She canna take any more, Cap'n! She's gonna blow!

Comments

-

You have a very good point, @jesmed1, and it should be a consideration for many different types of wokr — not just on heating systems. Some device — in this case the compression tank type system — can be wonderful, and very nearly bulletproof, but one needs to ask if down the line — if it's a house, for instance, after you sell it — is someone else going to be able to understand it and service it? Is even a service technician, 10 years down the line, going to be able to?

Br. Jamie, osb

Building superintendent/caretaker, 7200 sq. ft. historic house museum with dependencies in New England3 -

Xylem will take you to the cleaners. For compression tanks I go to Quality Tanks.

If your present tank has 2 end taps, it's straightforward to attach an add-on tank.

Trying to squeeze the best out of a Weil-McLain JB-5 running a 1912 1 pipe system.0 -

-

-

@delcrossv said:

"Only if they're idiots you wouldn't want to hire anyway. 😉"

Yeah, if this was my own house I would have kept the compression tank with the Airtrol, knowing that I'd be there when the boiler tech came for the annual service, and if he wasn't familiar with the Airtrol, I'd explain it and ask him not to drain the tank and refill it, as our boiler techs all seem to have been trained to do.

Our oil company's techs are good and know their stuff, but I'm not confident they all know what an Airtrol is or how to use it. So I bowed to modernity figuring the new generation of techs will more likely be familiar with a diaphragm tank than an Airtrol when no one is here to explain it.

2 -

-

And even when people do the "self education" thing, they may get it wrong.

There's a YouTube video still up by an older, experienced heating pro who "explains" how an Airtrol works. He even has an Airtrol cut in half to expose the innards while he talks about it. He explains the air tubes OK, but he fails entirely to mention the "baffle" feature that prevents the gravity circulation inside the pipe that's responsible for carrying aerated water from the tank back to the boiler and into the heating system. Which is the main point of the Airtrol.

He ends the video by saying "they were always a mystery to me because they never seemed to do much, and I don't think it would be a terrible tragedy if it wasn't there, because I didn't think it was very good anyway."

That's the first YouTube video that comes up on a search for "Airtrol tank fitting." So you can see why I'm skeptical that the next generation of techs is going to know what an Airtrol actually does.

(Dan Holohan's video explaining the Airtrol correctly is also on YouTube, as are one or two other correct explanations, but none of them come up as the first results, so guess which video most people will watch…)

1 -

I agree that is a good point. At the same time, I don't think servicing a compression tank is all that complicated.

And I’ve seen that video. Rubbish although the cutaway was cool. But not Dan’s, where can I find it?I’m sticking with my current setup for now. Preliminary calculations for system water volume put me north of 200 gallons. I used Gemini to figure out what size tank I need for max set point of 170 and static psii of 18, it was 29 gallons. That will increase once I add remaining pipes for water volume. So I expect I’ll get a 12 gallon tank from Quality Tanks.

—Eric

1 -

-

I've completed my estimation of the water in my system. It breaks down like this:

- Piping: 49

- Boiler: 5

- Radiators: 170

Total: 224 gallons. I then asked Gemini (Google's free AI tool) the following:

- For a boiler what size of compression tank for 18 psi and 224 gallons of water and a maximum temperature of 170 degrees?

This produced some formulas and explanatory text, with this conclusion:

- In summary, for a boiler system with 224 gallons of water, an initial pressure of 18 psi, and a maximum temperature of 170°F, a compression tank with a total volume of around 35 gallons (including a safety factor) would be a suitable choice based on these calculations.

This makes sense to me. So all I need to do now is install a supplemental tank with a capacity of 12 gallons, and I should be home free (current tank is 24 gallons). Quality Tanks makes such a tank.

In the meantime, I've lowered the setpoint to 160F and based on measurements so for, that seems to keep the pressure safely below 30 PSI.

—Eric

1 -

Use b&g's calculator or the formula in the b&g documentation.

0 -

Do you ever actually need even 160 to cover the heat loss given it was a gravity conversion and has a ton of mass?

0 -

That seems a bit off from the Wessel calculator, they calculate 47 gallons

I used 60° as starting temperature, 160 final

I'll try the Amtrol sizer also

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

In the B&G documentation there is Table I (Pressure Correction Factors). It's not clear to me how to use this table, as the column header says "ALLOWABLE SYSTEM PRESSURE INCREASE, PSI".

What value do I choose? A value is needed from this table to use the data from Table H: "Standard Tank Sizing Chart" since that chart assumes a static pressure of 12 PSI. I need static pressure 18 which is where Table I comes in.So I used the AI initially. My view is that it is just another tool. I would of course check it against other tools.

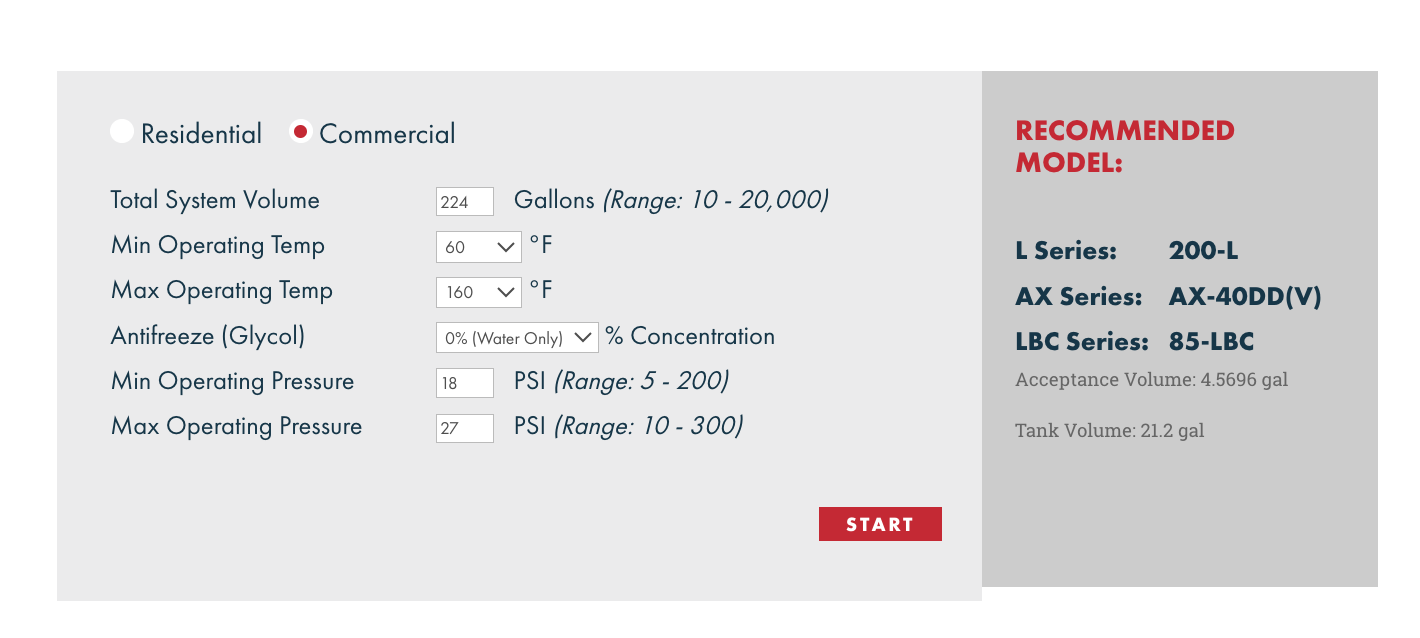

OK so I just ran the ESP-PLUS tool from B&G. The result is pretty close. I used 60 for Initial Temp, 160 for Max Temp, 18 for Initial Fill Pressure. and 30 for Max Pressure:

As for the 160, that is the value for the design day.

—Eric

0 -

OK - I ran it the B&B tool again with 28 as the max pressure and got a bigger number:

Maybe I would be better off buying a second 24g tank on FB Marketplace!

—Eric

0 -

Are you sure you have the radiator volume right? a large wider tube radiator is around 5 gallons.

0 -

Here is the Amtrol tank in a diaphragm type. I question the 224 gallons also?

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream0 -

Well let's think about it. Right now I'm on the wrong side of 30 PSI at 170F (170F was the setpoint I was using with an initial value of 10 PSI when doing my tests). So it seems reasonable that the tank is a little too small. But yeah maybe I got the 224 wrong. I'm pretty sure about the pipe estimates (I used factors from B&G for that calculation of volume). As for the rads, I used EDR numbers I calculated a while ago, and applied this formula:

- Rule of Thumb (based on surface area): Some older literature suggests that cast iron column radiators hold around 1.5 pints (approximately 0.1875 gallons) of water per square foot of surface area (EDR).

But no I never emptied a radiator and measured the volume. Actually that is something I could do once the heating season is over. I can wait now that I have a handle on the problem.

—Eric

0 -

These are about .14 gallon per ft^2 of edr and lower profile radiators are much less

0 -

Thanks! I’ll revisit my numbers.

I do have specs for some of the newer rads, but not the older ones, I don’t recall where I got the EDR values, they were in a chart I made some time ago. And like I said I can isolate one radiator to drain it and see what I get.—Eric

0 -

We have about 450 sq ft of EDR, and I've estimated our total water volume including pipes and boiler at somewhere between 100 and 140 gallons by different methods. But I think it's closer to 100 than to 140.

You look to have about double our EDR, so double 100+ gallons is 200+. I think you're right on if your EDR is correct.

0 -

OK, I checked a couple of rads against this gulde: Cast Iron Radiator Heating Capacity Guide from Columbia Heating Supply. My EDR numbers match the ones from that guide.

Also, we have about 900 EDR, about twice yours @jesmed1, so your 100 to 140 gallons would translate into 180 to 253 gallons (assuming similar increase in piping).

So assuming that my EDR numbers are OK, that takes us to mapping EDR to volume. Here's the rundown:

- 0.14 gallon per ft^2 of edr from @mattmia2

- 0.19 - the value I was using from the AI

- 0.2 gallons per foot of EDR sounds about right - from @jesmed1

So depending on that mapping, I guess I think my numbers are pretty close for volume. It's clear I have to add some capacity. If indeed my volume is less than 224 then I'm erring on the side of caution.

Also, we have about 900 EDR, about twice yours @jesmed1, so your 100 to 140 gallons would translate into 180 to 253 gallons (assuming similar increase in piping) for our system.

As I said before, I'm pretty comfortable at this point adding a 15 gallon supplemental tank to address my issue. Either than or go to an expansion tank and redo all my air management.

—Eric

0 -

Bottom line, if you are adding a tank, or upsizing error on the high side. The high static fill of 18 psi is sending the tank capacity up also.

With those online calculators you can play what if calcs. Try different fill pressures, different high temperature, system volume. See where it makes a jump in tank capacity. If you fall on the line, I would go up a size.

You want wiggle room if you do need to exceed the 160 SWT on a below design temperature period. So run the numbers with 180 as the high temperature also.

In some cases boilers with an indirect the boiler ,may boost to 180 or higher durning a DHW priority call.

Bob "hot rod" Rohr

trainer for Caleffi NA

Living the hydronic dream1 -

-

Hey, I was just here getting some help on my own heating issue(thanks all for that), but I decided to glance through here. I had a thought. Why not change out that T&P relief valve? What could it hurt? It's not going to solve your problem, but wouldn't it feel smart to put in a valve you know will open if needed? Just sayin'.

0 -

-

there is a tolerance in the valve and the gauge. if it got to 40 there's a problem but at 35 psig it could be the gauge is reading a little high and the valve is 15% high.

0 -

Three different gauges though. But I mean, the title of the post is: "She canna take any more, Cap'n! She's gonna blow!" I don't know how old the valve is.

0 -

A boiler has a pressure relief valve, it opens due to pressure only. A temperature and pressure relief valve (T&P) is for water heaters only.

When a pressure relief valve opens due to unusually high boiler pressure the worst thing you can do is replace a 30 PSI pressure relief valve with a 50 PSI pressure relief valve. Or just slapping on a new 30 PSI relief valve without figuring out why this safety device was doing its job and correcting the problem.

0 -

I'm not suggesting replacing a leaking or discharging valve with a higher PSI valve. I'm saying to consider replacing a valve that isn't opening with a new one, of the appropriate type, because it might be defective. It's a pretty small chance it leads to a problem, but why take that chance when you're here now?

Fair enough for pointing out it's not a T&P valve, I've never had to replace the relief valve on a boiler, and if I did, you can bet I'd check what valve specifications should be used, even when using a pro, because I've seen mistakes happen, and not every pro is as sharp as the folks who post on this board.

My point is that there are redundant safety systems, and a lot of industrial accidents have happened where one or more of them weren't maintained when they easily could have been. But hey, maybe it's overkill.

Come to think of it, I did have a boiler that bit the dust this way. I had just bought a home, and one day the boiler went way over temperature and kept firing until wire insulation in the control box melted and shorted. When we tried to restart it, it was clear that the boiler had been damaged. Neither the relief valve nor the high limit aquastat nor the low water cutoff had operated. Boiler replacement had already been scheduled fortunately, but I felt it was an unsafe event due to the potential for fire, or carbon monoxide release. I didn't spend a ton of time trying to figure out what happened since we were replacing the entire system anyway, but I think it's safe to say that the safety features of this installation were not in working order.

0 -

Usually when that happens either the gas valve got stuck open or the flame rolled out and it hadnt' actually overheated, the flam just was burning in the control box. Newer boilers have a thermostat outside the combustion chamber that turns off the gas valve if rollout happens but older boilers do not.

0 -

-

-

-

-

When we repaired wiring, the boiler heated right up to 220 and kettled immediately when the flame lit, because it was leaking or cracked. The high limit aquastat slept through the whole thing, relief valve did not open. Now I like to check on those things. Anyway I'll let this thread stay focused on the airtrol, which I know nothing about. If anyone wants to keep a suspect relief valve, what can I say. Just note that this information or similar comes on a tag from the relief valve manufacturer(this one is from a Watts) and I did not include the entire label. Now in my area, I've found that plumbers don't really offer this inspection, and it would likely be easier and cheaper to replace a suspect valve than inspect it unless it is a very large valve.

"WARNING: Following installation, the valve lever MUST be operated AT LEAST ONCE A YEAR by the boiler owner to insure that waterways are clear. Certain naturally occurring mineral deposits may adhere to the valve, rendering it inoperative. When manually operating the lever, water will discharge and precautions must be taken to avoid contact with hot water and to avoid water damage. BEFORE operating lever, check to see that a discharge line is connected to this valve directing the flow of hot water from the valve toa proper place of disposal otherwise personal injury may result. If no water flows, valve is inoperative. CALL A PLUMBER IMMEDIATELY."

and

"WARNING: REINSPECTION OF SAFETY RELIEFVALVES: Safety Relief Valves should be reinspected AT LEAST ONCE EVERY THREE YEARS by a licensed plumbing contractor or authorized inspection agency, to insure that the product has not been affected by corrosive water conditions and to insure that the valve and discharge line have not been altered or tampered with illegally. Certain naturally occurring conditions may corrode the valve or its components over time, rendering the valve inoperative. Such conditions are not detectable unless the valve and its components are physically removed and inspected. Do not attempt to conduct this inspection on your own. Contact your plumbing contractor for a reinspection to assure continuing safety. FAILURE TO REINSPECT THIS VALVE AS DIRECTED COULD RESULT IN UNSAFE PRESSURE BUILDUP WHICH CAN RESULT IN SERIOUS INJURY ORDEATH AND/OR SEVERE PROPERTY DAMAGE."

0 -

-

Do those hanger arms have a valve built in? do they have a drain to relieve the system pressure to check the precharge?

0 -

Thank you - this is very good advice.

—Eric

0 -

Nice installation! I may consider switching to diaphragm tanks in the future, but that will probably only be when I replace the boiler. I have limited space for such tanks and the compression tanks fits nicely between the floor joists. Plus my air management setup is for compression tanks (Integated Air Separator, ATF-12) and is working very well right now.

It was quite inexpensive procuring a second compression tank and an ATF-12.

—Eric

3

Categories

- All Categories

- 87.3K THE MAIN WALL

- 3.2K A-C, Heat Pumps & Refrigeration

- 61 Biomass

- 429 Carbon Monoxide Awareness

- 120 Chimneys & Flues

- 2.1K Domestic Hot Water

- 5.8K Gas Heating

- 115 Geothermal

- 166 Indoor-Air Quality

- 3.7K Oil Heating

- 77 Pipe Deterioration

- 1K Plumbing

- 6.5K Radiant Heating

- 395 Solar

- 15.7K Strictly Steam

- 3.4K Thermostats and Controls

- 56 Water Quality

- 51 Industry Classes

- 50 Job Opportunities

- 18 Recall Announcements