Vaporstat settings - low pressure vapor system

is this a typical settings for a low pressure vacumn system? Please advise

Comments

-

That's about as low as yu can go on a 4 psi vapourstat, so yes, that should work. You could go a bit higher — up to 0.5 psg — on the main — which would allow you to go a bit higher — up to 4 Ounces gauge — on the differential.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

It should be adjusted to the lowest settings so that the house heats on the coldest day and short cycling is kept to a minimum if possible.

0 -

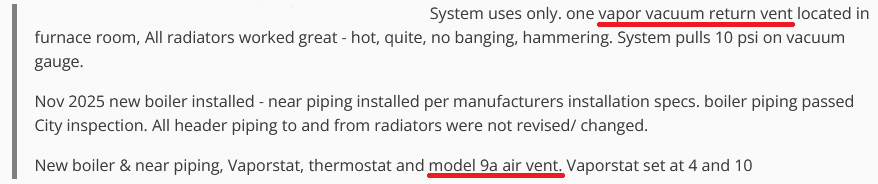

I have the same vaporstat on my steam system to replace the older pressurtrol. I have it set to about 2.25 PSI and the lowest differential. I only have it set higher like that because when I set it lower, it doesn't cut back in until 0 PSI, and when it gets to about 0 PSI on the gauge, I hear the main vents sucking IN air. I think my question is, is there any value to not letting your system go all the way to 0? Or does it not matter if the system loses all its pressure like that (when doing longer house-heat up cycle). (ignore settings in the photo, it's set higher now).

I'm only partially hijacking this thread I think, but I think it's "related".

But to the original post, I've had multiple pros on the phone and in person go uhhhhh I don't think a vaporstat is right, I think it needs to be a pressurtrol. But I'm pretty sure it's alright.

0 -

You never need the high pressure where a pressuretrol range lives in residential steam, even a vaporstat is more pressure than you need but like Ed implied, some people don't like the "short-cycling".

You might lower the Main setting down and increase the diff setting. Try the main at 1psi and the diff at 8 ounces or 4 ounces or something like that. You should be able to find a place where the pressure stays above zero without the Main being so high. With your Main set that high, you are no better than what a pressuretrol can do.

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

why are 0kpag and 0 psig not the same mark?

0 -

It doubles that chance that at least one mark is accurate, Honeywell being Honeywell and all

NJ Steam Homeowner.

Free NJ and remote steam advice: https://heatinghelp.com/find-a-contractor/detail/new-jersey-steam-help/

See my sight glass boiler videos: https://bit.ly/3sZW1el0 -

I've already answered @magewick up there. For @WillGreenlee , you do NOT have exactly the same vapourstat. I'm not sure which model yours is. Nevertheless, with the settings you have it should reset almost immediately when the burner stops. If it does not, I'd be most suspicious of the pigtail or the connection to the boiler. What does the pressure gauge read at cutout and cutin?

Also, and this may be a silly question, do you have a post purge and pre purge delay on the burner for the boiler? And if you do, are you sure that the vapourstat is not resetting much more quickly, but the post purge and pre purge delays are preventing the burner from restarting?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

-

The scales are different, one is kPa and the other is KG/CM^2. I would think 0 would still equal 0. And neither seem to compare well to their PSI scale.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

-

Hello! Sorry I didn't see it had some responses. It is model L408J1017. For those of you who are confused about the scale, yeahhh the scales on this thing got me real confused and I'm still a bit confused.

But to answer you question. At these settings. It cuts OUT about 2.25 PSI and cuts IN about 0.5 PSI (or even lower than that). If you set the main any lower, it cuts IN only when it taps basically 0.And reg pre-post purge delay. I have no idea what you're talkin about! Which probably isn't good. So if you can educate me I would appreciate it. I did NOT set up this boiler, it was installed by previous owner and I only did the pigtail/gauges/vaporstat.

0 -

OK. Something is off — but I'm not sure what. Based on the scale setting, it should cut out at 1.75 psig; it may be that the vapourstat calibration is off. It happens…

The cut in is another matter, and this is here the post purge and pre purge, if your boiler has them, comes in. Both of these are related to the burner's boiler — and not all boilers have it, though almost all oil burners, at least, do. What it is is the blower on the burner is intended to operate for a short time — usually 15 or 30 seconds — before the burner gets fuel and fires up. This is called a pre-purge. Then also the blower may run, again usually for 15 to 30 seconds, after the fuel is cut off and the flame stops. This is called a post purge. Where this can get confusing on steam systems like yours is that the vapourstat will cut out at some pressure — let's say 2.25 psig for the moment — but the blower will keep running for that post purge. However, it is quite possible that the vapourstat will cut back in while that post purge is running! Then what happens is that the burner control ignores the vapoustat (and the pressure!) and just keeps blowing, while the pressure drops further. Then… the post purge ends, and the burner control sees that the burner is still wanted — and starts the pre purge. By the time this all happens and the fire starts again, it isn't at all uncommon for the pressure to drop to near zero, or even zero.

That help?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

I have a new issue

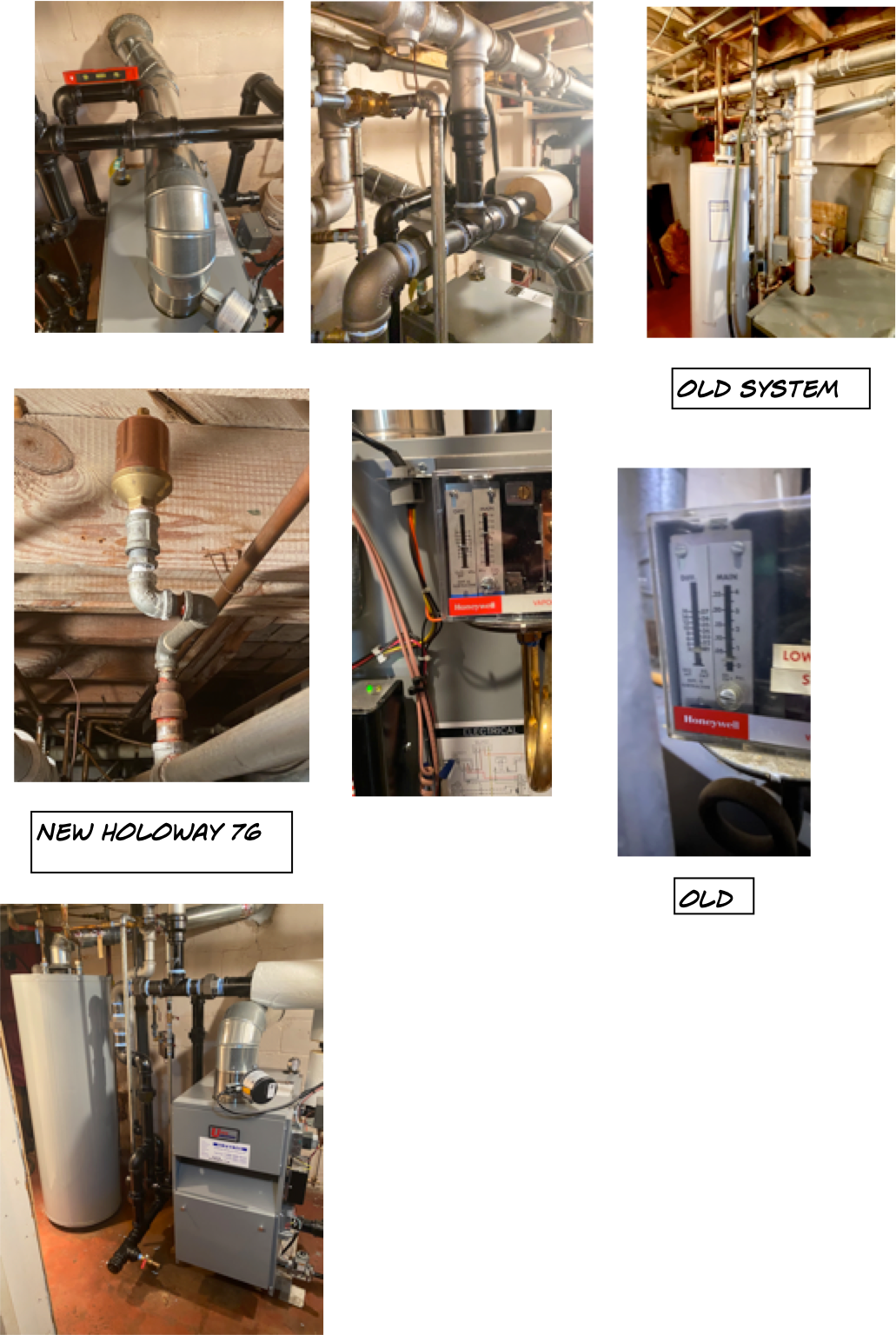

1967 to Nov 2025 - two pipe vapor vacuum system

Weill Mclain boiler was piped (single pipe directly into main healer) vaporstat conyrol. Radiators have no special elbows or traps (verified visual and with borescope) . System uses only. one vapor vacuum return vent located in furnace room, All radiators worked great - hot, quite, no banging, hammering. System pulls 10 psi on vacuum gauge.

Nov 2025 new boiler installed - near piping installed per manufacturers installation specs. boiler piping passed City inspection. All header piping to and from radiators were not revised/ changed.

New boiler & near piping, Vaporstat, thermostat and model 9a air vent. Vaporstat set at 4 and 10

Problem. upper level radiators not getting steam. lower level radiators - only upper half hot.

Please advise

0 -

pictures of system. were the vapor specialties that had the vent in the boiler room kept in place?

it could just need skimming.

where is the vaporstat set? is the vaporstat cycling? what is the edr of the system and the new boiler?

0 -

Pictures before and after, if possible. Something changed — and the question is what?

And what were the previous vapourstat settings? 4 and 10 may be too high.

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England0 -

Are the " one vapor vacuum return vent located in furnace room " and the " model 9a air vent " the same item ?

Did one replace the other ?

Was the " model 9a air vent " added ?

Does the system still pull 10 psi (?) vacuum ?

If the vacuum return vent was removed and a non vacuum vent was installed they did not do you any favors IMO.

National - U.S. Gas Boiler 45+ Years Old

Steam 300 SQ. FT. - EDR 347

One Pipe System0 -

My mistake - the model 9a vent. is actually a Halloway 76 vent.

Are the " one vapor vacuum return vent located in furnace room " and the " model 9a air vent " the same item ? Yes

Did one replace the other ? Yes

Was the " model 9a air vent " added ? new Halloway vent replaced the old Halloway vent

Does the system still pull 10 psi (?) vacuum ? yes

OLD 76 VENT -

the

0 -

0

Categories

- All Categories

- 87.5K THE MAIN WALL

- 3.3K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 430 Carbon Monoxide Awareness

- 122 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.9K Gas Heating

- 117 Geothermal

- 170 Indoor-Air Quality

- 3.8K Oil Heating

- 78 Pipe Deterioration

- 1K Plumbing

- 6.6K Radiant Heating

- 395 Solar

- 15.9K Strictly Steam

- 3.5K Thermostats and Controls

- 57 Water Quality

- 51 Industry Classes

- 51 Job Opportunities

- 18 Recall Announcements