correct. Note that the cooling load is usually around 1/2 the heating load which is a useful rule of thumb and holds true in your case.

Also, you mentioned that you keep the stat at 57 and override it as needed. That is a reason not to undersize the equipment as HL & HG are based on maintaining a constant temperature. You may need a tad extra to catch up in extreame weather although I am not for oversizing.

0 -

if you are indicating 100K required for 2400 sq ft that is over 41 btu/ sq ft

Light snowmelt systems start at 50 btu/ sq ft🤔

Maybe @GroundUp has some ballpark numbers, he works that Minnesota area?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I trust the numbers off CoolCalc and Load-Calc. I spent a little more time doing room-by-room and checking all the construction types, dimensions, and surface areas. The numbers in the spreadsheet reflect 5 realistic outdoor temps to heat and cool at indoor temps I use for my house Winter and Summer. 70-75K BTUh at -15F to heat is probably not far off. Likewise for 32-34k BTUh at 95F to cool.

The building is a 1904 church set onto a block basement in the 60's. By the time I figure in the conditioned entries and rear staircase, it's close to 2950 sq ft & 38,000 cube. Fairly tight, but I'm allowing for decent air exchange with ventilation fans and passive intakes, but not a dedicated heat exchange system. It's still a 2x4 balloon frame building, and I've gone as far as I plan to go with insulation, windows, and air infiltration. It's accounted for in the load calcs.

An 80k furnace at 95% efficiency will probably work. Not much headroom - maybe 5-10% when I'd prefer 20%. Likewise on 3-tons cooling - OK, but not much headroom. My goal is to make this comfortable, like my house. No setbacks - set, forget, let it purr along.

0 -

well you certainly want to cover worse case condition of -15. It look like that area rarely gets to that temperature going back to 2020 temperature data. Variable, modulating equipment is best so low load conditions do not cause short cycling.

An 80k at 95%= 76,000 btu/hr =25 BTU/ sq ft, sounding more reasonable for the structure you describe. Infiltration is a hard number to guesstimate. A blower door test would help nail that down

If you are comfortable that you will be comfortable go with those numbers.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Yes, rarely -15. We did get several days in a row with overnight lows around -10 last Winter. And a week later it was back above freezing Extreme swings are definitely more frequent than they were 20 years ago. Coasting through one cold night isn't a big deal, but several days in a row is a problem.

A blower door test sounds like a good idea. Changing the infiltration selection from 'average' to 'semi-tight' to 'tight' in software has less effect than defining 75 vs 200 cfm air turnover via exhaust fan. Maybe I'll look into active heat exchange. I kept it simple in my house - was running out of space, time, and $$ to install yet one more system.

Thanks to others for the advice.

0 -

The best money you will spend is getting the load are low as reasonably possible, while maintaining healthy IAQ. ASHRAE has suggested air changes for all types of buildings.

Heat recovery units, foam sealing any obvious leaks are all gifts that keep on giving.

Sounds like a fun project, got any pics you want to share of the building?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

I'm not sure you'll be able to run both gas heat & heat pump at the same time. The indoor coil is in the discharge of the furnace, it'll be in 120°+ air when the furnace is heating. Check the mfgr's paperworks, see what they say about simultaneous operation.

0 -

0

-

The pics above are all pre-2016. I did a lot of work on the building from 2012-2016 and then focused on making income instead of construction work! Its time to get back on the building project…

0 -

-

Yep. I have two electrostatic dust filters overhead at opposite sides of the nave/main shop. You can see one in the top pic. The grab the floaty stuff. I grab most of the dust at the source with a Delta drum collector. I attach a bench-top scoop to it when I'm sanding. The furnace returns are all enclosed steel ducts, with additonal filters at the wall registers. The HVAC stays very clean. Years ago I though about putting in a mini-split system for cooling. I realize that was dumb: A new furnace will be much shorter than the old one. It give me room for an evaporator in the plenum. Split heads would get filthy, and I'd be up on a ladder cleaning them every week…

Here is are recent pics of the interior ( the hoistway in the back is through the old altar/chancel area and lets me get heavy stuff to the basement. That's where the machine shop is):

Material handling works well. In and out of the storage racks close to the glass garage door. Buck up oversized stuff on sawhorses if I need to, and then right onto to the saw.

The old entry area had a low drop ceiling that covered attic access hatch. Typical 60's/70's awful remodel work. I tore out that part of the attic framing and made a loft. It still needs guardrails…

0 -

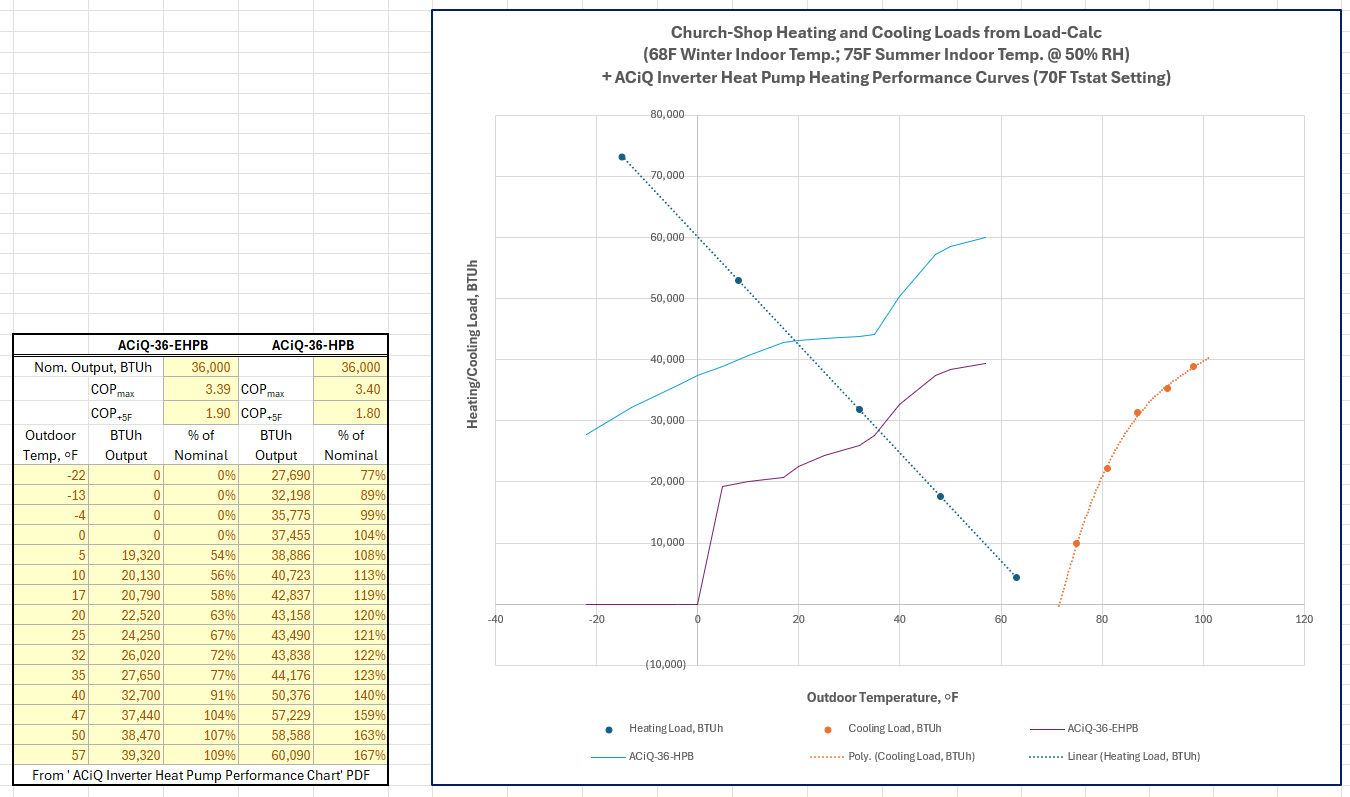

Here is a chart of my predicted heating and cooling loads with heating performance curves for two ACiQ inverter heat pumps (+5F and -20F rated, light blue and purple curves):

I gather the ACiQ-36-EHPB would cover my heating down to 35F, and the ACiQ-36-HPB would cover heating down to18F. Both publish a COP of 3.4, which I presume is max COP. Both publish a COP at +5F of ~1.8-1.9.

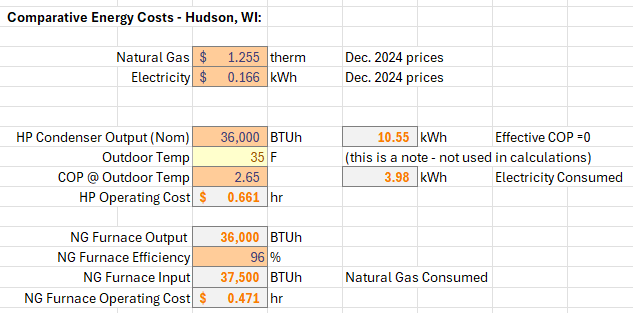

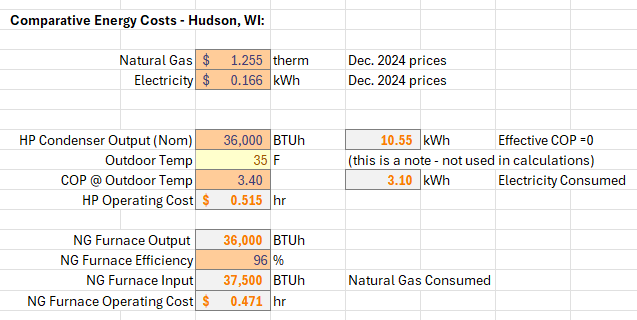

Here are the calcs I set up for energy costs:

I don't know what COP the ACiQ condensers would be at at the points where they cross my heating load line. I'm guessing aorund 2.65 (midway between ACiQ published high and low values, and looks about midway on the high and low outputs of their curves). Does that seem correct?

Even if I set my COP value at 3.4, it is still less expensive for gas is than electric (with Dec 2024 prices):

I suppose a better picture would include electrical consumption for the blower and controls , but thats a given for either an NG or ducted HP system. Then there is the pan heater for any HP condenser in MN (I call that essential, and am amazed how many folks don't have them). If I'm missing something here, please tell me!

0 -

ratio - I figured there wasn't an easy way to use the HP to assist the NG furnace on coldest days. Because of that and the fact that a 36k HP doesn't appear to help with heating costs in the shoulder season vs NG, I'm inclined to just use an inveretr AC only unit in this install. I suppose I could be concerned about gas supply failing while electricty still worked, and not having any heat. Pretty unlikely scneario.

0 -

I live in the city. Never in my life have we lost natural gas. Power, on the other hand᳟…

0 -

Yep. And the gas heating system won't run without electricity, either😉

hotrod - I hear you on indoor air quality. I'm considering this project as a residence for design purposes, and ASHRAE recommends a minimum of 0.35 ACH. With high cube per sq. ft. of floor, I'm looking at 220 cfm exchange. You'd be looking at 2-6 ACH for commercial space. That puts air exchange in the 1000's of cfm. If I'm in the building doing desk work, air exchange needs are low. The I go downstairs and weld or run the CNC plasma table and 'it all goes out the window.' An active heat exchange system is being considered. It's also one reason why I tend to want more headroom on the heating end. Of course, if I'm welding and have to push air outside, I'm also generating make-up heat.

0 -

Before I commit to the system hardware: Opinions on the merits of springing for a 'high efficiency/winter-rated' heat pump rated to heat my space down to 20F, vs. a 'standard efficiency' heat pump rated to heat the space down to 32F, vs an inverter cooling-only unit.

Presume I will be installng a natural gas furnace to accomadate heating down to a -12F, 99% design day, and that any inverter AC or HP option will handle cooling loads with similar efficiency. Hardware up-front for the standard HP over AC-only is +$1000. Hardware up-front for the 'high-efficiency' HP over AC-only is +$2000.

I'm presuming reliance on natural gas is a given. Based on current market rates and trends, I'm guessing it'll still be years before electricty will be cheaper than gas for heating. If I was required to swith to all electric, my panel would need to be upgraded or my other loads reduced, along with adding HP capacity to meet the heating loads.

From an install and programming perspective, I'm thinking any system using an NG furnace with a HP is about deciding where the setpoint should be to switch from electric to gas for heating. That seems trivial from a systems standpont, assuming we are not getting into parallel systems with additional ductowrk, controls, etc. It comes down to assessing projected energy costs, initial hardware costs, and likely maintenace costs for hardware (typically higher for more complex/more $$$ systems). Does that sound right?

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 118 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements